Introduction

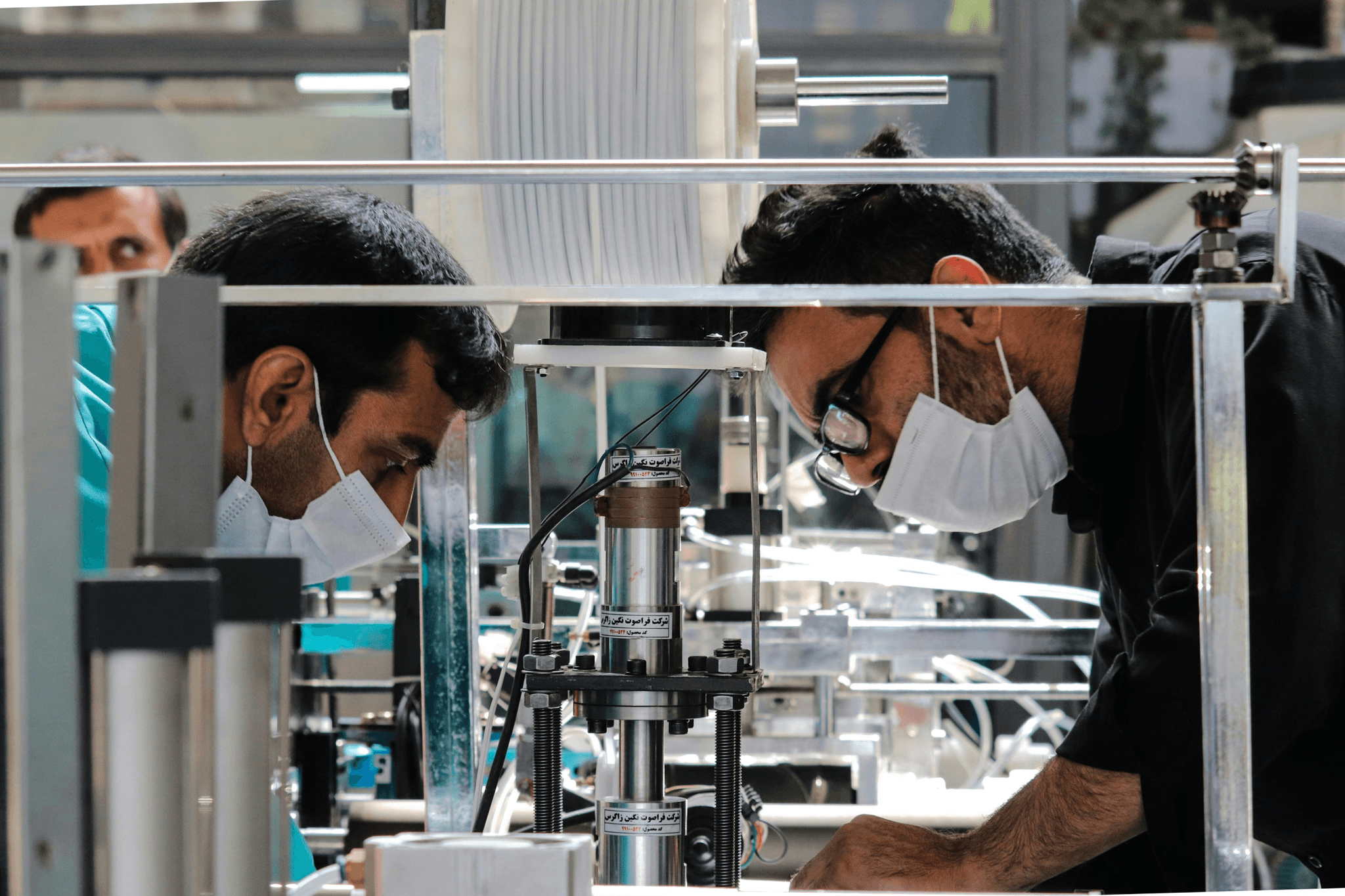

In the world of manufacturing, ensuring that products meet quality standards before they reach the market is paramount. One critical step in this process is the factory witness test, which serves as a checkpoint to verify that equipment and systems function as intended. This introduction will explore the significance of Factory Acceptance Testing (FAT), its importance in maintaining product integrity, and who plays a vital role in this process.

Understanding Factory Acceptance Testing

Factory Acceptance Testing (FAT) is a systematic approach used to validate equipment and systems before they leave the manufacturing facility. This testing phase involves rigorous assessments to ensure compliance with specifications and operational requirements. By conducting a factory witness test, stakeholders can confirm that all functionalities are in place, laying the groundwork for successful project execution.

Importance of Witnessing Factory Tests

Witnessing factory tests is crucial for several reasons; it not only guarantees product quality but also fosters trust between manufacturers and clients. When stakeholders are present during these tests, they can directly observe performance metrics and address any concerns on-site. The factory witness test acts as a safeguard against potential issues that could arise later in the production or operational phases.

Key Players in the FAT Process

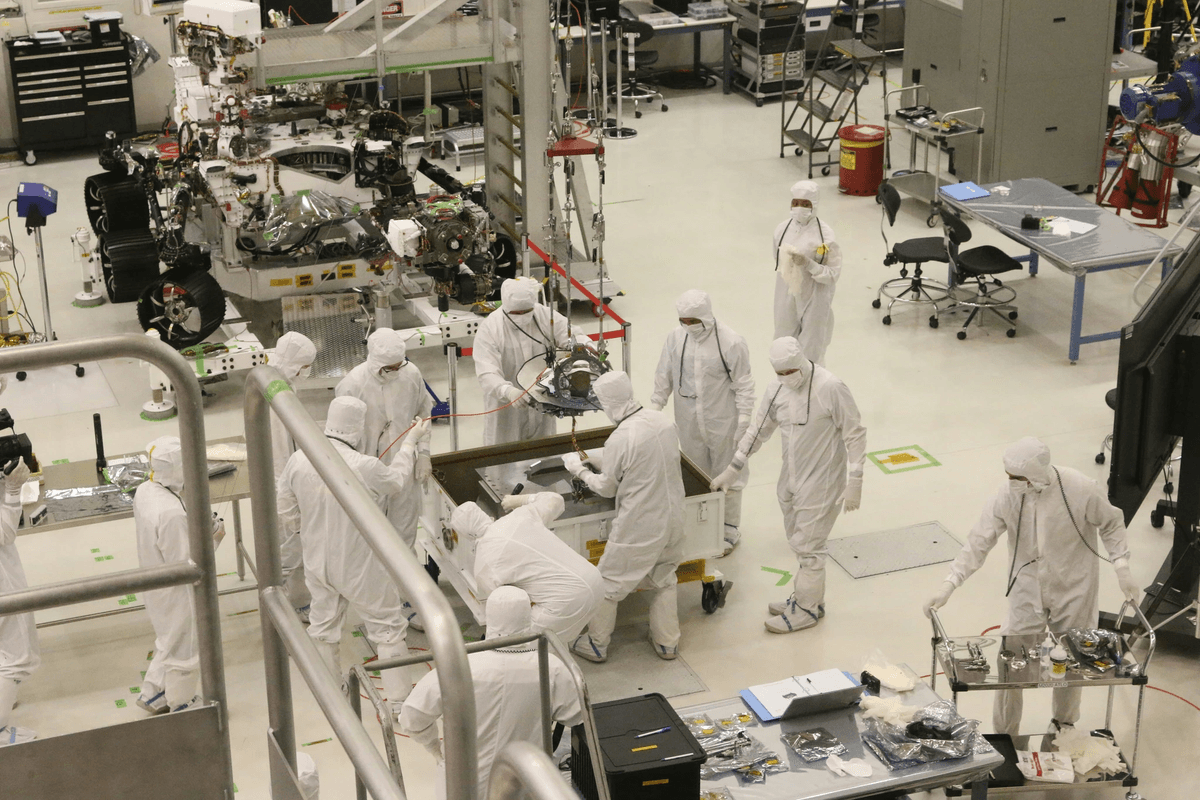

The FAT process involves various key players who contribute to its success, including manufacturers, clients, and third-party inspection agencies like China Inspection Pro. Each participant has specific responsibilities: manufacturers conduct the tests, clients evaluate results firsthand, and third-party inspectors provide unbiased oversight to ensure compliance with industry standards. Together, these players create an environment conducive to transparency and accountability during factory acceptance testing.

What is a Factory Acceptance Test?

Factory Acceptance Testing (FAT) is a critical process that ensures equipment and systems meet specified requirements before being shipped to the customer. This testing phase helps to validate that the product functions correctly and adheres to both quality standards and contractual obligations. Essentially, it’s a pre-shipment quality control measure designed to catch any issues before they become costly problems down the line.

Definition and Purpose

A Factory Acceptance Test is essentially an evaluation conducted at the manufacturer's facility to verify that a product meets its design specifications and operational requirements. The purpose of this test is not only to ensure functionality but also to confirm compliance with regulatory standards, thus safeguarding both the manufacturer and buyer from potential disputes or failures post-delivery. Engaging in a factory witness test allows stakeholders to witness firsthand how their equipment operates, promoting transparency throughout the manufacturing process.

Phases of the FAT Process

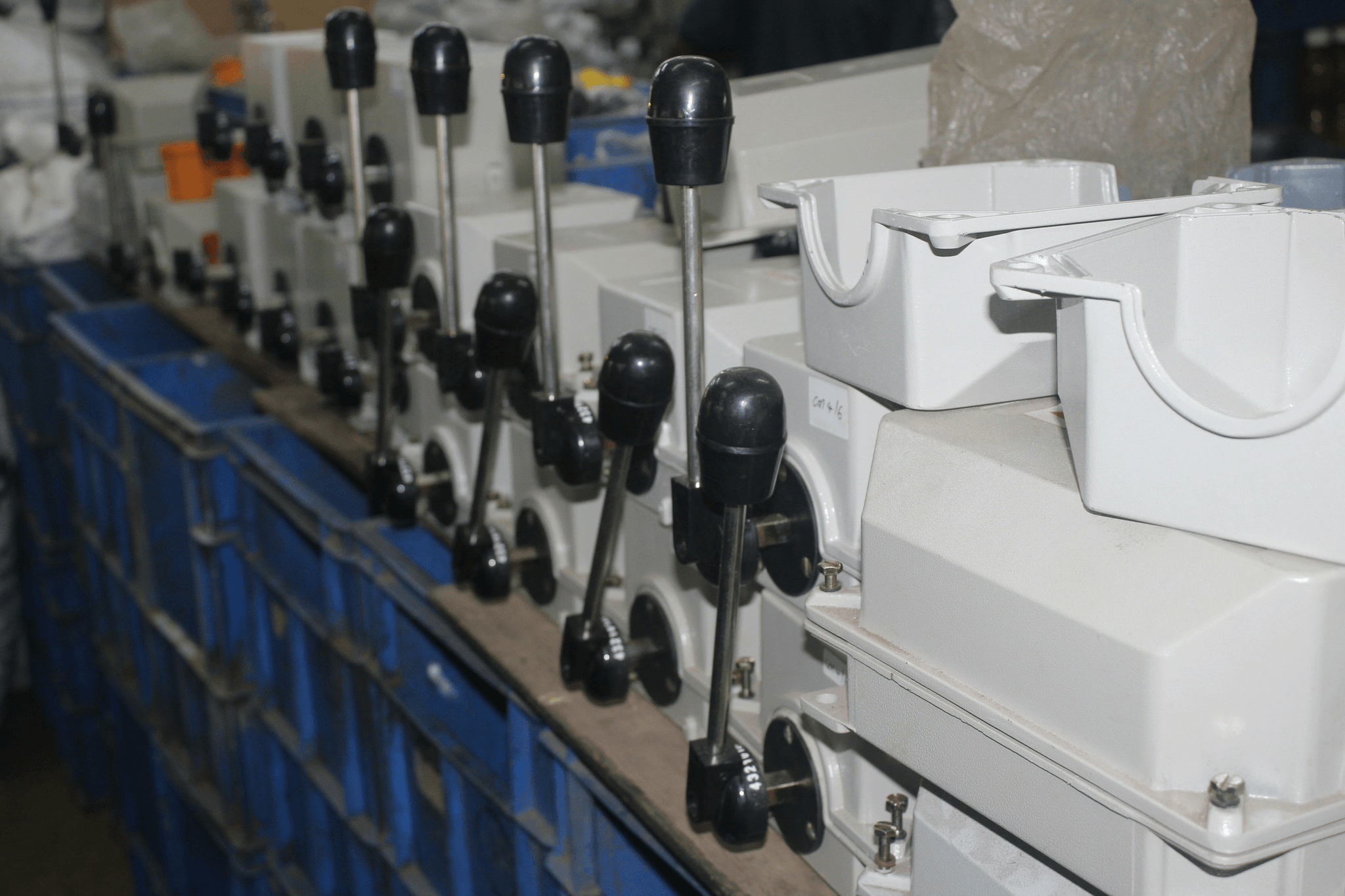

The FAT process typically unfolds in several key phases: preparation, execution, and documentation. During preparation, all necessary documentation, including test plans and acceptance criteria, are reviewed by all parties involved in the factory witness test. Execution involves performing various tests on the equipment while stakeholders observe; this phase is crucial for identifying any discrepancies or areas needing improvement before final acceptance.

Standards and Best Practices

To ensure effective Factory Acceptance Testing, adhering to established standards and best practices is essential. These may include international standards such as ISO 9001 for quality management systems or industry-specific guidelines tailored for particular products or sectors. Best practices also emphasize thorough documentation of each step of the factory witness test—this includes recording results, maintaining communication among stakeholders, and ensuring that corrective actions are taken promptly if issues arise during testing.

Benefits of Witnessing a Factory Acceptance Test

Witnessing a factory acceptance test (FAT) is not just a checkbox on a project plan; it’s an investment in quality and reliability. By being present during these tests, stakeholders can ensure that the products meet the specified requirements before they leave the factory floor. This proactive approach ultimately leads to better outcomes and fewer headaches down the line.

Ensuring Product Quality

One of the most significant benefits of witnessing a factory acceptance test is ensuring product quality. When you’re there in person, you can observe every detail and verify that the equipment operates as intended, adhering to all specifications. This hands-on involvement allows for immediate feedback and adjustments, which is crucial for maintaining high standards.

In addition, witnessing these tests helps confirm that manufacturers are using best practices and following industry standards throughout their processes. When issues arise during testing, they can be addressed on the spot rather than after delivery, preventing costly rework or replacements later. Ultimately, this level of scrutiny fosters confidence that what you receive will perform as promised.

Building Trust with Suppliers

Another compelling reason to participate in a factory witness test is building trust with suppliers. By actively engaging in this process, you demonstrate your commitment to quality and collaboration, which can strengthen your business relationships over time. Suppliers appreciate clients who take an interest in their operations; it shows you're invested in mutual success.

Moreover, consistent participation in FATs sends a message that your organization values transparency and accountability—qualities that are essential for long-term partnerships. As trust builds through these interactions, suppliers may be more inclined to prioritize your projects or offer additional insights into best practices and innovations within their operations. In essence, witnessing FATs transforms transactional relationships into collaborative partnerships.

Identifying Issues Early

Witnessing a factory acceptance test also plays a crucial role in identifying issues early on before products reach end-users or clients. During these tests, potential problems—whether technical glitches or design flaws—can surface while there’s still time to make necessary adjustments without incurring significant costs or delays. The earlier these issues are caught, the less likely they are to escalate into major setbacks later.

Having eyes on-site means you can ask questions directly and clarify any uncertainties about product functionality or performance expectations right away. This proactive approach not only saves time but also ensures everyone involved has aligned expectations moving forward—an absolute must for successful project execution! Ultimately, by catching issues early through FAT witnessing, organizations safeguard their investments against unforeseen complications down the road.

The Role of China Inspection Pro

China Inspection Pro plays a pivotal role in enhancing the integrity and reliability of factory acceptance tests (FATs). By providing comprehensive quality inspection services, they ensure that products meet the required standards before leaving the factory. Their expertise not only streamlines the FAT process but also fortifies relationships between buyers and suppliers.

Overview of Quality Inspection Services

China Inspection Pro offers a suite of quality inspection services tailored to various industries, ensuring that every aspect of production meets stringent quality benchmarks. Their team is adept at conducting thorough evaluations during factory witness tests, focusing on both product functionality and compliance with specifications. This proactive approach mitigates risks associated with subpar products entering the marketplace.

Methodologies for Effective FAT Witnessing

To conduct effective factory witness tests, China Inspection Pro employs a blend of systematic methodologies and best practices. They prioritize clear communication with all stakeholders involved, ensuring everyone is aligned on expectations and objectives before testing begins. Additionally, their inspectors utilize advanced tools and technologies to monitor performance metrics in real-time, allowing for immediate identification of any discrepancies or issues.

Case Studies of Successful Tests

Numerous case studies illustrate how China Inspection Pro has successfully facilitated factory acceptance tests across various sectors. In one instance, a major electronics manufacturer faced significant delays due to faulty components; however, through diligent FAT witnessing by China Inspection Pro, critical issues were identified early in the production cycle. This not only saved time but also ensured that the final product met all safety and quality standards before reaching consumers.

Preparing for a Factory Witness Test

Preparing for a factory witness test is akin to gearing up for a grand performance; every detail matters. The success of the test hinges on meticulous planning, clear communication, and an understanding of the protocols involved. By ensuring that all elements are in place, you can mitigate risks and maximize the effectiveness of the factory witness test.

Documentation and Protocols

Documentation is the backbone of any successful factory witness test. This includes everything from contracts and specifications to testing procedures and compliance checklists. Having comprehensive documentation ensures that everyone involved is on the same page, reducing misunderstandings and streamlining the testing process.

Protocols outline how tests will be conducted, specifying everything from safety measures to data recording methods. They serve as a guide during the factory witness test, helping participants adhere to best practices while maintaining quality standards. Ensure that all relevant documents are reviewed and approved well in advance to avoid last-minute scrambles.

Additionally, consider creating a checklist that details what needs to be reviewed before the actual test day arrives. This proactive approach not only keeps your team organized but also reinforces accountability among stakeholders involved in the factory witness test.

Assembling the Right Team

A successful factory witness test requires more than just good intentions; it demands a skilled team equipped with diverse expertise. Start by identifying key players who understand both technical specifications and industry standards related to your product or service. Their insight will be invaluable when assessing whether tests meet quality benchmarks.

Be sure to include representatives from various departments—engineering, quality assurance, procurement—so you have a well-rounded perspective during the testing process. Each team member can contribute unique insights that may reveal potential issues or improvements before they become costly problems down the line.

Lastly, ensure that your team is not only knowledgeable but also communicative and collaborative. A cohesive unit can adapt quickly if unexpected challenges arise during the factory witness test, ensuring smoother operations overall.

Questions to Ask Beforehand

Before embarking on your factory witness test journey, it's crucial to arm yourself with pertinent questions that will guide your preparations effectively. Start by asking about specific testing methodologies: What types of tests will be performed? Are there any unique considerations based on product requirements?

Next, inquire about logistics: How many days are allocated for testing? Will there be adequate time for troubleshooting if issues arise? Understanding these parameters helps set realistic expectations for everyone involved in the factory witness test.

Finally, don’t hesitate to ask about post-test procedures: How will results be documented? What follow-up actions are necessary if discrepancies occur? These inquiries not only clarify processes but also foster transparency between parties engaged in this critical phase of production.

Common Challenges in FAT Witnessing

Factory acceptance tests (FAT) are crucial for ensuring that products meet specified requirements before they reach the customer. However, witnessing a factory witness test comes with its own set of challenges that can complicate the process. Addressing these challenges proactively can help streamline the testing experience and ensure successful outcomes.

Communication Gaps

One of the most common hurdles in witnessing a factory witness test is communication gaps between stakeholders. Misunderstandings can arise from language barriers, technical jargon, or differing expectations regarding test procedures and outcomes. It's essential for all parties involved—suppliers, clients, and inspectors—to establish clear lines of communication and a shared understanding to avoid confusion during critical testing phases.

Regular updates and open dialogue are vital to bridging these gaps. Utilizing visual aids or translation services can also enhance comprehension among diverse teams. Ultimately, effective communication fosters collaboration and ensures everyone is on the same page during the factory acceptance test.

Technical Difficulties During Testing

Technical difficulties are another significant challenge that can arise during a factory witness test, potentially derailing the entire process. Equipment malfunctions or software glitches may occur unexpectedly, leading to delays and frustration among participants. These issues not only impact timelines but can also create doubts about product reliability if not addressed promptly.

To mitigate these risks, it's wise to conduct thorough pre-test checks on all equipment involved in the FAT process. Having technical support readily available during testing can also help resolve issues quickly when they arise. By preparing for potential technical difficulties ahead of time, stakeholders can maintain confidence in their factory acceptance tests.

Navigating Compliance and Regulations

Navigating compliance and regulations is an intricate aspect of witnessing a factory witness test that often presents its own set of challenges. Different industries have varying standards that must be adhered to; failing to comply with these regulations could result in costly setbacks or even legal ramifications down the line. Understanding which standards apply to your specific situation is crucial for smooth testing operations.

Additionally, keeping abreast of changing regulations requires vigilance from all parties involved in the FAT process. Regular training sessions or workshops on compliance matters can help ensure everyone is informed about current requirements and best practices related to factory acceptance tests. When compliance becomes second nature within your team, it paves the way for more efficient and effective witnessing experiences.

Conclusion

In wrapping up our exploration of Factory Acceptance Testing (FAT), it’s clear that this process is not just a box to check off; it’s a vital component in ensuring that products meet the necessary standards before they hit the market. The factory witness test serves as a pivotal moment where stakeholders can verify product quality and functionality firsthand, which ultimately leads to greater confidence in supplier relationships. By understanding the nuances of FAT, companies can better navigate the complexities of manufacturing and compliance.

Key Takeaways from Factory Tests

One of the most significant takeaways from factory tests is the assurance they provide regarding product quality. Witnessing a factory acceptance test allows stakeholders to identify potential issues early in the production process, reducing costly delays down the line. Moreover, fostering trust with suppliers becomes easier when both parties are aligned on expectations and outcomes during these crucial evaluations.

Future Trends in Factory Acceptance Testing

As technology continues to evolve, so too will the landscape of factory acceptance testing. We can expect increased automation and digital tools that streamline processes, making it easier for teams to conduct effective factory witness tests remotely or through augmented reality platforms. Additionally, sustainability practices will likely play a larger role, pushing manufacturers toward greener testing methods while still meeting compliance requirements.

Best Practices for Effective Witnessing

To maximize the benefits of witnessing a factory acceptance test, preparation is key. Assembling a knowledgeable team equipped with relevant documentation ensures that all aspects of the test are covered efficiently and effectively. Furthermore, engaging in open communication with suppliers beforehand can help address any potential challenges and clarify expectations—this proactive approach is crucial for successful outcomes during FAT.