Introduction

In today's fast-paced construction landscape, quality management in construction projects is more crucial than ever. The stakes are high, and the cost of overlooking quality can lead to significant setbacks, both financially and reputationally. By implementing robust quality control in construction projects, stakeholders can ensure that every aspect of a build meets established standards and expectations.

Understanding Quality Management in Construction

Quality management in construction projects encompasses a comprehensive approach to maintaining high standards throughout the entire lifecycle of a project. This involves not only establishing clear guidelines but also integrating industry best practices that promote efficiency and effectiveness. It’s about creating a framework where everyone involved understands their role in achieving excellence, thereby fostering an environment conducive to success.

The Importance of Risk Construction Management

Risk construction management plays a pivotal role in identifying potential pitfalls before they escalate into costly issues. By proactively assessing risks associated with construction quality assurance, project managers can implement strategies that mitigate these risks effectively. Focusing on quality risk management not only safeguards the project but also enhances overall safety for workers and stakeholders alike.

Why Quality Control Matters

Quality control in the construction industry is not just a checkbox on a compliance list; it’s the backbone of any successful project. A dedicated quality control construction company can help maintain rigorous standards that prevent defects and ensure client satisfaction from start to finish. Ultimately, prioritizing quality control translates into better durability, reduced rework costs, and an enhanced reputation within the competitive landscape of construction.

Define Quality Management Standards

Quality management in construction projects is not just a bureaucratic exercise; it’s the backbone of successful project execution. Establishing standards helps ensure that every team member knows what is expected, reducing confusion and enhancing productivity. By clearly defining these standards, we can also better manage risks associated with construction quality assurance.

Establishing Clear Expectations

Clear expectations are fundamental to quality control in construction projects. When everyone on the team understands their roles and responsibilities, it leads to fewer errors and higher efficiency. Setting measurable goals for quality management in construction projects allows for easier tracking of progress and performance, ultimately fostering a culture of accountability.

Integrating Industry Best Practices

Incorporating industry best practices into your quality management framework is essential for staying competitive in the construction industry. These practices provide a roadmap for achieving superior outcomes while minimizing risks associated with construction quality assurance. By benchmarking against leading firms, you can elevate your own processes and ensure that your approach to risk construction management is both effective and innovative.

Utilizing ISO 9001 Framework

The ISO 9001 framework offers a structured approach to quality control in the construction industry that can significantly enhance project outcomes. This internationally recognized standard focuses on process optimization and customer satisfaction, making it invaluable for any quality control construction company aiming to improve its operations. Adopting ISO 9001 not only helps streamline processes but also strengthens your organization's commitment to continuous improvement in managing quality risks.

Implement Robust Quality Control Processes

In the world of construction, quality control is not just a box to check; it's a vital process that ensures projects are completed to the highest standards. Implementing robust quality control processes is essential for effective quality management in construction projects, helping to identify and mitigate risks before they escalate into costly issues. By prioritizing quality control in construction projects, stakeholders can enhance overall project outcomes and build a reputation for excellence.

Regular Inspections and Audits

Regular inspections and audits are fundamental components of any successful quality control strategy in the construction industry. These practices allow teams to assess compliance with established standards, ensuring that every aspect of the project aligns with the defined quality management goals. Moreover, consistent oversight helps identify potential construction risks early on, allowing for timely interventions that safeguard project integrity.

Conducting thorough inspections not only enhances construction quality assurance but also fosters accountability among team members. By integrating periodic audits into your workflow, you create an environment where everyone is encouraged to uphold high standards of work. This proactive approach ultimately minimizes defects and reinforces a culture centered around risk construction management.

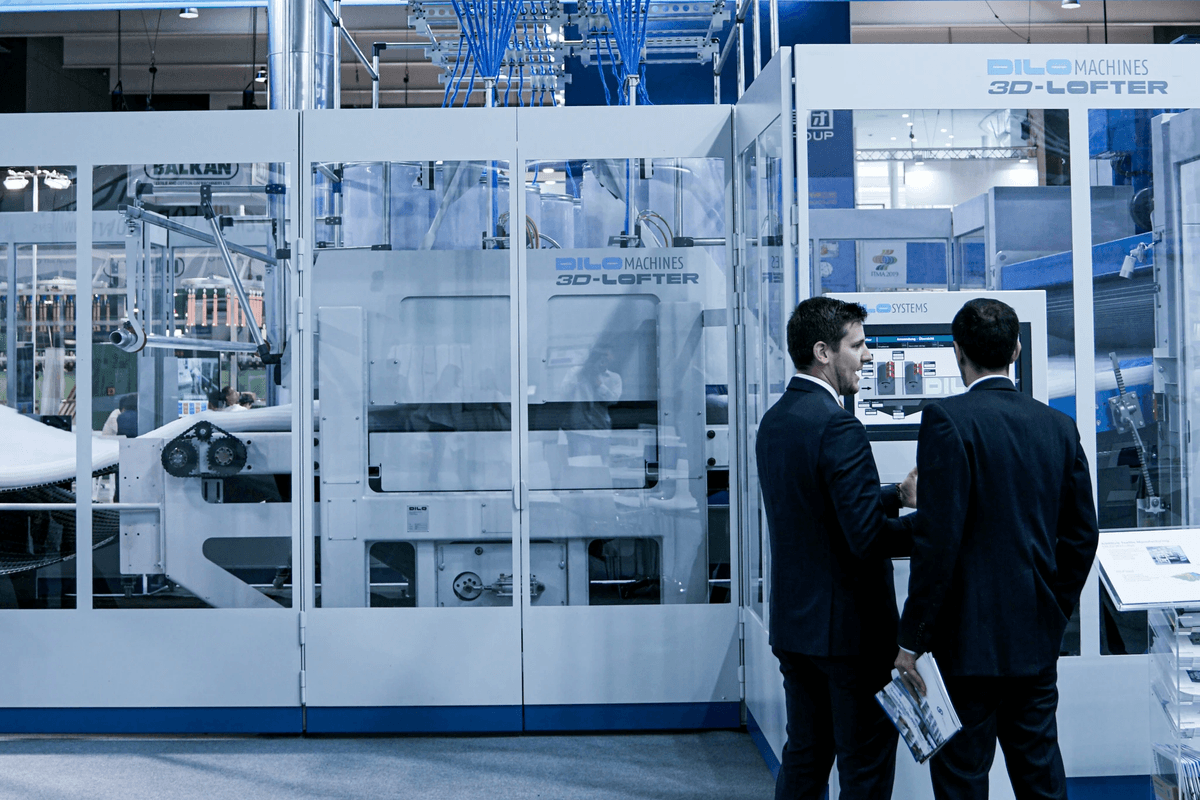

Role of a Quality Control Construction Company

A specialized quality control construction company plays an integral role in maintaining high-quality standards throughout the project lifecycle. These companies possess expertise in implementing best practices tailored to specific needs within the construction sector, ensuring that all aspects of risk management are effectively addressed. Their involvement helps streamline processes and enhances overall efficiency by focusing on both compliance and continuous improvement.

By collaborating with a dedicated quality control partner, organizations can leverage their experience in navigating complex regulations while minimizing potential pitfalls associated with poor-quality outputs. This partnership not only elevates the standard of work but also empowers teams to concentrate on their core competencies while trusting that their project's quality management needs are being met professionally. In essence, these companies serve as invaluable allies in achieving successful outcomes through meticulous oversight.

Staying Compliant with Regulations

Compliance with regulations is non-negotiable when it comes to effective quality risk management within the construction industry. Adhering to local building codes and safety standards ensures that projects meet legal requirements while safeguarding workers' health and safety on-site. Additionally, staying compliant bolsters an organization's reputation as a responsible entity committed to delivering top-notch results.

Regularly updating knowledge about changing regulations is crucial for all stakeholders involved in construction projects; this vigilance prevents potentially costly violations down the line. Integrating compliance checks into routine operations promotes a culture focused on excellence while reducing risks associated with non-compliance—an essential aspect of comprehensive risk construction management strategies. Ultimately, prioritizing regulatory adherence solidifies trust among clients and partners alike.

Train Your Team Effectively

Training your team is a cornerstone of effective quality management in construction projects. A well-trained workforce not only enhances the quality control in construction projects but also fosters an environment where everyone understands the importance of risk construction management. Emphasizing a culture of quality ensures that every team member is aligned with the project's goals, leading to better outcomes and fewer errors.

Fostering a Quality-First Culture

Creating a quality-first culture starts at the top and trickles down through every layer of the organization. When leadership prioritizes quality control in the construction industry, it sets an example for all employees to follow, reinforcing that quality management is everyone's responsibility. This cultural shift encourages open communication about potential issues, enabling proactive measures that minimize risks associated with construction.

Importance of Continuous Education

In an ever-evolving field like construction, continuous education is vital for maintaining high standards in quality control and risk management. Regular training sessions keep your team updated on industry best practices and emerging technologies that can enhance construction quality assurance efforts. Investing in ongoing education not only improves individual skill sets but also strengthens your overall approach to managing quality risks in construction projects.

Utilizing Training from Experts like China Inspection Pro

Partnering with specialized training providers like China Inspection Pro can significantly elevate your team's capabilities in managing quality control effectively. These experts offer tailored programs focused on specific aspects of quality management in construction projects, ensuring your team gains practical insights into industry standards and regulations. By leveraging such expertise, you can enhance your team's proficiency in navigating complex challenges related to risk management and improve overall project outcomes.

Leverage Technology for Quality Assurance

In today's fast-paced construction environment, leveraging technology is essential for effective quality management in construction projects. Digital tools not only enhance monitoring processes but also ensure that quality control in construction projects is maintained at the highest standards. By integrating these innovative solutions, construction teams can significantly improve their risk construction management strategies and overall project outcomes.

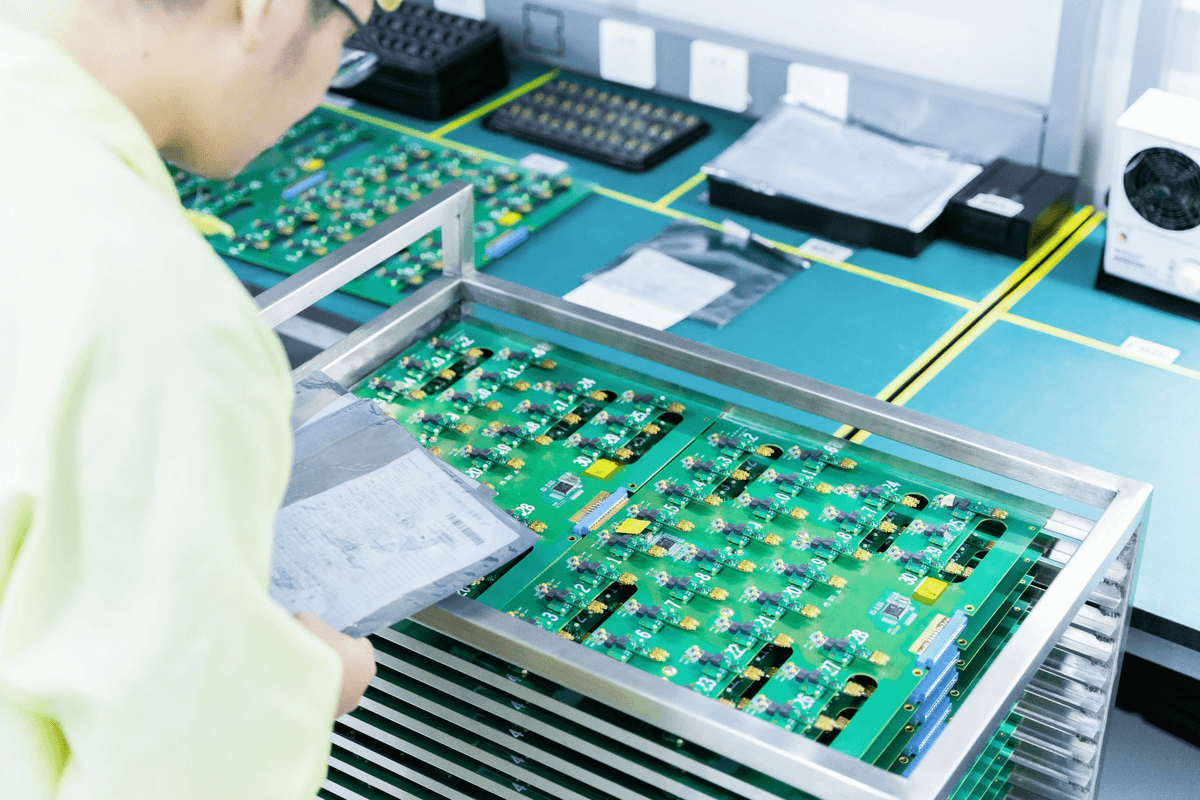

Digital Tools for Monitoring Quality

Digital tools have revolutionized how quality control in the construction industry is approached. From real-time data collection to advanced analytics, these technologies provide invaluable insights into project performance and compliance with established quality standards. Utilizing software solutions designed specifically for quality risk management allows teams to identify issues early, ensuring that corrective actions can be taken before they escalate into costly problems.

Moreover, mobile applications enable on-site teams to document inspections and track progress instantly, enhancing communication between all stakeholders involved in a project. This level of transparency not only fosters accountability but also reinforces a culture of quality assurance across the board. In an era where every detail counts, digital tools are indispensable allies in achieving excellence in construction quality assurance.

Benefits of Building Information Modeling

Building Information Modeling (BIM) is one of the most significant advancements in the realm of construction technology, offering numerous benefits for quality management in construction projects. BIM facilitates a collaborative approach by allowing all parties—architects, engineers, and contractors—to work from a single digital model that captures every aspect of the project lifecycle. This integration leads to improved accuracy and efficiency while minimizing errors related to design or execution.

Additionally, BIM enhances risk construction management by enabling teams to simulate various scenarios before actual implementation takes place. By visualizing potential challenges and conflicts early on, companies can devise effective mitigation plans that align with their quality control strategies. Ultimately, embracing BIM not only elevates the overall standard of work but also sets a benchmark for future projects within the industry.

Streamlining Communication

Effective communication is paramount when it comes to maintaining high-quality standards throughout any construction project. Leveraging technology allows teams to streamline communication channels among all stakeholders involved—from project managers to subcontractors—ensuring everyone stays informed about updates or changes related to quality control in construction projects. This coordinated effort minimizes misunderstandings and keeps everyone aligned with established goals.

With cloud-based platforms and collaborative tools at their disposal, teams can share documents instantly and provide feedback without delay; this agility is crucial when addressing concerns about potential risks or compliance issues during the build phase. Furthermore, regular updates through these platforms foster an environment where continuous improvement thrives as lessons learned from past experiences are easily accessible for future reference. In summary, effective communication powered by technology plays a vital role in achieving successful outcomes within the realm of construction risk management.

Conduct Regular Risk Assessments

In the world of construction, risk is as common as hard hats and safety vests. Conducting regular risk assessments is crucial for effective quality management in construction projects, ensuring that potential pitfalls are identified before they turn into costly problems. By embracing a proactive approach to risk construction management, teams can enhance the quality control in construction projects and safeguard project integrity.

Identifying Potential Construction Risks

Identifying potential construction risks is the first step in a comprehensive quality risk management strategy. These risks can range from environmental factors and site conditions to labor shortages and supply chain disruptions. A thorough assessment involves analyzing past projects, consulting with experienced professionals, and leveraging data analytics to pinpoint vulnerabilities that could affect quality control in the construction industry.

Strategies for Quality Risk Management

Once potential risks are identified, it’s time to implement strategies for effective quality risk management. This includes developing a robust framework that prioritizes communication among stakeholders, ensuring everyone is aware of potential issues and their implications on project timelines and budgets. Additionally, employing a dedicated quality control construction company can provide specialized expertise to navigate these challenges while maintaining high standards of construction quality assurance.

Developing Mitigation Plans

Developing mitigation plans is essential for addressing identified risks head-on before they escalate into significant issues affecting overall project success. These plans should outline specific actions to minimize the impact of each risk, such as alternative sourcing strategies or enhanced training programs for staff on safety protocols and best practices in quality control in construction projects. With well-crafted mitigation strategies in place, teams can move forward confidently, knowing they have a solid plan to maintain high-quality outcomes despite the uncertainties inherent in any construction endeavor.

Conclusion

In the ever-evolving landscape of construction, effective quality management in construction projects is not just a luxury—it's a necessity. The integration of risk construction management practices ensures that potential pitfalls are identified early, allowing teams to focus on delivering superior outcomes. Quality control in construction projects should be viewed as an ongoing commitment rather than a one-time checklist, paving the way for excellence within the industry.

Best Practices for Quality Control in Construction

Establishing best practices for quality control in the construction industry involves a multifaceted approach that prioritizes consistency and compliance. Regular training sessions, rigorous inspections, and adherence to established standards are crucial components that can significantly enhance overall project quality. By collaborating with a reputable quality control construction company, firms can leverage expertise and resources that streamline processes while ensuring high-quality results.

Emphasizing Quality Assurance in Projects

Quality assurance must be woven into every aspect of project planning and execution to truly make an impact on outcomes. This means not only setting clear expectations but also fostering an organizational culture where every team member understands their role in achieving quality objectives. With heightened emphasis on construction quality assurance, stakeholders can rest assured that their investments are safeguarded against risks associated with subpar performance.

The Path Forward in Construction Quality Management

Looking ahead, the path forward in quality management in construction projects will be defined by innovation and adaptability to emerging challenges. As technology continues to reshape the industry landscape, integrating digital tools into risk construction management will become increasingly vital for proactive decision-making. By focusing on continuous improvement through robust quality risk management strategies, companies can position themselves at the forefront of excellence within the competitive realm of construction.