Introduction

In the fast-paced world of manufacturing, ensuring product quality is paramount. Quality defects in manufacturing can lead to significant financial losses, tarnished reputations, and even safety hazards. As industries strive for perfection, understanding the nuances of these defects becomes essential for driving excellence in manufacturing quality.

Understanding Manufacturing Defects

Manufacturing defects encompass a wide range of issues that can arise during production processes. These include material defects, processing defects, dimensional defects, surface defects, safety defects, and packaging defects. Each type presents unique challenges that can compromise product integrity and customer satisfaction.

The Importance of Quality Control

Quality control serves as a crucial safeguard against the pitfalls associated with quality defects in manufacturing. By implementing rigorous inspection processes and standards, businesses can identify and rectify issues before products reach consumers. This proactive approach not only enhances product reliability but also fosters trust among customers and stakeholders alike.

The Role of China Inspection Pro

China Inspection Pro plays a pivotal role in addressing quality concerns across various manufacturing sectors. With expertise in identifying material defects and assessing processing efficiencies, this service provider helps companies maintain high standards throughout their supply chains. By leveraging such inspection services, manufacturers can significantly reduce risks related to dimensional defects and ensure compliance with safety regulations tied to packaging defects.

Defining Quality Defects in Manufacturing

In the world of manufacturing, understanding quality defects is crucial for ensuring product reliability and customer satisfaction. Quality defects in manufacturing can arise from various sources, leading to significant challenges for businesses. By identifying and categorizing these defects, manufacturers can implement effective strategies to mitigate risks and enhance overall production quality.

Types of Quality Defects

Quality defects in manufacturing can be broadly categorized into several types: material defects, processing defects, dimensional defects, surface defects, safety defects, and packaging defects. Material defects often stem from the use of substandard raw materials that fail to meet specified requirements. Processing defects occur during the production process due to improper handling or machine malfunctions, while dimensional and surface defects relate to inaccuracies in measurements or finishes that can affect product functionality.

Recognizing these types of quality defects is essential for manufacturers aiming to drive excellence in manufacturing quality. Each defect type presents unique challenges that require tailored approaches for resolution. By systematically addressing these categories of quality issues, companies can significantly reduce their defect rates and improve overall productivity.

The Impact of Defects on Businesses

The impact of quality defects in manufacturing extends far beyond the immediate costs associated with rework or returns; it affects brand reputation and customer trust as well. When products fail to meet quality standards due to material or processing flaws, businesses risk losing customers who may turn to competitors offering more reliable alternatives. Furthermore, safety defects can lead not only to financial losses but also legal repercussions if consumers are harmed by faulty products.

Additionally, dimensional and surface defects may result in increased production costs as manufacturers invest time and resources into correcting issues that could have been prevented through proper quality control measures. Packaging defects also pose significant risks; improper packaging can lead to product damage during transit or miscommunication regarding product specifications on retail shelves. Ultimately, addressing these various types of quality issues is vital for maintaining a competitive edge in today's market.

Case Studies of Manufacturing Failures

Several high-profile case studies highlight the consequences of neglecting quality control in manufacturing processes. One notable example involves a major automotive company that faced massive recalls due to safety-related design flaws—demonstrating how critical it is for manufacturers to prioritize safety defect prevention throughout their operations. Similarly, a tech giant experienced significant backlash when a batch of smartphones was released with severe surface and dimensional flaws that rendered them unusable.

These failures underscore the importance of implementing robust inspection protocols at every stage—from sourcing materials through final assembly—to identify potential issues before they escalate into costly problems down the line. By learning from past mistakes within their industries regarding material and processing deficiencies as well as other forms of quality errors like packaging missteps—manufacturers can adapt their practices accordingly while striving towards continuous improvement initiatives aimed at driving excellence in manufacturing quality.

Material Defects and Their Implications

Material defects can significantly impact the quality of manufactured products, leading to a cascade of issues. These defects often arise from the use of subpar raw materials or improper handling during the manufacturing process. Identifying these common material defects is crucial for manufacturers aiming to drive excellence in manufacturing quality and ensure customer satisfaction.

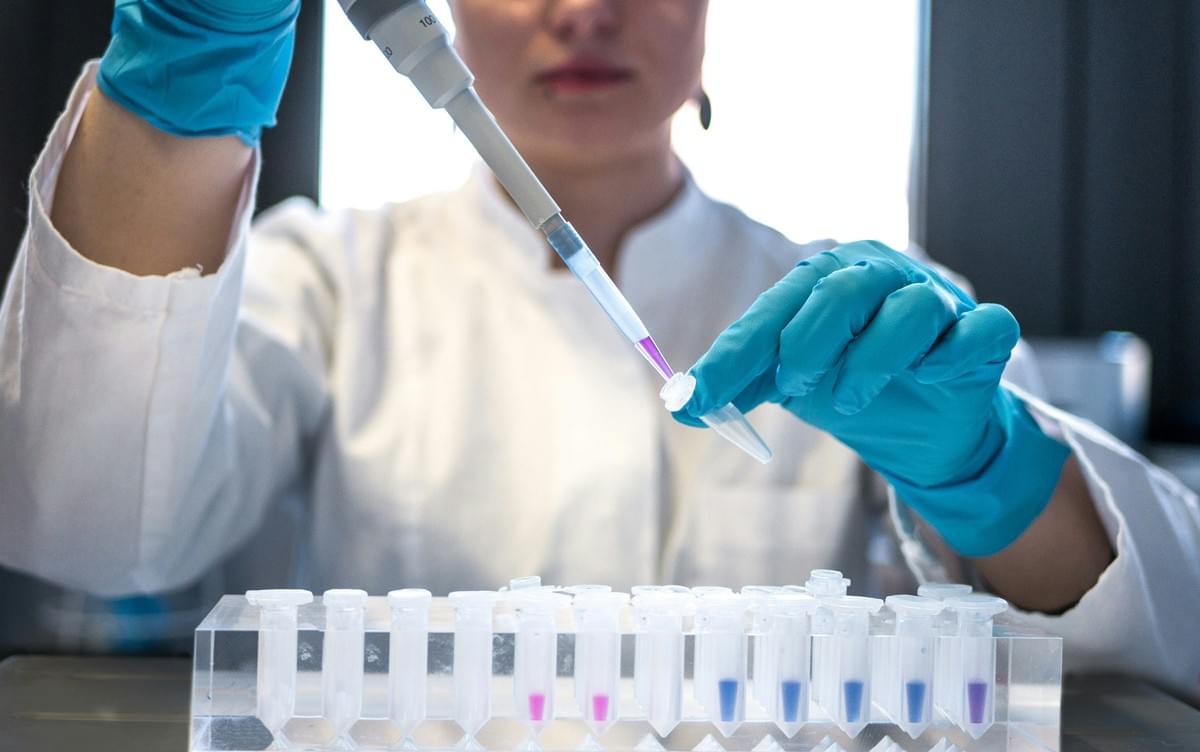

Identifying Common Material Defects

Common material defects include issues such as contamination, inconsistencies in composition, and physical flaws like cracks or voids. Contamination can occur at any stage, whether during production or transportation, affecting the integrity of the final product. By recognizing these quality defects in manufacturing early on, companies can implement corrective actions before they escalate into more significant problems.

Consequences of Low-Quality Materials

The consequences of using low-quality materials extend beyond just immediate product failures; they can lead to safety defects that endanger consumers and tarnish brand reputation. Additionally, businesses may face increased costs due to returns, repairs, or recalls stemming from defective products. In severe cases, companies might even face legal ramifications if safety standards are compromised due to material deficiencies.

Strategies to Mitigate Material Defects

To mitigate material defects effectively, manufacturers should establish stringent supplier evaluation processes and conduct regular audits of incoming materials. Investing in advanced testing technologies can help identify potential flaws before they become problematic in production lines. Furthermore, fostering strong relationships with suppliers ensures a consistent flow of high-quality materials while also allowing for collaborative problem-solving when issues arise.

Processing Defects and Optimization

In the realm of manufacturing, processing defects are a significant concern that can lead to various quality defects in manufacturing. These defects arise during the transformation of raw materials into finished products, often due to errors in machinery, human oversight, or inadequate processes. Understanding these nuances is crucial for manufacturers aiming to enhance product quality and reduce waste.

Understanding Processing Defects

Processing defects can manifest in numerous ways, including dimensional defects and surface defects that compromise the integrity of the final product. Common causes include improper machine calibration, inadequate training for operators, or subpar operational procedures. Identifying these issues early on is essential; otherwise, they can lead to safety defects and increase costs associated with rework or product recalls.

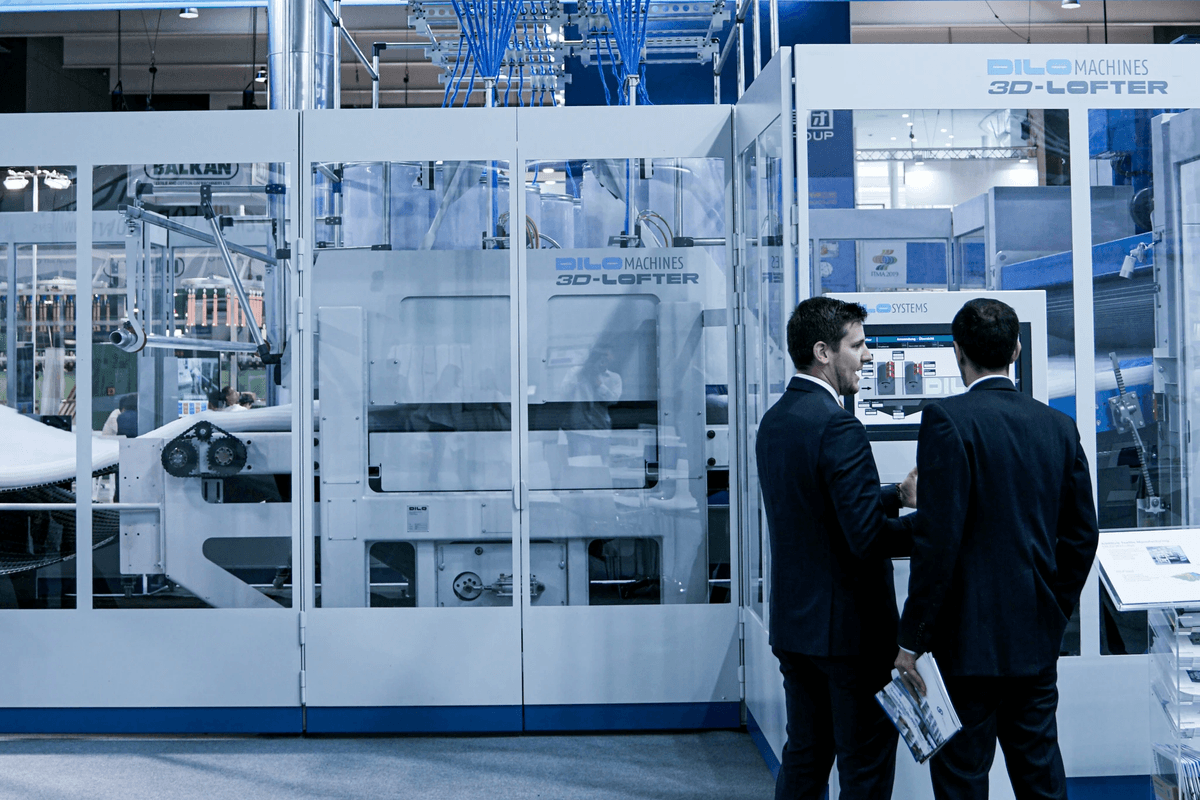

Techniques to Drive Excellence in Manufacturing Quality

To drive excellence in manufacturing quality, companies must implement robust techniques that address processing defects head-on. Techniques such as lean manufacturing principles help streamline processes while minimizing waste and inefficiencies. Additionally, integrating advanced technologies like automation and real-time monitoring systems can significantly reduce the likelihood of both dimensional and surface defects occurring during production.

The Importance of Continuous Improvement

Continuous improvement is not just a buzzword; it's a vital philosophy for any manufacturing operation looking to minimize quality defects in manufacturing over time. This iterative approach encourages organizations to regularly assess their processes for potential enhancements while fostering a culture where employees are empowered to suggest improvements actively. By focusing on ongoing optimization efforts, businesses can effectively mitigate material defects and ensure high standards across all aspects of production.

Dimensional and Surface Defects

In the realm of manufacturing, dimensional and surface defects are critical quality defects that can significantly impact product performance and customer satisfaction. These defects often arise from a variety of factors, including improper tooling, environmental conditions, or inadequate quality control measures during production. Understanding how these issues occur is essential for manufacturers aiming to drive excellence in manufacturing quality.

How Dimensional Defects Occur

Dimensional defects typically arise when products do not meet specified tolerances or measurements, leading to parts that are either too large or too small. Common causes include machine calibration errors, wear and tear on machinery, or even human error during assembly processes. The implications of these dimensional defects can be severe; they can lead to product failures in the field, increased scrap rates, and costly rework.

Moreover, the interplay between material selection and processing techniques can exacerbate dimensional issues. For instance, using low-quality materials may result in warping or shrinkage during cooling processes after molding or machining. Therefore, addressing both material defects and dimensional precision is vital for ensuring overall product integrity.

Addressing Surface Defects in Manufacturing

Surface defects refer to imperfections visible on the exterior of a product that can affect its functionality as well as aesthetic appeal. These might include scratches, dents, discoloration, or rough finishes resulting from inadequate handling during production or poor finishing processes. To combat surface defects effectively, manufacturers must implement rigorous inspection protocols at various stages of production.

One effective strategy involves employing advanced surface treatment technologies such as polishing or coating to enhance durability while minimizing imperfections. Additionally, training staff on proper handling techniques can mitigate risks associated with surface damage during transportation and storage. By focusing on both prevention and remediation strategies for surface defects, businesses can maintain high standards of quality control.

Industry Examples of Dimensional and Surface Issues

Numerous industries have experienced notable failures due to dimensional and surface issues that highlight the importance of stringent quality control measures. For example, in the automotive sector, a prominent manufacturer faced significant recalls when it was discovered that certain parts did not meet specified tolerances—leading to safety concerns among consumers due to potential malfunctions in critical systems like brakes or steering.

Similarly, electronics manufacturers often encounter challenges with surface defects that compromise device aesthetics or functionality; one case involved smartphones where cosmetic blemishes led to consumer dissatisfaction despite high operational performance metrics. These examples underscore how overlooking quality defects in manufacturing—whether they be related to dimensions or surfaces—can lead not only to financial losses but also reputational damage within competitive markets.

Safety and Packaging Defects

In the world of manufacturing, safety and packaging defects can be the proverbial straw that breaks the camel's back. These defects not only jeopardize consumer safety but can also lead to substantial financial losses and damage to a company's reputation. Addressing these issues is crucial for maintaining high standards in quality control and ensuring that products reach consumers in optimal condition.

The Critical Nature of Safety Defects

Safety defects are paramount because they pose direct risks to consumers, often leading to injuries or even fatalities. In industries such as automotive or pharmaceuticals, even minor quality defects in manufacturing can have catastrophic consequences, making rigorous testing and inspection non-negotiable. The public's trust hinges on manufacturers' commitment to eliminating safety defects through stringent quality assurance protocols.

Common Packaging Defects and Solutions

Packaging defects can range from inadequate sealing to labeling errors, each carrying its own set of implications for product integrity and consumer satisfaction. For instance, improper sealing may expose products to contamination, while incorrect labels can mislead consumers about usage instructions or ingredients. Solutions include implementing automated packaging systems that enhance accuracy and conducting regular quality inspections to identify potential packaging flaws before they reach the market.

Regulatory Implications of Safety and Packaging Issues

Regulatory bodies impose strict guidelines on manufacturers regarding safety defects and packaging standards, with non-compliance leading to severe penalties or product recalls. Companies must stay informed about evolving regulations surrounding quality control processes to avoid legal repercussions while ensuring their products meet industry standards for safety and packaging integrity. Adopting proactive measures not only mitigates risk but also fosters a culture of excellence that drives continuous improvement across all facets of manufacturing.

Conclusion

In the world of manufacturing, understanding and addressing quality defects is paramount to ensuring product integrity and customer satisfaction. From Material Defects to Processing Defects, each type poses unique challenges that can ripple through a business's reputation and bottom line. By adopting best practices for defect prevention and leveraging quality inspection services, manufacturers can not only enhance their processes but also secure a competitive edge in the marketplace.

Best Practices for Defect Prevention

To effectively combat quality defects in manufacturing, it’s essential to implement robust best practices that focus on prevention rather than correction. Regular training sessions for employees can help them recognize potential issues related to Dimensional Defects or Surface Defects before they escalate into larger problems. Furthermore, incorporating feedback loops within production lines allows teams to continuously improve processes and drive excellence in manufacturing quality.

Establishing clear standards and guidelines for materials used is crucial in minimizing Material Defects as well. This includes selecting high-quality suppliers who adhere to strict safety protocols and conducting regular audits of incoming materials. Ultimately, a proactive approach toward defect prevention fosters a culture of quality that permeates every level of the organization.

Leveraging Quality Inspection Services

Quality inspection services play an indispensable role in identifying and mitigating various types of defects throughout the manufacturing process. By employing specialized teams who are trained to spot Safety Defects or Packaging Defects early on, businesses can reduce waste and enhance product reliability significantly. These services provide an objective assessment that helps companies stay compliant with industry regulations while maintaining high standards.

Moreover, utilizing technology such as automated inspection systems can streamline the detection of Processing Defects by providing real-time data analysis during production runs. This allows manufacturers to make immediate adjustments before defective products reach consumers, thereby safeguarding brand reputation. Ultimately, investing in comprehensive quality inspection services is an investment in long-term success.

The Future of Quality Control in Manufacturing

Looking ahead, the future of quality control in manufacturing appears promising with advancements in technology paving the way for more efficient defect detection methods. Innovations such as artificial intelligence and machine learning are set to revolutionize how manufacturers identify Material Defects or assess Surface Defects on-the-fly during production cycles. These tools not only enhance precision but also allow for predictive analytics that anticipate potential issues before they arise.

As consumer expectations continue to rise regarding product safety and performance, businesses must adapt by prioritizing rigorous quality control measures across all stages of production—be it addressing Safety Defects or ensuring optimal packaging solutions are employed consistently. The integration of smart technologies alongside traditional practices will be key in driving excellence in manufacturing quality moving forward.