Introduction

In today's fast-paced marketplace, understanding supplier quality roles and responsibilities has never been more crucial. With the increasing complexity of supply chains, businesses must ensure that their suppliers meet high-quality standards to remain competitive. This introduction sets the stage for a deeper exploration of how effective management of supplier quality can drive organizational success.

Understanding Supplier Quality Roles

Supplier quality roles encompass a range of functions that are essential for maintaining product integrity and consistency. These roles often include quality managers, auditors, and inspectors who work collaboratively to enforce standards and implement improvements. By clearly defining these roles within an organization, businesses can foster accountability and streamline processes related to supplier audits and performance monitoring.

Importance of Supplier Responsibilities

The importance of supplier responsibilities cannot be overstated; they form the foundation upon which successful partnerships are built. Suppliers must not only deliver products that meet specifications but also actively engage in continuous improvement initiatives. When suppliers take ownership of their responsibilities, it leads to enhanced supplier quality improvements and ultimately benefits both parties involved.

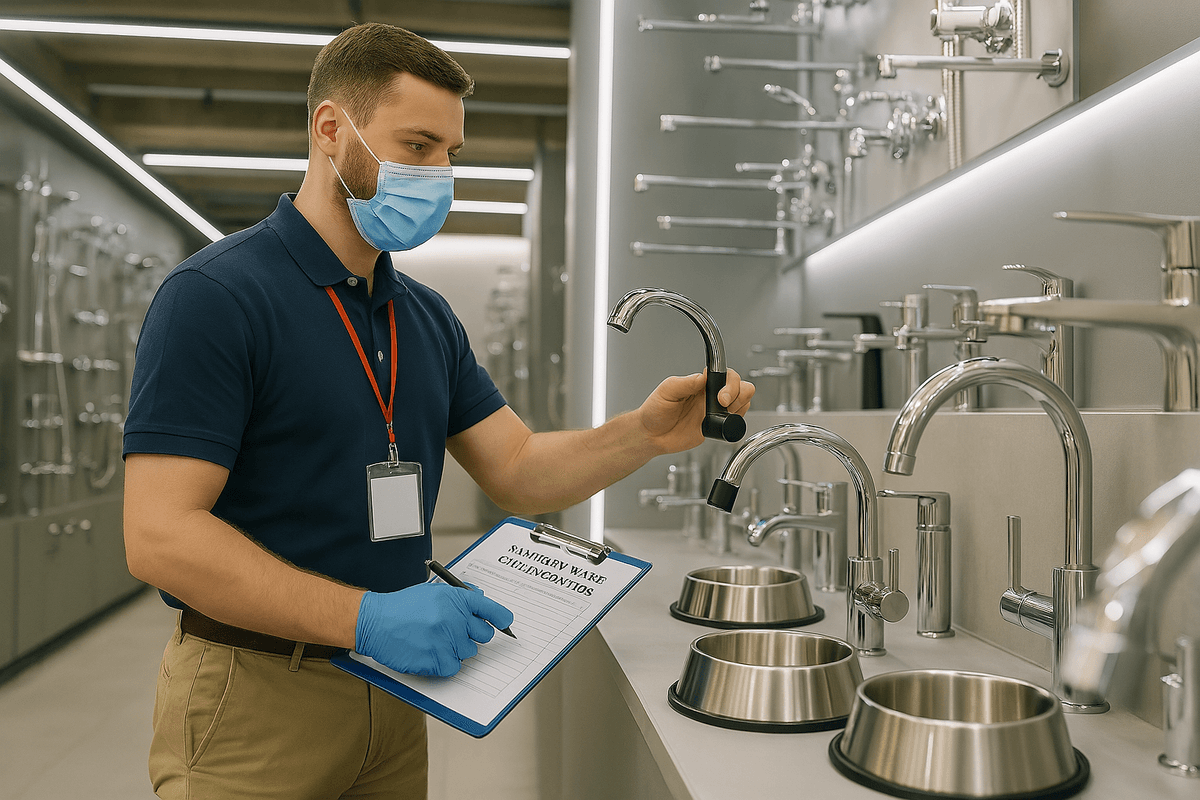

Overview of Quality Inspection

Quality inspection serves as a critical checkpoint in the supply chain process, ensuring that products conform to established standards before they reach the end consumer. This process involves meticulous evaluation through various methods such as visual inspections, testing, and audits—each designed to catch potential issues early on. By integrating robust quality inspection practices into their operations, companies can significantly reduce risks associated with poor-quality goods while promoting effective supplier performance monitoring.

The Backbone of Supplier Quality

In the intricate world of supplier quality, understanding the roles and responsibilities is crucial. Supplier quality roles and responsibilities encompass a wide range of tasks that ensure products meet specified standards before they reach consumers. This section delves into the foundational aspects of supplier quality management, highlighting the significance of defined roles, key responsibilities, and effective engagement strategies with suppliers.

Defining Roles in Quality Control

Quality control is not just a buzzword; it's the lifeblood of any successful supply chain. Within this framework, various supplier quality roles and responsibilities come into play, from quality assurance inspectors to compliance officers who ensure that every product adheres to industry standards. Defining these roles clearly helps organizations maintain consistency in their processes and establishes accountability among team members.

Each role contributes uniquely to overall quality assurance efforts; for example, while some focus on testing products against specifications, others might be involved in developing training programs for suppliers to enhance their own quality practices. This collaborative approach ensures that everyone understands their part in achieving high-quality outcomes. Ultimately, well-defined roles lead to improved communication and a more cohesive strategy towards supplier audits and performance monitoring.

Key Responsibilities of Quality Managers

Their key responsibilities include overseeing audits, implementing corrective actions based on findings, and continuously evaluating supplier performance against established metrics. By actively engaging with suppliers during these processes, they foster an environment where continuous improvement is not just encouraged but expected.

Moreover, effective communication skills are paramount for quality managers as they must relay expectations clearly while also being receptive to feedback from suppliers regarding challenges faced during production or delivery phases. This two-way street enhances relationships and leads to better collaboration on future projects—essentially creating a cycle of ongoing improvement rather than a one-off effort focused solely on inspections or audits.

Engaging Suppliers for Quality Assurance

Engaging suppliers effectively is where the magic happens in ensuring robust supplier quality roles and responsibilities are upheld throughout the supply chain process. By fostering open lines of communication about expectations surrounding product standards and delivery timelines, organizations can build trust with their suppliers—an essential component for successful partnerships in today's competitive markets.

Regular workshops or training sessions can be instrumental in enhancing understanding around quality expectations while also providing an opportunity for suppliers to voice concerns or suggestions regarding processes that could lead to better outcomes—a win-win scenario! Furthermore, leveraging technology such as performance monitoring tools can help both parties track progress over time, ensuring that any necessary adjustments are made swiftly.

Supplier Audits: A Deep Dive

Supplier audits are a crucial aspect of maintaining high standards in supplier quality roles and responsibilities. These evaluations help organizations ensure that their suppliers meet the required quality benchmarks and adhere to industry regulations. By understanding what to expect during these audits, companies can foster better relationships with suppliers while also enhancing their overall quality assurance processes.

What to Expect in Supplier Audits

During a supplier audit, organizations can expect a systematic review of the supplier's processes, documentation, and overall compliance with agreed-upon standards. Auditors will assess various aspects such as production methods, quality control measures, and adherence to safety regulations. This comprehensive examination not only highlights areas where suppliers excel but also identifies potential gaps that need addressing for effective supplier quality improvements.

The audit process typically includes interviews with key personnel, observation of operations, and review of records related to previous performance monitoring efforts. Suppliers should be prepared to showcase their commitment to continuous improvement and demonstrate how they fulfill their roles and responsibilities in maintaining product quality. Ultimately, these audits serve as a valuable opportunity for both parties to enhance collaboration toward achieving mutual goals.

Benefits of Regular Audits

Regular supplier audits offer numerous benefits that go beyond mere compliance checks; they play a pivotal role in strengthening supplier relationships and ensuring consistent product quality. One significant advantage is the identification of potential risks before they escalate into larger issues—think of it as preventive maintenance for your supply chain! By routinely evaluating suppliers' practices, businesses can foster an environment focused on continuous improvement within their supply chain.

Moreover, these audits help establish benchmarks for performance monitoring by providing insights into how suppliers measure up against industry standards or internal expectations. This information is invaluable when assessing the effectiveness of current partnerships or determining whether changes are necessary for future collaborations. In short, regular audits contribute significantly to enhanced trust between companies and their suppliers by promoting transparency around quality roles and responsibilities.

How to Prepare for an Audit

Preparation is key when it comes to ensuring successful supplier audits—after all, you wouldn’t want your favorite restaurant running out of ingredients! To get ready for an audit, both parties should engage in open communication regarding expectations and requirements well ahead of time. Suppliers should compile relevant documentation such as quality manuals, previous audit reports, corrective action plans (CAPs), and evidence showcasing ongoing improvements made over time.

Additionally, conducting internal pre-audits can help identify any discrepancies or areas needing attention before the official evaluation takes place. This proactive approach not only demonstrates commitment but also allows suppliers to align themselves more closely with customer expectations regarding performance monitoring metrics. By taking these steps seriously during preparation phases leading up to an audit day itself—everyone involved will undoubtedly benefit from improved outcomes related specifically back towards enhancing overall supplier quality roles and responsibilities.

The Art of Supplier Quality Improvements

In the realm of supplier quality management, continuous improvement is not just a buzzword; it’s an essential practice that drives success. Supplier quality improvements hinge on identifying weaknesses and transforming them into strengths, ensuring that products meet or exceed expectations. By focusing on effective solutions and monitoring performance, organizations can create a culture of excellence in supplier relationships.

Identifying Areas for Improvement

The first step in making meaningful supplier quality improvements is to conduct a thorough assessment of current processes and outputs. This involves analyzing data from supplier audits, customer feedback, and internal quality assessments to pinpoint specific areas where suppliers may be falling short. Engaging with suppliers during this phase is crucial; they often have insights into their own operations that can illuminate potential enhancements.

Moreover, it's important to consider the broader context when identifying areas for improvement. Factors such as market trends, technological advancements, and shifts in consumer preferences can all influence what constitutes acceptable quality standards. By staying attuned to these dynamics, businesses can ensure that their expectations align with evolving industry norms while holding suppliers accountable for their roles and responsibilities.

Implementing Effective Solutions

Once areas for improvement are identified, the next step is implementing effective solutions tailored to each situation. This may involve refining existing processes, investing in new technologies, or enhancing training programs for both internal teams and suppliers alike. Clear communication about supplier quality roles and responsibilities during this implementation phase fosters collaboration—ensuring everyone understands their part in achieving the desired outcomes.

Additionally, fostering a culture of continuous learning can facilitate smoother transitions when changes are made. Encouraging open dialogue between stakeholders allows for real-time feedback and adjustments as needed throughout the implementation process. This proactive approach not only aids in overcoming resistance but also strengthens partnerships by demonstrating commitment to shared goals.

Measuring the Impact of Improvements

To truly gauge the effectiveness of any implemented changes, robust measurement practices must be established as part of supplier performance monitoring efforts. Key performance indicators (KPIs) should be defined early on—these might include defect rates, delivery times, or compliance levels with agreed-upon standards related to supplier audits. Regularly reviewing these metrics enables organizations to assess whether improvements are translating into tangible benefits.

Moreover, it’s essential to celebrate successes along the way; recognizing achievements keeps motivation high among all parties involved in maintaining supplier quality roles and responsibilities. Continuous evaluation not only highlights what works but also uncovers new opportunities for further enhancements—creating a virtuous cycle of improvement within your supply chain ecosystem.

In conclusion, mastering the art of supplier quality improvements requires diligence at every stage—from identifying weaknesses through implementing tailored solutions all the way to measuring outcomes effectively. By embracing this comprehensive approach alongside regular supplier audits and ongoing performance monitoring practices, businesses can cultivate stronger relationships with their suppliers while driving overall operational excellence.

Supplier Performance Monitoring Essentials

Supplier performance monitoring is crucial for maintaining high standards in supplier quality roles and responsibilities. By effectively tracking and evaluating supplier performance, companies can ensure that their suppliers meet quality expectations and deliver products that align with organizational goals. This not only enhances product quality but also fosters stronger relationships with suppliers, paving the way for fruitful collaborations.

Key Metrics for Performance Evaluation

When it comes to evaluating supplier performance, having the right metrics is essential. Commonly used metrics include defect rates, on-time delivery percentages, and adherence to specifications—all of which directly relate to supplier quality roles and responsibilities. By focusing on these key indicators, organizations can identify areas requiring improvement and make informed decisions about future engagements with suppliers.

Additionally, customer feedback plays a vital role in assessing supplier performance; after all, the end-users are the ultimate judges of quality. Monitoring these metrics consistently allows businesses to establish benchmarks that guide their supplier audits and drive supplier quality improvements over time. Ultimately, a data-driven approach to evaluation ensures that suppliers are held accountable for their contributions.

Tools for Effective Monitoring

In today’s digital age, leveraging technology is indispensable for effective monitoring of supplier performance. Various software solutions offer robust capabilities for tracking key metrics in real-time while providing insights into trends over time—making them invaluable tools in managing supplier quality roles and responsibilities. From dashboards that visualize data to automated notifications about deviations from expected performance levels, these tools simplify the monitoring process.

Moreover, integrating these tools with existing enterprise resource planning (ERP) systems can enhance visibility across supply chains while streamlining communication between stakeholders involved in supplier audits or assessments. Regularly using such tools helps organizations maintain an ongoing dialogue with suppliers about their performance levels—ensuring transparency and accountability remain at the forefront of any partnership aimed at achieving superior product quality.

Continuous Improvement Practices

Continuous improvement practices are vital when it comes to enhancing overall supplier performance monitoring efforts. Organizations should adopt methodologies like Lean Six Sigma or Kaizen to foster a culture of ongoing enhancement within their supply chains—this aligns closely with both supplier audits and efforts aimed at driving significant improvements in quality outcomes. By encouraging collaboration between internal teams and suppliers alike, organizations can identify inefficiencies or bottlenecks that hinder optimal performance.

Training programs focused on building capabilities around best practices also play a crucial role in aligning suppliers’ operations with desired standards—a win-win situation that reinforces both parties' commitment to excellence in their respective roles within the supply chain ecosystem! Furthermore, regularly revisiting established processes ensures they evolve alongside changing market demands or technological advancements—ultimately leading toward sustained success through effective management of supplier quality roles and responsibilities.

Leveraging Quality Inspection Services

In today’s fast-paced global market, leveraging quality inspection services is crucial for maintaining supplier quality roles and responsibilities. Effective collaboration with inspection agencies can help streamline processes, enhance product quality, and ensure compliance with industry standards. By integrating these services into the supply chain, companies can achieve significant improvements in supplier performance monitoring.

Collaborating with China Inspection Pro

China Inspection Pro offers a unique opportunity for businesses looking to enhance their supplier quality roles and responsibilities through dedicated quality inspection services. This collaboration allows companies to tap into a wealth of expertise in supplier audits, ensuring that every product meets stringent quality criteria before it reaches the end consumer. By working closely with such inspection agencies, businesses can proactively address potential issues and implement necessary supplier quality improvements.

Moreover, using China Inspection Pro enables organizations to establish clear expectations regarding product specifications and delivery timelines. This clarity fosters better communication between suppliers and buyers, which is essential for effective supplier performance monitoring. Ultimately, this partnership not only streamlines operations but also builds a foundation of trust that enhances overall business relationships.

How Quality Inspection Enhances Supplier Relationships

Quality inspections serve as a bridge between suppliers and buyers by ensuring both parties understand their roles and responsibilities clearly. When suppliers are held accountable through regular audits and inspections, they are more likely to take ownership of their processes which leads to improved product outcomes. This accountability cultivates an environment where continuous improvement is not just encouraged but expected—leading to significant advancements in overall supplier performance monitoring.

Furthermore, consistent engagement through inspections provides valuable feedback that suppliers can utilize for ongoing enhancements in their operations. When suppliers see tangible benefits from adhering to established quality standards, they become more invested in maintaining high levels of performance—ultimately resulting in better products for customers. Thus, incorporating robust inspection practices not only strengthens supplier relationships but also reinforces the importance of shared responsibility among all stakeholders involved.

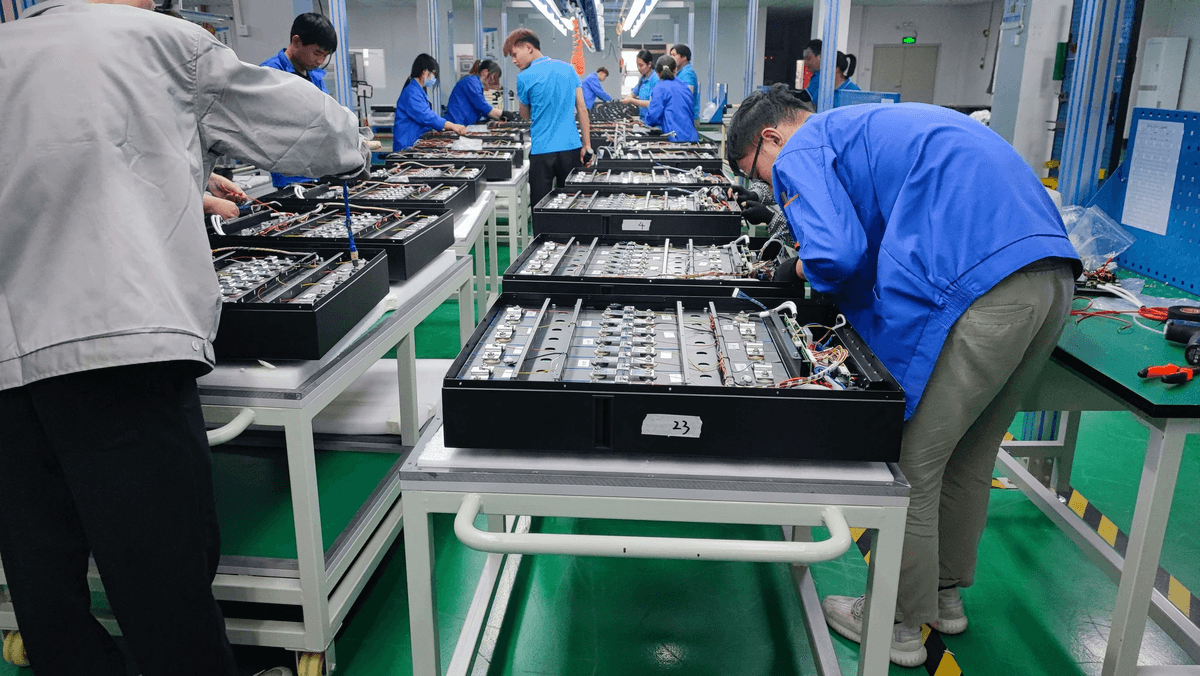

Real-World Examples of Quality Success

Numerous companies have successfully harnessed the power of quality inspections to transform their supply chains significantly. For instance, a leading electronics manufacturer faced persistent issues with defective components from overseas suppliers; after implementing regular audits through an inspection service like China Inspection Pro, they saw defect rates plummet by over 30%. This remarkable improvement was primarily due to enhanced communication about supplier quality roles and responsibilities alongside proactive measures taken during the auditing process.

Another success story comes from a clothing retailer that struggled with inconsistent fabric quality from its suppliers abroad; by adopting rigorous inspection protocols before shipment approval, they achieved substantial reductions in returns due to defects—boosting customer satisfaction ratings significantly as well! These examples illustrate how leveraging thorough inspections leads not only to immediate benefits but also long-term gains in maintaining robust supplier performance monitoring systems.

Conclusion

In the ever-evolving landscape of supplier quality management, organizations must adapt to new challenges and opportunities. The future will likely see a greater emphasis on collaboration between suppliers and manufacturers, focusing on transparency and shared goals. By understanding supplier quality roles and responsibilities, businesses can foster an environment where continuous improvement thrives.

The Future of Supplier Quality Management

Looking ahead, technology will play a pivotal role in transforming how we approach supplier audits and performance monitoring. With advancements in data analytics and machine learning, companies can gain deeper insights into their suppliers' operations, leading to more informed decision-making. This proactive approach not only enhances supplier quality improvements but also strengthens the overall supply chain resilience.

Building Strong Supplier Partnerships

Establishing robust partnerships with suppliers is essential for maintaining high standards of quality across the board. Open communication, mutual respect, and shared responsibility are key ingredients for successful collaborations that lead to meaningful supplier quality roles and responsibilities. When both parties are invested in each other's success, it paves the way for innovative solutions that benefit everyone involved.

Final Thoughts on Quality Roles and Responsibilities

In conclusion, effective supplier performance monitoring is not just a box-ticking exercise; it's about cultivating relationships that drive excellence in product quality. By prioritizing supplier audits and actively engaging in continuous improvement efforts, companies can ensure they are not just meeting standards but exceeding them. As we move forward, embracing these principles will be crucial for those looking to thrive in a competitive marketplace.