Introduction

In the fast-paced world of electronics, the significance of PCB quality control cannot be overstated. As the backbone of modern electronic devices, printed circuit assemblies (PCAs) require meticulous attention to detail throughout their manufacturing and assembly processes. From circuit card assembly to final testing, ensuring quality at every stage is essential for creating reliable products that meet industry standards.

Understanding PCB Quality Control Essentials

PCB quality control encompasses a series of systematic processes designed to ensure that each printed circuit board meets specific performance criteria before it is integrated into larger systems. This includes everything from initial design verification to final inspection, where techniques such as optical inspection play a crucial role in identifying defects early on. By understanding these essentials, manufacturers can minimize errors and enhance the reliability of their circuit board products.

Importance of Quality in PCB Manufacturing

Quality in PCB manufacturing is not just a checkbox on a compliance form; it's vital for operational efficiency and customer satisfaction. Poorly manufactured PCBs can lead to device failures, increased warranty claims, and tarnished reputations for manufacturers. Therefore, prioritizing quality control measures throughout the PCB assembly board lifecycle ensures that each component functions correctly within its intended application.

Key Stages in PCB Quality Assurance

The journey towards ensuring top-notch PCB quality involves several key stages that must be meticulously executed. These stages include design reviews, material inspections, and various testing methods tailored to assess functionality and durability under different conditions. By focusing on these critical phases of quality assurance in both PCB manufacturing and assembly, companies can significantly reduce defects and improve overall product performance.

Overview of PCB Quality Control

In the world of electronics, ensuring the reliability and performance of printed circuit assemblies (PCAs) is paramount. PCB quality control encompasses a range of practices aimed at maintaining high standards throughout the manufacturing process. From raw materials to finished products, effective quality control measures are essential for minimizing defects and ensuring that each circuit board meets industry specifications.

Defining PCB Quality Control

PCB quality control is a systematic approach that involves monitoring and evaluating various stages of pcb manufacturing and assembly to guarantee product excellence. This process includes both preventive measures and corrective actions to address any discrepancies that may arise during production. By implementing stringent quality control protocols, manufacturers can enhance the reliability of their circuit card assemblies, ultimately leading to better end-user satisfaction.

Quality control in PCB assembly goes beyond simply checking for visible defects; it also involves rigorous testing methods such as optical inspection and functional assessments. These techniques help identify potential issues early in the production cycle, reducing waste and improving overall efficiency. In essence, defining PCB quality control means committing to a comprehensive strategy that prioritizes precision at every step.

The Role of PCB Assembly Manufacturer

The role of a PCB assembly manufacturer is crucial in upholding high standards of quality throughout the production process. These manufacturers are responsible for not only fabricating printed circuit boards but also ensuring that each assembly meets stringent industry requirements for performance and durability. By integrating advanced technologies like automated optical inspection into their workflow, these manufacturers can significantly enhance their pcb quality control efforts.

Moreover, a reputable pcb assembly manufacturer will implement best practices in both design and fabrication phases to minimize potential errors or defects in circuit board production. This proactive approach helps maintain consistency across all assemblies while fostering innovation through continuous improvement initiatives. Ultimately, these manufacturers serve as gatekeepers for delivering high-quality products that meet customer expectations.

Understanding Circuit Card Assembly

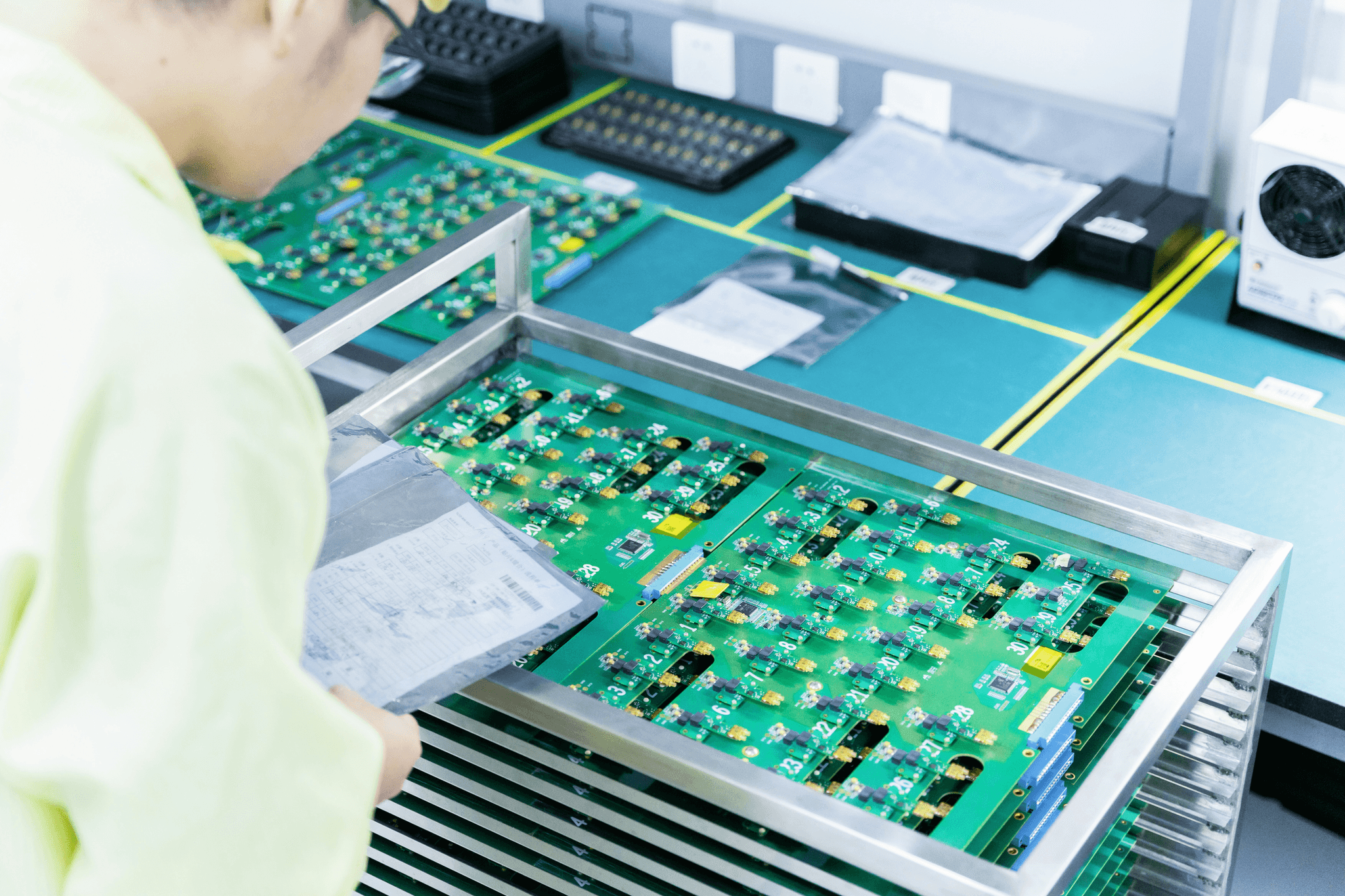

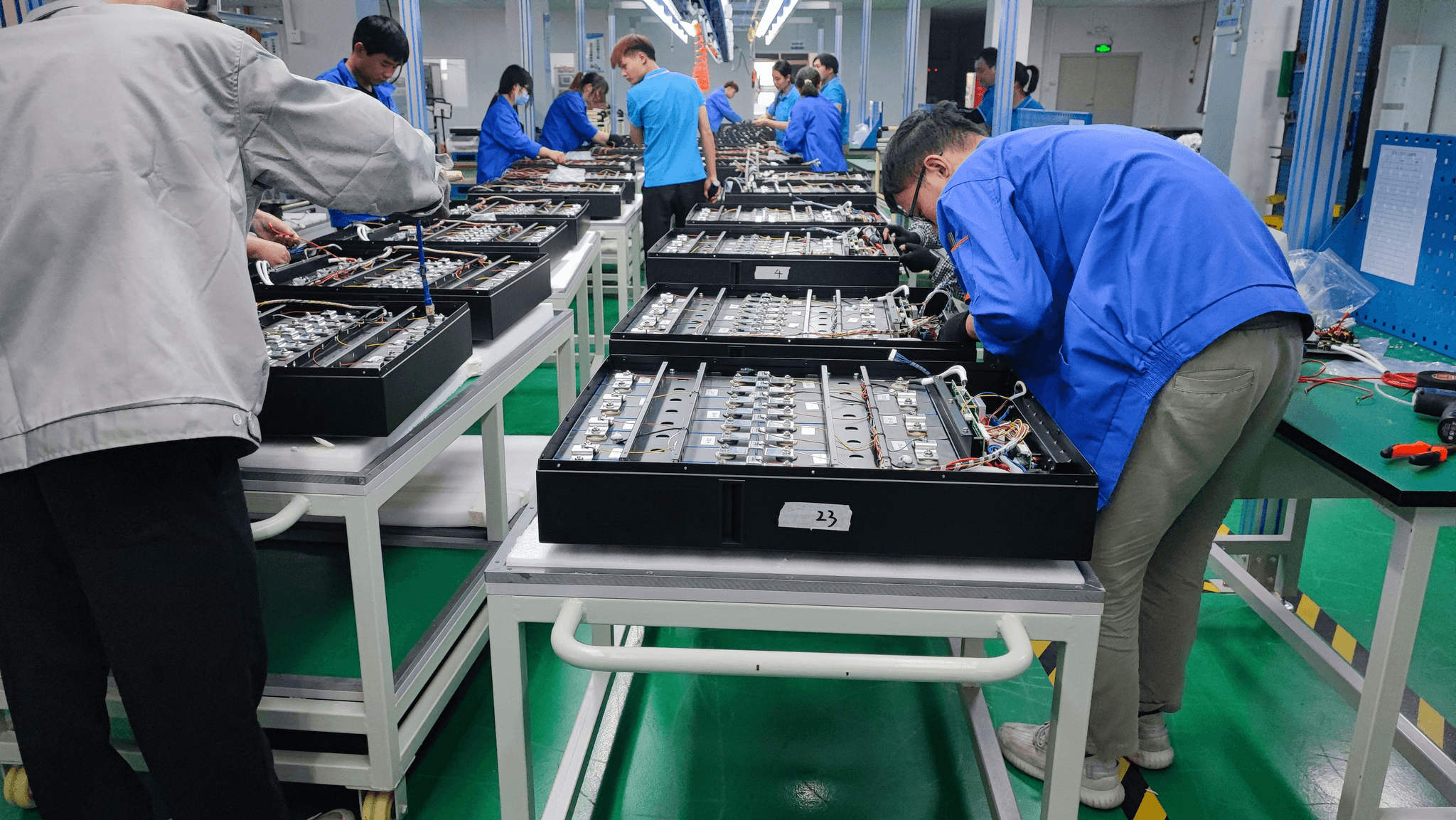

Circuit card assembly (CCA) refers to the intricate process involved in assembling electronic components onto printed circuit boards (PCBs). This phase is critical within the broader context of pcb manufacturing and assembly because it directly affects how well electronic devices function once they reach consumers' hands. A thorough understanding of CCA processes allows manufacturers to optimize workflows while emphasizing critical aspects like soldering techniques and component placement accuracy.

Effective circuit card assembly requires precision equipment, skilled technicians, and robust quality assurance practices to ensure optimal performance under various conditions. Techniques such as visual inspection play an essential role here by allowing operators to detect flaws before they escalate into more significant issues down the line—ultimately supporting efficient pcb quality control efforts across multiple projects simultaneously. As technology continues evolving, staying informed about advancements in CCA processes will empower manufacturers to deliver superior products consistently.

Quality Control Techniques in PCB Manufacturing

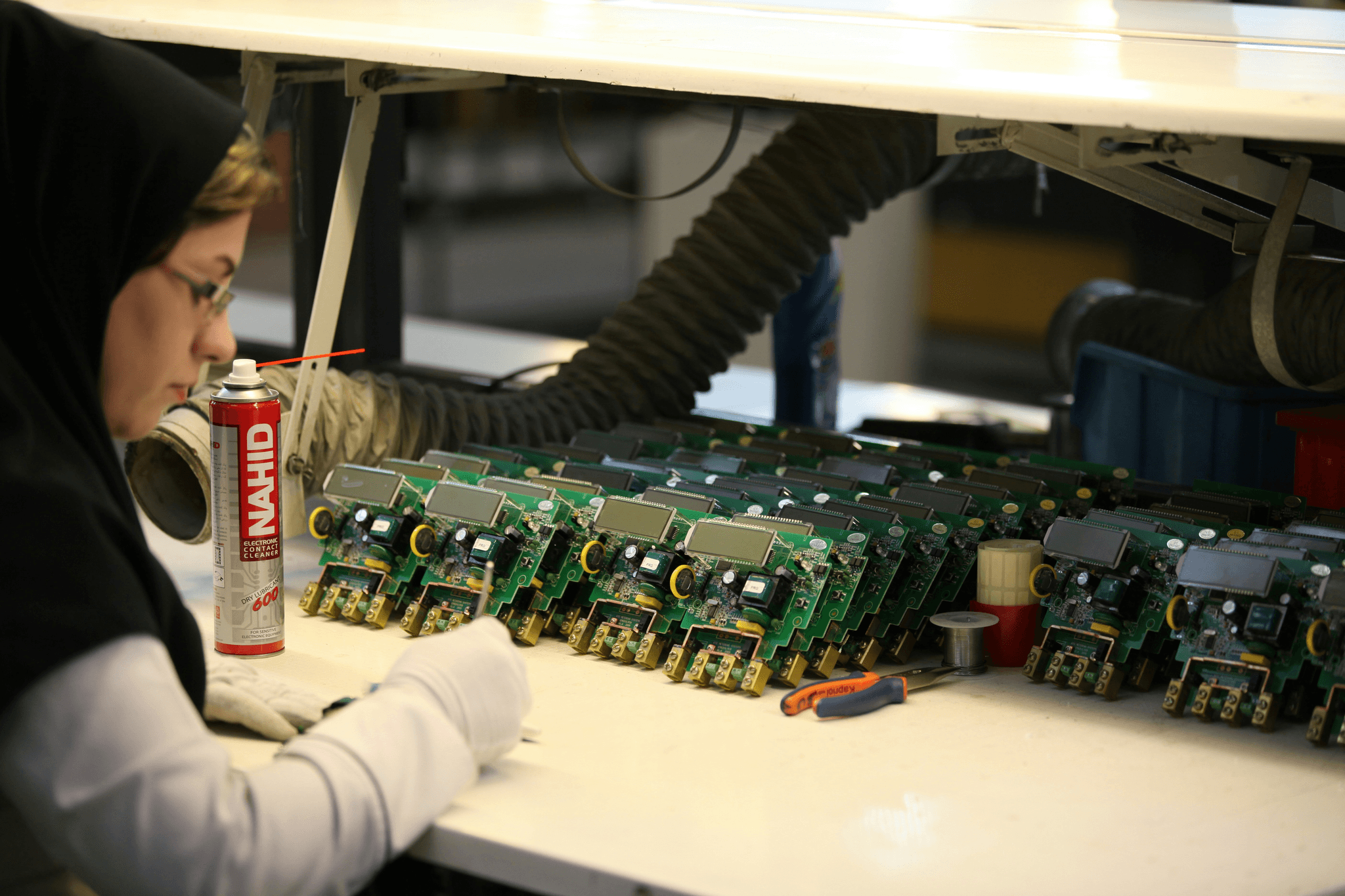

In the intricate world of PCB manufacturing and assembly, ensuring top-notch quality is paramount. Various quality control techniques play a crucial role in maintaining the integrity of printed circuit assemblies and circuit card assemblies alike. Let’s delve into these techniques, focusing on visual inspection, automated optical inspection technology, and the indispensable human touch of manual inspection.

Visual Inspection and Optical Inspection

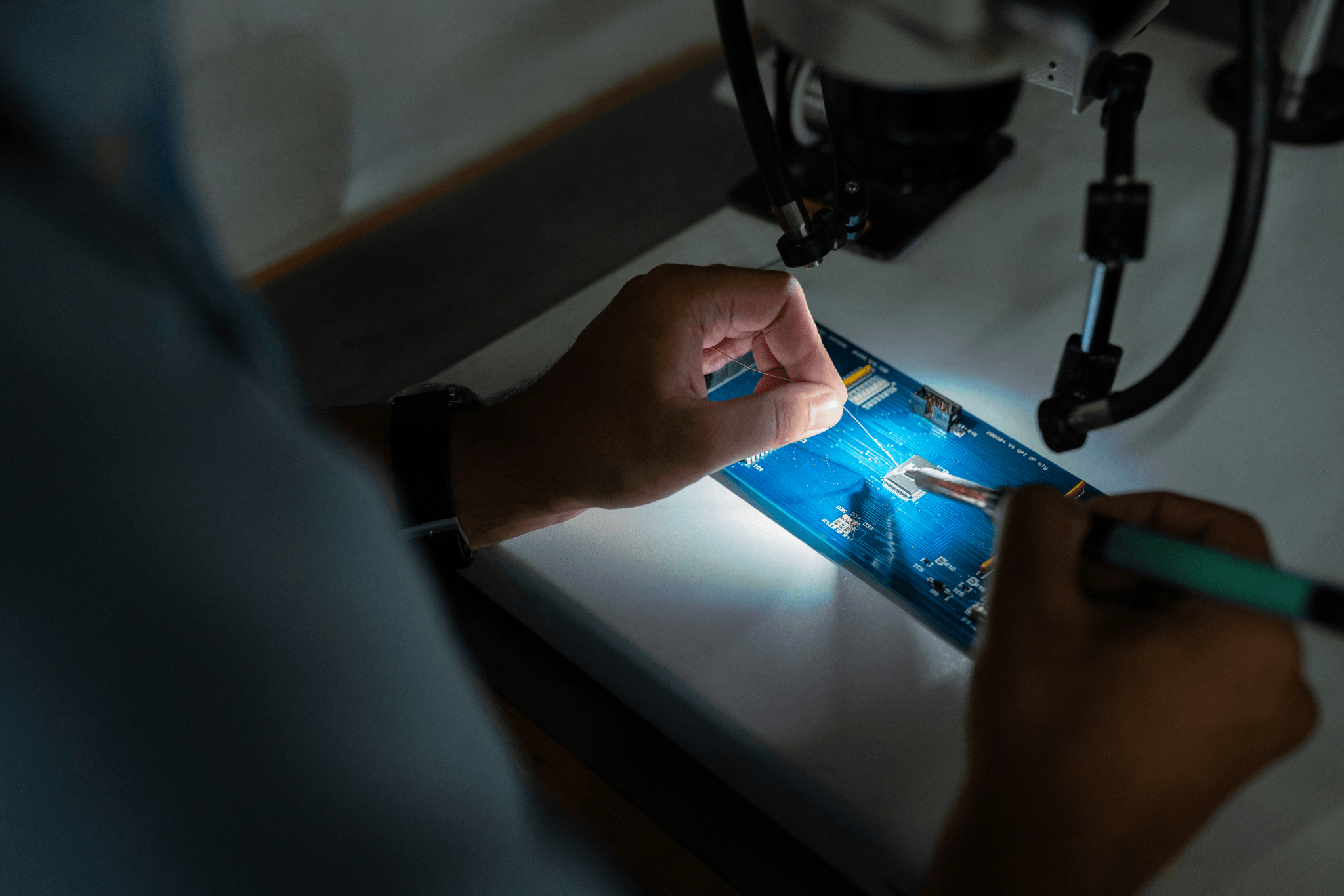

Visual inspection is one of the most fundamental yet effective methods in PCB quality control. It involves scrutinizing circuit boards for visible defects such as solder bridges, missing components, or misalignments that could compromise functionality. This technique often employs optical inspection tools to enhance accuracy, allowing inspectors to catch potential issues before they escalate into larger problems during the manufacturing process.

Optical inspection systems utilize advanced cameras and software to analyze printed circuit assemblies at high speeds, significantly reducing human error while increasing efficiency. By integrating these tools into the quality control workflow, PCB assembly manufacturers can ensure that every circuit board meets stringent standards before moving on to further testing stages. Ultimately, combining visual inspections with optical technologies creates a robust first line of defense against defects.

Automated Optical Inspection Technology

Automated Optical Inspection (AOI) technology has revolutionized PCB quality control by introducing speed and precision into the inspection process. AOI systems use sophisticated algorithms to detect flaws in printed circuit assemblies by comparing images against predefined standards for each component on a circuit board. This allows manufacturers to identify discrepancies quickly—whether it's a misplaced resistor or an incorrect solder joint—ensuring that only flawless products proceed through production.

The beauty of AOI lies not just in its speed but also in its ability to provide consistent results across large volumes of PCBs. As production scales up, maintaining quality becomes increasingly challenging; however, AOI systems can tirelessly monitor every board without fatigue or oversight common with manual checks. Consequently, this technology has become an essential tool for any serious PCB assembly manufacturer aiming to uphold high-quality standards.

Importance of Manual Inspection

Despite advancements in automation like AOI technology, manual inspection remains an integral part of effective PCB quality control strategies. Human inspectors bring invaluable intuition and experience that machines cannot replicate; they can spot subtle anomalies that automated systems might overlook due to their reliance on programmed parameters alone. This human element adds depth to the overall assessment process during both initial inspections and final checks before products are shipped out.

Moreover, manual inspections foster a culture of meticulousness among teams involved in printed circuit assembly and manufacturing processes. When skilled technicians actively engage with each PCB assembly board during inspections, it enhances their understanding of potential pitfalls within their workflows—leading to continuous improvement over time. Thus, while automation streamlines processes significantly, incorporating manual checks ensures comprehensive oversight throughout production cycles.

Standards and Regulations

In the realm of PCB manufacturing and assembly, adherence to established standards and regulations is paramount for ensuring quality control. These guidelines not only help in maintaining consistency but also enhance the reliability of printed circuit assemblies (PCAs). By understanding and implementing these standards, PCB assembly manufacturers can significantly improve their production processes.

Key Industry Standards for PCB Quality

There are several key industry standards that govern PCB quality control, including IPC-A-610 for acceptability of electronic assemblies, IPC-2221 for generic design requirements, and IPC-6012 which outlines the specifications for rigid PCBs. Each standard addresses specific aspects of circuit card assembly, ensuring that all components meet stringent quality criteria. Compliance with these standards not only boosts product reliability but also fosters customer trust in the final product.

Moreover, adhering to these industry benchmarks allows PCB assembly manufacturers to streamline their processes while minimizing defects during production. This results in enhanced efficiency throughout the supply chain and ultimately leads to superior printed circuit assembly products. As a result, companies that prioritize compliance with these key industry standards often find themselves at a competitive advantage in the marketplace.

Compliance in PCB Manufacturing and Assembly

Compliance in PCB manufacturing and assembly is essential for meeting both customer expectations and regulatory requirements. Manufacturers must implement rigorous quality control measures throughout every stage of production—from design through to final inspection—to ensure that each circuit board meets required specifications. This commitment to compliance not only mitigates risks associated with defective products but also enhances overall operational efficiency.

To achieve compliance, manufacturers often rely on a combination of automated optical inspection technology and manual inspections during various phases of production. By integrating these techniques into their workflows, they can detect potential issues early on, reducing costly rework or recalls later down the line. Ultimately, a strong focus on compliance helps ensure that every PCB assembly board produced meets market demands while maintaining high-quality standards.

Role of IPC Standards in Quality Assurance

IPC standards play a crucial role in establishing benchmarks for quality assurance within the electronics manufacturing industry. These guidelines provide comprehensive frameworks that address everything from design principles to performance metrics across various types of printed circuit assemblies (PCAs). By following IPC standards closely, manufacturers can foster an environment where continuous improvement becomes part of their organizational culture.

Furthermore, adherence to IPC standards enhances communication between different stakeholders involved in the PCB manufacturing process—engineers, designers, suppliers—creating a unified approach toward achieving high-quality outcomes consistently over time. The result is improved collaboration within teams as they work towards common goals centered around pcb quality control initiatives. In this way, IPC standards serve as both a roadmap for success and a catalyst for innovation within the field.

Testing Methods for PCB Assembly Boards

Testing methods are crucial in ensuring the quality and reliability of printed circuit assemblies (PCBs). These methods not only help in identifying defects early but also enhance the overall efficiency of the PCB manufacturing and assembly process. By implementing rigorous testing procedures, PCB assembly manufacturers can ensure that their circuit card assemblies meet industry standards and customer expectations.

Functional Testing Procedures

Functional testing procedures are designed to verify that a PCB assembly board operates according to its intended specifications. This type of testing assesses the functionality of each component on the circuit board, ensuring that everything from resistors to integrated circuits works harmoniously. By conducting thorough functional tests, manufacturers can catch potential failures before they escalate into costly issues down the line, reinforcing effective PCB quality control.

In practice, functional testing may involve both automated systems and manual assessments. Automated test equipment (ATE) can quickly execute a series of predefined tests, while manual inspection adds an extra layer of scrutiny through visual inspection techniques. Together, these approaches ensure that every aspect of the printed circuit assembly is validated against its design requirements.

In-Circuit Testing Explained

In-circuit testing (ICT) is another essential method used to evaluate PCB assembly boards during production. Unlike functional tests that check overall performance, ICT focuses on individual components within the circuit card assembly by measuring electrical characteristics directly at various points on the board. This technique allows for precise identification of faults such as shorts or open circuits in real-time.

The beauty of in-circuit testing lies in its ability to catch defects early in the manufacturing process, significantly reducing rework costs and enhancing overall efficiency in PCB manufacturing and assembly. With ICT's high level of accuracy, manufacturers can confidently assure clients about their products' reliability while maintaining strict pcb quality control standards throughout production runs.

Thermal and Environmental Testing

Thermal and environmental testing are crucial for assessing how well a PCB assembly board will perform under varying conditions over time. These tests simulate extreme temperatures and environmental factors like humidity or vibration to gauge how resilient a printed circuit board is when subjected to real-world scenarios. Such rigorous evaluations are essential for industries where reliability is paramount—think aerospace or medical devices—where failure is not an option.

By incorporating thermal cycling tests or humidity exposure assessments into their quality control protocols, PCB assembly manufacturers can predict potential failures before they occur during actual use. This proactive approach not only improves product durability but also enhances customer satisfaction by delivering robust solutions backed by stringent pcb quality control measures.

Partnering with Quality Inspection Services

In the realm of PCB manufacturing and assembly, partnering with quality inspection services can make a world of difference. These partnerships not only ensure that products meet stringent quality standards but also enhance overall efficiency in the production process. By leveraging expert insights and advanced technologies, businesses can significantly improve their PCB quality control measures.

Benefits of Working with China Inspection Pro

Choosing to work with a dedicated service like China Inspection Pro offers numerous advantages for PCB assembly manufacturers. First, they provide access to specialized knowledge in circuit card assembly, ensuring that every aspect of the process meets industry standards. Additionally, their expertise in optical inspection technology helps identify defects early on, preventing costly errors down the line.

Another significant benefit is the flexibility and scalability they offer to manufacturers. Whether it's a small batch or large-scale production run, these inspection services can adapt to meet varying needs while maintaining high-quality standards. This adaptability is crucial in an industry where demand can fluctuate rapidly and where precision is key to delivering reliable printed circuit assemblies.

How Quality Inspection Enhances PCB Quality Control

Quality inspections play an essential role in enhancing overall PCB quality control by providing systematic checks throughout the manufacturing process. By implementing rigorous testing methods such as visual inspections and automated optical inspection, manufacturers can detect flaws before they escalate into serious issues. This proactive approach not only saves time but also boosts customer confidence in their products.

Moreover, thorough inspections help maintain compliance with key industry standards that govern PCB manufacturing and assembly practices. When manufacturers adhere to these regulations through effective quality control measures, they position themselves as trustworthy suppliers within the market. Ultimately, this commitment to excellence fosters long-term relationships with clients who prioritize reliability in their circuit board solutions.

Actionable Insights from Quality Inspections

Engaging with quality inspection services yields actionable insights that are invaluable for continuous improvement in PCB manufacturing processes. Regular reports detailing findings from inspections provide data-driven feedback that helps identify recurring issues or trends affecting product quality. Armed with this information, manufacturers can implement targeted strategies to enhance their processes and reduce defects over time.

Additionally, these insights often lead to better resource allocation within the production line—whether it’s optimizing labor for manual inspections or investing in more advanced optical inspection equipment for automated checks. The result is a streamlined operation that not only improves efficiency but also elevates overall product integrity across all printed circuit assemblies produced by a manufacturer.

By integrating these actionable insights into everyday practices, companies can foster a culture of quality that permeates every layer of production—from initial design through final assembly—ultimately leading to stronger products built on a foundation of solid pcb quality control principles.

Conclusion

In the ever-evolving landscape of PCB manufacturing and assembly, enhancing quality control is not just a goal but a necessity. By integrating advanced techniques such as optical inspection and rigorous testing methods, manufacturers can ensure that every circuit card assembly meets the highest standards. The commitment to maintaining stringent pcb quality control processes ultimately leads to superior products and increased customer satisfaction.

Enhancing Quality Control in PCB Manufacturing

To enhance quality control in PCB manufacturing, companies must adopt a multifaceted approach that includes both automated and manual inspections. Automated Optical Inspection (AOI) technology plays a crucial role in identifying defects early in the production process, while manual inspection provides an experienced set of eyes to catch subtler issues that machines might miss. Together, these methods create a robust framework for ensuring that each printed circuit assembly meets industry standards.

Future Trends in PCB Quality Assurance

Looking ahead, the future of pcb quality control will likely be shaped by advancements in technology and evolving industry standards. The integration of artificial intelligence and machine learning into inspection processes promises to revolutionize how we approach circuit board quality assurance, making it faster and more accurate than ever before. Additionally, as sustainability becomes increasingly important, manufacturers will need to focus on eco-friendly practices while maintaining high-quality outputs.

Building Stronger Products with Quality Focus

Fostering a culture centered around quality is essential for building stronger products in the realm of pcb assembly boards. Companies that prioritize pcb quality control not only improve their manufacturing processes but also enhance their reputation within the industry. By collaborating with experienced pcb assembly manufacturers who share this commitment to excellence, businesses can ensure they deliver reliable and durable products that stand the test of time.