Introduction

In today's fast-paced manufacturing landscape, the significance of quality inspection services cannot be overstated. These services ensure that products meet safety standards and comply with regulatory requirements, safeguarding both consumers and businesses alike. As companies increasingly rely on global supply chains, understanding how to navigate the third party inspection agency list becomes crucial for maintaining product integrity and brand reputation.

Understanding Quality Inspection Services

Quality inspection services are essential in monitoring and evaluating the manufacturing process to ensure that products meet specified criteria before they reach consumers. This encompasses various types of inspections, including in-process checks, final product assessments, and preshipment inspections. By implementing a robust inspection sampling plan, manufacturers can identify defects early on, minimizing costly recalls and enhancing overall product quality.

The Importance of Third Party Inspections

Third party inspections are vital for an unbiased assessment of product quality. Engaging an independent consumer product testing company allows manufacturers to gain insights into their processes from a fresh perspective while building trust with stakeholders. Moreover, these inspections help mitigate risks associated with manufacturing defects and non-compliance by providing expert evaluations that reinforce operational standards.

Choosing the Right Inspection Agency

Selecting the right inspection agency from a comprehensive third party inspection agency list can be daunting but is essential for ensuring effective quality control measures are in place. Factors such as agency credentials, industry experience, and customer reviews should play a significant role in your decision-making process. Additionally, understanding what does NPI mean in manufacturing can help you align your goals with an agency that specializes in new product introduction strategies tailored to enhance quality assurance.

Why Quality Inspection Services Matter

Quality inspection services are essential for ensuring that products meet safety standards and regulatory compliance. In an era where consumers are more informed and discerning, the stakes have never been higher. By investing in quality inspection services, businesses can avoid costly recalls and legal issues while fostering customer trust.

Ensuring Product Safety and Compliance

Ensuring product safety is a non-negotiable aspect of manufacturing quality inspection. Quality inspection services help verify that products comply with industry regulations, reducing the risk of harmful defects reaching consumers. When manufacturers engage a reputable third party inspection agency, they enhance their credibility by demonstrating a commitment to safety and compliance.

Reducing Risks in Manufacturing

Manufacturing is fraught with risks, from production errors to supply chain disruptions. Implementing an effective inspection sampling plan can significantly mitigate these risks by identifying potential issues early in the process. By prioritizing quality inspections throughout production phases, companies can reduce waste, minimize rework costs, and ultimately improve their bottom line.

Enhancing Brand Reputation

A strong brand reputation is built on consistent quality and reliability; this is where consumer product testing companies come into play. By utilizing quality inspection services, brands can ensure their products not only meet but exceed customer expectations. When consumers know they can trust a brand’s commitment to quality through regular inspections—like preshipment inspections—they are more likely to become loyal advocates.

Key Components of Manufacturing Quality Inspection

When it comes to manufacturing quality inspection, several key components work together to ensure that products meet safety and compliance standards. These components include in-process inspections, final product inspections, and thorough documentation and reporting. Each plays a crucial role in maintaining the integrity of quality inspection services throughout the production cycle.

In-Process Inspections

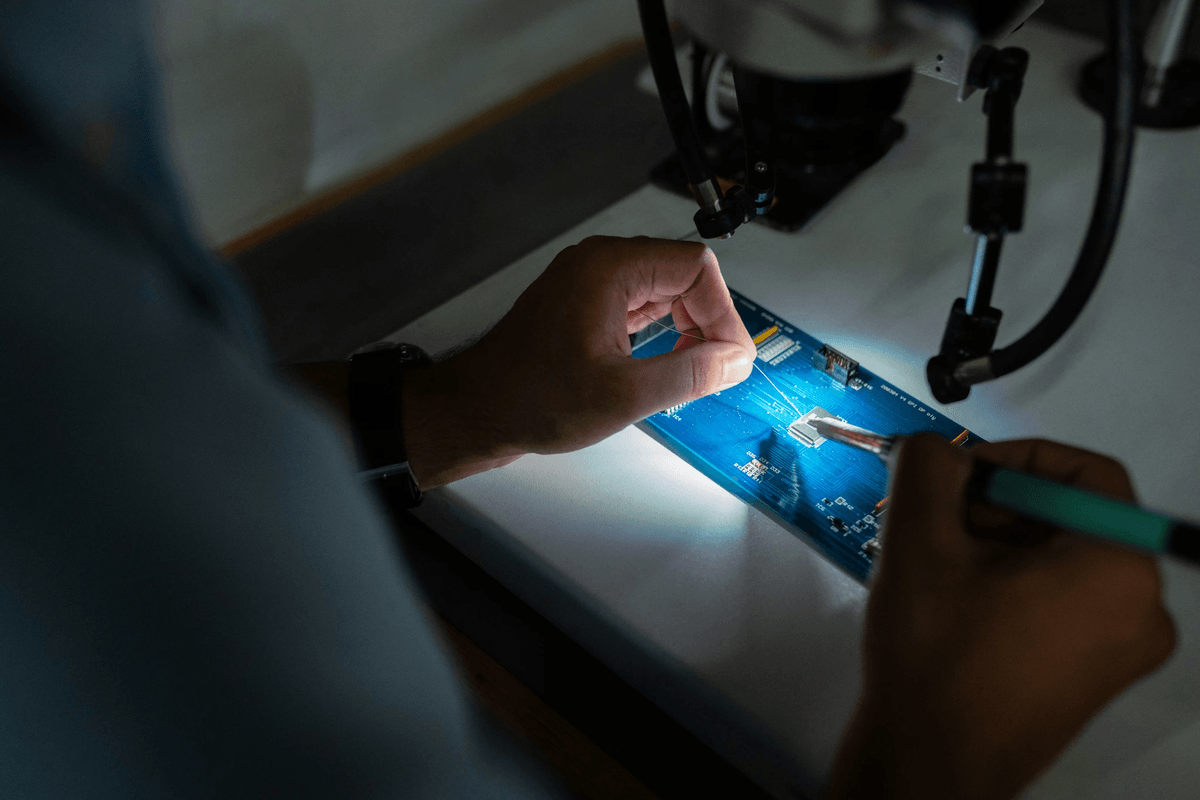

In-process inspections are essential for identifying defects early in the manufacturing process, which can save both time and resources down the line. These inspections involve regular checks at various stages of production, allowing manufacturers to catch issues before they escalate into larger problems. By utilizing a third party inspection agency list for these checks, companies can ensure an unbiased evaluation that enhances overall product quality.

Implementing an effective inspection sampling plan during in-process inspections is vital for achieving accurate results without disrupting workflow. This proactive approach not only mitigates risks but also aligns with what does NPI mean in manufacturing—ensuring that new products are developed with quality control at the forefront. Ultimately, in-process inspections contribute significantly to reducing waste and improving efficiency within manufacturing operations.

Final Product Inspections

Final product inspections serve as the last line of defense before goods reach consumers or retailers. These comprehensive evaluations assess whether products meet all specifications and regulatory requirements outlined by industry standards or consumer expectations. Engaging a reputable consumer product testing company for these assessments adds credibility and ensures compliance with safety regulations.

During final product inspections, attention is given to aesthetic qualities as well as functional performance, ensuring that every item is not only safe but also market-ready. The insights gained from these evaluations can bolster brand reputation by demonstrating a commitment to quality assurance—a factor increasingly valued by consumers today. Additionally, conducting thorough final checks helps prevent costly returns or recalls that could arise from undetected faults.

Documentation and Reporting

Documentation and reporting are critical components of any effective manufacturing quality inspection strategy. Detailed records provide evidence of compliance with industry standards while offering insights into trends over time—essential information for continuous improvement initiatives within organizations. A robust documentation process ensures that all findings from both in-process and final product inspections are meticulously recorded.

Moreover, clear reporting helps stakeholders understand inspection outcomes quickly and effectively; this transparency fosters trust between manufacturers and their clients or partners alike. Utilizing data from documentation can also inform future decisions regarding supplier selection from a third party inspection agency list or adjustments needed in production processes based on previous outcomes. Emphasizing proper documentation not only enhances accountability but also reinforces the importance of maintaining high-quality standards across all aspects of manufacturing.

Navigating the Third Party Inspection Agency List

When it comes to quality inspection services, navigating the third party inspection agency list can be daunting. With so many options available, it’s crucial to find an agency that aligns with your manufacturing quality inspection needs. This section will guide you through identifying top agencies, evaluating their credentials, and balancing cost against quality.

Top Agencies to Consider

There are several reputable agencies that stand out in the realm of quality inspection services. Companies like SGS, Intertek, and Bureau Veritas have established themselves as leaders in the industry by providing comprehensive inspections tailored for various sectors. When exploring the third party inspection agency list, these names should be at the forefront of your research due to their proven track records and extensive service offerings.

In addition to these giants, consider niche agencies that specialize in specific areas relevant to your products or industry. For instance, if you're looking into consumer product testing companies, organizations like UL and TUV Rheinland focus heavily on safety standards for consumer goods. Selecting from this diverse pool can enhance your manufacturing quality inspection process significantly.

Evaluating Agency Credentials

Once you've identified potential candidates from the third party inspection agency list, it's time to evaluate their credentials meticulously. Start by verifying their certifications—look for ISO certifications or accreditations relevant to your industry as they indicate a commitment to maintaining high standards in quality inspection services. Furthermore, check client testimonials and case studies; real-world success stories can provide insight into how well an agency performs under pressure.

Don’t overlook the importance of experience; agencies with a long-standing presence often have refined processes for conducting inspections effectively. Additionally, inquire about their inspectors' qualifications—ensuring they possess relevant training and expertise is vital for accurate assessments during manufacturing quality inspections. A thorough credential evaluation will help you choose an agency that meets your specific needs.

Cost vs. Quality

One of the most challenging aspects of selecting a third party inspection agency is balancing cost against quality in your decision-making process. While it may be tempting to go with lower-cost options on the third party inspection agency list, remember that cutting corners could lead to significant issues down the line—especially when considering what does NPI mean in manufacturing contexts where precision matters greatly. Investing in higher-quality services often pays off through reduced risks and enhanced compliance with safety regulations.

To navigate this dilemma effectively, create a clear budget while also prioritizing essential qualities such as experience and reputation over price alone. Engage potential agencies in discussions about their pricing structures; some may offer flexible packages or discounts for long-term contracts that could fit within your financial framework without sacrificing service excellence. Ultimately, finding a balance between cost and quality ensures you receive top-notch inspections without breaking the bank.

Insights on What NPI Means in Manufacturing

In the realm of manufacturing, New Product Introduction (NPI) is a critical process that dictates how new products transition from concept to market-ready items. Understanding what NPI means in manufacturing is vital for companies striving for quality and efficiency. It encompasses various stages, including design validation, production planning, and quality inspection services to ensure that each product meets industry standards before hitting the shelves.

Definition and Importance

NPI refers to the structured approach used by manufacturers to launch new products effectively. Its importance cannot be overstated; a well-executed NPI process minimizes risks associated with product defects and ensures compliance with safety regulations. By integrating quality inspection services into the NPI framework, businesses can identify potential issues early on and make necessary adjustments before full-scale production begins.

NPI Best Practices

To maximize the benefits of NPI, manufacturers should adopt best practices that include cross-functional collaboration among design, engineering, and quality assurance teams. Regular reviews during the development phase can help align objectives and refine product specifications based on feedback from third party inspection agency lists or consumer product testing companies. Additionally, implementing an effective inspection sampling plan during prototype testing allows for timely identification of flaws while ensuring that final products are ready for preshipment inspection without any hitches.

Impact on Quality Control

The impact of a robust NPI process on quality control is significant; it establishes a foundation for ongoing assessments throughout the product lifecycle. By focusing on what does NPI mean in manufacturing, companies can create a culture centered around continuous improvement and proactive problem-solving. This not only enhances brand reputation but also reduces costs associated with recalls or rework by ensuring that manufacturing quality inspections are thorough and comprehensive right from the start.

Consumer Product Testing Companies Explained

In today’s competitive marketplace, consumer product testing companies play a crucial role in ensuring that products meet safety and quality standards. These organizations provide essential quality inspection services that help manufacturers avoid costly mistakes and ensure compliance with regulations. By leveraging third party inspection agency lists, businesses can identify reliable partners to enhance their manufacturing quality inspection processes.

Leading Companies in the Industry

Several leading consumer product testing companies have established themselves as go-to resources for manufacturers seeking reliable quality inspection services. Organizations like SGS, Intertek, and Bureau Veritas are renowned for their expertise and comprehensive testing capabilities across various industries. These companies not only offer insights into what does NPI mean in manufacturing but also provide tailored solutions that address specific industry needs.

Types of Tests Offered

Consumer product testing companies provide a wide range of tests designed to evaluate product safety, performance, and compliance with regulatory standards. Common tests include mechanical assessments, chemical analyses, and durability evaluations tailored to specific materials or products. By implementing an effective inspection sampling plan, manufacturers can ensure that their goods consistently meet quality benchmarks before reaching consumers.

How Testing Impacts Market Success

The impact of rigorous testing on market success cannot be overstated; it directly influences brand reputation and consumer trust. Products that pass thorough inspections not only comply with legal requirements but also stand out in a crowded marketplace as reliable options for buyers. Additionally, preshipment inspections conducted by reputable consumer product testing companies help mitigate risks associated with defective goods reaching the market, ultimately contributing to sustained business growth.

Crafting an Effective Inspection Sampling Plan

An effective inspection sampling plan is crucial for maintaining high standards in manufacturing quality inspection. It allows businesses to assess product quality without having to inspect every single item, which can be time-consuming and costly. By strategically selecting samples, companies can ensure that they are meeting regulatory requirements and consumer expectations while optimizing their resources.

Importance of Sampling in Quality Control

Sampling plays a pivotal role in quality control as it provides a practical approach to evaluating large quantities of products. Through a well-structured sampling plan, businesses can identify defects early on, reducing the risk of non-compliance and enhancing overall product safety. This is particularly important when working with third party inspection agencies, which rely on effective sampling methods to deliver accurate assessments.

Moreover, understanding what does NPI mean in manufacturing—New Product Introduction—highlights the significance of testing during the initial stages of production. Proper sampling ensures that new products meet established standards before they hit the market, thereby protecting brand reputation and consumer trust. Ultimately, effective sampling not only safeguards product quality but also streamlines the preshipment inspection process.

Best Practices for Developing a Plan

Developing an effective inspection sampling plan requires careful consideration and adherence to best practices. First, it's essential to define clear objectives based on specific quality criteria relevant to your products; this sets the foundation for your sampling strategy. Next, leveraging data from previous inspections or consumer product testing companies can inform your sample size and selection methods.

Additionally, incorporating statistical techniques can enhance the reliability of your results—think along the lines of acceptance sampling plans that determine how many items should be inspected based on lot size and acceptable defect rates. Regularly reviewing and updating your plan will also ensure it remains relevant as production processes evolve or new regulations emerge within quality inspection services.

Common Pitfalls to Avoid

While crafting an inspection sampling plan may seem straightforward, there are several common pitfalls that manufacturers should avoid at all costs. One major mistake is underestimating sample sizes; too small a sample may lead to inaccurate conclusions about overall product quality and compliance levels with industry standards set by third party inspection agencies.

Another frequent error involves neglecting documentation; without proper records detailing your methodology and findings from inspections, it becomes challenging to track improvements or justify decisions made during audits or reviews by external stakeholders like consumer product testing companies. Lastly, failing to involve cross-functional teams—including production staff and quality assurance professionals—can result in a disjointed approach that undermines the effectiveness of your entire quality control strategy.

The Role of Preshipment Inspections

When it comes to ensuring product quality before shipment, preshipment inspections play a pivotal role. These inspections are conducted to verify that products meet the required specifications and standards, thus safeguarding against potential issues down the line. By incorporating preshipment inspections into your quality inspection services strategy, you can significantly reduce the risk of costly returns and customer dissatisfaction.

Benefits of Preshipment Inspections

Preshipment inspections offer a multitude of benefits that can enhance your manufacturing quality inspection process. First and foremost, they help in identifying defects or non-compliance issues before the products leave the factory, which can save time and money. Additionally, these inspections bolster trust in your brand by ensuring that only high-quality products reach consumers, thus enhancing your overall reputation in the market.

Moreover, utilizing a third party inspection agency list for preshipment inspections adds an extra layer of objectivity to the process. This impartiality is crucial for maintaining transparency and credibility with stakeholders, including suppliers and customers alike. Ultimately, investing in preshipment inspection services not only mitigates risks but also positions your business as a leader in quality assurance.

Key Steps in the Process

To effectively implement preshipment inspections within your manufacturing workflow, there are several key steps to follow. First, establish clear criteria based on product specifications and industry standards; this will serve as your benchmark during the inspection process. Next, select a qualified consumer product testing company from your third party inspection agency list to conduct thorough evaluations at predetermined stages.

Once you've identified an agency, it's essential to develop an inspection sampling plan that outlines how many items will be inspected and which specific attributes will be assessed. This systematic approach ensures comprehensive coverage while minimizing disruption to production schedules. Finally, after completing the inspections, compile detailed reports highlighting any findings or recommendations for improvement—this documentation is invaluable for continuous quality enhancement.

Real-World Examples of Success

One notable success story involving preshipment inspections comes from a leading electronics manufacturer that faced significant challenges with defective units reaching customers post-shipment. By integrating rigorous preshipment quality inspection services into their processes—specifically through collaboration with a reputable consumer product testing company—they were able to reduce defect rates by over 30%. This not only improved customer satisfaction but also saved them millions in potential recalls.

Another example can be found within the apparel industry where brands have successfully leveraged preshipment inspections to ensure compliance with safety regulations while maintaining high-quality standards across their product lines. By utilizing insights gained from what does NPI mean in manufacturing (New Product Introduction), these companies have streamlined their processes further by implementing corrective actions based on past inspection outcomes—ultimately fostering innovation alongside reliability.

In conclusion, embracing preshipment inspections is not just about compliance; it’s about building a robust foundation for long-term success through effective manufacturing quality inspection practices.

Conclusion

In the ever-evolving landscape of manufacturing, selecting quality inspection services is not just a checkbox on your to-do list; it’s a critical investment in your business's future. The right third party inspection agency can offer invaluable insights and ensure that your products meet industry standards, ultimately safeguarding your reputation. As you navigate the extensive third party inspection agency list, prioritize agencies that align with your specific needs and values.

Selecting Quality Inspection Services Wisely

Choosing the right quality inspection services involves more than just comparing prices; it’s about finding an agency that understands the nuances of your industry. A thorough evaluation of their credentials and past performance can provide clarity on what they bring to the table. Additionally, don’t hesitate to ask questions about their approach to manufacturing quality inspection and how they handle challenges like preshipment inspections or unexpected product issues.

Benefits of Regular Inspections

Regular inspections are essential for maintaining high standards in product safety and compliance, reducing risks associated with manufacturing defects. By integrating routine checks into your workflow, you can catch potential issues before they escalate into costly problems or recalls. Moreover, consistent quality assurance not only protects consumers but also enhances brand reputation—because nothing says trustworthy quite like a commitment to excellence.

Embracing Quality for Business Growth

Embracing a robust quality inspection framework is crucial for sustainable business growth in today’s competitive market. Understanding what does NPI mean in manufacturing can help streamline processes and improve overall efficiency by adopting best practices throughout production cycles. When companies invest in consumer product testing companies and develop effective inspection sampling plans, they position themselves for success by ensuring their products consistently meet consumer expectations.