Introduction

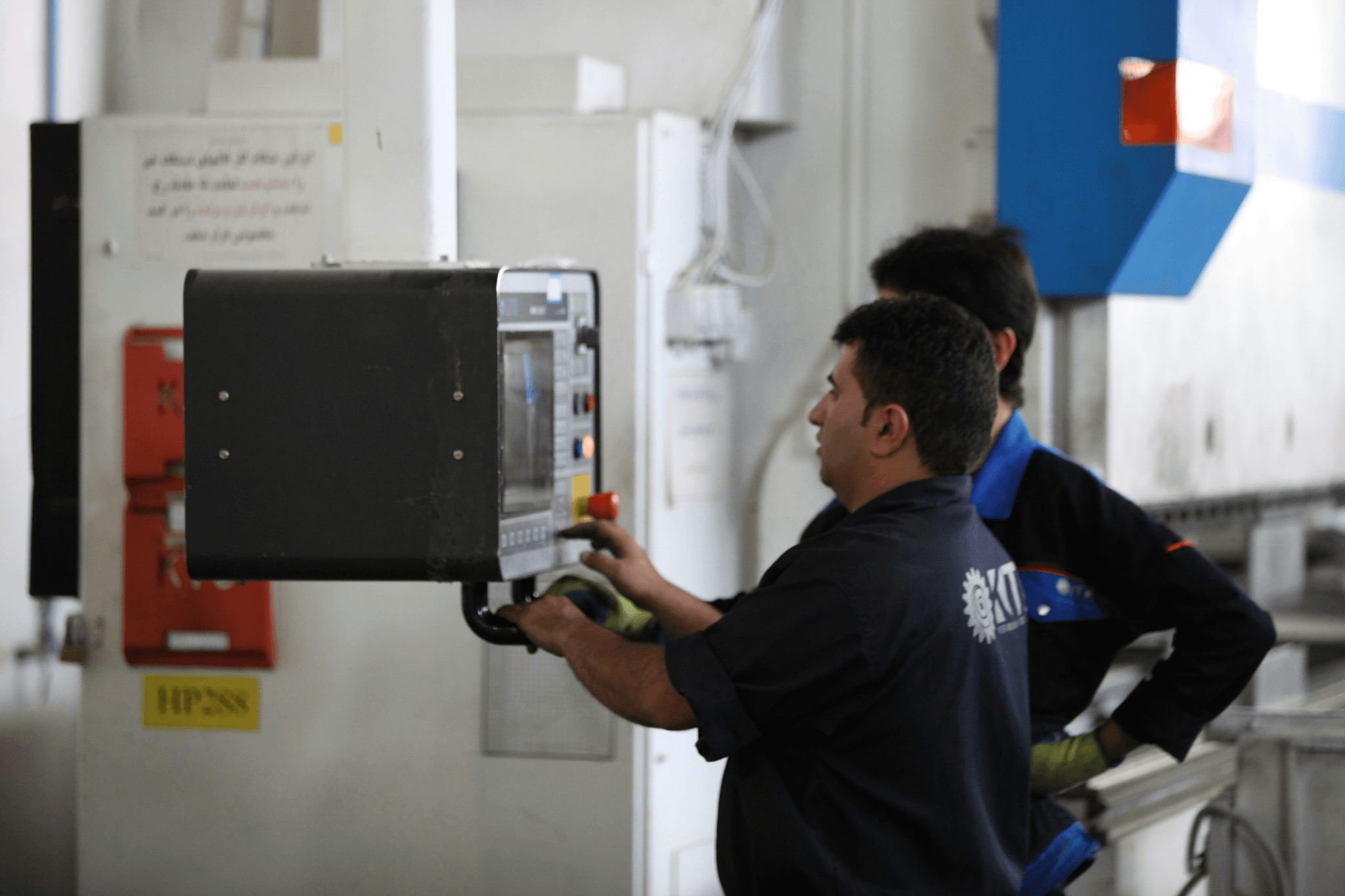

In the world of manufacturing and production, equipment inspection is not just a formality; it's a crucial practice that ensures safety, compliance, and efficiency. Regular checks on machinery and tools can prevent accidents, enhance productivity, and save costs in the long run. By understanding the essentials of equipment inspection, businesses can create a safer environment for their employees while also adhering to industry standards.

Understanding Equipment Inspection Essentials

Equipment inspection involves systematically evaluating machinery to ensure it meets safety and operational standards. This process is vital not only for compliance but also for maintaining the longevity of your assets. Knowing where to find children's product certificates or how to check material test certificates can significantly streamline this process and enhance safety protocols.

The Importance of Regular Checks

Regular checks are essential in identifying potential issues before they escalate into costly problems or hazardous situations. The importance of food quality cannot be overstated either; routine inspections help maintain high standards that protect consumers and uphold brand integrity. By integrating consistent equipment inspections into operational routines, companies can safeguard their reputation while ensuring compliance with regulations.

Key Aspects of Safe Equipment Operation

Safe equipment operation hinges on several key aspects: proper training, regular maintenance, and thorough inspections. Utilizing food packaging testing methods ensures that materials used are safe for consumption while adhering to quality standards. Partnering with a reliable QC company can further enhance these practices by providing expert insights into effective inspection techniques and certification processes.

Overview of Equipment Inspection

Equipment inspection is a critical process that ensures machinery and tools are functioning correctly and safely. Regular checks are not just a regulatory obligation; they also protect workers, enhance productivity, and minimize downtime. Understanding the nuances of equipment inspection can save businesses from costly accidents and inefficiencies.

Types of Equipment Needing Inspection

Various types of equipment require regular inspection to maintain safety standards and operational efficiency. This includes industrial machinery, construction tools, food processing equipment, and even children's products that must adhere to specific safety regulations. Knowing where to find children's product certificates can streamline this process, ensuring compliance with safety standards.

Common Inspection Standards

Inspection standards vary by industry but generally include guidelines set by organizations like OSHA (Occupational Safety and Health Administration) or ISO (International Organization for Standardization). These standards dictate the frequency of inspections, methods used for evaluating equipment condition, and documentation requirements such as an inspection certificate. Adhering to these common inspection standards not only fulfills legal obligations but also reinforces the importance of food quality in related sectors.

Benefits of Regular Equipment Evaluation

Conducting regular equipment evaluations provides numerous benefits that extend beyond mere compliance with regulations. It helps identify potential issues before they escalate into major problems, thus reducing repair costs over time. Moreover, consistent inspections contribute to improved safety protocols within the workplace while enhancing overall operational efficiency—crucial aspects when considering food quality checking in production environments.

Conducting Thorough Equipment Inspections

Conducting thorough equipment inspections is essential for ensuring safety and efficiency in any operational environment. A systematic approach helps identify potential issues before they escalate, saving time and resources. Here’s how to effectively navigate the inspection process while utilizing the right tools and management strategies.

Step-by-Step Inspection Process

The step-by-step inspection process begins with a comprehensive review of the equipment's operational manual, which outlines specific safety guidelines and maintenance schedules. Next, visually inspect the equipment for any visible signs of wear or damage, such as rust or frayed cables—these are often indicators that something may be amiss. Following this, perform functional tests to ensure that all components are operating correctly; this includes checking controls, alarms, and other critical features.

Documentation plays a crucial role in equipment inspection; keep detailed records of your findings as these will serve as proof of compliance with safety standards. When it comes to where to find children's product certificates or material test certificates, having organized documentation can streamline this process significantly. Finally, conclude your inspection by addressing any identified issues promptly—after all, timely interventions can prevent costly downtimes.

Tools Required for Effective Inspections

To conduct effective inspections, you’ll need a variety of tools tailored to the specific type of equipment being evaluated. Common tools include torque wrenches for checking fasteners' tightness, multimeters for electrical testing, and calipers for measuring dimensions accurately—each plays an integral role in ensuring thorough evaluations. Additionally, software applications designed for tracking inspections can enhance efficiency by organizing data and scheduling future checks.

When performing food quality checking or food packaging testing specifically, specialized tools like pH meters or moisture analyzers may also be necessary to guarantee compliance with health standards. Remember that using appropriate tools not only enhances accuracy but also reinforces the credibility of your inspection certificate when presenting findings to stakeholders or regulatory bodies. Ultimately, investing in quality inspection tools pays off by safeguarding both personnel and products.

Tips for Efficient Inspection Management

Efficient inspection management hinges on establishing a routine that prioritizes regular checks while allowing flexibility for unexpected challenges. Create a checklist tailored to each piece of equipment so that no detail is overlooked during inspections; this ensures consistency across all evaluations while making it easier to track progress over time. Moreover, training staff on best practices related to equipment inspection can enhance their ability to identify potential issues quickly.

Utilizing technology such as mobile apps designed for quality control (QC) company purposes can further streamline your processes by enabling real-time reporting and data collection during inspections—this is particularly useful when managing multiple pieces of equipment across various locations. Additionally, fostering open communication among team members encourages knowledge sharing about common pitfalls encountered during inspections; learning from each other’s experiences can lead to improved practices overall.

In conclusion, implementing these strategies will not only make your equipment inspections more effective but also contribute significantly toward maintaining high standards in safety and quality assurance across operations.

Where to Find Children’s Product Certificate

Navigating the world of children’s products can be daunting, especially when it comes to ensuring safety through proper certification. Understanding where to find a children's product certificate is crucial for manufacturers, retailers, and consumers alike. This certification not only assures compliance with safety standards but also builds trust in the marketplace.

Importance of Certification for Safety

Certification plays a vital role in maintaining safety standards for children's products. It ensures that items are tested and verified against specific regulations, minimizing potential hazards like choking or chemical exposure. The importance of food quality extends beyond just edible items; it encompasses all products intended for children, making certification indispensable in safeguarding their well-being.

How to Locate Relevant Documentation

Finding the right documentation for children’s product certificates can be straightforward if you know where to look. Start by checking with reputable QC companies that specialize in product inspections; they often provide access to these certificates as part of their services. Additionally, manufacturers should keep records readily available on their websites or upon request, ensuring transparency and ease of access for consumers looking to verify safety credentials.

Avoiding Common Certification Pitfalls

While seeking out children's product certificates, it's essential to avoid common pitfalls that could lead to misinformation or non-compliance. One major mistake is relying solely on verbal assurances without verifying the actual inspection certificate; always ask for documentation! Furthermore, ensure that your sources are legitimate—scams can occur if you don't conduct thorough equipment inspections on your information sources as well.

Food Quality Checking: Best Practices

Ensuring food quality is paramount in today's marketplace, where consumer safety and satisfaction are top priorities. Regular food quality checking not only helps maintain standards but also builds trust with customers. By implementing best practices in food inspections, businesses can enhance their reputation and compliance with regulations.

Understanding the Importance of Food Quality

Food quality directly impacts consumer health and safety, making its importance undeniable. Poor-quality food can lead to serious health issues, recalls, and damage to a brand's reputation. Regular equipment inspection in food processing facilities ensures that all machinery operates correctly, which is essential for maintaining high food quality standards.

Moreover, understanding where to find children's product certificates becomes crucial when dealing with products intended for younger consumers. These certificates verify that items meet safety regulations and are free from harmful substances—an essential aspect of ensuring overall food quality. Thus, businesses must prioritize obtaining accurate inspection certificates to demonstrate their commitment to safety.

Techniques for Effective Food Quality Inspections

Effective food quality inspections require a systematic approach that combines various techniques tailored to specific needs. First off, visual inspections should be conducted regularly; this includes checking for any signs of contamination or spoilage in both raw materials and finished products. Additionally, implementing routine laboratory tests can help verify the safety and composition of the foods being processed.

Another key technique involves utilizing equipment inspection protocols during production processes to ensure machinery is functioning optimally—after all, faulty equipment can compromise product integrity! Training staff on how to check material test certificates also plays an important role; they should know what to look for regarding compliance with industry standards. By employing these techniques consistently, companies can significantly improve their food quality outcomes.

Utilizing Food Packaging Testing for Safety

Food packaging testing is an often-overlooked aspect of ensuring overall product safety and quality—it plays a vital role in protecting edible goods from external contaminants. Packaging serves as the first line of defense against spoilage or contamination; therefore, it must meet stringent safety standards through regular testing protocols conducted by reputable QC companies.

To ensure effective packaging testing results, businesses should implement a thorough analysis process that includes evaluating materials used in packaging as well as conducting stress tests under various conditions—this helps identify potential weaknesses before they become problems! Furthermore, knowing how to check material test certificates associated with packaging materials allows companies to validate their choices effectively while avoiding common pitfalls related to non-compliance.

In conclusion, prioritizing food quality checking through best practices not only safeguards consumer health but also enhances brand credibility within the market landscape—a win-win situation!

The Role of QC Companies in Inspections

In the world of equipment inspection and quality control, QC companies play a pivotal role in ensuring compliance with safety standards. These organizations specialize in evaluating products and processes to verify that they meet regulatory requirements and industry benchmarks. Their expertise is crucial for businesses aiming to maintain high-quality standards while avoiding costly penalties or recalls.

How QC Companies Ensure Compliance

QC companies employ a variety of methods to ensure compliance during equipment inspections. They conduct thorough assessments based on established regulations and guidelines, ensuring that every aspect of the equipment meets safety requirements. Additionally, these companies often provide inspection certificates that serve as proof of compliance, which can be vital for manufacturers looking to demonstrate their commitment to quality.

Furthermore, QC firms help businesses navigate the complex landscape of certifications, such as where to find children's product certificates or how to check material test certificates effectively. By offering insights into best practices for food quality checking and food packaging testing, they empower companies to enhance their safety protocols significantly. Ultimately, partnering with a reputable QC company can streamline operations and elevate overall product quality.

Partnering with China Inspection Pro for Success

This specialized QC company offers tailored inspection services that focus on equipment inspection and food quality checking across various industries. With their extensive network and local expertise, they simplify the process of obtaining essential documentation like inspection certificates.

China Inspection Pro excels at helping clients understand the importance of food quality by implementing rigorous testing protocols during inspections. Their team is well-versed in identifying potential pitfalls related to certification processes—making them invaluable when navigating where to find children's product certificates or ensuring compliance with international standards. By collaborating closely with clients, they foster an environment where quality improvement becomes an ongoing mission rather than a one-time task.

Real-Life Cases of Quality Improvement

Real-life cases highlight how effective partnerships with QC companies lead to meaningful improvements in product quality and compliance rates. For instance, a manufacturer faced challenges meeting industry standards related to equipment inspection; after engaging China Inspection Pro's services, they not only achieved compliance but also enhanced their internal processes significantly through targeted feedback from inspectors.

Another success story involves a food processing company that struggled with maintaining consistent food quality checking practices across its facilities. After implementing recommendations from their QC partner regarding food packaging testing procedures and regular audits, they saw marked improvements in both product consistency and customer satisfaction levels—demonstrating the tangible benefits of investing in professional inspections.

These examples illustrate how crucial it is for businesses to prioritize collaboration with experienced QC companies as part of their overall strategy for maintaining high-quality standards while navigating complex regulatory landscapes.

Conclusion

In the realm of safety and compliance, consistent equipment inspection is non-negotiable. Regular checks not only ensure that machinery operates efficiently but also safeguard employees and consumers alike. By prioritizing inspections, organizations can significantly reduce risks associated with faulty equipment, leading to a safer working environment.

Ensuring Safety Through Consistent Inspections

The importance of regular equipment inspection cannot be overstated; it’s the backbone of operational safety. Whether it’s machinery in a factory or tools in a workshop, consistent checks help identify wear and tear before they lead to accidents. Moreover, when companies embrace thorough inspections, they foster a culture of safety that resonates through every level of the organization.

Regularly inspecting equipment also ties directly into the broader framework of compliance with industry standards and regulations. This not only protects employees but also enhances a company’s reputation by demonstrating commitment to quality and safety practices. Ultimately, consistent inspections are an investment in both human capital and organizational integrity.

The Value of Accurate Inspection Certificates

When it comes to proving that your equipment meets necessary standards, accurate inspection certificates are invaluable assets. These documents serve as proof that thorough assessments have been conducted on machinery or products—think of them as badges of honor for your operations! They are particularly crucial when you need to show compliance during audits or when seeking partnerships with other businesses.

Knowing where to find children's product certificate documentation is essential for manufacturers targeting family-oriented markets. An accurate certificate not only ensures regulatory compliance but also builds trust with consumers who prioritize safety for their little ones. In an age where information is readily available online, being able to locate these certificates quickly can save time and prevent potential pitfalls.

Moving Forward: Implementing Best Practices

To elevate your approach towards inspections, adopting best practices is key—this includes integrating food quality checking into your routine evaluations if you’re in the food industry! Understanding the importance of food quality means recognizing that poor standards can lead to dire consequences for health and business reputation alike. Utilizing methods like food packaging testing ensures that products remain safe from contamination throughout their lifecycle.

Partnering with reputable QC companies can streamline this process by providing expert insights into how to check material test certificates effectively. These partnerships not only enhance your inspection protocols but also position your business favorably within competitive markets. In conclusion, embracing a culture centered around diligent inspections will pave the way for sustained success and safety across all operations.