Introduction

In today's fast-paced industrial landscape, ensuring the quality of products and services is more critical than ever. Third-party inspections have emerged as a vital component in maintaining high standards across various sectors. These inspections not only verify compliance with industry regulations but also foster trust among consumers and stakeholders alike.

Understanding Third Party Inspections

Third-party inspections involve an independent entity assessing the quality of goods and services produced by a company. This process helps to identify any discrepancies or issues that may arise during production, ensuring that the final output meets established standards. By engaging different types of inspectors, businesses can enhance their production quality management practices and reduce the risk of defects.

The Importance of Quality Assurance

Quality assurance plays a pivotal role in the production of quality goods and services, as it establishes a framework for consistent performance and reliability. Without proper quality assurance measures in place, companies may face significant setbacks such as recalls, reputational damage, or financial losses. Therefore, implementing effective inspection protocols is essential to safeguard not only product integrity but also consumer trust.

Meet the Three Types of Inspectors

When it comes to third-party inspections, there are three primary types of inspectors: quality control inspectors, non-destructive testing inspectors, and social compliance auditors. Each type brings unique expertise to the table—whether it's evaluating manufacturing processes through a quality inspection table or conducting thorough piping inspection checklists for safety assessments. Understanding these roles is crucial for businesses aiming to navigate complex supply chains while upholding ethical standards.

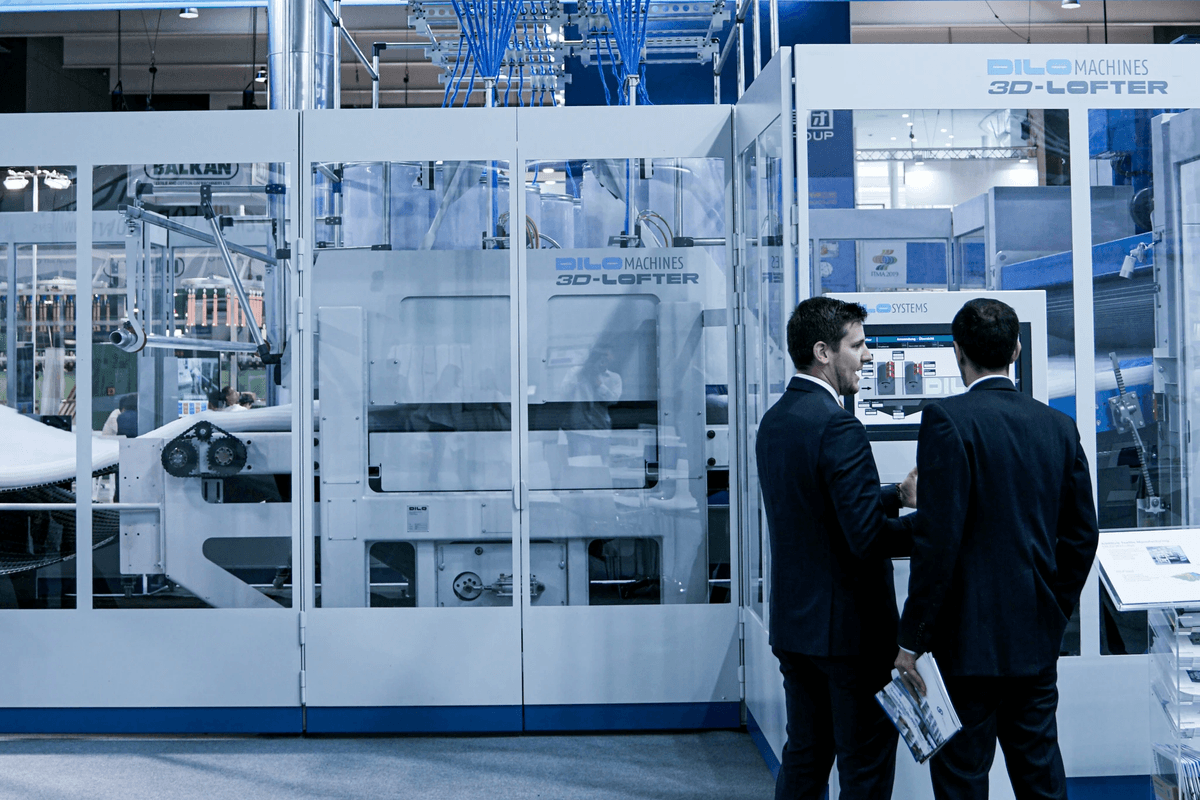

Quality Control Inspectors

Quality control inspectors play a pivotal role in ensuring that the production of quality goods and services meets industry standards. These professionals are the gatekeepers of quality assurance, meticulously evaluating processes and products to prevent defects before they reach consumers. Their expertise directly impacts production quality management, making them essential in any manufacturing environment.

Role in Production Quality Management

In the realm of production quality management, quality control inspectors serve as critical participants who oversee the entire inspection process. They ensure that all products adhere to specified standards and regulations, which is vital for maintaining customer trust and satisfaction. By identifying potential issues early on, these inspectors help reduce waste and minimize costly recalls.

Quality control inspectors also collaborate closely with production teams to develop best practices that enhance product reliability. Their insights can lead to improved manufacturing techniques and more efficient workflows, ultimately benefiting the bottom line. This proactive approach is crucial for companies striving to produce high-quality goods consistently.

Methods Used in Quality Inspections

When it comes to methods used in quality inspections, a variety of techniques are employed depending on the type of product being evaluated. Common practices include visual inspections, measurements with calibrated tools, and functional tests designed to assess performance against established criteria. Each method serves a specific purpose in verifying that products meet required specifications.

For instance, when inspecting electronic components, specialized testing methods might be utilized to ensure functionality without causing damage—a perfect segue into non-destructive testing practices. Similarly, piping inspection checklists may be used in industries where safety is paramount; these checklists outline critical areas for evaluation during inspections. Ultimately, these diverse methods contribute significantly to effective production quality management.

Key Tools: The Quality Inspection Table

One indispensable tool for quality control inspectors is the quality inspection table—an organized space where various inspections take place efficiently and effectively. This table typically includes compartments for tools, samples under scrutiny, and documentation related to inspections performed or pending review. Having all necessary materials at hand allows inspectors to work systematically while maintaining focus on their tasks.

The design of a well-equipped quality inspection table can significantly enhance productivity by reducing time spent searching for tools or documents during critical evaluations. Additionally, this setup fosters an environment conducive to thorough assessments—essential when dealing with complex items such as electronic components or intricate piping systems outlined in specific checklists. In essence, an effective quality inspection table is vital for ensuring consistency across all types of inspectors involved in the process.

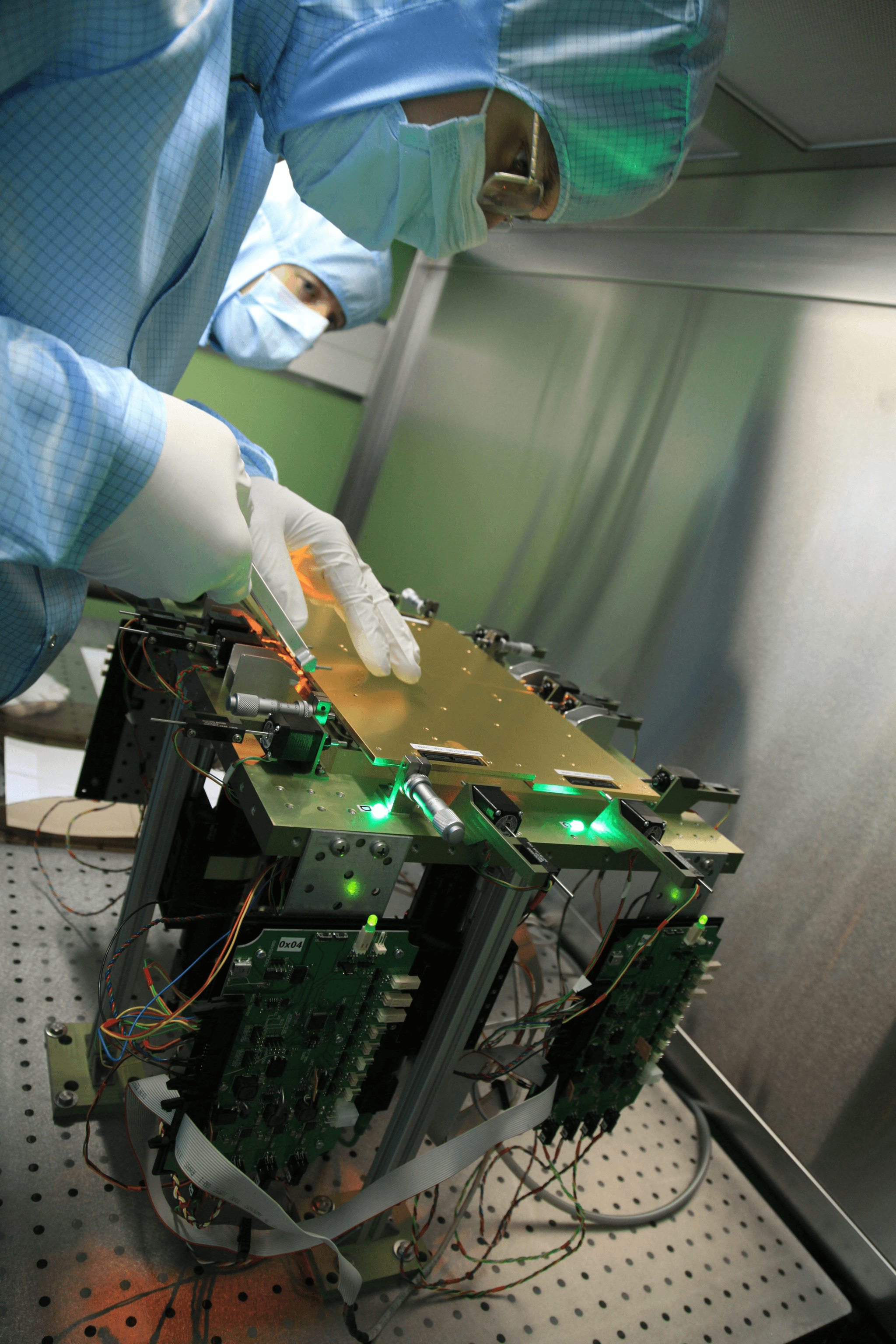

Non-Destructive Testing Inspectors

Non-destructive testing (NDT) inspectors play a pivotal role in ensuring the integrity and reliability of products without causing any damage. This type of inspectors utilizes advanced techniques to evaluate materials, components, and structures across various industries. By employing NDT methods, they help maintain high standards in the production of quality goods and services.

Introduction to Testing of Electronic Components

When it comes to the testing of electronic components, non-destructive testing is essential for assessing functionality without compromising the product's integrity. NDT methods such as ultrasonic testing, X-ray inspection, and thermal imaging are commonly employed to identify defects in sensitive electronic parts. These techniques ensure that only high-quality components make their way into consumer products, safeguarding both manufacturers and end-users alike.

Techniques for Piping Inspection Checklists

Creating an effective piping inspection checklist is crucial for maintaining safety and performance in various industrial settings. Non-destructive testing inspectors utilize several techniques such as visual inspection, magnetic particle testing, and radiographic examination to assess piping systems thoroughly. By following a comprehensive checklist during inspections, these inspectors can identify potential issues before they escalate into costly failures or safety hazards.

Applications Across Various Industries

The applications of non-destructive testing are vast and span numerous industries including aerospace, automotive, construction, and energy sectors. Each industry relies on this type of inspectors to ensure compliance with safety standards while also enhancing production quality management practices. From evaluating welds in pipelines to inspecting aircraft components, NDT plays an integral role in guaranteeing the production of quality goods and services across the board.

Social Compliance Auditors

Social compliance auditors play a crucial role in ensuring that companies adhere to ethical standards throughout their supply chains. These inspectors assess working conditions, labor practices, and environmental impacts to ensure the production of quality goods and services. By conducting thorough social compliance audits, they help businesses maintain integrity and accountability, which is essential in today’s global marketplace.

What is a Non Conformity Report

A Non Conformity Report (NCR) is a critical tool used by social compliance auditors to document instances where a company fails to meet established standards or regulations. This report highlights discrepancies in production quality management, such as unsafe working conditions or violations of labor laws. By identifying these issues, an NCR serves as a foundation for corrective actions that promote the production of quality goods and services.

Ensuring Ethically Produced Goods

The role of social compliance auditors extends beyond merely identifying issues; they actively work with organizations to ensure ethically produced goods. They evaluate supply chain practices against established benchmarks and industry standards, ensuring that all aspects of production align with ethical guidelines. This diligence not only fosters trust among consumers but also encourages companies to prioritize responsible sourcing throughout their operations.

Impact on Global Supply Chains

The impact of social compliance audits on global supply chains cannot be overstated; these inspections shape how businesses operate across borders. By enforcing ethical standards and promoting transparency, social compliance auditors help mitigate risks associated with non-compliance, which can lead to significant financial penalties and reputational damage. Ultimately, these efforts contribute significantly to the overall integrity of the market by fostering an environment where ethically produced goods are prioritized over mere profit margins.

Conclusion

In an increasingly competitive global market, the importance of quality assurance cannot be overstated. Every sector, from manufacturing to service industries, relies on various types of inspectors to ensure that products and services meet rigorous standards. By prioritizing quality, companies not only enhance their reputation but also increase customer satisfaction and loyalty.

Why Quality Matters in Every Sector

Quality is the backbone of successful production of quality goods and services across all sectors. It directly impacts customer trust and brand integrity, making it essential for businesses to implement effective production quality management practices. Without a robust framework for quality assurance—supported by diligent inspections—the risk of defects rises dramatically, leading to costly recalls and diminished market share.

Choosing the Right Type of Inspector

Selecting the appropriate type of inspector is crucial for maintaining high standards in any operation. Each type brings unique expertise; for instance, quality control inspectors focus on production processes while non-destructive testing inspectors are key in evaluating electronic components without compromising their integrity. Understanding what is a non-conformity report can also help businesses identify areas needing improvement and select auditors who specialize in social compliance audits to ensure ethical practices throughout their supply chain.

Elevate Your Standards with China Inspection Pro

China Inspection Pro offers comprehensive solutions that elevate your standards through expert inspections tailored to your needs. With a keen focus on diverse types of inspectors—from those specializing in piping inspection checklists to those adept at assessing electronic components—you can rest assured that every aspect of your production process is scrutinized for excellence. By embracing such thorough oversight, you not only enhance product reliability but also position your brand as a leader committed to delivering top-tier quality.