Introduction

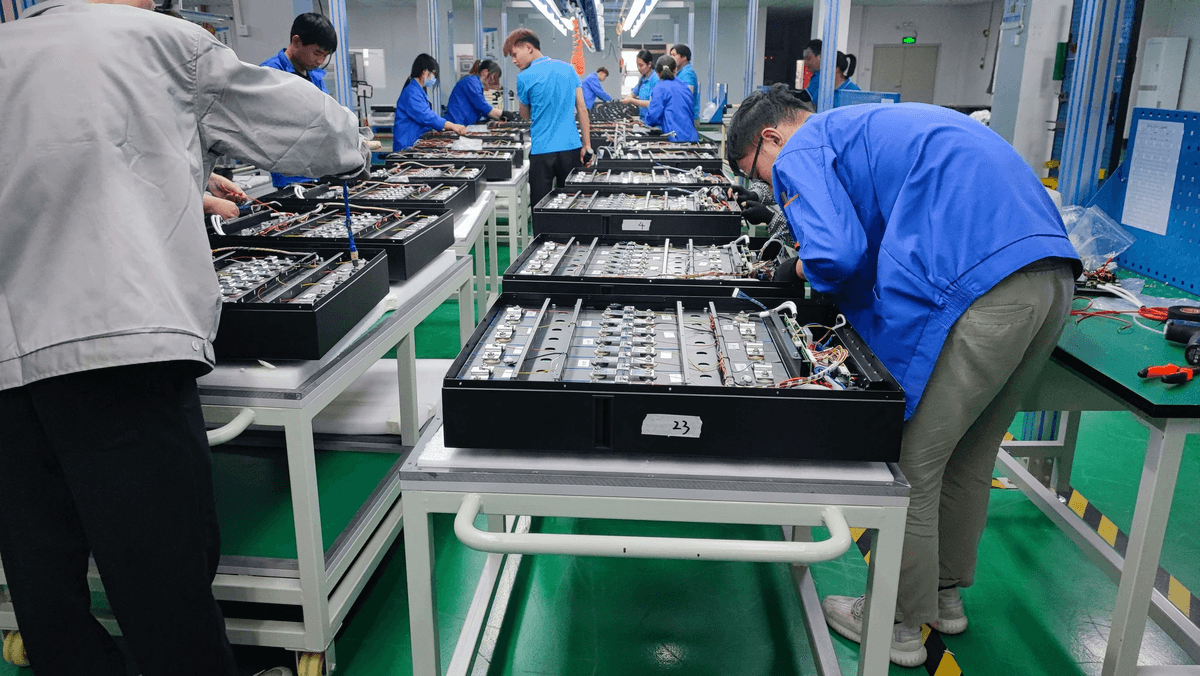

In today's global marketplace, ensuring product quality before shipment is critical for businesses aiming to maintain their reputation and customer satisfaction. Preshipment inspection serves as a vital checkpoint in the supply chain, allowing companies to assess the quality of goods before they reach consumers. This proactive approach not only mitigates risks but also reinforces trust between suppliers and buyers, making it an essential practice in supplier quality management.

Understanding the Importance of Preshipment Inspection

Preshipment inspection acts as a safeguard against defects and non-compliance with specifications, ensuring that products meet established standards before leaving the factory. By conducting thorough checks at this stage, businesses can avoid costly returns and damage to their brand reputation. The importance of this process cannot be overstated; it directly influences customer satisfaction and long-term loyalty.

Key Roles in Supplier Quality Management

Supplier quality roles and responsibilities are crucial for maintaining high standards throughout the production process. These roles often involve collaboration between various stakeholders, including suppliers, manufacturers, and third-party inspection services. Effective communication among these parties ensures that everyone is aligned on expectations, leading to improved product quality and reduced risk of defects.

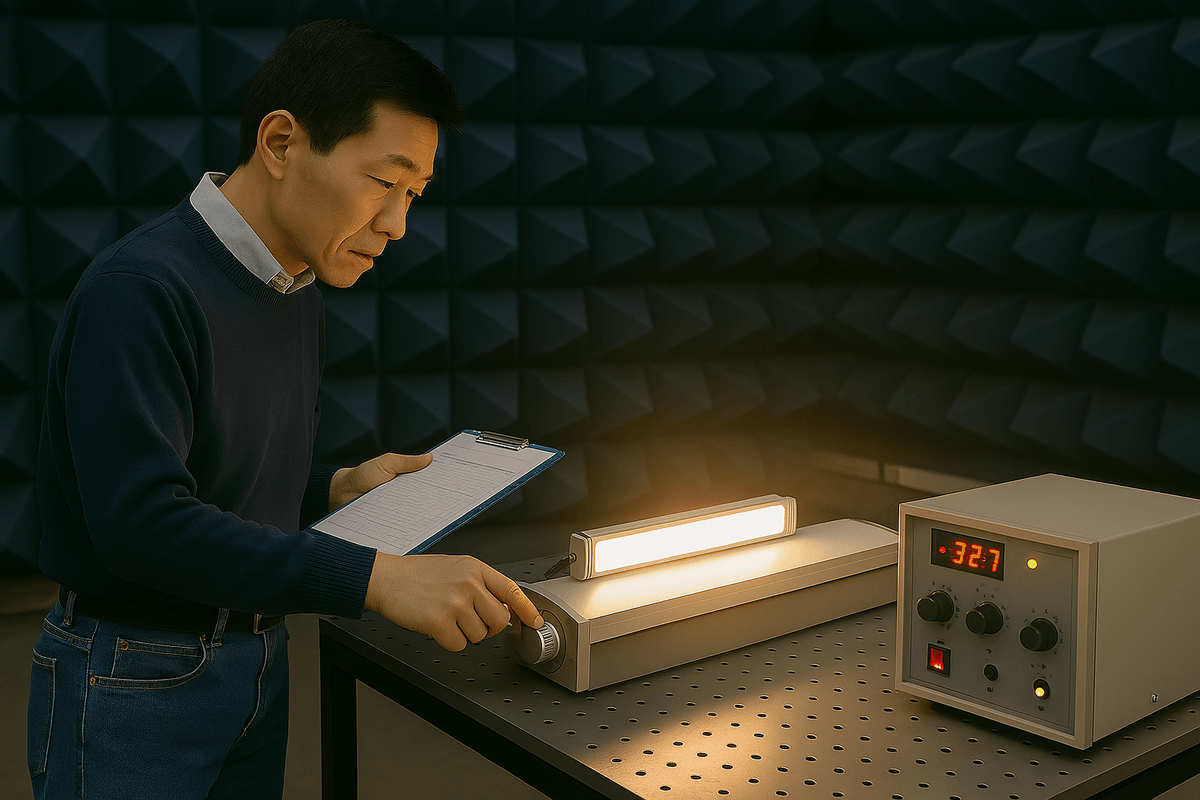

Overview of Third Party Inspection Services

Third party inspection services play an indispensable role in validating manufacturing processes and product integrity. These independent agencies provide unbiased assessments that help companies identify potential issues early on, thus facilitating smoother operations down the line. Whether you're navigating the third party inspection agency list or seeking specific expertise like textile testing or consumer product testing company services, understanding these options can significantly enhance your manufacturing quality inspection efforts.

What is Preshipment Inspection?

Preshipment inspection is a crucial quality control step in the manufacturing process. It involves evaluating products before they leave the factory, ensuring they meet specified standards and customer expectations. By conducting a preshipment inspection, businesses can minimize risks associated with defective products and enhance overall supplier quality roles and responsibilities.

Definition and Purpose

At its core, preshipment inspection is an assessment of goods before shipment to verify their quality, quantity, and compliance with contractual requirements. The purpose of this inspection is to identify any discrepancies or defects that could affect product performance or customer satisfaction. By implementing preshipment inspections, companies can safeguard their reputation and ensure that only high-quality products reach the market.

Types of Inspections Available

There are several types of preshipment inspections available to cater to different needs in the manufacturing landscape. These include visual inspections, where inspectors check for aesthetic flaws; functional testing, which evaluates product performance; and packaging inspections that ensure safe transit conditions. Additionally, textile testing plays a vital role in assessing fabric quality for textile products—an essential aspect of manufacturing quality inspection.

Benefits of Conducting a Preshipment Inspection

The benefits of conducting a preshipment inspection are manifold and directly impact brand reputation and customer trust. First, it helps identify defects early on, reducing costly returns or reworks later in the supply chain. Second, engaging third party inspection services can provide an unbiased evaluation of product quality—offering peace of mind that your goods meet industry standards before they hit the shelves.

The Role of Textile Testing in Quality Assurance

Textile testing plays a pivotal role in ensuring that fabrics meet the required quality standards before they reach consumers. It involves a series of assessments conducted on textiles to evaluate their performance, durability, and safety. This process is essential for maintaining high-quality manufacturing and upholding supplier quality roles and responsibilities throughout the supply chain.

What is Textile Testing?

So, what is textile testing? It refers to the systematic examination of textiles to determine their physical and chemical properties, which can include everything from tensile strength to colorfastness. By utilizing third party inspection services, manufacturers can gain an unbiased evaluation of their products, ensuring compliance with industry standards and regulations.

Textile testing also includes various methods such as visual inspections, laboratory tests, and field evaluations to assess fabric quality comprehensively. This multifaceted approach helps identify any potential issues that could arise during production or after the product reaches the market. Ultimately, it ensures that consumers receive safe and reliable textile products.

Importance of Testing for Fabric Quality

The importance of testing for fabric quality cannot be overstated; it directly impacts consumer safety and satisfaction. Preshipment inspection processes often incorporate textile testing to verify that materials meet specified requirements before they are shipped out from manufacturing facilities. This proactive approach significantly reduces the risk of defects or recalls down the line.

Moreover, effective textile testing aids in maintaining brand reputation by guaranteeing that products meet consumer expectations regarding durability and performance. For businesses relying on supplier quality roles and responsibilities, understanding how fabric performs under various conditions can inform better sourcing decisions and enhance product offerings. In essence, thorough testing serves as a safeguard against costly errors in production.

Standards and Certifications in Textile Testing

Standards and certifications play a crucial role in textile testing by providing benchmarks against which products can be evaluated. Various organizations set these standards—such as ASTM International or ISO—that outline specific criteria for different types of fabrics across multiple applications. Compliance with these standards not only ensures product safety but also enhances credibility among stakeholders.

Additionally, certifications can serve as a marketing tool for brands looking to differentiate themselves in a competitive marketplace; consumers are more likely to trust products backed by recognized certifications from reputable consumer product testing companies. By adhering to established guidelines during preshipment inspection processes through third party inspection agencies, manufacturers can assure clients that they prioritize quality assurance at every stage of production.

In summary, textile testing is an indispensable component of quality assurance within the manufacturing sector—ensuring fabrics are safe, durable, and compliant with industry standards while reinforcing supplier quality roles along the way.

Navigating the Third Party Inspection Agency List

When it comes to ensuring quality in manufacturing, knowing how to navigate the third party inspection agency list is critical. Selecting the right agency can mean the difference between a smooth production process and a costly setback. With many options available, it’s essential to understand how to make an informed choice that aligns with your specific needs for preshipment inspection.

How to Choose the Right Agency

Choosing the right third party inspection services provider is like finding a needle in a haystack—challenging but crucial. Start by identifying what you need; whether it's preshipment inspection or specialized textile testing, knowing your requirements helps narrow down your options. Additionally, consider agencies that have experience in your industry; this ensures they understand supplier quality roles and responsibilities specific to your sector.

Next, look for agencies that offer comprehensive services tailored to your product type. For instance, if you’re dealing with textiles, ensure they specialize in what is textile testing and can provide relevant certifications. Finally, read reviews and testimonials from previous clients; this will give you insights into their reliability and service quality.

Evaluating Agency Credentials and Experience

Once you've shortlisted potential agencies from the third party inspection agency list, it's time to dive deeper into their credentials and experience. Verify their certifications—agencies should be accredited by recognized bodies that assure compliance with international standards for manufacturing quality inspection. This will not only validate their expertise but also ensure that they adhere to best practices in preshipment inspections.

Experience matters! Agencies with a solid track record of working with various manufacturers are more likely to understand complex supply chains and can manage supplier quality roles effectively. Don't hesitate to ask about their past projects or any case studies showcasing their success in textile testing or other relevant areas.

Top Agencies for Manufacturing Quality Inspection

While there are countless agencies out there, a few stand out as leaders in providing top-notch manufacturing quality inspection services. Companies like SGS, Bureau Veritas, and Intertek are renowned for their rigorous standards in preshipment inspections across various industries—including textiles! These agencies not only offer what is textile testing but also provide extensive global reach and local expertise.

Another noteworthy mention is TUV Rheinland; they excel at ensuring compliance with safety regulations while maintaining high-quality standards throughout the supply chain process. If you're looking for consumer product testing companies specifically focused on textiles or other consumer goods, these agencies should definitely be on your radar.

Remember: investing time upfront in selecting the right agency pays off later when you see enhanced product quality and reduced risk of non-compliance issues!

Supplier Quality Roles and Responsibilities

In the realm of manufacturing, supplier quality roles and responsibilities are paramount to ensuring that products meet the required standards before they reach consumers. Effective management of these roles not only streamlines processes but also enhances overall product quality. With preshipment inspection playing a crucial role in this equation, understanding these responsibilities is essential for maintaining a competitive edge.

Defining Responsibility Across the Supply Chain

Defining responsibility across the supply chain is vital for achieving consistent quality in manufacturing. Each participant, from suppliers to manufacturers to third party inspection services, must understand their specific roles and how they contribute to product integrity. Clarity in supplier quality roles and responsibilities helps prevent misunderstandings that could lead to defects or delays, ultimately impacting customer satisfaction.

Importance of Communication with Suppliers

Effective communication with suppliers is critical for maintaining high-quality standards throughout the production process. Regular dialogue ensures that everyone involved understands expectations regarding preshipment inspection protocols and what constitutes acceptable fabric quality—especially when discussing what is textile testing and its implications for production. By fostering open lines of communication, businesses can address potential issues proactively, thereby enhancing collaboration and trust.

Ensuring Compliance with Quality Standards

Ensuring compliance with quality standards is a non-negotiable aspect of supplier quality management. It involves rigorous monitoring of processes through tools like the third party inspection agency list to identify reliable partners who adhere strictly to industry regulations. Moreover, understanding terms such as NPI (New Product Introduction) in manufacturing can aid companies in implementing effective strategies that guarantee alignment with established benchmarks—ultimately securing brand reputation through diligent consumer product testing company partnerships.

Leveraging Consumer Product Testing Companies

In today's competitive market, ensuring the quality of your products is paramount. That's where consumer product testing companies come into play, providing essential services that bolster your business's credibility and reliability. By leveraging these specialized firms, you can enhance your preshipment inspection processes and ensure that every item meets the required standards before it reaches consumers.

What They Do for Your Business

Consumer product testing companies focus on evaluating various aspects of products to ensure they meet safety and quality standards. This includes conducting thorough textile testing to assess fabric durability, colorfastness, and other critical characteristics that define quality in textiles. Additionally, these companies often provide insights into compliance with industry regulations, helping businesses navigate the complex landscape of supplier quality roles and responsibilities.

By engaging a consumer product testing company, you can streamline your manufacturing quality inspection processes while gaining valuable feedback on product performance. Their expertise allows you to identify potential issues before they escalate into costly problems or affect your brand’s reputation. Ultimately, this proactive approach leads to higher customer satisfaction and loyalty.

Choosing the Right Testing Partner

Selecting an appropriate consumer product testing company is crucial for maximizing the benefits of their services. Start by reviewing the third party inspection agency list available online; this can help you identify reputable firms with a track record in your specific industry. When narrowing down options, consider factors such as experience in textile testing, accreditation from recognized organizations, and client testimonials.

Moreover, it's essential to evaluate how well each agency aligns with your company's values and goals—after all, a good partnership enhances both parties' reputations in the marketplace. Look for agencies that offer comprehensive services beyond just preshipment inspection; they should also provide guidance on compliance with relevant standards and certifications in textile testing. This holistic approach ensures that you're not just checking off boxes but genuinely improving product quality.

Impact on Brand Reputation and Customer Trust

Engaging a reliable consumer product testing company can significantly enhance your brand's reputation among consumers and industry stakeholders alike. By consistently delivering high-quality products backed by thorough inspections—including preshipment inspections—you demonstrate commitment to excellence that resonates with customers seeking trustworthy brands. When consumers know they've chosen a brand focused on quality assurance through rigorous textile testing practices, their trust deepens.

Furthermore, positive experiences lead to word-of-mouth recommendations—an invaluable asset in today’s digital age where reviews can make or break a business's reputation overnight. The impact of partnering with reputable agencies extends beyond immediate sales; it influences long-term customer relationships built on trustworthiness and reliability within supplier quality roles and responsibilities throughout the supply chain.

In conclusion, leveraging consumer product testing companies not only fortifies your manufacturing processes but also elevates your brand's standing in an increasingly discerning market.

Conclusion

In the world of manufacturing and supply chain management, preshipment inspection plays a crucial role in ensuring product quality before items reach consumers. Understanding what is textile testing and its significance helps businesses maintain high standards, while leveraging third party inspection services can streamline the quality assurance process. By recognizing supplier quality roles and responsibilities, companies can foster better relationships with their suppliers and ultimately enhance their overall operational efficiency.

Key Takeaways for Effective Inspections

Effective inspections are vital to maintaining product integrity and customer satisfaction. One key takeaway is the importance of conducting thorough preshipment inspections to catch potential defects early in the process. Additionally, understanding what does NPI mean in manufacturing—New Product Introduction—can help teams navigate changes in production while still adhering to quality standards.

Enhancing Quality Through Collaboration

Collaboration between manufacturers and third party inspection agencies can significantly boost product quality. By working together, organizations can share insights on best practices related to textile testing and other critical evaluations that impact consumer safety and satisfaction. This synergy not only fosters a culture of continuous improvement but also strengthens brand reputation through consistent delivery of high-quality products.

Continuous Improvement in Manufacturing Processes

Continuous improvement should be at the heart of every manufacturing operation, especially when it comes to implementing effective preshipment inspections and utilizing consumer product testing companies for additional verification. Regularly revisiting processes allows businesses to adapt swiftly to changing market demands while ensuring compliance with industry standards outlined in the third party inspection agency list. Ultimately, a commitment to ongoing enhancement will lead to superior products that resonate with consumers.