Introduction

In the world of footwear production, the significance of footwear inspection cannot be overstated. Quality assurance is paramount, as it directly impacts customer satisfaction and brand reputation. A robust quality control process ensures that every pair of shoes meets the established standards, making inspections a vital part of the manufacturing journey.

Importance of Footwear Inspection in Quality Control

Footwear inspection serves as a critical checkpoint in the quality control process, helping manufacturers identify defects before products reach consumers. This proactive approach not only reduces returns and complaints but also strengthens trust between brands and customers. By prioritizing thorough inspections, companies can enhance their overall quality management strategies while safeguarding their market position.

Key Elements for Effective Footwear Quality Management

To achieve effective footwear quality management, businesses must focus on several key elements that contribute to success. These include establishing clear inspection criteria, utilizing advanced quality testing services, and training staff to adhere to these standards consistently. By integrating these components into their operations, companies can foster a culture of excellence that resonates throughout their product lines.

Understanding ISO Standards for Footwear

ISO standards provide a framework for ensuring consistent quality across various types of footwear products. Familiarity with these guidelines enables manufacturers to implement best practices in quality control and assurance effectively. By aligning with ISO standards, businesses can demonstrate their commitment to high-quality products while gaining a competitive edge in the marketplace.

Establish Clear Inspection Criteria

To ensure that footwear inspection is effective, establishing clear inspection criteria is paramount. Quality assurance begins with defining what constitutes acceptable standards for various types of footwear. By setting these benchmarks, manufacturers can streamline their quality control processes and enhance overall product reliability.

Defining Standards for Quality Assurance

Defining standards for quality assurance involves identifying the specific attributes that footwear must meet to be considered acceptable. These standards often encompass aspects like durability, aesthetics, comfort, and safety features, which are essential in maintaining customer satisfaction. A well-defined set of criteria not only aids in quality management but also helps in minimizing defects during production.

Specifications for Different Footwear Types

Different types of footwear come with their own unique specifications that must be adhered to during the quality inspection process. For instance, athletic shoes may prioritize breathability and flexibility, while formal shoes might focus on aesthetic appeal and material quality. Understanding these nuances ensures that the right quality testing services are applied to each category of footwear.

Utilizing ISO Standards for Consistency

Incorporating ISO standards into the inspection criteria provides a globally recognized framework for consistency in quality control practices. ISO standards outline specific requirements that help organizations maintain high-quality outputs while minimizing risks associated with non-compliance. By aligning with these guidelines during footwear inspection, manufacturers can achieve a higher level of trust and credibility in their products.

Use of Effective Quality Testing Services

When it comes to ensuring the quality of footwear, employing effective quality testing services is paramount. These services play a crucial role in verifying that products meet established standards and specifications, ultimately supporting quality assurance and control efforts. With various types of testing available, businesses can tailor their approach to meet specific needs and ensure compliance with ISO standards.

Types of Quality Testing Available

Quality testing for footwear encompasses a range of assessments designed to evaluate different aspects of the product. Common types include material testing, durability tests, and safety evaluations, each aimed at identifying any potential issues that could affect performance or consumer safety. By utilizing diverse testing methods, companies can enhance their quality management practices and maintain high standards throughout the production process.

Selecting Reputable Quality Inspection Providers

Choosing the right quality inspection provider is essential for effective footwear inspection and overall product integrity. Look for providers with a strong reputation in the industry who adhere to recognized ISO standards and have extensive experience in footwear quality control. A reputable provider will not only offer comprehensive quality testing services but will also be committed to continuous improvement and customer satisfaction.

China Inspection Pro's Expertise in Footwear

China Inspection Pro stands out as a leading expert in footwear inspection within the realm of quality management. With years of experience working with various brands, they offer tailored solutions that encompass all aspects of quality assurance—from initial inspections to final product assessments. Their commitment to excellence ensures that every pair of shoes meets rigorous standards, making them an invaluable partner for any business focused on maintaining high-quality footwear.

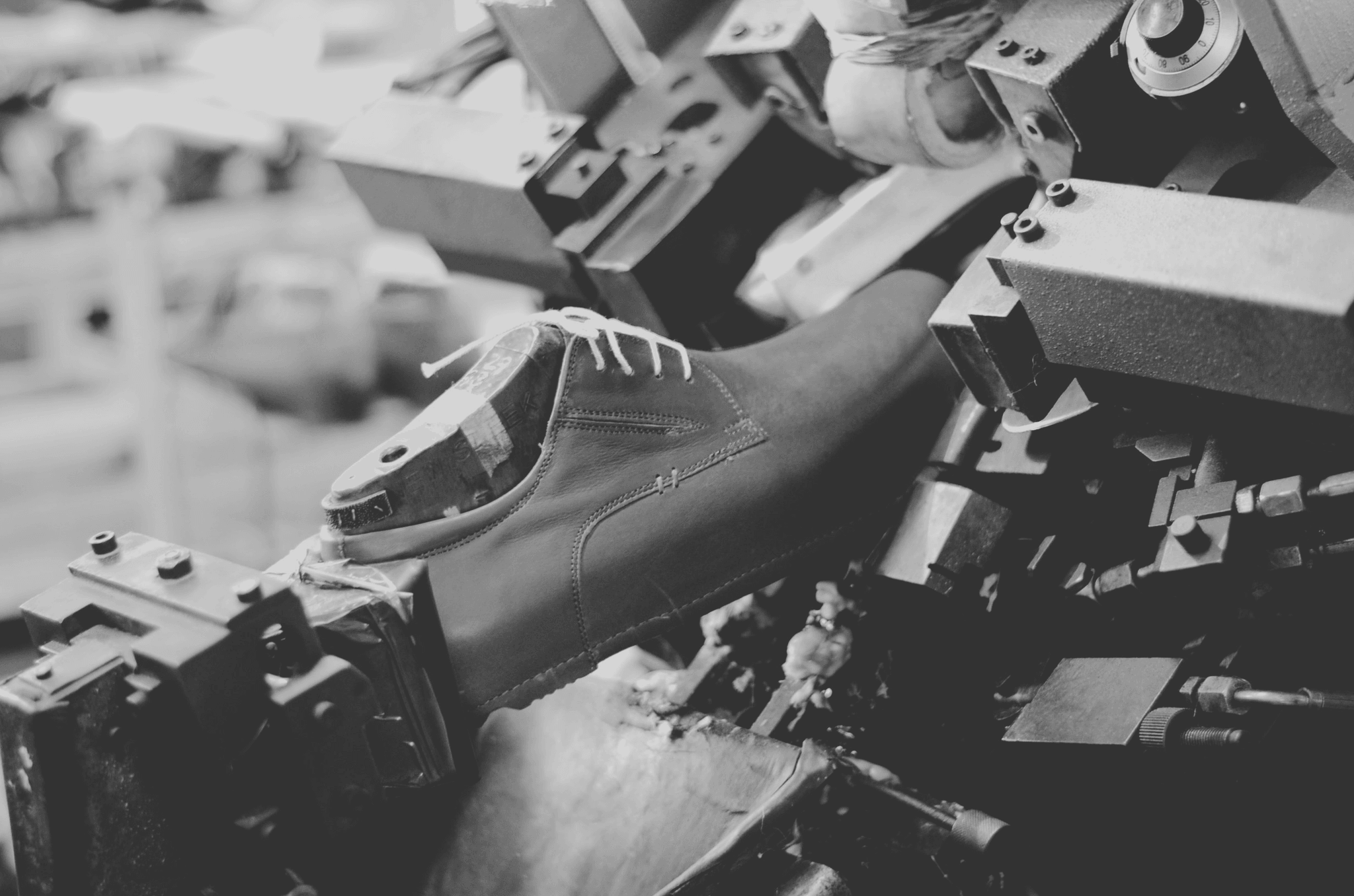

Conduct Visual Inspections Thoroughly

In the realm of footwear inspection, visual assessments play a pivotal role in ensuring quality assurance. The aesthetics of footwear are not just about looks; they can significantly affect consumer perception and brand reputation. A thorough visual inspection helps identify defects that could compromise the overall quality control of the product before it reaches the customer.

Importance of Aesthetics in Quality

Aesthetics are crucial in the footwear industry, as they directly influence a customer's buying decision. When consumers view a pair of shoes, their first impression is often based on appearance, which includes color consistency, stitching quality, and overall finish. Thus, effective quality management must prioritize aesthetics during inspections to maintain high standards and satisfy consumer expectations.

Identifying Common Visual Defects

During footwear inspections, several common visual defects can arise that need to be identified promptly to ensure quality assurance. These include issues such as uneven seams, discoloration, scuff marks, or misaligned patterns that may detract from the shoe's appeal. Recognizing these defects early on is essential for maintaining rigorous quality control and preventing financial losses associated with returns or damaged reputations.

Tools and Methods for Effective Inspection

To conduct effective visual inspections in footwear quality testing services, various tools and methods can be employed to enhance accuracy and efficiency. Magnifying glasses or digital cameras can help inspectors closely examine intricate details that might otherwise go unnoticed by the naked eye. Additionally, checklists aligned with ISO standards provide a structured approach to ensure all critical aspects of aesthetic evaluation are covered during each inspection process.

Perform Functional Testing

Functional testing is a critical component of the footwear inspection process that ensures products meet performance expectations. This phase goes beyond mere aesthetics, focusing on how well the footwear performs under real-world conditions. By integrating quality assurance practices into functional testing, manufacturers can effectively identify any shortcomings before shoes reach consumers.

Assessing Footwear Performance

When assessing footwear performance, various factors come into play, including durability, traction, and support. Quality control measures must be in place to evaluate how well a shoe withstands different conditions and uses over time. Utilizing ISO standards during this assessment can help establish benchmarks that ensure consistency across different types of footwear.

Importance of Fit, Comfort, and Safety

Fit, comfort, and safety are paramount in functional testing; after all, no one wants to wear shoes that feel like medieval torture devices! Poorly fitting shoes can lead to discomfort or even injury, making quality management essential in the design and manufacturing stages. Quality assurance processes must prioritize these elements to guarantee that every pair meets consumer expectations for comfort and safety.

Methods for Functional Quality Testing

There are several methods for conducting functional quality testing on footwear; these include wear tests, pressure mapping, and slip resistance evaluations. Each method offers unique insights into how a shoe performs under various conditions while adhering to established quality control standards. By employing a combination of these techniques alongside reputable quality testing services, manufacturers can ensure their products not only look good but also perform exceptionally well.

Implementing Quality Control Checklists

In the realm of footwear inspection, implementing quality control checklists is a surefire way to streamline processes and enhance product quality. These checklists serve as a roadmap for ensuring that every aspect of quality assurance is addressed, from materials to final product performance. By having a structured approach, companies can maintain consistency and meet the rigorous demands of quality management.

Creating Comprehensive Checklists

Creating comprehensive checklists is essential for effective footwear inspection and quality control. These lists should encompass all critical areas, including material specifications, stitching integrity, and compliance with ISO standards. A well-structured checklist not only aids inspectors in identifying defects but also ensures that each pair of shoes meets established benchmarks for quality assurance.

To develop these checklists, it’s vital to involve key stakeholders in the footwear production process—designers, manufacturers, and quality testing services experts can provide invaluable insights into what needs to be assessed. Regularly reviewing and refining these lists keeps them relevant as new materials or technologies emerge in the industry. Ultimately, a robust checklist empowers teams to uphold high standards throughout the production cycle.

Training Staff on Inspection Procedures

Once comprehensive checklists are created, training staff on inspection procedures becomes crucial for successful implementation. Employees must understand how to utilize these tools effectively during footwear inspections while adhering to established quality control protocols. This not only enhances their skills but also fosters a culture of accountability within the organization.

Training sessions should include practical demonstrations on how to identify defects using the checklist as a guide—this hands-on approach reinforces learning and builds confidence among staff members. Furthermore, incorporating real-life scenarios into training can help employees better understand common pitfalls in footwear inspection and how to avoid them. Investing time in staff training translates directly into improved product quality and customer satisfaction.

Regular Updates to Reflect Current Standards

Quality management isn't static; it evolves alongside industry trends and regulatory requirements—hence the need for regular updates to inspection checklists. Keeping pace with changes in ISO standards or advancements in manufacturing techniques ensures that your footwear inspection processes remain relevant and effective over time. An outdated checklist can lead to oversights that compromise product integrity.

To facilitate timely updates, organizations should establish a review schedule that aligns with industry developments or internal audits—this proactive approach helps maintain high standards of quality assurance across all products. Additionally, involving team members who are directly involved in inspections provides valuable feedback on what aspects need refinement based on their experiences on the ground level. By fostering an environment where continuous improvement is prioritized, companies can significantly enhance their overall quality control efforts.

Documentation and Reporting

In the realm of footwear inspection, documentation and reporting serve as the backbone of effective quality management. Accurate records not only provide a clear overview of quality assurance processes but also facilitate informed decision-making. By maintaining detailed documentation, companies can track their quality control efforts over time, ensuring that any deviations from established ISO standards are promptly addressed.

Importance of Accurate Records

Accurate records in footwear inspection are crucial for establishing a reliable history of product quality. They help identify trends and patterns that may indicate recurring issues or areas for improvement within the production process. Moreover, these records serve as vital evidence during audits or regulatory checks, ensuring compliance with industry standards and bolstering overall confidence in your quality testing services.

Using Data for Continuous Improvement

Data derived from thorough documentation can be leveraged to foster continuous improvement in quality control practices. By analyzing inspection results, companies can pinpoint weaknesses in their processes and implement corrective actions effectively. This proactive approach not only enhances the overall quality assurance framework but also aligns with ISO standards aimed at elevating product integrity across the board.

Leveraging Reports to Meet Regulatory Requirements

Reports generated from footwear inspection activities play a pivotal role in meeting various regulatory requirements imposed by governing bodies. These documents provide transparency and accountability, showcasing adherence to established quality management protocols. Additionally, well-structured reports can highlight compliance with ISO standards, making it easier for businesses to navigate inspections while reinforcing their commitment to excellence in quality control.

Conclusion

In the realm of footwear production, the importance of a robust footwear inspection process cannot be overstated. Quality assurance is not just a checkbox; it’s an ongoing commitment to excellence that ensures every pair of shoes meets or exceeds customer expectations. By implementing effective quality control measures, manufacturers can significantly reduce defects and enhance overall product reliability.

Key Takeaways on Footwear Inspection Process

Footwear inspection serves as a critical component of quality management, ensuring that each product adheres to established ISO standards. Clear criteria for quality assurance must be defined to streamline the inspection process and facilitate consistent outcomes across different footwear types. Ultimately, thorough inspections lead to fewer returns and increased customer satisfaction, thereby solidifying a brand's reputation in a competitive market.

Enhancing Product Quality with Effective Inspections

Implementing effective quality testing services is essential for enhancing product quality at every stage of production. Regular visual inspections paired with functional testing allow manufacturers to identify potential issues early on, reducing costly rework or recalls later in the supply chain. By prioritizing quality inspection processes, businesses can foster innovation while maintaining high standards that resonate with consumers.

The Role of Quality Management in Success

Quality management plays an integral role in the overall success of any footwear brand. It encompasses not only rigorous footwear inspections but also continuous improvement based on data-driven insights from past performance metrics. As companies embrace these practices, they cultivate trust among consumers and stakeholders alike, ultimately driving growth and sustainability within the industry.