Introduction

In the world of industrial machinery, the phrase machine inspection should be at the forefront of every operator's mind. Understanding machine inspection importance is not just a matter of routine; it’s a critical component that ensures safety, efficiency, and longevity of equipment. Regular evaluations can significantly reduce downtime and unexpected failures, making it essential for any business reliant on machinery.

Understanding Machine Inspection Importance

What is a machine inspection? At its core, it's a systematic examination aimed at identifying potential issues before they escalate into costly repairs or accidents. The importance of machine inspections cannot be overstated; they serve as both preventative measures and compliance checks that uphold safety standards in various industries.

Key Benefits of Regular Machinery Evaluations

Regular machinery evaluations provide numerous benefits that extend beyond mere compliance. They help in maintaining operational efficiency by ensuring machines run at optimal performance levels, thus saving costs associated with energy waste and inefficiency. Moreover, these inspections foster a culture of safety within the workplace, reducing the likelihood of accidents caused by faulty equipment.

Overview of Inspection Types

When diving into the realm of machine inspections, you may wonder: what are the 4 types of inspection? Each type serves unique purposes ranging from visual checks to more complex non-destructive testing techniques designed to assess structural integrity without causing damage. Additionally, understanding what are the three main types of inspections—routine, detailed, and audits—can further clarify how different approaches contribute to overall machinery health and operational success.

What is a Machine Inspection?

Definition and Purpose

So, what is a machine inspection? At its core, a machine inspection is a systematic examination of machinery to assess its condition and performance. The purpose of this inspection goes beyond mere compliance; it's about safeguarding workers, enhancing productivity, and prolonging the life of the equipment.

Key Components of an Inspection

When conducting a machine inspection, several key components come into play. First off, visual assessments are performed to spot any obvious signs of wear or damage. Then there are functional tests to evaluate how well the machinery operates under normal conditions. Lastly, documentation plays an essential role in tracking findings over time and ensuring that all inspections are recorded for future reference.

Importance for Safety and Efficiency

Regular evaluations help prevent accidents caused by malfunctioning equipment while also optimizing operational efficiency by ensuring machines run at peak performance levels. Ultimately, investing in routine inspections not only protects employees but also enhances the bottom line by minimizing downtime and repair costs.

What Are the 4 Types of Inspection?

Each type serves a distinct purpose and plays a significant role in ensuring machinery operates smoothly without unexpected failures. Let's delve into the four primary types of inspection that every industry professional should be familiar with.

Visual Inspection Explained

Visual inspection is often the first line of defense in machine inspection. This method involves a thorough examination of machinery components, looking for any signs of wear, damage, or misalignment that may not be immediately apparent during regular operations. While it may seem simple, this type of inspection can reveal critical issues before they escalate into costly repairs or safety hazards.

During a visual inspection, inspectors check for leaks, corrosion, cracks, and other physical anomalies that could compromise machine integrity. It's essential to have trained professionals conduct these inspections to ensure nothing is overlooked; after all, what is a machine inspection without keen eyes scrutinizing every detail? Regular visual inspections not only enhance safety but also contribute to extending equipment lifespan.

Functional Testing and Its Relevance

Functional testing takes machine inspection a step further by assessing whether equipment performs its intended functions correctly. This process involves running machines under normal operating conditions to verify their efficiency and effectiveness. If any discrepancies arise during functional testing, they can indicate underlying issues that require immediate attention.

This type of testing is particularly relevant in industries where precision is paramount; think aerospace or medical devices where even minor malfunctions can lead to severe consequences. By integrating functional testing into regular maintenance schedules, organizations can proactively address potential problems before they disrupt operations—essentially preventing what are often costly breakdowns down the line.

Non-Destructive Testing Techniques

Non-destructive testing (NDT) techniques are advanced methods used in machine inspections that allow for thorough evaluation without causing damage to the equipment being tested. These techniques include ultrasonic testing, magnetic particle testing, and radiographic testing—each designed to identify internal flaws or inconsistencies without compromising structural integrity. NDT plays an invaluable role in ensuring safety standards are met while minimizing downtime associated with traditional destructive methods.

Understanding non-destructive testing is vital when considering what are the 4 types of inspection available today; it's like having X-ray vision for your machines! By detecting hidden defects early on through NDT techniques, companies can save on repair costs and avoid catastrophic failures that could halt production entirely.

Maintenance Inspections and Their Impact

Maintenance inspections encompass both scheduled and unscheduled checks aimed at keeping machinery running efficiently over time—think of them as routine health check-ups for your equipment! These inspections evaluate overall condition while addressing any wear-and-tear issues before they escalate into more significant problems requiring extensive repairs or replacements.

The impact of consistent maintenance inspections cannot be overstated; they enhance operational reliability while reducing unexpected downtimes significantly—a win-win situation! By prioritizing maintenance within their overall strategy regarding what are the three main types of inspections performed regularly across industries today will lead businesses toward greater productivity levels long-term.

What Are the Three Main Types of Inspections?

When diving into the world of machine inspection, it's crucial to understand that not all inspections are created equal. There are three main types of inspections that serve distinct purposes and cater to different aspects of machinery evaluation. These types include routine inspections, detailed inspections, and audits or compliance inspections—each playing a vital role in ensuring machinery operates safely and efficiently.

Routine Inspections Essentials

Routine inspections are the bread and butter of machine inspection practices. Conducted regularly, these inspections focus on identifying any early signs of wear or malfunction before they escalate into major issues. By implementing routine machine inspection protocols, businesses can enhance safety measures, minimize downtime, and improve overall efficiency in their operations.

During a routine inspection, a machine inspector typically checks for obvious signs of wear and tear such as leaks, unusual noises, or misalignments. These checks may be scheduled daily or weekly depending on the machinery's usage intensity. Regularly performed routine inspections not only prolong the lifespan of equipment but also ensure compliance with safety regulations.

Detailed Inspections Defined

Detailed inspections take a deeper dive into the intricacies of machinery performance compared to their routine counterparts. This type involves a thorough examination that often includes disassembling parts for an in-depth look at components that might not be visible during standard checks. A detailed machine inspection is essential when there is suspicion of significant issues or after major repairs have been completed.

Machine inspectors conducting detailed inspections utilize specialized tools and techniques to assess critical components like gears, bearings, and electrical systems meticulously. The findings from these detailed evaluations provide invaluable data that can inform maintenance strategies moving forward. Ultimately, this level of scrutiny helps prevent unexpected breakdowns by addressing potential problems before they become catastrophic failures.

Audits and Compliance Inspections

Audits and compliance inspections are all about ensuring adherence to industry standards and regulations—think of them as the watchdogs in the realm of machine inspection! These evaluations assess whether organizations meet specific legal requirements related to safety practices and equipment maintenance protocols aimed at protecting workers' health and ensuring operational integrity.

A machine inspector involved in audits will review documentation related to previous inspections while also examining current practices on-site for compliance with established guidelines. The results from these audits can lead to recommendations for improvements or even penalties if significant violations are found. Ultimately, regular audits help foster a culture of accountability within organizations while emphasizing the importance of consistent quality assurance in machinery management.

Role of a Machine Inspector

When we talk about machine inspection, the role of a machine inspector becomes paramount. A machine inspector is not just a title; it embodies a set of skills and responsibilities that ensure machinery operates safely and efficiently. Understanding what is a machine inspector entails recognizing their critical contribution to maintaining optimal performance in industrial settings.

Skills and Qualifications Required

To excel in machine inspection, one must possess a blend of technical expertise and analytical skills. Knowledge in mechanical engineering or related fields is often essential, as well as familiarity with various types of inspections—like visual inspection or non-destructive testing techniques. Moreover, certifications specific to safety standards can significantly enhance credibility, helping inspectors understand complex machinery and identify potential issues effectively.

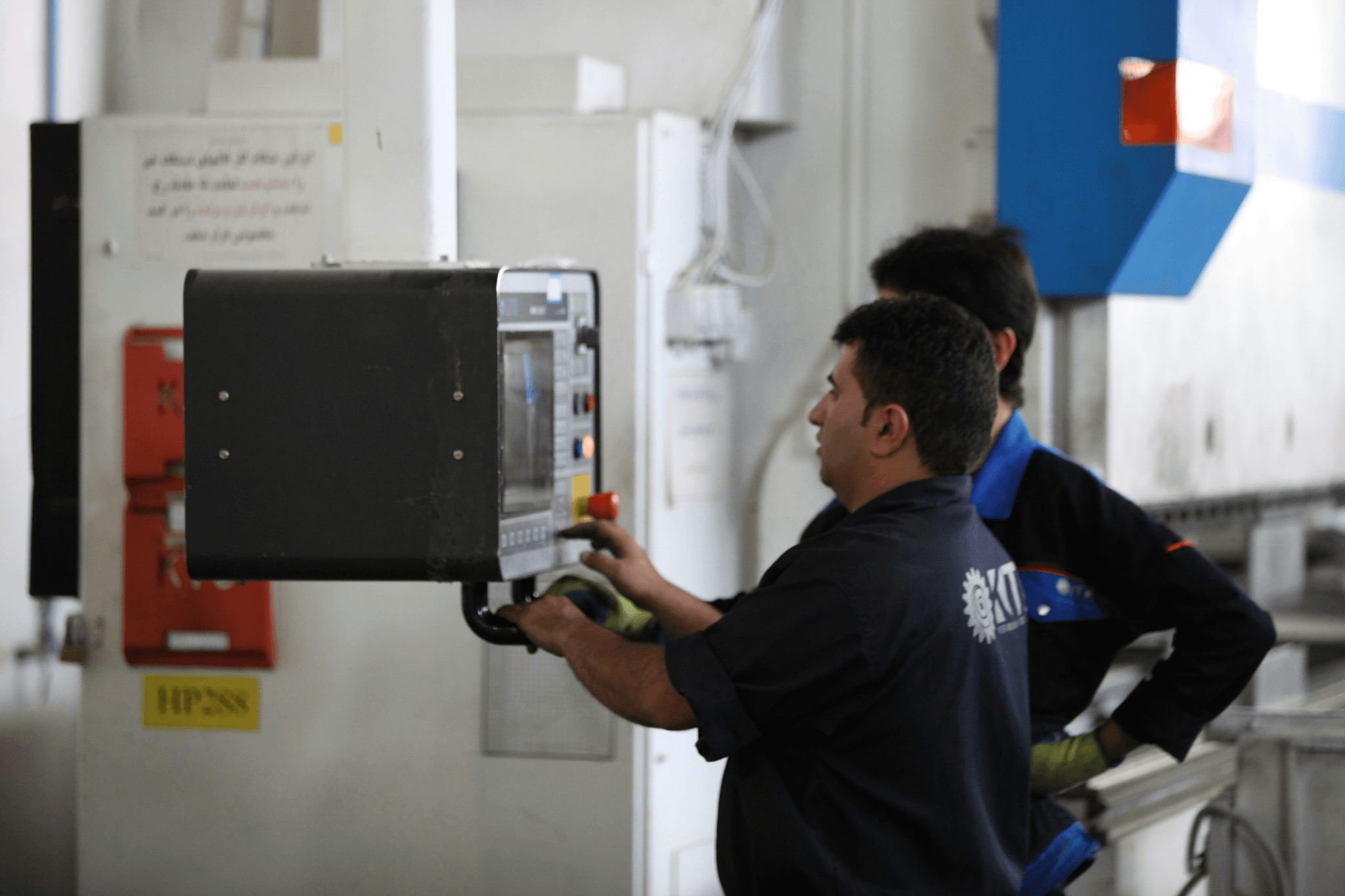

Daily Responsibilities and Tasks

The daily tasks of a machine inspector are varied but crucial for operational success. Inspectors conduct regular evaluations by performing what are the three main types of inspections: routine checks, detailed assessments, and compliance audits to ensure machinery adheres to safety regulations. They also document findings meticulously, prepare reports on machinery conditions, and communicate any necessary repairs or maintenance needs to relevant teams—ultimately ensuring that every piece of equipment remains up to standard.

Importance in Industrial Settings

The importance of machine inspectors in industrial settings cannot be overstated; they are the unsung heroes behind safe operations. Regular machine inspections help prevent costly breakdowns while promoting workplace safety—this is where understanding what is a machine inspection becomes vital for any business reliant on heavy machinery. By identifying potential failures before they escalate into serious problems, these professionals play an integral role in enhancing productivity and minimizing downtime across industries.

Choosing the Right Inspection Services

A well-conducted machine inspection can prevent costly downtimes and enhance productivity. With various options available, understanding what to look for can make all the difference.

Factors to Consider for Quality Assurance

Quality assurance in machine inspection revolves around several key factors that ensure effective evaluations. First, consider the inspector's qualifications; a certified machine inspector brings expertise that guarantees thorough assessments. Additionally, the methodologies employed—whether they involve visual inspections or non-destructive testing—should align with industry standards to ensure safety and reliability.

Another essential factor is technology use; modern tools can significantly enhance accuracy during inspections. For example, utilizing advanced diagnostic equipment during functional testing can provide insights into machinery performance that traditional methods might miss. Lastly, customer reviews and case studies are invaluable resources; they offer real-world examples of how a service has performed in various industrial settings.

Spotlight on China Inspection Pro

China Inspection Pro stands out as a leading provider in the realm of machine inspections, offering comprehensive services tailored to diverse industries. Their team comprises highly qualified machine inspectors who specialize in various types of inspections, including routine checks and detailed evaluations. With a strong focus on quality assurance, they utilize cutting-edge technology to deliver precise results.

One of their standout features is their commitment to transparency; clients receive detailed reports post-inspection that outline findings clearly and concisely. This level of detail not only aids in compliance with regulations but also helps businesses understand what areas require attention moving forward. By choosing China Inspection Pro, companies are investing in a partner dedicated to enhancing machinery safety and efficiency through meticulous evaluations.

Cost vs. Value in Machinery Inspection

When evaluating inspection services, it's essential to weigh cost against value rather than simply opting for the cheapest option available. While budget constraints are valid concerns, skimping on quality can lead to more significant expenses down the line due to machinery failures or safety incidents stemming from inadequate inspections. Therefore, understanding what is included in each service package becomes vital.

For instance, comprehensive machine inspections often come at a higher price but provide long-term benefits through preventative maintenance insights and enhanced operational efficiency—what some might call a penny saved is a penny earned. Moreover, investing in reputable inspection services ensures compliance with regulations like ISO standards or OSHA requirements—a factor that could save companies from hefty fines or legal issues later on. Ultimately, finding balance between cost and value will lead businesses towards better decision-making when it comes to machinery health.

Conclusion

In the realm of industrial operations, regular machine evaluations play a pivotal role in ensuring optimal performance and safety. The significance of thorough machine inspection cannot be overstated; it not only enhances machinery longevity but also minimizes downtime and operational risks. By implementing consistent evaluations, businesses can maintain their competitive edge while safeguarding their workforce.

Importance of Regular Machine Evaluations

Regular machine evaluations are essential for identifying potential issues before they escalate into costly problems. Understanding what is a machine inspection allows organizations to proactively address wear and tear, ensuring that all components function as intended. This preventive approach not only boosts efficiency but also fosters a culture of safety, where employees feel secure in their working environment.

Knowledge Gaps in Machine Inspections

Despite the clear benefits, many industries still grapple with knowledge gaps regarding what are the 4 types of inspection or what are the three main types of inspections. Such gaps can lead to inadequate assessments and missed opportunities for improvement. By enhancing awareness and training around these critical inspection categories, companies can better leverage machine inspections to optimize performance.

Finding the Right Inspection Partner

Choosing the right inspection partner can significantly influence the effectiveness of your machine inspections. A competent machine inspector should possess a blend of technical skills and industry experience to deliver comprehensive evaluations tailored to your needs. Ultimately, investing time in selecting an expert will ensure that you receive maximum value from your machinery inspections while bridging any existing knowledge gaps.