Introduction

In the modern landscape of manufacturing, the interplay between production and quality is a critical factor that determines success. Understanding what production and quality entail is essential for companies aiming to thrive in competitive markets. As businesses strive for efficiency, the relationship between these two elements becomes increasingly significant.

Understanding Production and Quality Dynamics

At its core, production refers to the processes involved in creating goods, while quality encompasses the standards that those goods must meet. The question What is production and quality? often arises in discussions about manufacturing efficacy, highlighting how intertwined these concepts are. By grasping their dynamics, organizations can better navigate challenges related to output and compliance with customer expectations.

The Importance of Manufacturing Processes

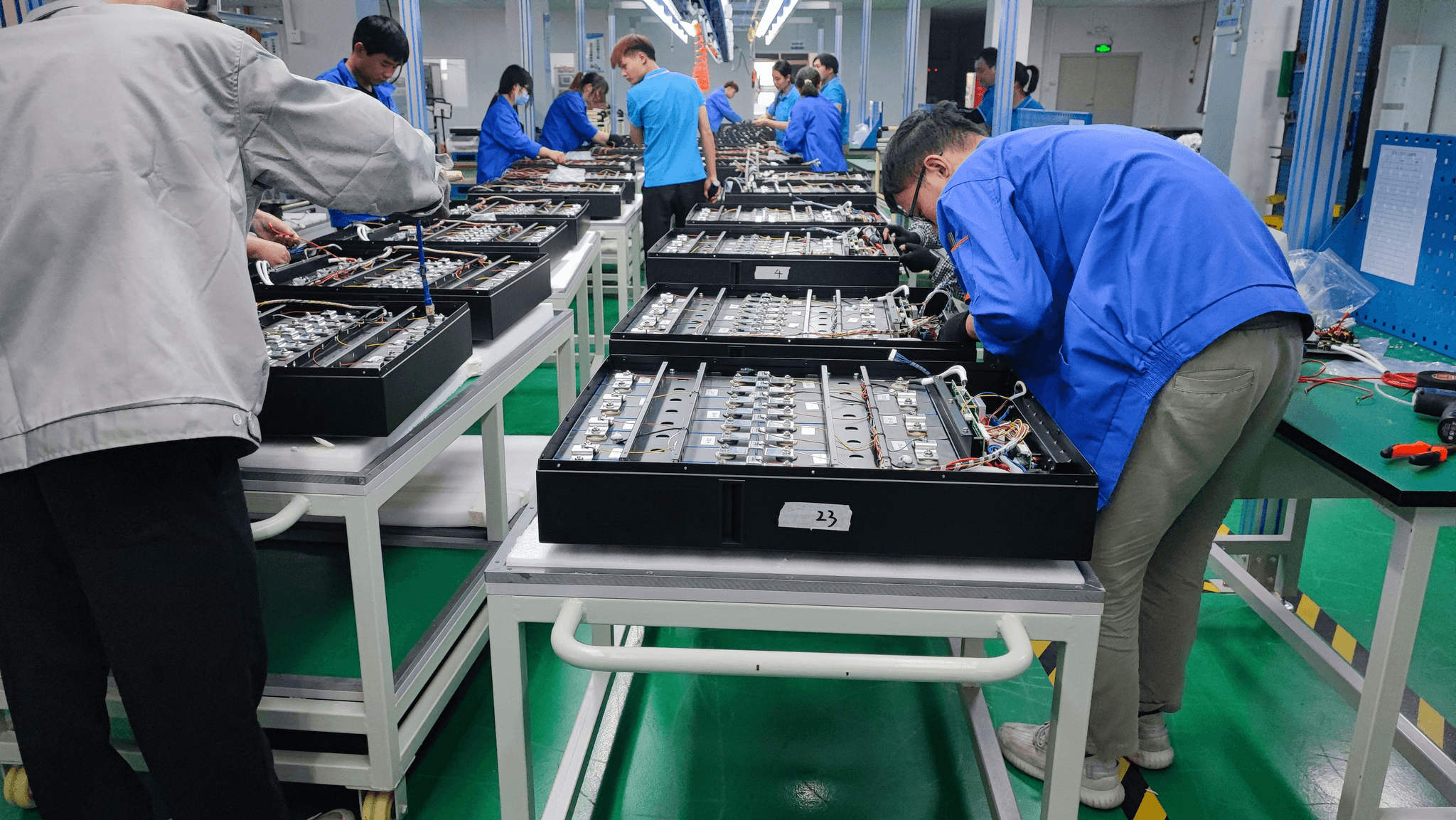

Manufacturing processes serve as the backbone of any production operation, dictating how efficiently products are created while ensuring they meet established quality benchmarks. When exploring what does the production and quality department do?, it's clear that this team oversees both aspects to maintain a seamless flow from raw materials to finished products. Without effective manufacturing processes, achieving high levels of both production and quality becomes an uphill battle.

Quality Control: The Unsung Hero

Quality control often operates behind the scenes but plays a pivotal role in maintaining high standards throughout the manufacturing process. Many wonder what is more important: production or quality? While quantity may drive immediate profits, it’s ultimately quality that fosters customer loyalty and long-term success. By prioritizing robust quality control measures, organizations can ensure their products not only meet but exceed market expectations.

Defining Production and Manufacturing

In the realm of industry, understanding the concepts of production and quality is crucial. Production refers to the processes involved in creating goods, while quality pertains to the standards that these goods must meet. Thus, when we ask, What is production and quality? we are essentially exploring how these two elements interact to create successful products.

What is Production and Quality?

Production encompasses all activities related to converting raw materials into finished products ready for market consumption. Quality, on the other hand, focuses on ensuring that these products meet specific standards and requirements set by both manufacturers and consumers. The relationship between quality and production is vital; without effective quality control measures in place, even the most efficient production lines can yield subpar results.

Key Differences Between Production and Manufacturing

While often used interchangeably, production and manufacturing have distinct meanings that reflect their roles in business operations. Manufacturing typically refers to the actual conversion of raw materials into finished goods through various processes like assembly or fabrication. In contrast, production includes a broader spectrum of activities from planning to logistics—essentially everything involved in getting a product from concept to consumer.

Real-World Examples of Production Strategies

Consider a company like Apple; they exemplify excellence in both production strategies and maintaining high-quality standards. Their meticulous approach ensures that every iPhone not only meets design specifications but also adheres to rigorous quality checks before hitting shelves worldwide. Another example can be found in Toyota's just-in-time manufacturing model, which emphasizes efficiency while prioritizing product quality—a perfect illustration of balancing what is more important: production or quality?

The Role of Quality Control

Quality control is the backbone of any successful manufacturing process, ensuring that production and quality go hand in hand. This department plays a crucial role in maintaining standards and preventing defects, which ultimately influences customer satisfaction and brand reputation. Understanding what the production and quality department does can shed light on its significance within the larger context of manufacturing.

What Does the Production and Quality Department Do?

The production and quality department is responsible for overseeing every aspect of manufacturing to ensure that products meet established standards. This includes conducting inspections, implementing testing protocols, and providing feedback to improve processes. By asking What does the production and quality department do?, one can appreciate how it serves as a bridge between raw materials and finished goods, ensuring that each product not only meets specifications but also satisfies customer expectations.

In addition to maintaining standards, this department also analyzes data to identify trends in quality issues, enabling proactive measures for improvement. They collaborate closely with production teams to establish best practices that enhance both efficiency and output without sacrificing quality. Ultimately, their work lays the foundation for a seamless integration of production strategies focused on delivering high-quality products.

Importance of Quality in the Manufacturing Process

Quality is paramount in the manufacturing process because it directly affects customer satisfaction and loyalty. When consumers receive products that meet or exceed their expectations, they are more likely to return for future purchases—this is where understanding What is production and quality? becomes essential for businesses aiming for longevity in competitive markets. High-quality standards can lead to fewer returns, reduced waste, and increased profitability.

Moreover, a strong emphasis on quality can differentiate a brand from its competitors in an overcrowded marketplace. Companies known for their commitment to excellence often enjoy enhanced reputations, making them more appealing choices for consumers who prioritize reliability over price alone. In this context, understanding What is more important: production or quality? leans heavily towards prioritizing quality as a means of sustaining long-term success.

How Quality Control Impacts Production Efficiency

The relationship between quality control and production efficiency cannot be overstated; effective quality management leads directly to improved operational performance. By minimizing defects through rigorous testing protocols, companies can reduce downtime caused by rework or recalls—a scenario every manufacturer dreads when pondering What is the relationship between quality and production?. Efficient processes driven by robust quality assurance measures allow manufacturers to produce more while wasting less.

Additionally, integrating continuous feedback loops from the production line into the quality control process fosters an environment of ongoing improvement. Employees become more engaged when they see how their work directly contributes to higher product standards; this synergy enhances overall morale while driving productivity up a notch or two! Thus, investing time in refining both aspects—production practices alongside stringent quality controls—is crucial for achieving optimal results.

The Relationship Between Production and Quality

In the world of manufacturing, understanding the intricate relationship between production and quality is crucial for success. What is production and quality? Essentially, production refers to the processes involved in creating goods, while quality denotes the standards that those goods must meet. The relationship between quality and production is symbiotic; high-quality inputs lead to better outputs, which in turn enhances overall production efficiency.

What is the Relationship Between Quality and Production?

The relationship between quality and production can be likened to a well-choreographed dance; each element relies on the other to create a seamless performance. When we ask, What is more important, production or quality? we often find that prioritizing one can adversely affect the other. For instance, focusing solely on quantity may lead to shortcuts in quality control, resulting in defective products that ultimately undermine production efforts.

Quality assurance plays a vital role in what does the production and quality department do by ensuring that every step of the manufacturing process meets predefined standards. This proactive approach not only minimizes waste but also boosts customer satisfaction—a key factor in long-term success. Therefore, recognizing this relationship helps manufacturers strike a balance that enhances both productivity and product integrity.

Balancing Quantity and Quality in Manufacturing

Balancing quantity and quality in manufacturing is akin to walking a tightrope—too much emphasis on one side can tip over into chaos on the other side. Manufacturers must navigate this delicate balance by implementing robust processes that maintain high-quality standards while maximizing output. The ongoing challenge lies in meeting customer demands without compromising product excellence.

To achieve this equilibrium, companies often adopt lean manufacturing principles that emphasize waste reduction while ensuring consistent product quality throughout their operations. By integrating regular assessments into their workflows, manufacturers can identify areas needing improvement without sacrificing speed or efficiency. Ultimately, finding harmony between production and quality not only secures competitive advantages but also fosters brand loyalty among consumers.

Case Study: Toyota's Production System

One of the most celebrated examples of effectively managing the relationship between production and quality can be found in Toyota's Production System (TPS). Renowned for its commitment to both efficiency and excellence, TPS employs just-in-time inventory management alongside rigorous quality checks at every stage of production. This holistic approach illustrates how prioritizing what does the production and quality department do can yield remarkable results.

Toyota's philosophy emphasizes continuous improvement (Kaizen), encouraging employees at all levels to contribute ideas for enhancing both productivity and product standards actively. The result? A manufacturing powerhouse known for delivering vehicles with exceptional reliability—a testament to how effective integration of these two critical aspects leads to overall business success. As such, TPS serves as an invaluable case study for any organization looking to refine its own practices around balancing quantity with unwavering commitment to quality.

What Is More Important: Production or Quality?

In the ongoing debate of production and quality, understanding their interdependence is crucial. While some may argue that production holds the key to profitability, others contend that quality is the foundation of customer satisfaction and brand loyalty. So, what is more important: production or quality? The answer often lies in finding a balance between the two that aligns with an organization's goals.

Comparative Analysis of Production and Quality

To truly grasp what is production and quality, one must analyze their roles within manufacturing processes. Production focuses on creating goods efficiently, emphasizing speed and volume, while quality ensures that these goods meet or exceed standards set by both regulations and consumer expectations. This comparison highlights a fundamental question: What is the relationship between quality and production? When both elements function harmoniously, organizations can achieve operational excellence.

However, prioritizing one over the other can lead to significant pitfalls. For instance, an overemphasis on rapid production may result in subpar products that fail to satisfy customers' needs—ultimately harming brand reputation. Conversely, concentrating solely on quality may slow down output rates and lead to missed market opportunities. Thus, a comparative analysis reveals that neither can thrive without considering the other.

Industry Perspectives on Quality vs. Production

Different industries have varying perspectives on whether production or quality takes precedence. In sectors like automotive manufacturing or pharmaceuticals, stringent regulations necessitate a focus on quality; any lapse could lead to catastrophic consequences for consumers and companies alike. On the other hand, industries such as fast fashion prioritize quick turnover rates in response to ever-changing trends, often at the expense of product longevity.

What does the production and quality department do in this context? It serves as a bridge between these competing priorities—ensuring efficient workflows while maintaining rigorous standards for output consistency and safety. Ultimately, industry perspectives reveal a spectrum where both elements are critical but weighted differently based on specific operational contexts.

Customer Expectations and Quality Standards

When it comes to customer expectations regarding production and quality, there’s no room for compromise; consumers demand excellence across all touchpoints of their experience with a brand. Today’s informed customers are not just looking for affordable products; they want assurance that what they purchase meets high-quality standards—regardless of how quickly it's produced. This shift has led many businesses to ask themselves: What is more important—production or quality?

Moreover, adhering to established benchmarks for product performance fosters trust among consumers—a vital component in maintaining long-term relationships with clients who expect consistency from brands they choose to support. Therefore, businesses must recognize that meeting customer expectations requires an integrated approach where both production efficiency and uncompromising quality coexist harmoniously.

Strategies for Enhancing Production and Quality

In the fast-paced world of manufacturing, enhancing production and quality is not just a goal; it’s a necessity. The interplay between these two elements can make or break a business. By adopting strategic approaches, companies can ensure that both production and quality thrive harmoniously.

Integrating Quality Control in Production Planning

To understand what is production and quality, one must recognize how essential it is to weave quality control into the very fabric of production planning. This means establishing protocols that ensure every stage of the manufacturing process meets predetermined quality standards. By doing so, organizations can address potential issues before they escalate, ultimately leading to improved efficiency and reduced waste.

Moreover, what does the production and quality department do? This department plays a pivotal role in ensuring that production plans incorporate robust quality checkpoints throughout the process. When planning integrates these checkpoints effectively, it becomes easier to balance the relationship between quality and production, ensuring neither aspect suffers at the expense of the other.

Continuous Improvement Practices in Manufacturing

Continuous improvement practices are vital for maintaining high standards in both production and quality. These practices encourage companies to regularly assess their processes, seeking out areas for enhancement while promoting a culture of innovation among employees. Emphasizing this approach allows manufacturers to adapt quickly to changing market demands while maintaining consistent product excellence.

When exploring what is more important—production or quality—it’s clear that continuous improvement helps bridge this gap by fostering an environment where both can flourish together. Regularly evaluating performance metrics enables organizations to identify trends that may affect either aspect negatively, thus ensuring proactive measures are taken before problems arise.

Ultimately, understanding what is the relationship between quality and production becomes clearer when continuous improvement is prioritized; each component supports and elevates the other.

Partnering with Experts like China Inspection Pro

In today’s global marketplace, partnering with industry experts like China Inspection Pro can significantly enhance your approach to managing production and quality. These professionals provide invaluable insights into best practices tailored specifically for your manufacturing needs while ensuring compliance with international standards.

By leveraging such expertise, businesses can better navigate challenges associated with balancing quantity versus quality in their operations—an ongoing struggle many face when scaling up production levels without compromising on product integrity. Furthermore, these partnerships often lead to implementing innovative solutions that streamline processes while adhering strictly to customer expectations regarding product reliability.

In summary, understanding what does the production and quality department do extends beyond internal operations; it also encompasses building relationships with external partners who specialize in enhancing both facets effectively.

Conclusion

In the intricate dance of manufacturing, mastering the balance of production and quality is paramount. Companies must recognize that while production drives revenue, quality ensures sustainability and customer satisfaction. The challenge lies in harmonizing these two elements to create a seamless workflow that maximizes output without compromising standards.

Mastering the Balance of Production and Quality

To truly understand what is production and quality, one must appreciate their interdependence. Striking the right balance means acknowledging that neither can thrive in isolation; they are two sides of the same coin. Organizations that prioritize both aspects often find themselves leading their industries, as they not only meet but exceed customer expectations.

Enhancing Manufacturing Through Quality Control

What does the production and quality department do? This vital team oversees processes to ensure products meet stringent standards before reaching consumers. By integrating robust quality control measures into every stage of manufacturing, companies can enhance efficiency, reduce waste, and ultimately deliver superior products that resonate with customers.

Future Trends in Production and Quality Management

Looking ahead, what is more important: production or quality? The future suggests a shift towards prioritizing quality as consumers become more discerning about product integrity. As technology advances, we can expect innovative solutions that further intertwine production and quality—creating smarter systems where each complements the other seamlessly.