Introduction

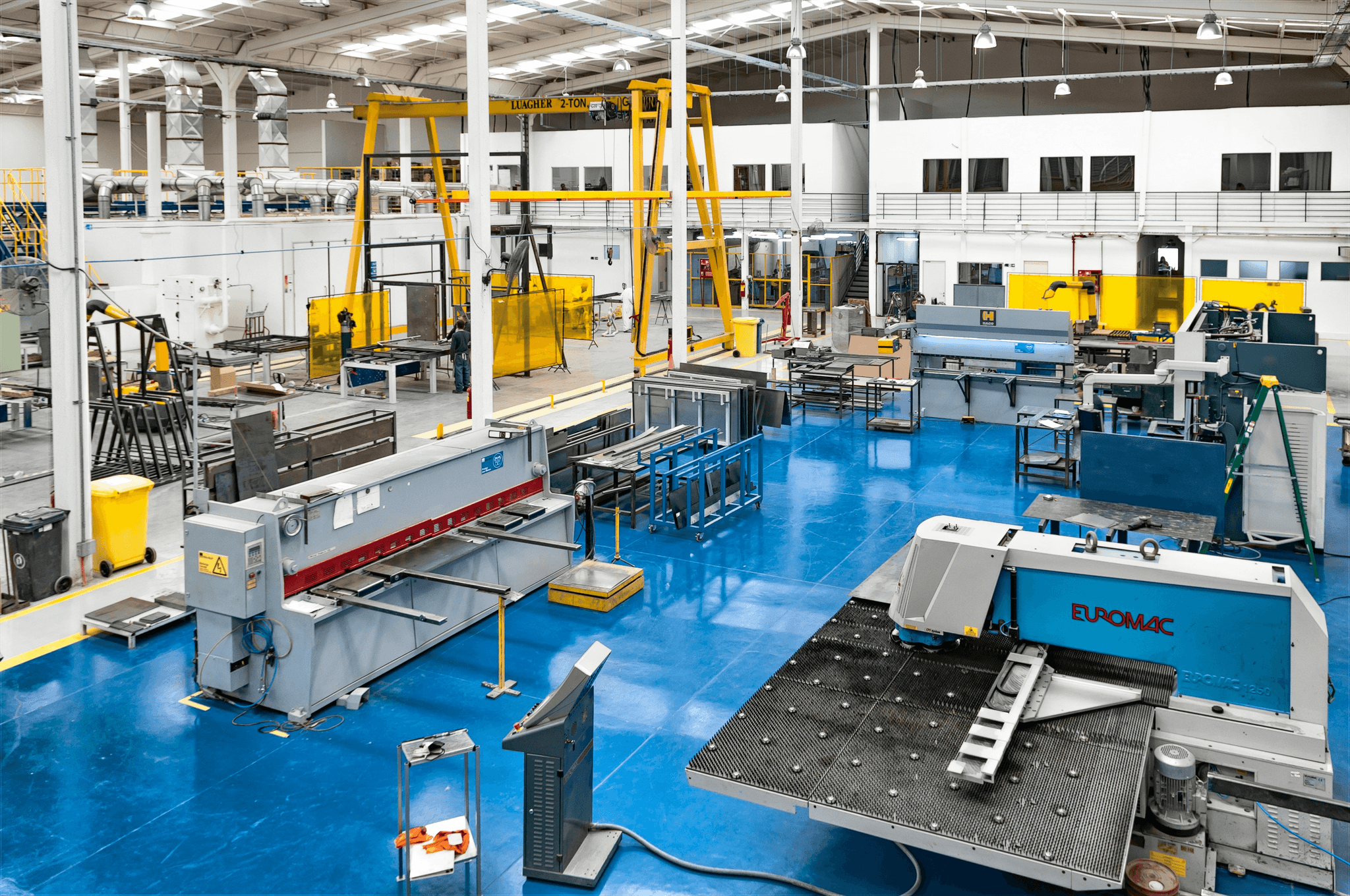

In the fast-paced world of manufacturing, inspections are not just a box to check; they are the backbone of quality assurance. Understanding the importance of inspections can mean the difference between a product that shines on the shelf and one that flops miserably. With various types of inspections, from pre-production quality checks to factory witness tests, manufacturers can safeguard their reputation and ensure customer satisfaction.

Understanding the Importance of Inspections

Inspections serve as critical checkpoints throughout the manufacturing process, ensuring that products meet established standards before they reach consumers. By implementing different types of inspections—such as production inspection and quality inspections—manufacturers can identify potential issues early on, saving time and resources in the long run. The significance of these quality checks cannot be overstated; they not only protect brand integrity but also foster trust with customers who expect nothing less than excellence.

How Inspections Ensure Quality and Safety

Quality inspections play a pivotal role in maintaining safety standards within various industries. By conducting thorough evaluations at different stages—pre-production, in-process, and post-production—companies can mitigate risks associated with faulty products or unsafe practices. These rigorous quality checks help build a culture of safety and accountability, setting a high bar for performance across all manufacturing operations.

The Role of China Inspection Pro

Enter China Inspection Pro: your trusted partner in navigating the complex landscape of manufacturing inspections. With expertise in various types of inspections, including factory witness tests and compliance assessments, they provide tailored solutions for businesses looking to elevate their quality assurance processes. Their commitment to excellence ensures that every product meets stringent standards before it leaves the factory floor.

Types of Inspections in Manufacturing

In the manufacturing landscape, inspections are critical for maintaining quality and ensuring compliance with industry standards. Various types of inspections play a role in this process, each tailored to specific phases of production. Understanding these inspections helps businesses not only to meet customer expectations but also to avoid costly mistakes.

Overview of Quality Inspections

Quality inspections serve as the backbone of any manufacturing process, ensuring that products meet specified standards before they reach consumers. There are several types of quality inspections, including pre-production checks, in-process evaluations, and post-production assessments. Each type focuses on different aspects of the product lifecycle, allowing manufacturers to catch defects early and reduce waste.

Quality checks can vary significantly based on the industry and product type; however, they all share a common goal: delivering defect-free products to customers. By implementing rigorous quality inspections throughout the production journey, companies can enhance their reputation and build customer trust. Ultimately, a robust inspection regime is not just about compliance—it's about fostering a culture of excellence.

Importance of Production Inspections

Production inspections are vital for maintaining quality during the manufacturing process itself. These types of inspections ensure that products are made according to specifications while minimizing errors that could lead to costly reworks or recalls later on. By integrating production inspection into their workflow, manufacturers can identify issues early on and make necessary adjustments before it's too late.

The importance of these checks cannot be overstated; they serve as a real-time feedback loop that helps maintain consistency across batches. Moreover, regular production inspections help streamline operations by identifying inefficiencies or bottlenecks in real time. In essence, investing in thorough production inspection processes enhances both product quality and overall operational efficiency.

Factory Witness Tests Explained

Factory witness tests represent one specific type of inspection where clients or third-party inspectors observe testing procedures firsthand at the manufacturer's facility. This allows stakeholders to verify that products meet specified criteria before shipment or delivery—a crucial step for many industries where safety is paramount. The factory witness test provides an additional layer of assurance that quality standards are being upheld consistently.

During these tests, various parameters such as functionality and durability are evaluated under controlled conditions while observers take detailed notes on performance outcomes. This hands-on approach not only builds trust between manufacturers and clients but also reinforces accountability within the production team regarding adherence to quality standards. By incorporating factory witness tests into their overall inspection strategy, companies can further solidify their commitment to delivering high-quality products.

Pre-Production Inspections

Pre-production inspections are critical in the manufacturing process, acting as the first line of defense against potential quality issues. These inspections focus on assessing the materials and components before they enter the production phase, ensuring that everything meets specified standards. By addressing concerns early on, businesses can avoid costly rework and delays later in the production cycle.

What to Expect from Pre-Production Quality Checks

During pre-production quality checks, expect a thorough examination of raw materials, components, and production processes. Inspectors will evaluate compliance with specifications and standards while conducting factory witness tests to verify that suppliers can meet quality expectations. This proactive approach not only identifies potential problems but also establishes a baseline for subsequent types of inspections throughout the manufacturing process.

Benefits of Early Quality Inspections

The benefits of early quality inspections cannot be overstated; they help prevent costly mistakes down the line. By identifying defects or discrepancies before production begins, companies can make necessary adjustments without incurring significant costs or delays. Additionally, these checks foster better communication between manufacturers and suppliers, leading to stronger partnerships built on trust and reliability.

Key Factors to Assess Before Production

Before kicking off production, there are several key factors to assess during pre-production inspections that can significantly impact product quality. First and foremost is verifying that all materials meet required specifications—this includes checking for certifications and testing reports related to safety and performance standards. Furthermore, understanding the factory's capabilities through factory witness tests ensures that they have adequate equipment and trained personnel ready to execute your vision effectively.

In-Process Inspections

In-process inspections are crucial for maintaining quality throughout the manufacturing process, ensuring that products meet specifications before they reach the final stages. These inspections allow manufacturers to identify potential issues early on, thus reducing waste and preventing costly rework. By implementing effective in-process quality checks, businesses can enhance their overall production efficiency and maintain high-quality standards.

Monitoring Production Quality in Real Time

Real-time monitoring during production is essential for catching defects as they occur, rather than discovering them at the end of the line. This proactive approach to quality inspections allows teams to adjust processes or materials immediately, minimizing disruptions and ensuring consistency across batches. By employing various types of inspections throughout production, manufacturers can safeguard their products' integrity while optimizing workflow.

Techniques for Effective In-Process Quality Checks

To maximize the effectiveness of in-process quality checks, several techniques can be employed, such as statistical process control (SPC) and visual inspections during critical phases of production. Using factory witness tests can also provide valuable insights into whether processes align with specified standards and help identify any deviations promptly. Incorporating a mix of these techniques ensures that all types of inspections are covered adequately throughout the manufacturing process.

How to Address Issues During Production

When issues arise during production, swift action is paramount to mitigate risks associated with quality lapses. Establishing a clear communication channel among team members facilitates immediate reporting and resolution of problems as they occur, leading to quicker adjustments in workflow or material use. Additionally, conducting root cause analysis post-issue helps refine future processes and informs better practices for various types of inspections moving forward.

Post-Production Inspections

Post-production inspections are the final frontier in the quality assurance journey of any manufacturing process. These inspections serve as a critical checkpoint to ensure that products meet the required standards before they hit the market. By focusing on the types of inspections applicable at this stage, businesses can avoid costly mistakes and enhance customer satisfaction.

Final Quality Inspections: What to Look For

When conducting final quality inspections, there are several key factors to keep in mind. First, assess the overall appearance and functionality of the product; this includes checking for defects, ensuring proper labeling, and confirming that all features work as intended. Additionally, it's essential to verify compliance with any relevant safety standards and regulations—this is where factory witness tests can come into play, ensuring products meet industry benchmarks.

Another important aspect is verifying packaging integrity; after all, a well-packaged product not only protects its contents but also reflects positively on your brand. Quality checks at this stage should also include random sampling from production lots to confirm consistency across batches. Remember, thorough final quality inspections can save you from potential recalls or reputational damage down the line.

The Risks of Skipping Post-Production Quality Checks

Skipping post-production quality checks is like sending your child off to school without a lunchbox—risky and potentially disastrous! Without these crucial inspections, you run the risk of releasing defective products into the market, which can lead to customer dissatisfaction and harm your brand's reputation. Moreover, failing to conduct these types of inspections may result in non-compliance with industry regulations, exposing your business to legal liabilities.

Another risk involves financial implications; if defects are discovered after products have been shipped out, it could lead to costly returns or even litigation from unhappy customers. In some cases, manufacturers might also face increased scrutiny from regulatory bodies if they consistently skip these essential quality checks. Ultimately, neglecting post-production inspections could set off a domino effect that jeopardizes both profitability and brand trust.

Common Pitfalls in Final Inspections

Even seasoned professionals can stumble upon common pitfalls during final inspections that may compromise product quality. One major pitfall is relying solely on visual inspection methods without utilizing more objective measures like factory witness tests or automated equipment for verification. This could lead to overlooking subtle defects that might not be immediately visible but could cause significant issues later on.

Another mistake is underestimating documentation; failing to maintain thorough records during post-production quality checks can create confusion down the line if discrepancies arise regarding specific batches or production runs. Additionally, rushing through these types of inspections due to time constraints often results in missed opportunities for catching defects early on—remember that haste makes waste!

In conclusion, effective post-production inspections are vital for maintaining high-quality standards throughout your manufacturing process. By understanding what to look for during these final checks and avoiding common pitfalls along the way, you’ll ensure a smoother path toward delivering exceptional products while safeguarding your brand's reputation.

Regulatory and Compliance Inspections

Regulatory and compliance inspections are crucial for ensuring that products meet industry standards and legal requirements. Different sectors, from pharmaceuticals to electronics, have specific regulations that must be adhered to, making it essential for businesses to understand the landscape of compliance in their industry. Navigating these regulations can be complex, but with the right approach, companies can ensure they meet all necessary quality checks.

Navigating Compliance in Different Industries

Each industry has its own set of compliance requirements that dictate what types of inspections should be conducted. For instance, the food industry mandates strict health and safety standards, while electronics may require factory witness tests to verify safety certifications. Understanding these nuances helps businesses implement appropriate quality inspections tailored to their specific needs.

Moreover, industries like automotive and medical devices often face rigorous regulatory scrutiny; thus, a robust inspection process is non-negotiable. It’s not just about ticking boxes; it’s about embedding quality at every stage of production inspection to mitigate risks effectively. Companies that stay informed about compliance changes can better navigate potential pitfalls and maintain high-quality standards.

Importance of Third-Party Quality Inspections

Third-party quality inspections play a vital role in maintaining objectivity and credibility in the inspection process. Engaging an external provider ensures that your quality checks are unbiased and adhere strictly to regulatory standards without any internal conflicts of interest. This is particularly important when dealing with types of inspections that require specialized knowledge or equipment.

Moreover, third-party inspectors often bring a wealth of experience from various industries, allowing them to identify potential issues more effectively than internal teams might. They can conduct factory witness tests or audits that provide a fresh perspective on your processes while also helping you improve operational efficiency through their insights. Ultimately, investing in third-party inspections can save businesses time and money by catching issues early before they escalate into larger problems.

Role of China Inspection Pro in Regulatory Compliance

China Inspection Pro serves as an invaluable partner for companies looking to ensure compliance with both local and international regulations. With expertise across various industries, they specialize in conducting comprehensive quality inspections tailored specifically for each client's needs—whether it's pre-production checks or post-production evaluations. Their thorough understanding of different types of inspections means they can help clients navigate complex regulatory landscapes seamlessly.

Additionally, China Inspection Pro conducts factory witness tests which serve as critical checkpoints during production runs—ensuring everything adheres to specified standards before mass distribution occurs. By leveraging their services for regulatory compliance, businesses not only safeguard their products but also bolster their reputation within the market as providers committed to quality assurance practices.

In conclusion, understanding regulatory requirements is essential for maintaining product integrity across various industries while avoiding costly setbacks due to non-compliance issues. Partnering with organizations like China Inspection Pro ensures your company remains ahead by implementing effective inspection strategies tailored specifically for your sector's unique challenges.

Conclusion

In today’s competitive manufacturing landscape, understanding the various types of inspections is crucial for maintaining quality and safety. From pre-production quality checks to post-production inspections, each type plays a significant role in ensuring that products meet industry standards and customer expectations. Embracing comprehensive inspection strategies can lead to reduced defects, enhanced reputation, and ultimately, greater profitability.

Benefits of Comprehensive Inspection Types

Implementing a variety of quality inspections offers numerous benefits that can significantly enhance production processes. By conducting factory witness tests and thorough production inspections, businesses can identify potential issues before they escalate into costly problems. Moreover, these types of inspections foster a culture of quality within the organization, encouraging teams to prioritize excellence at every stage of production.

Choosing Quality Inspections for Your Business

When selecting the right type of quality checks for your business, it's essential to consider your specific needs and industry requirements. Different types of inspections serve unique purposes; for instance, pre-production checks help mitigate risks early on while in-process inspections ensure real-time monitoring during manufacturing. By aligning your inspection strategy with your operational goals, you can effectively safeguard product integrity and compliance.

Final Thoughts on Ensuring Quality Standards

In conclusion, investing in a robust inspection framework is not just about compliance; it’s about building trust with customers through consistent quality delivery. The importance of various types of inspections cannot be overstated—each step from pre-production to post-production plays a pivotal role in achieving high-quality outcomes. As we navigate an increasingly complex marketplace, prioritizing effective quality inspections will set businesses apart and pave the way for sustainable success.