Introduction

In the world of product manufacturing, ensuring durability and performance is paramount. One of the most effective methods to test a product's resilience against corrosion and environmental stress is the Salt Spray Test. This testing method simulates harsh conditions to evaluate how well products can withstand exposure to salt-laden environments, making it an essential tool in various industries.

Overview of Salt Spray Testing

The Salt Spray Test, also known as the salt fog test, is a standardized method used to assess the corrosion resistance of materials and coatings. By exposing products to a saline mist in controlled conditions, manufacturers can predict how items will perform over time when faced with real-world challenges such as humidity and salt exposure. This test not only helps in determining product longevity but also aids in refining materials and coatings for better performance.

Significance of Product Performance Testing

Product Performance Test plays a critical role in maintaining quality assurance across industries ranging from automotive to electronics. By understanding how products perform under various conditions, companies can make informed decisions about design modifications or material selections that enhance reliability. The Importance of Product Performance Test cannot be overstated; it directly impacts customer satisfaction and brand reputation by ensuring that only high-quality products reach the market.

The Role of Reliability Testing

Reliability testing encompasses various methodologies aimed at assessing how consistently a product performs its intended function over time. Within this framework, the Salt Spray Test serves as a vital component, especially for products expected to face corrosive environments. By incorporating reliability testing into their development processes, manufacturers not only improve their offerings but also reduce costs associated with failures and recalls down the line.

Understanding the Salt Spray Test

The Salt Spray Test is a widely recognized method used to evaluate the corrosion resistance of materials and coatings. This testing procedure simulates harsh environmental conditions, specifically those that involve exposure to salt-laden environments, which is crucial for industries such as automotive, aerospace, and marine. By understanding the purpose and methodology behind this test, companies can ensure their products stand up to the rigors of real-world use.

Purpose and Basics of Salt Spray Testing

The primary purpose of the Salt Spray Test is to assess how well materials can resist corrosion over time when exposed to saline environments. This test involves placing samples in a controlled chamber where a saline solution is atomized into a fine mist, replicating conditions similar to coastal areas or industrial sites. The results help manufacturers determine product durability and longevity, making it an essential part of any comprehensive Product Performance Test strategy.

In addition to evaluating corrosion resistance, the Salt Spray Test can identify weaknesses in coatings or surface treatments before products reach consumers. Understanding these vulnerabilities allows manufacturers to make necessary adjustments early in the production cycle. Thus, this testing not only enhances product quality but also boosts consumer confidence in performance.

Standards Governing Salt Spray Test

Several international standards govern how the Salt Spray Test should be conducted, ensuring consistency and reliability across different testing facilities. Notable standards include ASTM B117 and ISO 9227, which outline specific procedures for sample preparation, test duration, and evaluation criteria. Adhering to these guidelines ensures that results are comparable and meaningful across various applications.

Compliance with these standards also plays a critical role in regulatory requirements for many industries; failure to meet these benchmarks could result in costly recalls or safety issues down the line. Therefore, understanding these standards is vital for anyone involved in Product Performance Testing or quality assurance processes. It helps organizations maintain industry credibility while delivering high-quality products that meet customer expectations.

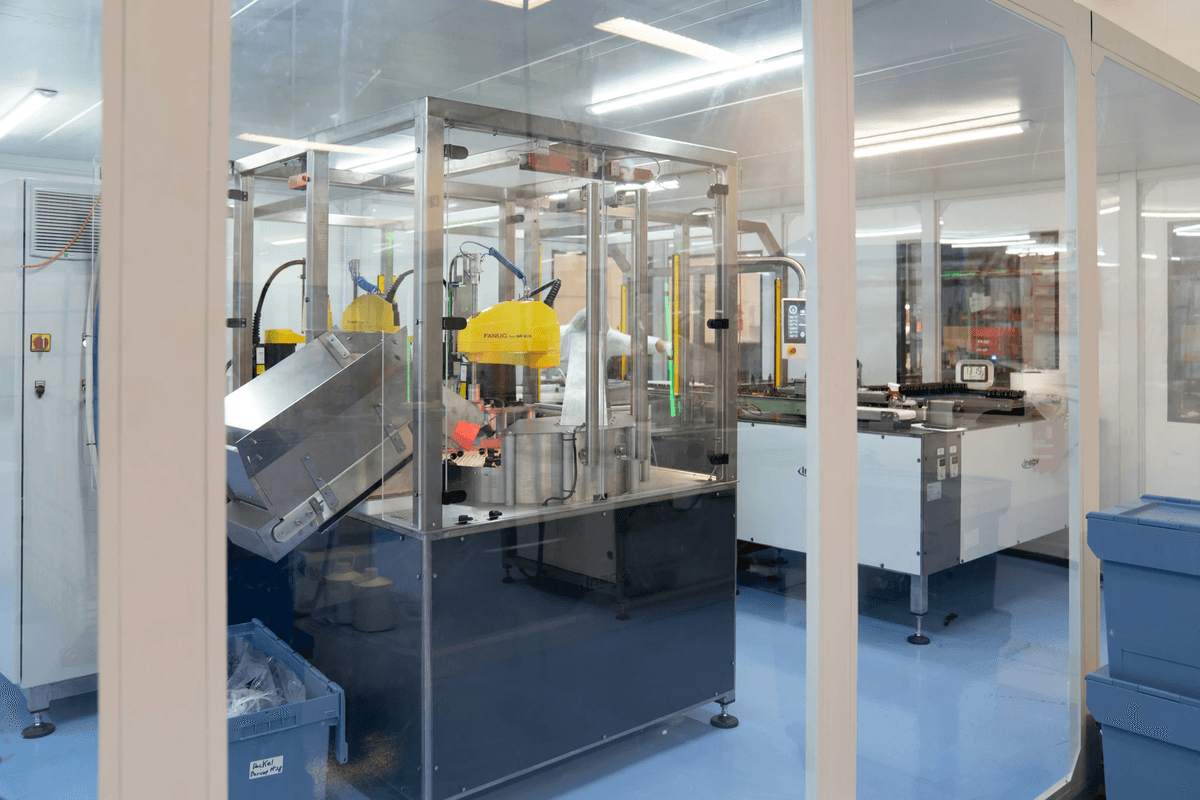

How China Inspection Pro Conducts Salt Spray Tests

China Inspection Pro employs state-of-the-art testing equipment designed specifically for conducting comprehensive Salt Spray Tests efficiently and accurately. Their facilities are equipped with advanced salt spray chambers that maintain precise temperature and humidity levels throughout testing cycles—key factors influencing corrosion rates during assessments. By following established standards like ASTM B117 rigorously, they ensure every test yields reliable data relevant for various applications.

Moreover, China Inspection Pro emphasizes thorough documentation of each testing phase—from sample preparation through analysis—allowing clients complete transparency regarding their product’s performance characteristics under simulated corrosive conditions. This meticulous approach not only enhances trust but also provides customers with actionable insights into potential improvements needed before market release. In doing so, they highlight both the advantages and disadvantages of salt spray tests effectively within their reports.

By employing such rigorous methodologies in conducting tests while adhering strictly to industry standards like ISO 9227 ensures that clients receive accurate evaluations tailored specifically toward enhancing product performance through informed decision-making processes—crucial steps toward achieving long-lasting success!

Application of Salt Spray Test

The Salt Spray Test is widely recognized for its utility across various industries, serving as a benchmark for assessing the corrosion resistance of materials and coatings. This test simulates harsh environmental conditions, making it an essential tool in sectors where durability is paramount. Its application spans from automotive to aerospace, ensuring that products can withstand the elements without compromising quality.

Industries Utilizing the Salt Spray Test

Numerous industries rely on the Salt Spray Test to validate their products' performance against corrosion. The automotive industry frequently employs this test to evaluate protective coatings on vehicles, ensuring they can endure salt-laden roads and adverse weather conditions. Similarly, marine and aerospace sectors utilize the Salt Spray Test to guarantee that components maintain integrity when exposed to salty air or seawater.

In addition to these prominent fields, construction and electronics also benefit from this testing method. For instance, construction materials like steel reinforcements are tested for long-term durability in coastal environments where salt exposure is inevitable. Electronics manufacturers conduct Salt Spray Tests on circuit boards and connectors, ensuring reliability amidst humidity and corrosive elements.

Real-World Examples of Application

Real-world applications of the Salt Spray Test underscore its significance in product performance validation. For example, a leading automotive manufacturer recently implemented extensive Salt Spray Testing on its new line of vehicles to ensure that paint finishes could resist corrosion over time—a crucial factor in customer satisfaction and brand reputation.

In another instance, a well-known electronics firm utilized this testing method to assess their newly developed waterproof smartphone cases before launch; results indicated that certain designs could withstand prolonged exposure without degradation. These examples highlight how critical the application of the Salt Spray Test is in various industries striving for excellence.

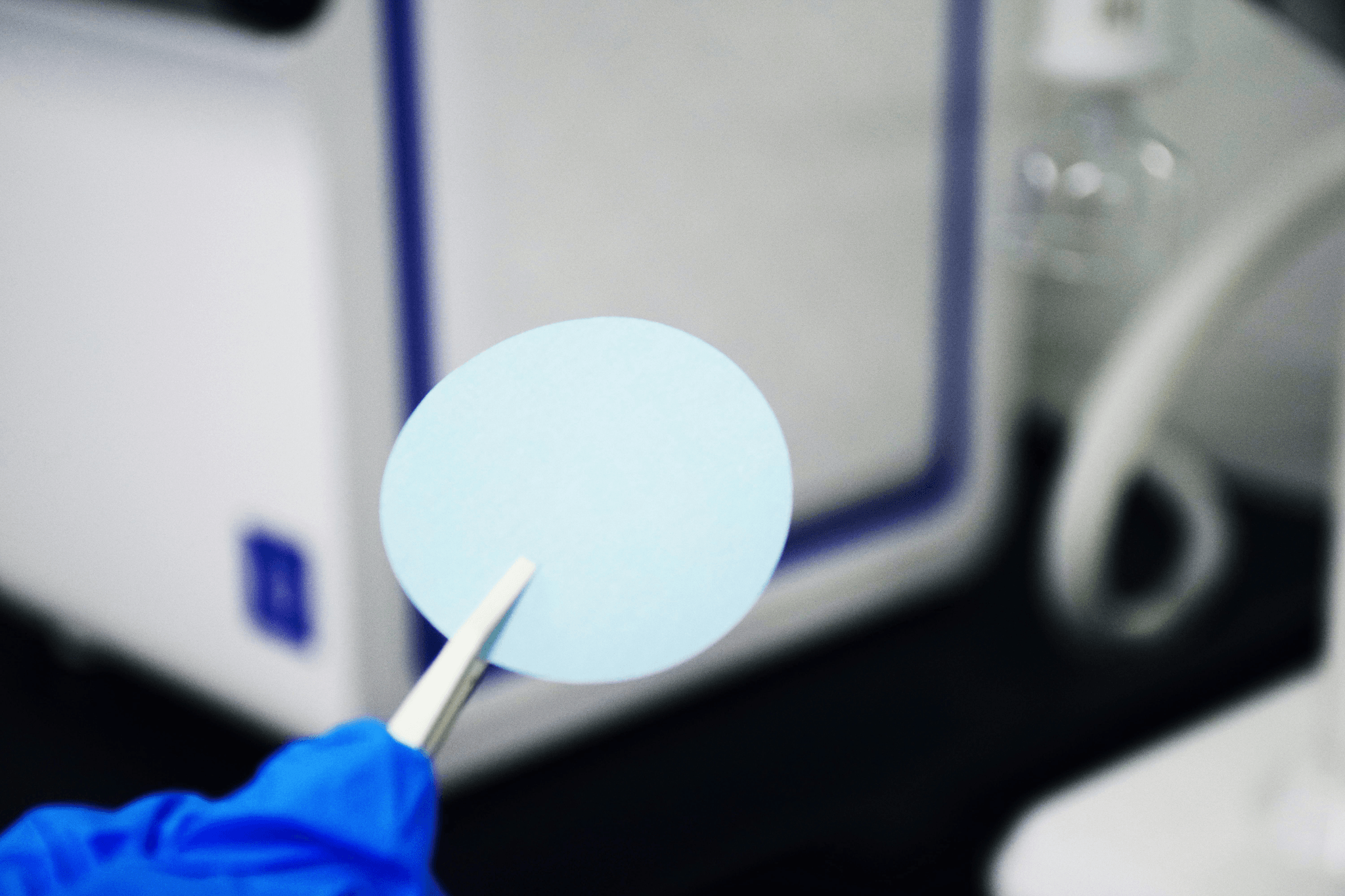

Common Testing Equipment for Salt Spray Test

The effectiveness of the Salt Spray Test hinges not only on methodology but also on reliable testing equipment designed specifically for this purpose. Commonly used apparatus includes salt spray chambers that create a controlled environment with fine mist salinity levels—typically set according to specific standards like ASTM B117 or ISO 9227.

These chambers often come equipped with features such as temperature controls and humidity monitoring systems to simulate real-world conditions accurately. Additionally, accessories like sample holders and data logging devices help streamline the process by facilitating precise measurements during testing phases—crucial steps in any comprehensive Product Performance Test.

Advantages and Disadvantages of Salt Spray Test

The Salt Spray Test has become a staple in the world of product performance testing, especially for evaluating corrosion resistance. However, like any testing method, it comes with its own set of advantages and disadvantages. Understanding these can help manufacturers make informed decisions about when to utilize the Salt Spray Test in their quality assurance processes.

Pros of Using Salt Spray Testing

One of the primary advantages of the Salt Spray Test is its ability to simulate harsh environmental conditions that products may face in real-world applications. This provides valuable insights into how materials will perform over time, allowing manufacturers to identify potential weaknesses early on. Additionally, the testing equipment used for salt spray testing is generally standardized and widely available, making it accessible for various industries.

Another pro is the relatively quick turnaround time for results compared to other types of performance testing. With controlled environments and established protocols, businesses can conduct tests efficiently without extensive delays. Furthermore, successful outcomes from salt spray tests can enhance a product's marketability by demonstrating its durability and reliability.

Lastly, the Salt Spray Test helps in compliance with international standards required by many industries. Meeting these standards not only boosts consumer confidence but also ensures that products are safe and reliable under various conditions. The importance of product performance tests like this cannot be overstated when it comes to maintaining brand reputation.

Limitations and Criticisms

Despite its benefits, there are limitations associated with the Salt Spray Test that cannot be overlooked. One major criticism is that while it simulates corrosive environments, it may not accurately represent all real-world conditions a product might face throughout its lifecycle. For instance, factors such as humidity levels or specific chemical exposure are not always accounted for in standard salt spray tests.

Moreover, some argue that relying solely on this test could lead manufacturers to overlook other critical aspects of product performance testing. It’s essential to balance salt spray results with other types of performance testing for a comprehensive understanding of a product's durability under varied conditions. This brings us back to the importance of product performance tests as part of an integrated quality assurance strategy.

Finally, another limitation lies in potential variability between different batches or setups within salt spray testing procedures themselves. Inconsistencies can arise due to variations in equipment calibration or environmental factors during testing phases—factors that could skew results significantly if not properly controlled.

When to Choose Salt Spray Over Other Tests

Choosing when to use the Salt Spray Test often depends on specific project goals or industry requirements; however, certain scenarios make it particularly advantageous. If your primary concern is assessing corrosion resistance specifically for metal components or coatings exposed to saline environments (like marine applications), then this test becomes invaluable due to its targeted focus on those issues.

Additionally, if you're operating within industries governed by strict regulations requiring certification through standardized tests (such as automotive or aerospace), then opting for the Salt Spray Test can facilitate compliance checks efficiently while providing credible evidence about your product’s durability against corrosion over time.

However, it's vital not just to rely solely on one type but rather integrate various types of performance testing into your overall strategy—this ensures you capture a well-rounded view regarding how products stand up against diverse challenges they may encounter post-launch!

Importance of Product Performance Testing

In today's competitive market, the significance of product performance testing cannot be overstated. It serves as a critical checkpoint for ensuring that products meet industry standards and consumer expectations. The Salt Spray Test is one of the most widely recognized methods within product performance testing, specifically designed to evaluate the corrosion resistance of materials.

Why Performance Testing Matters

Performance testing matters because it helps manufacturers identify potential weaknesses in their products before they hit the market. This proactive approach not only saves time and resources but also protects brand reputation by ensuring that products perform reliably under various conditions. The Application Salt Spray Test is particularly valuable as it simulates harsh environments, providing insights into how products will fare in real-world scenarios.

Impact on Quality Assurance

The impact of performance testing on quality assurance is profound; it establishes a foundation for product reliability and customer satisfaction. By integrating rigorous tests like the Salt Spray Test into their quality assurance processes, companies can detect flaws early on and implement necessary improvements. This commitment to quality ultimately leads to fewer returns and higher customer trust, reinforcing a company's standing in the marketplace.

Case Studies Demonstrating Importance

Numerous case studies illustrate the importance of thorough performance testing in various industries. For instance, a well-known automotive manufacturer discovered through salt spray testing that certain components were prone to corrosion when exposed to saltwater environments; this finding allowed them to switch materials before production began, saving millions in potential warranty claims. Similarly, electronics companies have utilized salt spray tests to ensure that their devices withstand humidity and exposure without compromising functionality—showcasing how essential these tests are across diverse applications.

Types of Performance Testing

When it comes to ensuring the durability and reliability of products, performance testing plays a crucial role. Various types of performance tests exist, each designed to evaluate specific characteristics and behaviors under different conditions. Among these, the Salt Spray Test stands out for its ability to simulate corrosive environments, making it a favorite in industries where resistance to rust and corrosion is vital.

Overview of Different Performance Tests

Performance testing encompasses a wide array of methodologies tailored to assess product resilience across various parameters. From mechanical stress tests that evaluate structural integrity to thermal cycling tests that gauge temperature resilience, the landscape is rich with options. The Salt Spray Test specifically measures how materials withstand exposure to saline conditions, providing valuable insights into long-term durability in real-world applications.

Comparing Product Performance Test with Others

While the Salt Spray Test is instrumental in assessing corrosion resistance, it's essential to compare it with other product performance tests for a comprehensive evaluation strategy. For example, while fatigue testing examines how materials endure repeated loading cycles, environmental testing might look at overall performance under fluctuating temperatures or humidity levels. Each test has its unique advantages and disadvantages; thus, understanding their strengths can help companies choose the most appropriate method based on their specific needs.

Selecting the Right Test for Your Product

Choosing the right type of performance test hinges on several factors including product application and industry standards. For instance, if you’re developing outdoor equipment subjected to harsh weather conditions, incorporating the Salt Spray Test would be essential due to its focus on corrosion resistance. Conversely, products requiring strength assessments may benefit more from tensile or compression tests; evaluating these aspects ensures thorough validation throughout all steps of product performance testing.

Steps of Product Performance Test

When embarking on a Product Performance Test, particularly one that includes the Salt Spray Test, it’s essential to follow a structured approach. This ensures that you gather reliable data and insights on how your product withstands various conditions. Understanding the steps involved can help streamline the process and enhance the overall effectiveness of the testing.

Preparation for Performance Testing

Preparation is crucial when conducting any performance test, especially when dealing with rigorous standards like those seen in Salt Spray Tests. First, ensure that all necessary testing equipment is calibrated and ready for use; this includes spray chambers, salt solutions, and environmental controls to mimic real-world conditions. Additionally, selecting representative samples of your product is key—these should be identical to those intended for end-use to guarantee accurate results during your Application Salt Spray Test.

Next up is creating a thorough testing plan that outlines variables such as duration, temperature, and humidity levels during the Salt Spray Test. This plan should align with established standards governing performance tests to ensure compliance and relevance. Finally, don’t forget about safety protocols; handling corrosive materials requires precautions to protect both personnel and equipment.

Executing the Product Performance Test

Once preparation is complete, it's time to dive into executing the Product Performance Test itself! Begin by placing your samples in the designated chamber following strict guidelines established by relevant standards for Salt Spray Testing. The environment must be monitored closely throughout the test duration—typically ranging from 24 hours to several weeks—to ensure consistent conditions.

During execution, keep an eye out for any anomalies or unexpected reactions from your products; these observations can provide valuable insights into their performance under stressors like corrosion or environmental factors. After completing the Salt Spray Test duration as per your plan, carefully remove samples for further assessment while documenting all relevant data meticulously.

Analyzing and Reporting Results

After executing your tests comes perhaps one of the most critical phases: analyzing and reporting results! Start by examining each sample closely for signs of corrosion or degradation—this will help you determine how well they performed during the Application Salt Spray Test compared to expectations outlined in your initial plan. Utilize comparative analysis against control samples if available; this helps contextualize findings within industry benchmarks or previous tests.

Once you have gathered all necessary data from visual inspections and any quantitative measurements taken during testing (like weight loss), compile these findings into a comprehensive report. This report should clearly outline not only results but also implications regarding product durability based on Advantages and Disadvantages of Salt Spray Test outcomes observed throughout testing phases.

In conclusion, following these steps will not only enhance understanding but also underscore the Importance of Product Performance Testing in ensuring quality assurance across industries reliant on durable products!

Conclusion

In wrapping up our discussion on the Salt Spray Test and its relevance in product performance testing, it’s essential to emphasize its critical role in evaluating corrosion resistance. This method serves various industries, providing insights that help manufacturers enhance product durability. Understanding both the advantages and disadvantages of the Salt Spray Test equips businesses to make informed decisions about their testing strategies.

Key Takeaways on Salt Spray Testing

The Salt Spray Test is a standardized method for assessing the corrosion resistance of materials and coatings, simulating harsh environmental conditions. It is widely recognized across industries for its reliability and effectiveness in predicting long-term performance. However, it’s crucial to remember that while this test has many strengths, it also has limitations that should be considered when selecting testing equipment or methodologies.

Summary of Product Performance Testing Benefits

Product performance testing is paramount in ensuring that products meet safety and quality standards before reaching consumers. It not only helps identify potential failures but also enhances customer satisfaction by delivering reliable products. By understanding the importance of product performance tests, including the application of the Salt Spray Test, companies can significantly improve their quality assurance processes.

Final Thoughts on Reliability Testing Importance

Reliability testing is more than just a checkbox; it's a commitment to excellence in manufacturing and design processes. The insights gained from various types of performance testing—including the Salt Spray Test—allow businesses to innovate confidently while minimizing risk. Ultimately, investing in rigorous reliability testing practices leads to better products that stand the test of time and environmental challenges.