Introduction

In today's fast-paced manufacturing landscape, understanding the essentials of quality control is paramount for ensuring product excellence. Quality management hinges on various types of inspections in quality control, each serving a unique purpose to uphold standards and meet consumer expectations. As industries evolve, the role of quality assurance specialists becomes increasingly vital in navigating these complexities and implementing effective inspection services.

Understanding Quality Control Essentials

Quality control is not just a buzzword; it’s a systematic approach that ensures products meet specified requirements and standards. At its core, quality assurance encompasses all activities aimed at maintaining and improving product integrity throughout the production process. By grasping the fundamentals of quality management, organizations can better leverage different types of inspection to elevate their offerings.

The Importance of Inspection Types

Inspection types in quality control are crucial for identifying defects early in the production cycle, ultimately saving time and resources. Each type serves a distinct function—ranging from visual inspections to more technical measurement methods—ensuring that every aspect of a product is scrutinized for compliance with quality standards. Understanding these inspection types allows companies to tailor their quality assurance strategies effectively.

How Inspections Impact Product Quality

The impact of inspections on product quality cannot be overstated; they serve as the gatekeepers between subpar output and customer satisfaction. Consistent application of rigorous inspection services leads to higher-quality products that foster brand loyalty and reduce returns or recalls. By prioritizing thorough inspections within their quality management processes, organizations can cultivate a reputation for excellence that resonates with consumers.

Overview of Quality Control

Quality control is the backbone of any successful manufacturing process, ensuring that products meet established standards and customer expectations. It encompasses a variety of practices and methodologies aimed at maintaining high levels of quality and assurance throughout production. Understanding the types of inspection in quality control is essential for identifying defects early and ensuring that the final product aligns with quality management goals.

Definition and Key Concepts

At its core, quality control refers to the systematic processes used to monitor and evaluate product quality throughout its lifecycle. This includes everything from raw material inspection to final product testing, ensuring that each stage adheres to predetermined specifications. Key concepts in this realm include defect prevention, continuous improvement, and adherence to industry standards—each playing a vital role in effective quality management.

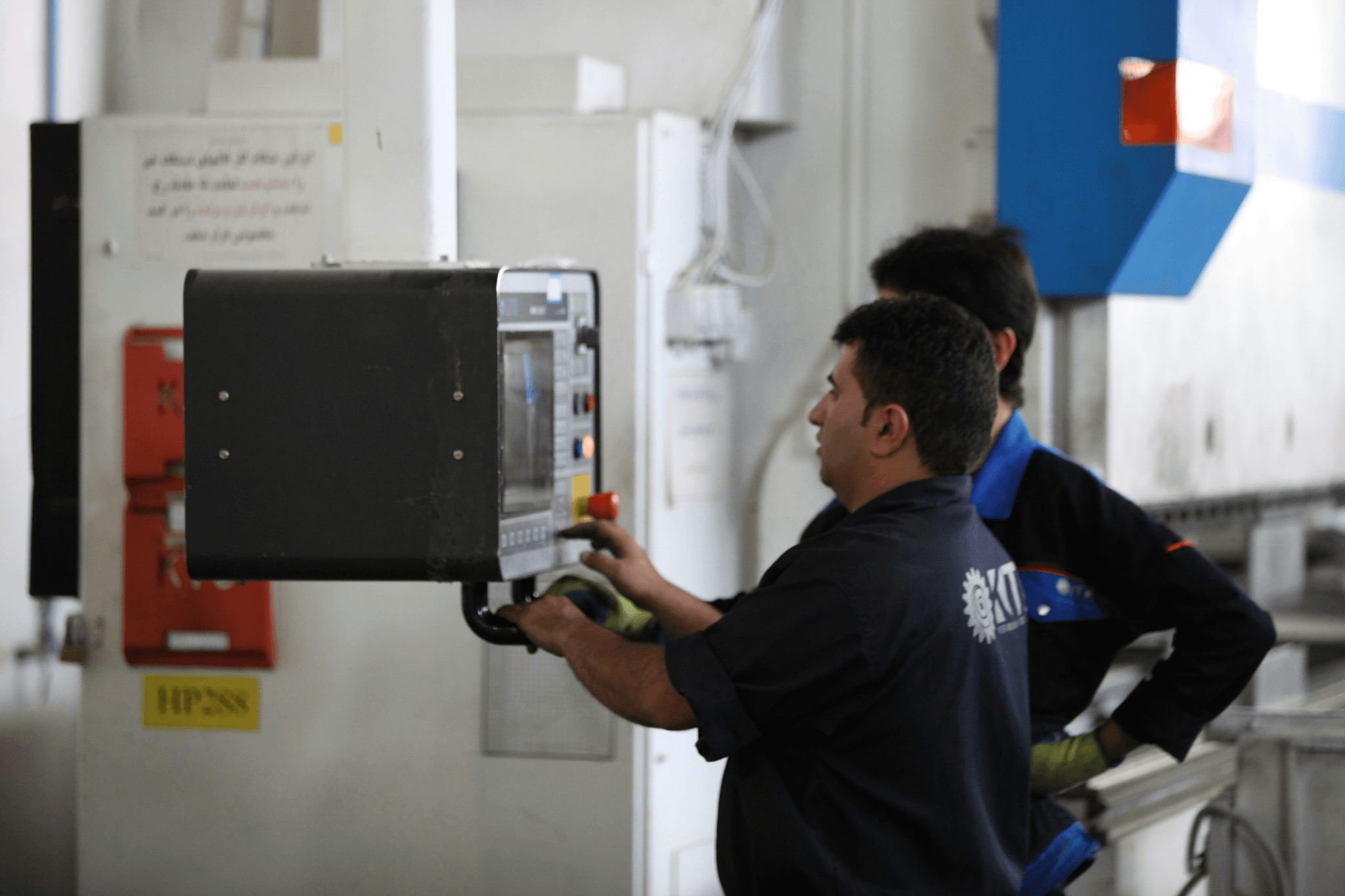

Role of Quality Assurance Specialists

Quality assurance specialists are the unsung heroes behind successful quality control systems; they are responsible for implementing strategies that uphold product integrity. These professionals analyze processes, develop testing protocols, and ensure compliance with regulations while fostering a culture of quality within organizations. Their expertise not only enhances the overall efficiency of inspection services but also helps in training staff on best practices related to quality assurance.

Importance of Quality Management

Quality management is crucial for any organization aiming for long-term success; it involves planning, controlling, and improving all aspects related to product quality. By integrating various types of inspection in quality control into their operations, companies can minimize waste, reduce costs, and enhance customer satisfaction through consistent delivery of high-quality products. Ultimately, effective quality management leads to increased competitiveness in the market while reinforcing a brand's reputation for excellence.

Visual Inspection Techniques

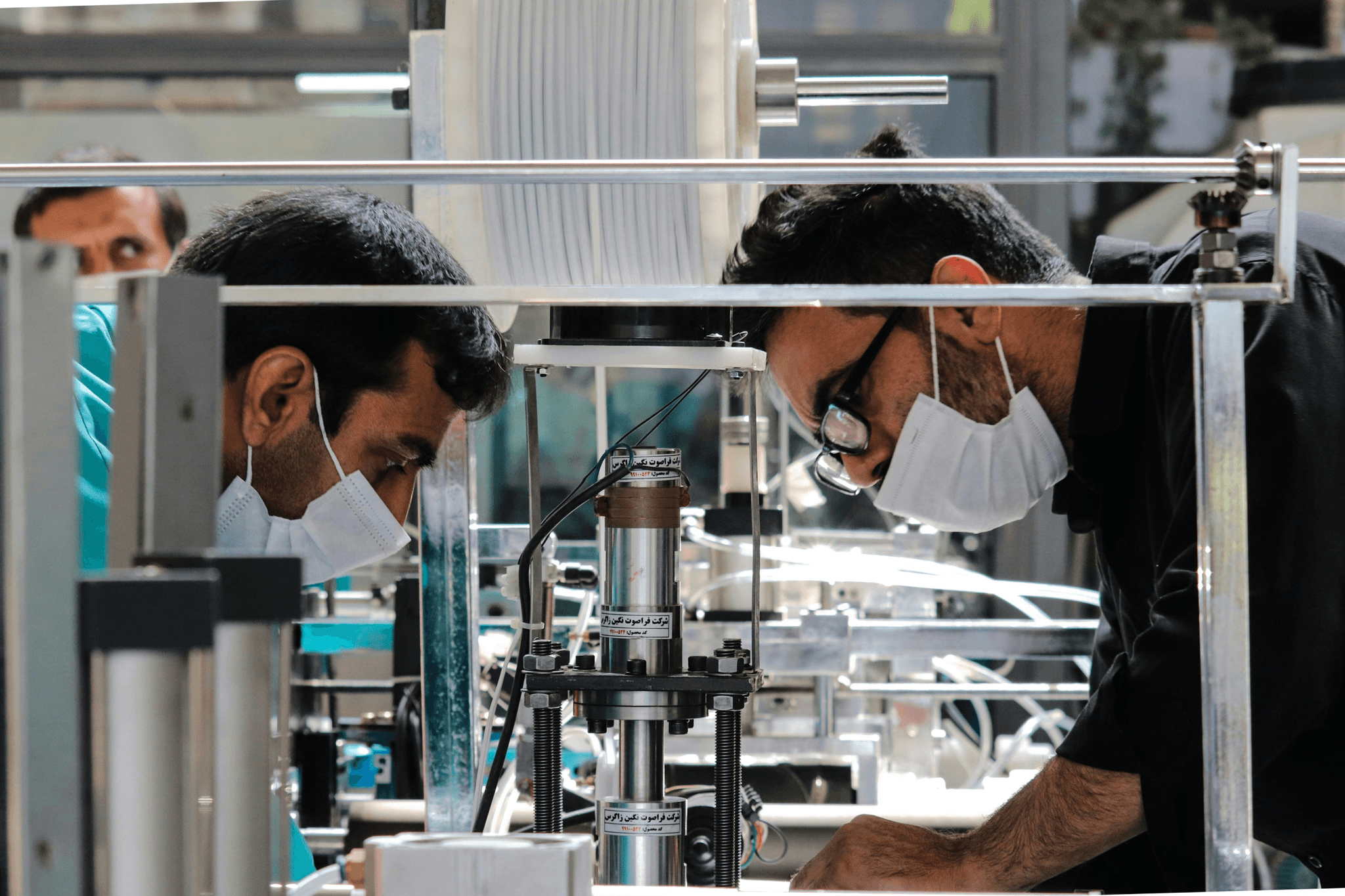

Visual inspection is a cornerstone of quality control, serving as one of the most fundamental types of inspection in quality management. This technique involves examining products or components with the naked eye or using magnification tools to identify defects, inconsistencies, or non-conformance to standards. The process is essential for ensuring that products meet quality assurance requirements before they reach consumers.

Purpose and Processes of Visual Inspection

The primary purpose of visual inspection is to detect visible defects that could compromise the quality and assurance of a product. It typically involves trained quality assurance specialists who follow established protocols to systematically assess items based on predefined criteria. The processes may include checking for surface imperfections, verifying dimensions, and ensuring compliance with specifications—all crucial for maintaining high-quality standards in production.

Incorporating visual inspections into the manufacturing process enhances overall efficiency by catching issues early on, which can save both time and resources down the line. Additionally, this type of inspection in quality control can be performed at various stages of production—from raw materials to finished goods—ensuring consistent oversight throughout the manufacturing lifecycle.

Benefits of Visual Quality Inspection

One significant benefit of visual quality inspection is its cost-effectiveness; it requires minimal equipment compared to more complex testing methods while still providing reliable results. Furthermore, this type of inspection allows for immediate feedback during production processes, enabling manufacturers to address issues promptly rather than after extensive testing has been completed. As a result, visual inspections contribute significantly to reducing waste and rework costs associated with defective products.

Moreover, visual inspections foster a culture of accountability among workers since they are directly involved in monitoring product quality during their tasks. This engagement not only boosts morale but also encourages adherence to best practices in quality management across teams. Ultimately, effective visual inspections lead to higher customer satisfaction due to improved product reliability and performance.

Real-World Applications in Manufacturing

Visual inspection techniques are widely used across various industries including automotive, electronics, food processing, and pharmaceuticals—each relying on these checks as part of their quality control systems. For instance, in automotive manufacturing, inspectors examine components such as body panels or mechanical parts for surface defects that could affect performance or aesthetics before assembly lines proceed further.

In electronics manufacturing, visual inspections play a critical role in identifying soldering defects on circuit boards—a vital step that ensures functionality and safety before products hit the market. By implementing thorough visual inspections within these sectors, companies can maintain rigorous standards that align with industry regulations while enhancing their overall reputation for producing high-quality goods.

Measurement and Testing Inspections

Measurement and testing inspections play a crucial role in quality control, ensuring that products meet specified standards before they reach consumers. These types of inspection in quality control involve a variety of tools and techniques designed to assess the physical characteristics of products, from dimensions to material properties. The accuracy and reliability of these methods are essential for effective quality assurance, as they directly influence product performance and customer satisfaction.

Tools and Methods Used in Measurement

In the realm of measurement inspections, various tools are employed to maintain high standards within quality management processes. Calipers, micrometers, gauges, and laser measurement systems are just a few examples of instruments used by quality assurance specialists to obtain precise measurements. Additionally, advanced technologies like 3D scanning and coordinate measuring machines (CMM) are revolutionizing how we conduct quality inspections by providing detailed data that enhances overall accuracy.

These tools not only help identify deviations from specifications but also streamline the inspection process itself. By utilizing automated systems alongside traditional measurement methods, organizations can significantly reduce human error while increasing throughput during inspections. Ultimately, choosing the right combination of tools is vital for effective quality control across diverse industries.

Ensuring Accuracy Through Testing

Ensuring accuracy through rigorous testing is paramount in maintaining product integrity within any quality assurance framework. Various testing methods—such as tensile tests for strength evaluation or hardness tests—are employed to verify that materials meet required specifications before they enter production lines. By implementing systematic testing protocols throughout the manufacturing process, companies can catch defects early on and prevent costly rework or recalls down the line.

Moreover, statistical process control (SPC) techniques play an integral role in monitoring ongoing production quality through real-time data analysis. This proactive approach not only helps maintain consistency but also fosters continuous improvement within organizations’ quality management practices. As a result, businesses can build stronger reputations based on their commitment to delivering high-quality products consistently.

Case Studies in Effective Measurement

Examining case studies provides valuable insights into effective measurement practices that enhance overall product quality through diligent inspection services. For instance, a leading automotive manufacturer implemented advanced laser scanning technology during their assembly line inspections to ensure precise fitment of components—a critical aspect of vehicle safety and performance. As a result, they reported a significant reduction in warranty claims related to assembly issues due to enhanced measurement accuracy.

Another notable example involves an electronics company that utilized automated optical inspection (AOI) systems during PCB manufacturing processes to detect defects at an early stage effectively. This proactive measure allowed them to minimize waste while improving yield rates significantly—demonstrating how integrating modern technologies into traditional inspection approaches can yield impressive results within any type of inspection in quality control framework.

In summary, adopting robust measurement tools coupled with effective testing protocols is essential for achieving excellence in product development and manufacturing processes alike—ultimately leading towards better customer satisfaction through superior-quality offerings.

Destructive vs. Non-Destructive Testing

When it comes to ensuring product quality, understanding the types of inspection in quality control is crucial. Destructive testing involves evaluating a material's properties by subjecting it to conditions that ultimately lead to its failure, while non-destructive testing (NDT) allows for assessment without damaging the item being tested. Both methods are integral to quality assurance, each serving distinct purposes depending on the context and requirements of quality management.

Understanding Both Testing Types

Destructive testing provides valuable insights into a material's strength and durability, making it essential for applications where failure analysis is critical. Common methods include tensile tests, impact tests, and fatigue tests that reveal how materials behave under stress until they break or deform irreversibly. Conversely, non-destructive testing employs techniques such as ultrasonic, radiographic, and magnetic particle inspections to assess materials without compromising their integrity—ideal for ongoing quality inspection in production environments.

When to Use Each Method

Choosing between destructive and non-destructive testing hinges on several factors including the stage of production, cost considerations, and safety requirements. For instance, destructive methods may be employed during initial prototype development where understanding material limits is vital; however, once products move into mass production, non-destructive techniques become indispensable for continuous quality assurance. Ultimately, effective quality management necessitates a balanced approach that leverages both types of inspections at appropriate stages throughout the product lifecycle.

Industry Examples of Testing Applications

In aerospace engineering, destructive testing is often used to evaluate components like turbine blades under extreme conditions before they are approved for flight—ensuring safety through rigorous analysis. Meanwhile, in manufacturing sectors such as automotive or construction materials where reliability is paramount but costs must be managed carefully, non-destructive methods like ultrasonic testing play a pivotal role in routine quality inspections without incurring additional losses from damaged products. These industry-specific applications highlight how different types of inspection in quality control can significantly impact overall product performance and customer satisfaction.

Role of Inspection Services in Quality Assurance

In the realm of quality management, inspection services play a pivotal role in ensuring that products meet established standards and specifications. These services offer a systematic approach to quality assurance, identifying potential defects before they reach the consumer. By integrating various types of inspection in quality control, organizations can significantly enhance their overall product quality and customer satisfaction.

How Inspection Services Enhance Quality

Inspection services are essential in maintaining high standards of quality and assurance throughout the production process. By employing various types of inspection methods, these services can detect flaws or inconsistencies that may compromise product integrity. This proactive approach not only helps prevent costly recalls but also fosters trust between manufacturers and consumers by ensuring that only high-quality products reach the market.

Moreover, quality inspection conducted by trained professionals allows for a thorough evaluation of each product's performance against industry benchmarks. This meticulous attention to detail ensures compliance with regulatory requirements while also identifying areas for improvement within the manufacturing process itself. Ultimately, effective inspection services contribute to a culture of continuous improvement within organizations, reinforcing their commitment to quality management.

Choosing the Right Inspection Partner

Selecting an appropriate inspection partner is crucial for businesses aiming to uphold rigorous quality control standards. Companies should consider factors such as expertise in specific types of inspection in quality control, industry experience, and technological capabilities when evaluating potential partners. The right choice can lead to improved efficiency and effectiveness in achieving desired outcomes while minimizing risks associated with product defects.

Furthermore, it’s important for organizations to establish clear communication channels with their chosen inspection services provider. This collaboration enables both parties to align on expectations regarding quality assurance processes and reporting mechanisms. A strong partnership not only enhances overall product reliability but also empowers companies to adapt swiftly to changing market demands or regulatory requirements.

Spotlight on China Inspection Pro

China Inspection Pro stands out as a leading provider of comprehensive inspection services tailored for diverse sectors such as manufacturing and logistics. Their expertise encompasses various types of inspections in quality control—including visual inspections, measurement testing, and both destructive and non-destructive testing methods—ensuring robust oversight throughout production cycles. With a commitment to delivering unparalleled service, they help businesses navigate complex supply chains while maintaining stringent standards for quality management.

The team at China Inspection Pro consists of highly skilled quality assurance specialists who leverage cutting-edge technology alongside traditional methodologies to ensure accuracy and reliability in inspections. Their focus on fostering strong relationships with clients allows them to provide customized solutions that cater specifically to individual business needs while enhancing overall operational efficiency. Through their dedicated efforts, China Inspection Pro exemplifies how effective inspection services can elevate product integrity across industries.

Conclusion

In wrapping up our exploration of quality control and the various types of inspection, it's clear that these processes are pivotal in ensuring product quality and operational efficiency. Quality assurance is not just a checklist; it’s a culture that organizations must embrace to thrive in competitive markets. By understanding the nuances of different inspection types in quality control, businesses can better safeguard their reputation and customer satisfaction.

Key Takeaways About Inspection Types

One of the most important takeaways is recognizing that each type of inspection in quality control serves a unique purpose tailored to specific needs. Whether it’s visual inspections, measurement tests, or destructive versus non-destructive testing, each method contributes significantly to overall quality management. Quality assurance specialists play a critical role in this landscape, guiding organizations through the maze of inspections to ensure compliance with industry standards.

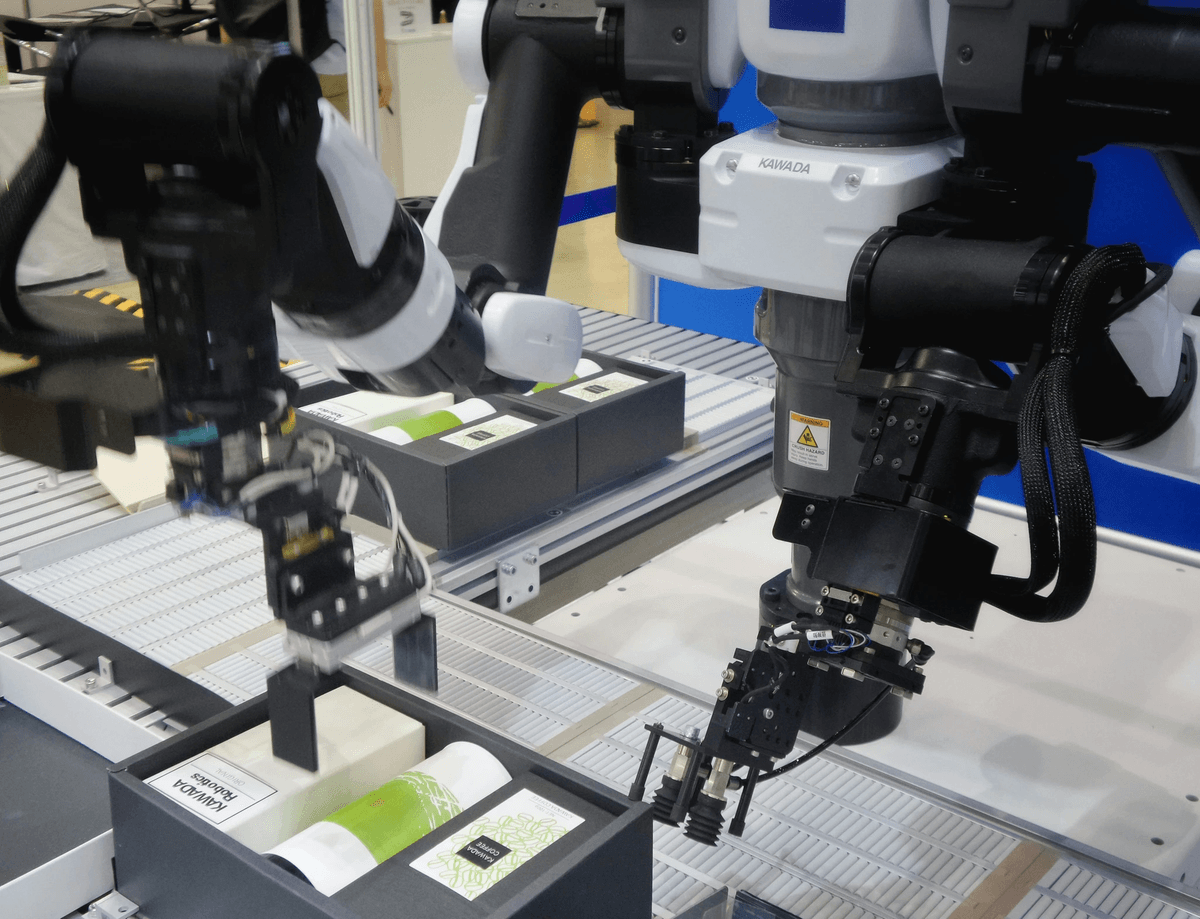

Future Trends in Quality Control

As we look ahead, technological advancements are set to revolutionize the field of quality control and inspection services. Automation and artificial intelligence are expected to enhance accuracy and efficiency in various types of inspections, making them more reliable than ever before. Additionally, as industries evolve, so too will the expectations surrounding quality assurance; companies will need to adapt quickly to maintain high standards.

Encouraging a Culture of Quality Assurance

Fostering a culture centered around quality assurance is essential for any organization aiming for long-term success. This means not only investing in training for employees but also encouraging open communication about quality issues as they arise. By embedding this mindset into every level of operation, companies can ensure that every type of inspection in quality control becomes an integral part of their workflow rather than an afterthought.