Introduction

Quality inspection is the backbone of any robust quality assurance system, ensuring that products meet specified standards before they reach consumers. With various types of quality inspection available, organizations can effectively monitor and maintain quality and control throughout their production processes. Understanding these methods not only enhances product reliability but also builds trust with customers, which is vital in today’s competitive market.

Understanding Quality Inspection Basics

At its core, quality inspection involves evaluating products or services to ensure they meet predetermined criteria for quality assurance. This encompasses a range of activities—from visual checks to complex testing methodologies—designed to identify defects and ensure compliance with industry standards. By familiarizing ourselves with the different types of quality inspection, businesses can implement tailored strategies that optimize their quality control efforts.

Why Quality Inspection Matters

Quality inspection is crucial because it directly impacts customer satisfaction and brand reputation; a single defect can lead to significant backlash in today’s consumer-driven world. Moreover, effective quality assurance practices help reduce costs associated with returns and rework by catching issues early in the production process. Ultimately, prioritizing quality inspections fosters a culture of excellence within organizations, driving continuous improvement in both products and processes.

The Importance of Quality Testing Services

Quality testing services are essential for validating the integrity and performance of products before they hit the market. These services not only encompass various types of inspections but also provide detailed insights into product functionality and safety—elements that are non-negotiable for consumer trust. By leveraging comprehensive testing solutions, companies can enhance their overall quality assurance strategy while minimizing risks associated with subpar products.

Visual Inspection

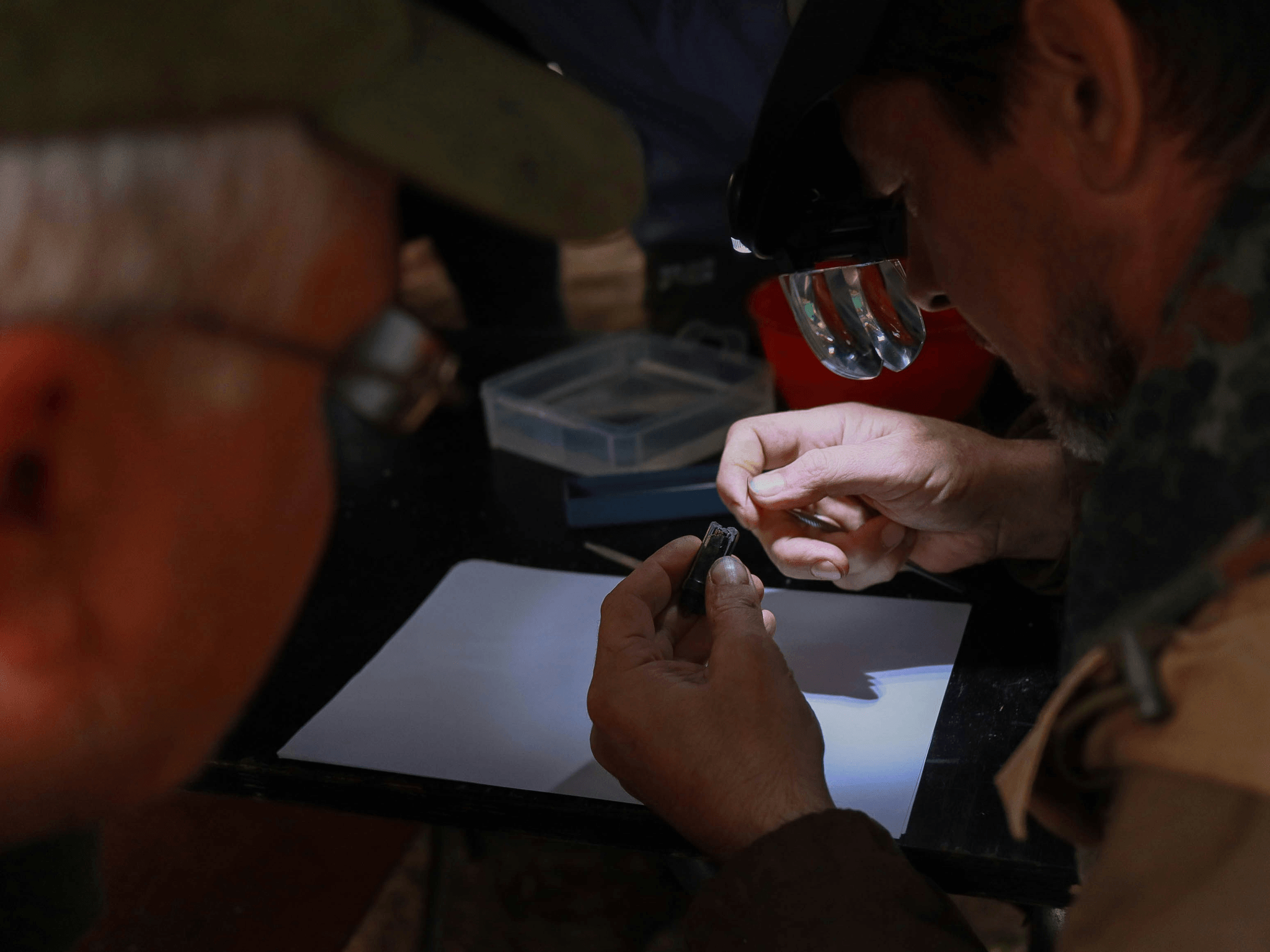

In the realm of quality inspection, visual inspection stands out as one of the most fundamental and widely used techniques. It involves examining products or materials with the naked eye, often enhanced by tools such as magnifying glasses or cameras, to identify defects or irregularities. This method is crucial for ensuring that quality assurance standards are met before products reach consumers.

What is Visual Inspection?

Visual inspection refers to the process of assessing a product's appearance and condition through direct observation. This type of quality inspection is essential in various industries, including manufacturing, construction, and food production, where visual cues can indicate potential issues. By focusing on aspects like color, texture, and overall finish, inspectors can catch problems early in the production line—saving time and resources while maintaining high standards for quality assurance.

Applications of Visual Inspection

Visual inspection finds its way into numerous applications across different sectors. In manufacturing, it aids in checking for surface defects on components before assembly; in food processing, it ensures that products meet safety and aesthetic criteria; while in construction, it helps verify that materials adhere to specifications. The versatility of this technique makes it an integral part of quality control processes across industries looking to uphold their commitment to quality and quality assurance.

Benefits of Visual Inspection

The benefits of visual inspection extend beyond just catching defects; they also play a significant role in enhancing overall efficiency within production lines. By implementing this type of quality testing service early on, companies can reduce waste and minimize costly recalls due to defective products reaching consumers. Furthermore, visual inspections foster a culture of accountability among workers who understand the importance of maintaining high standards for both quality control and overall product integrity.

Dimensional Inspection

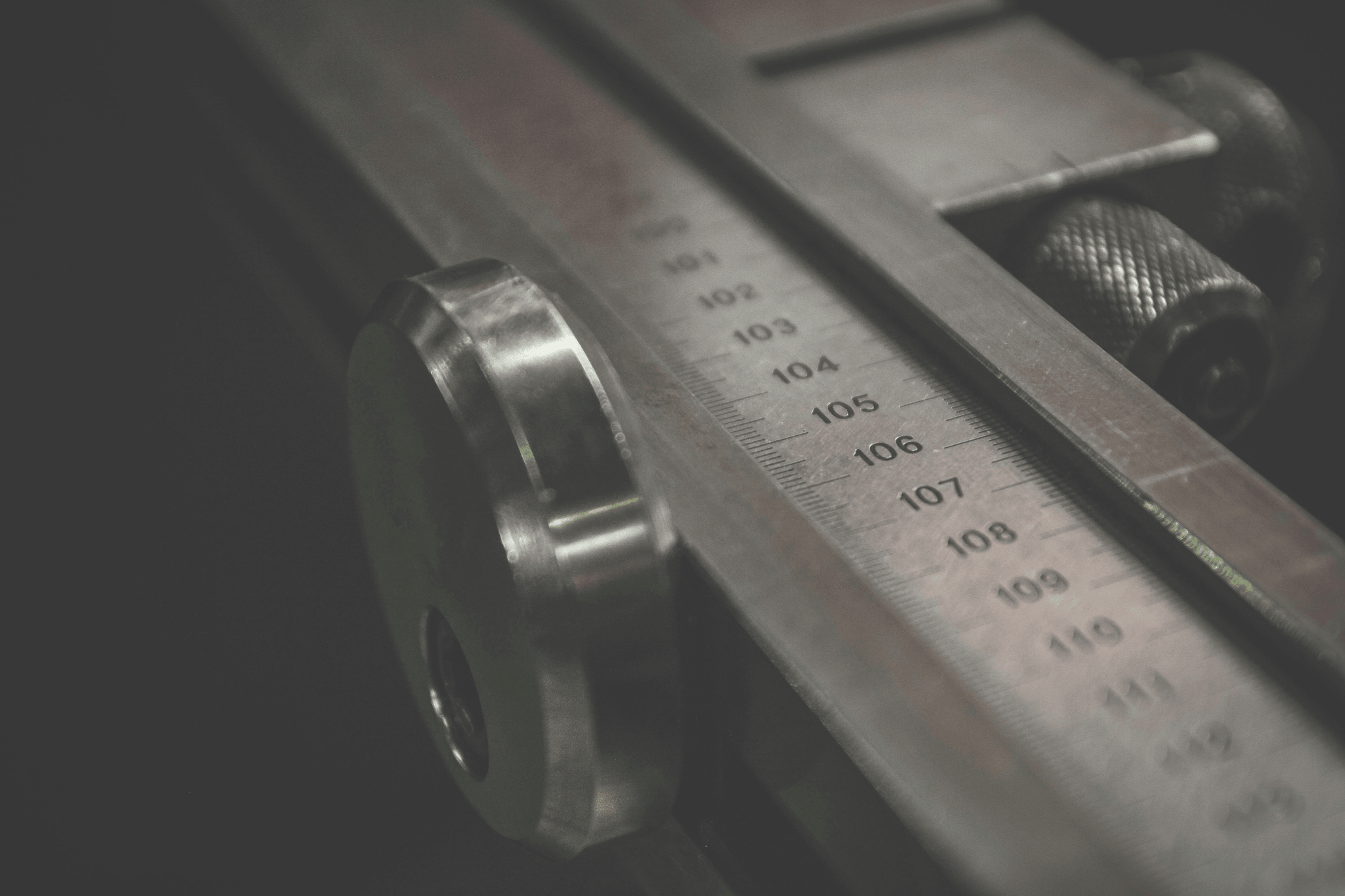

In the realm of quality inspection, dimensional inspection plays a pivotal role in ensuring that products meet specified design and engineering standards. This type of quality inspection focuses on measuring physical dimensions, such as length, width, height, and angles, to verify that they align with predetermined specifications. By employing dimensional inspection techniques, manufacturers can maintain high standards of quality assurance and prevent costly errors in production.

Overview of Dimensional Inspection

Dimensional inspection is a systematic process used to assess the physical characteristics of an object against its design specifications. It encompasses various methods such as manual measurement with calipers or micrometers and advanced techniques like laser scanning or coordinate measuring machines (CMM). This type of quality assurance not only helps identify deviations from the desired dimensions but also enhances overall product reliability and safety.

Tools Used in Dimensional Inspection

A variety of tools are utilized in dimensional inspection to ensure accuracy and precision in measurements. Common instruments include calipers for basic measurements, micrometers for finer details, and CMMs for complex geometries. Additionally, laser scanners provide rapid data collection for intricate parts, making them invaluable in modern quality testing services aimed at achieving superior quality control.

Importance for Quality Control

The significance of dimensional inspection cannot be overstated when it comes to maintaining effective quality control processes. By regularly implementing this type of quality inspection, manufacturers can detect discrepancies early on—saving time and resources while ensuring compliance with industry standards. Ultimately, robust dimensional inspection practices contribute significantly to overall product integrity and customer satisfaction by reinforcing the principles of quality assurance.

Functional Testing

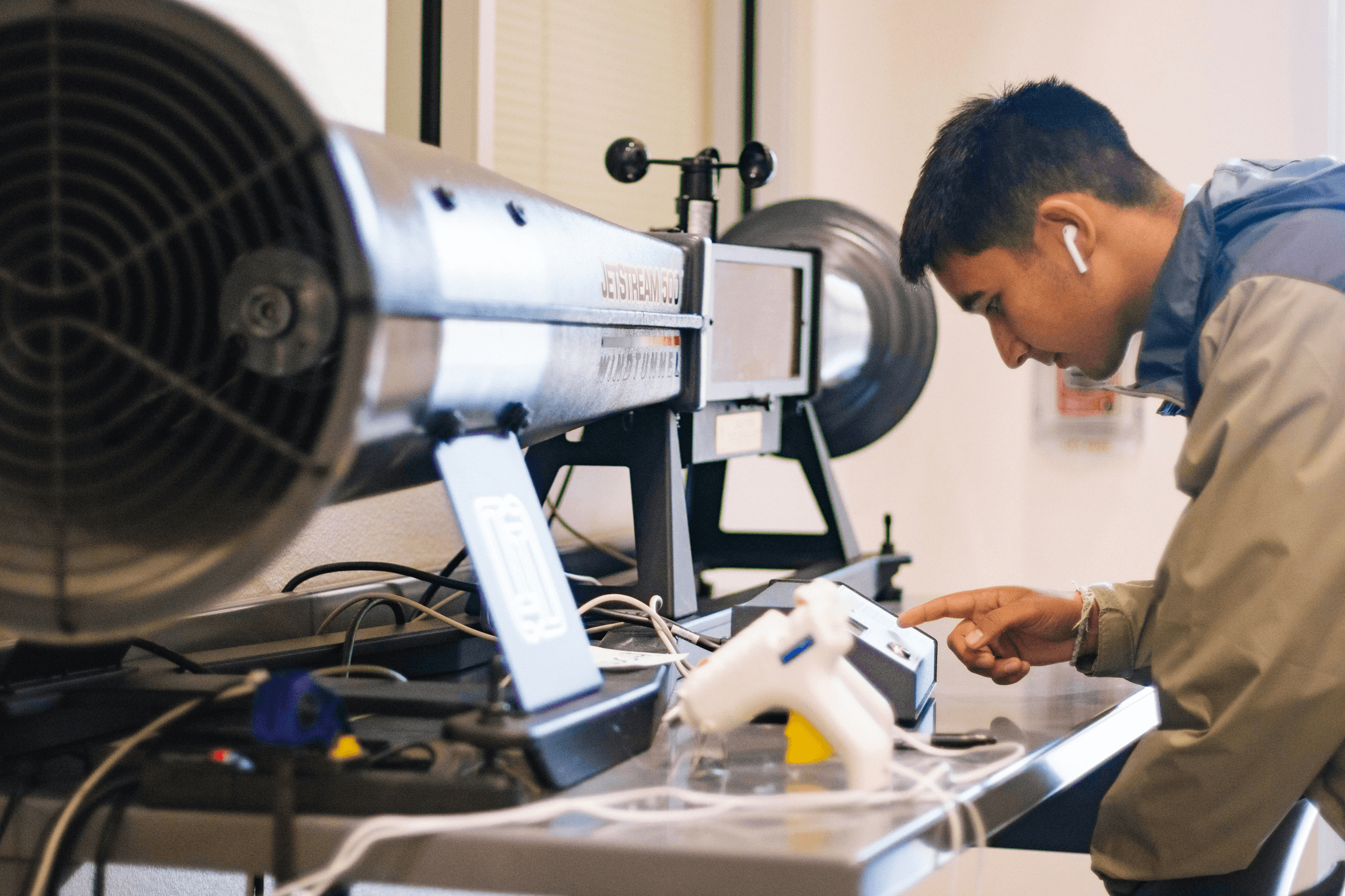

Functional testing is a critical component of the quality inspection landscape, ensuring that products meet their intended use and performance criteria. It involves evaluating the functionality of a product against its specifications to determine whether it performs as expected. This type of quality inspection plays a vital role in quality assurance, helping to identify defects before they reach consumers.

Defining Functional Testing

At its core, functional testing assesses how well a product operates in real-world scenarios. It examines whether the features and functions work as intended, focusing on user experience and satisfaction. By implementing this form of quality control, organizations can ensure that their products not only meet technical specifications but also deliver on consumer expectations.

Real-world Examples of Functional Testing

Consider the automotive industry: functional testing is essential for ensuring that every feature—from brakes to infotainment systems—works seamlessly before vehicles hit the road. In software development, functional testing verifies that applications perform their designated tasks without glitches or errors, enhancing user trust and satisfaction. These examples highlight how various types of quality inspection are vital across different sectors to maintain high standards in quality assurance and control.

How Functional Testing Ensures Quality

Functional testing contributes significantly to overall quality assurance by identifying potential issues early in the production process. This proactive approach allows manufacturers to rectify problems before products reach the market, reducing costs associated with recalls or customer dissatisfaction later on. Ultimately, effective functional testing reinforces both quality and control within an organization’s processes, fostering a culture of continuous improvement in their quality testing services.

Destructive Testing

Destructive testing is a vital component of quality inspection, particularly when it comes to assessing the durability and reliability of materials and products. This method involves subjecting items to stress until failure, allowing engineers to understand their limits and performance characteristics. While it might sound harsh, this type of quality inspection is crucial for ensuring that products meet stringent safety and quality assurance standards.

Introduction to Destructive Testing

Destructive testing serves as a rigorous approach within the realm of quality assurance, focusing on evaluating materials by pushing them to their breaking points. This can include tensile tests, impact tests, or fatigue tests that reveal how materials behave under extreme conditions. By understanding how products fail, companies can enhance their design processes and improve overall quality control measures.

When to Use Destructive Testing

Destructive testing is particularly useful in industries where safety is paramount, such as aerospace, automotive, and construction. It's employed when non-destructive methods may not provide sufficient insights into material properties or structural integrity. For instance, if a company is developing a new alloy for aircraft components, they may need to conduct destructive tests to ensure that the material can withstand extreme stress without compromising safety.

Insights from Destructive Testing

The insights gained from destructive testing can significantly inform product development and manufacturing processes in terms of quality assurance quality. By identifying potential weaknesses before mass production begins, companies can make informed decisions about material selection and design modifications. Ultimately, this type of quality inspection not only enhances product reliability but also fosters consumer trust in brands committed to high standards of quality control.

Conclusion

In wrapping up our exploration of the various types of quality inspection, it's clear that each method plays a vital role in ensuring products meet stringent standards. From visual checks to destructive testing, these techniques collectively contribute to robust quality assurance practices. Understanding the nuances of quality control not only enhances product reliability but also fosters consumer trust.

Key Takeaways on Quality Inspection Types

The types of quality inspection discussed—visual, dimensional, functional, and destructive—each serve unique purposes in the broader context of quality assurance. Visual inspection is often the first line of defense against defects, while dimensional inspection ensures that products meet precise specifications. Functional testing guarantees that items operate as intended, and destructive testing provides critical insights into material integrity—all essential components for effective quality control.

How China Inspection Pro Elevates Quality Assurance

China Inspection Pro stands out in the realm of quality assurance by offering comprehensive quality testing services tailored to diverse industries. Their expertise spans all types of quality inspection methods, ensuring that clients receive meticulous evaluations that enhance product safety and compliance with international standards. By leveraging advanced technology and a dedicated team, China Inspection Pro elevates the standard for quality and control across supply chains.

Next Steps for Implementing Quality Control Solutions

To implement effective quality control solutions, businesses should first assess their specific needs based on the types of quality inspection most relevant to their products. Engaging with professionals like those at China Inspection Pro can provide invaluable insights into establishing robust processes for ongoing evaluation and improvement. As you embark on this journey towards enhanced quality assurance, remember that proactive measures today lead to higher customer satisfaction tomorrow.