Introduction

In today's fast-paced tech landscape, the importance of quality control in smartphones cannot be overstated. With millions of devices rolling off assembly lines, ensuring that each smartphone meets rigorous standards is crucial for both manufacturers and consumers alike. Quality control not only safeguards a brand's reputation but also enhances user experience by minimizing defects and maximizing functionality.

Importance of Quality Control in Smartphones

Quality control is the backbone of smartphone production, influencing everything from safety to performance. When inspecting a smartphone, manufacturers must focus on various elements such as Quantity, Package & Packaging, Product Style & Construction, and more to ensure that every device is up to par. A robust quality control process can prevent costly recalls and foster consumer trust in a brand's offerings.

Key Aspects for Inspecting a Smartphone

Inspecting a smartphone involves several key aspects that go beyond mere aesthetics; it requires a thorough examination of internal components as well as external features. Key areas include Logo, Labelling & Markings to verify authenticity and compliance with industry standards, along with Measurement Data to ensure proper dimensions and specifications are met. Each facet contributes significantly to the overall performance and durability of the device.

How to Ensure Product Excellence

To achieve product excellence in smartphones, manufacturers must adopt comprehensive testing protocols covering Functional & Performance Tests alongside meticulous checks on Product Workmanship. This includes evaluating battery life efficiency, software functionality, and even aesthetic details like assembly quality and cosmetic finishes. By prioritizing these elements during inspections, companies can deliver reliable products that satisfy customer expectations while standing out in an increasingly competitive market.

Quantity, Package & Packaging

Ensuring All Components Are Accounted For

The first step in inspecting a smartphone is to ensure that all components are accounted for. This means meticulously checking each item against a comprehensive list that includes accessories like chargers, earphones, and manuals—no one wants to find their new phone missing its charging cable! An accurate inventory not only guarantees customer satisfaction but also prevents costly returns or replacements down the line.

It's essential to have an efficient system in place for tracking these components during production and packaging. By doing so, you can streamline your quality control process while minimizing errors. Remember, each missing part can tarnish your product's reputation in a market where consumers expect nothing less than perfection.

Assessing Packaging Integrity

Once you've confirmed that all components are present, it's time to assess packaging integrity—a critical step in inspecting a smartphone. The outer box should be sturdy enough to withstand shipping conditions without compromising its contents; after all, no one wants their shiny new device arriving battered and bruised! Look for signs of wear or damage on both the exterior and interior packaging materials.

Additionally, ensure that protective elements like foam inserts or bubble wrap are effectively securing the smartphone within its box. Poor packaging can lead to significant issues such as screen cracks or internal damage during transit—definitely not what you want when aiming for top-notch product workmanship!

Sustainable Packaging Options

In today's eco-conscious world, sustainable packaging options are becoming increasingly important when inspecting a smartphone. Consumers are more likely to support brands that prioritize environmentally friendly practices—so why not make sustainability part of your quality control checklist? Consider using recyclable materials or biodegradable options that maintain product integrity while reducing environmental impact.

Moreover, adopting sustainable practices can enhance your brand image and set you apart from competitors who may still rely on traditional packaging methods. Not only does this resonate with eco-minded consumers but it also contributes positively toward global sustainability efforts—a win-win situation! So when you're evaluating Quantity, Package & Packaging during inspections, remember: going green is good business!

Product Style & Construction

Evaluating Design Elements

The first step in inspecting a smartphone's design elements is to assess how visually appealing and user-friendly it is. Factors such as color schemes, button placements, and screen-to-body ratios play a significant role in consumer preference. Moreover, ergonomics should not be overlooked; a phone that feels good in hand can enhance the overall user experience.

In addition to aesthetics, functional design elements must be evaluated for practicality. Are the buttons easily accessible? Is the layout intuitive for new users? These considerations are essential when determining whether a smartphone meets modern usability standards.

Lastly, innovative features—like foldable screens or edge displays—should be scrutinized for both their novelty and functionality. While they may look sleek on paper, do they hold up under real-world usage? Ensuring that these design elements serve a purpose will elevate your inspection process.

Material Quality Check

Material quality is another crucial factor when inspecting a smartphone; after all, what good is an eye-catching design if it’s made from subpar materials? The choice of materials affects everything from durability to feel in hand. Checking for premium materials like aluminum or Gorilla Glass can indicate that a manufacturer values quality over cost-cutting measures.

During your inspection, it's vital to consider how these materials withstand daily wear and tear. Conducting scratch tests or assessing resistance to drops can provide insights into long-term performance. Remember: even minor compromises in material quality can lead to significant issues down the line.

Furthermore, eco-friendliness should also be part of your material assessment checklist. As consumers become more environmentally conscious, sustainable materials are increasingly becoming non-negotiable features of modern smartphones. Keeping an eye on this trend could set your inspection apart from others focusing solely on traditional metrics.

Durability and Build Quality

Durability is often tested through rigorous functional and performance tests; however, it begins with solid build quality during the manufacturing process itself. Inspecting how components fit together—are there gaps or misalignments?—can reveal potential weaknesses before they manifest as problems for users later on.

A great test of durability involves subjecting smartphones to extreme conditions: heat exposure, moisture resistance checks, and drop simulations are all standard practices in this realm of inspection. The goal here is simple: ensure that your device can survive everyday mishaps without turning into an expensive paperweight!

Finally, build quality also encompasses attention to detail—a hallmark of superior craftsmanship that distinguishes high-end devices from their budget counterparts. Look closely at seams and joints during your inspection; any irregularities could indicate poor workmanship that compromises both aesthetics and longevity.

Logo, Labelling & Markings

When inspecting a smartphone, the logo, labelling, and markings play a crucial role in ensuring product authenticity and compliance with industry standards. These elements not only represent the brand but also provide essential information to consumers. A thorough inspection of these components can significantly enhance the overall quality assurance process.

Authenticity of Branding

The authenticity of branding is vital when inspecting a smartphone; counterfeit products can lead to consumer mistrust and potential safety hazards. Check for consistent logo placement, color accuracy, and design details that align with the manufacturer's specifications. Authentic logos should exhibit high-quality printing or engraving without any signs of fading or smudging—after all, first impressions matter!

Compliance with Labelling Standards

Compliance with labelling standards is another key aspect when inspecting a smartphone. Labels must adhere to local regulations regarding safety information, energy consumption ratings, and manufacturing details. Ensuring that all required markings are present not only protects consumers but also helps manufacturers avoid legal issues down the line.

Ensuring Clear and Informative Markings

Clear and informative markings are essential for user experience when inspecting a smartphone; they guide users in understanding product features and usage instructions. Labels should be legible, using appropriate font sizes and colors that contrast well with their background for easy readability. Moreover, including QR codes or NFC tags can enhance user engagement by linking to additional resources or support services.

Measurement Data

When it comes to inspecting a smartphone, measurement data serves as the backbone of quality assurance. Accurate dimensions and specifications ensure that all components fit seamlessly within the device, which is crucial for both functionality and aesthetics. This section dives into the essential aspects of measurement data that every manufacturer should meticulously evaluate.

Assessing Dimensions and Specifications

The first step in assessing dimensions and specifications is to verify that each component adheres to the predetermined measurements set forth during the design phase. This includes checking everything from screen size to button placements, ensuring that all parts align perfectly for optimal user experience. Any discrepancies in these measurements can lead to issues such as improper fitting or malfunctioning features, emphasizing the importance of this inspection stage.

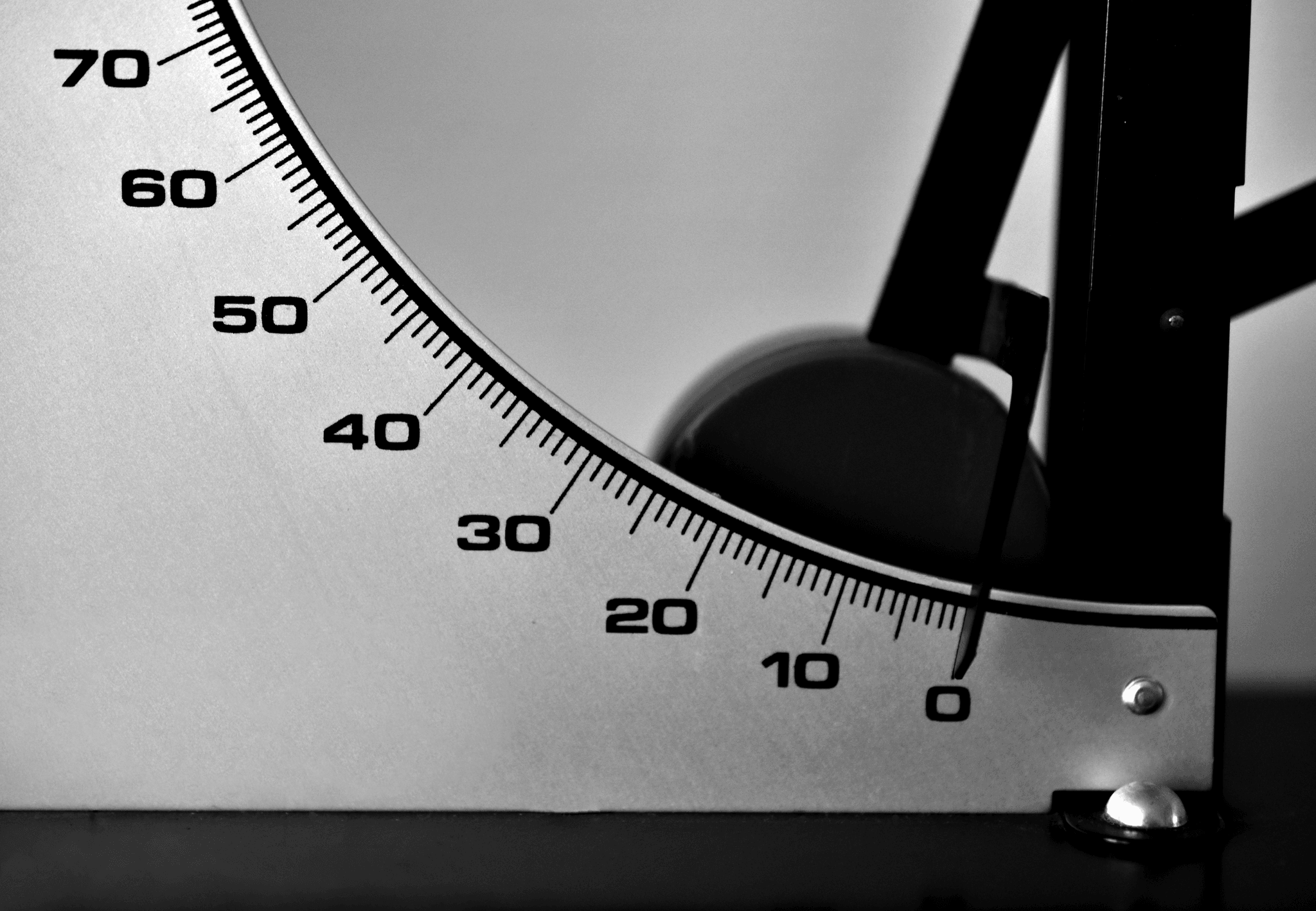

Weight and Balance Considerations

Weight and balance are not just about heft; they play a significant role in user comfort and device usability. When inspecting a smartphone, it’s vital to assess whether its weight distribution feels natural in hand—too heavy on one side can lead to an awkward grip during use. Additionally, an ideal weight contributes to portability without sacrificing durability or performance, making this aspect crucial for any quality control checklist.

Calibration of Components

Calibration of components ensures that various elements function harmoniously together within the smartphone ecosystem. This involves checking sensors like accelerometers, gyroscopes, and cameras to confirm they operate within specified parameters for accuracy and reliability. Proper calibration not only enhances performance but also directly impacts user satisfaction—after all, who wants a phone that misreads gestures or takes blurry photos?

Functional & Performance Tests

When it comes to inspecting a smartphone, functional and performance tests are the ultimate litmus test for quality assurance. These tests not only reveal how well a device performs but also ensure that it meets consumer expectations and industry standards. By meticulously examining aspects such as battery life, software functionality, and connectivity, manufacturers can guarantee that their smartphones deliver an exceptional user experience.

Battery Life and Charging Efficiency

Battery life is often the crown jewel of any smartphone's appeal; after all, who wants to be tethered to a charger? During inspections, it's crucial to evaluate not just how long the battery lasts under typical usage but also its charging efficiency. A smartphone with subpar battery performance can lead to customer dissatisfaction, which is why this aspect should never be overlooked when considering Quantity, Package & Packaging.

Software Functionality and User Experience

Software functionality is another cornerstone of inspecting a smartphone; if the software runs like molasses on a winter day, users will quickly lose patience. Testing should encompass everything from app responsiveness to system updates and overall user experience—after all, the best hardware in the world is useless without seamless software integration. Neglecting this vital component would undermine efforts in Product Style & Construction as well as compromise customer satisfaction.

Connectivity Tests: Wi-Fi, Bluetooth, and Cellular

In today's hyper-connected world, ensuring robust connectivity through Wi-Fi, Bluetooth, and cellular networks is non-negotiable for any smartphone inspection process. Connectivity issues can frustrate users and tarnish brand reputation faster than you can say dropped call. Thorough testing guarantees that every device meets stringent standards before hitting store shelves—an essential step in ensuring Product Workmanship meets consumer demands.

Product Workmanship

When it comes to inspecting a smartphone, product workmanship is a crucial aspect that can make or break the user experience. This stage focuses on the quality of assembly and overall aesthetic appeal, ensuring that each component fits perfectly and functions seamlessly. A smartphone with poor workmanship can lead to issues down the line, affecting not just performance but also customer satisfaction.

Inspecting Assembly Quality

Inspecting assembly quality involves a thorough examination of how various components fit together within the smartphone. This includes checking for proper alignment of parts, secure connections, and the overall integrity of the device. If there are discrepancies in assembly quality, such as loose screws or misaligned screens, it could indicate a lapse in manufacturing standards that might compromise both functionality and durability.

Identifying Cosmetic Defects

Identifying cosmetic defects is another essential part of product workmanship when inspecting a smartphone. This includes looking for scratches, dents, or discoloration on the exterior surfaces that could detract from its visual appeal. A flawless finish is vital; even minor imperfections can lead customers to question the overall quality of the device and may affect their purchasing decisions.

Ensuring Attention to Detail

Ensuring attention to detail is paramount in achieving high-quality product workmanship during inspections. From precise logo placements to clean labelling and markings, every little detail counts toward creating an exceptional user experience. By focusing on these finer points during inspection—along with quantity checks for all components—manufacturers can guarantee that their smartphones not only perform well but also look great while doing so.

Conclusion

In the fast-paced world of technology, inspecting a smartphone is no small feat. Quality assurance plays a pivotal role in ensuring that every device meets the high standards demanded by consumers. By focusing on various aspects such as quantity, package & packaging, product style & construction, and more, businesses can deliver products that not only function well but also resonate with users.

The Essential Checklist for Inspecting a Smartphone

Start by verifying the quantity of components included in the package; nothing sets off alarm bells faster than missing parts! Next, assess the packaging for integrity and sustainability—after all, first impressions matter. Don’t forget to evaluate product style & construction; ensure that design elements are not just aesthetically pleasing but also functional and durable.

Moving on to logo, labelling & markings, it’s essential to confirm brand authenticity and compliance with labeling standards—no one wants counterfeit devices! Measurement data should be meticulously checked; dimensions and specifications must align with what’s promised. Finally, conduct thorough functional & performance tests alongside inspecting product workmanship for any cosmetic defects or assembly quality issues—this will guarantee an exceptional user experience.

How China Inspection Pro Can Help

Navigating the landscape of quality control can be daunting, but that's where China Inspection Pro steps in to simplify things. With expertise in inspecting smartphones, they offer tailored solutions that cover every aspect from quantity checks to functional testing. Their team ensures that all components are accounted for and packaging is up to par while maintaining sustainable practices.

Moreover, they specialize in evaluating product style & construction along with logo verification and compliance checks for labelling & markings. By leveraging their services, companies can rest assured that their devices meet rigorous measurement data standards while excelling in performance tests—ultimately leading to satisfied customers who trust your brand.

Final Thoughts on Quality Assurance

Quality assurance isn’t just an afterthought; it’s the backbone of successful smartphone production. In today's competitive market, meticulous inspecting a smartphone ensures longevity and customer satisfaction through reliable functionality and stylish design elements. Remember: it's not just about creating a device; it's about crafting an experience through careful attention to detail in every part—from quantity checks to robust performance tests.

So whether you’re looking at package integrity or ensuring flawless product workmanship, make quality control your priority—it pays off! With partners like China Inspection Pro at your side, you’ll navigate this journey smoothly while delivering products that stand out in both quality and design.