Introduction

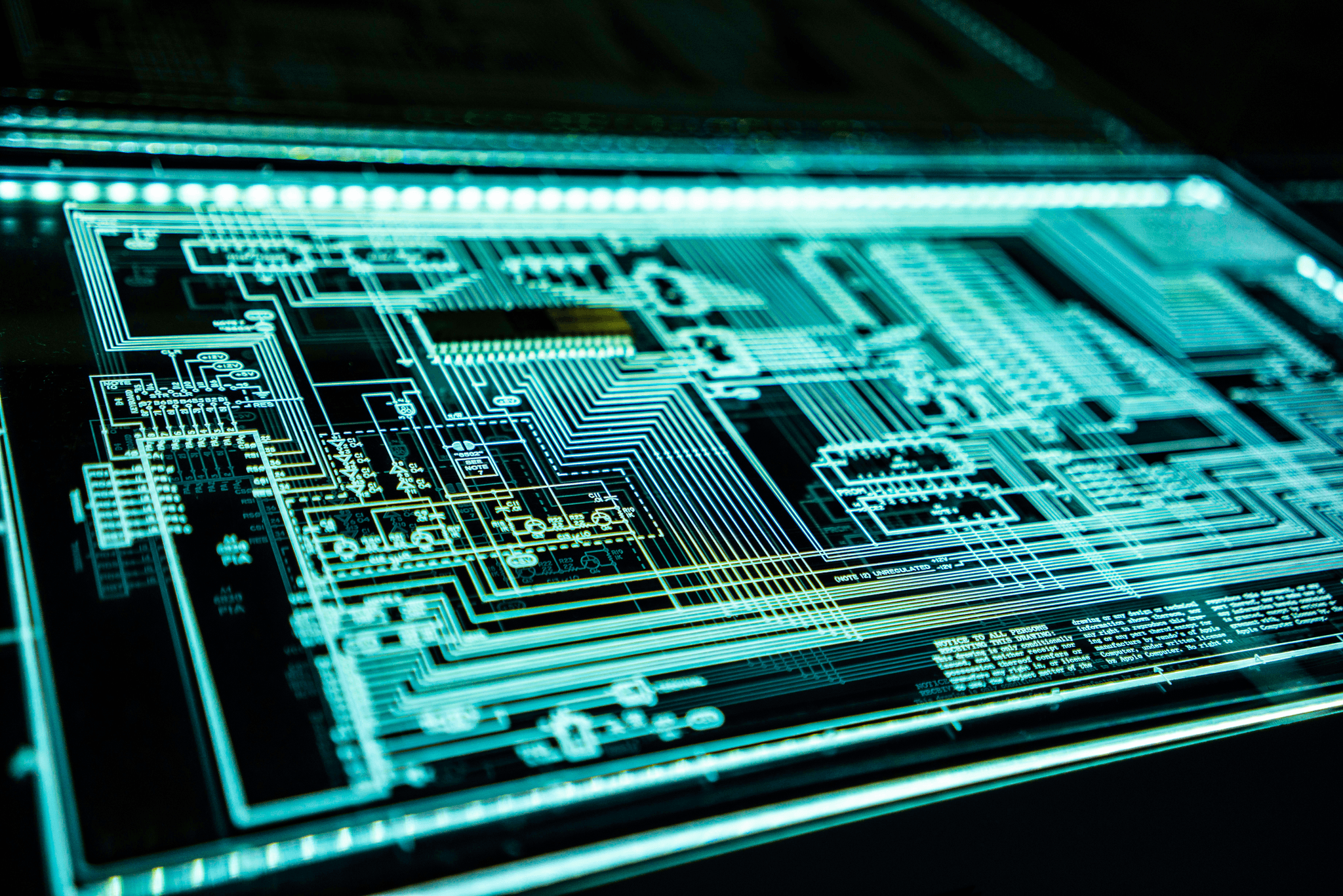

In the fast-paced world of electronics, ensuring top-notch PCB quality control is paramount. As the backbone of virtually all electronic devices, printed circuit boards (PCBs) must meet stringent quality standards to guarantee reliability and performance. With the increasing complexity of circuit board designs and the demand for miniaturization, effective quality control strategies become essential to mitigate risks associated with defects in printed board assembly.

Understanding PCB Quality Control Importance

PCB quality control plays a critical role in maintaining the integrity of electronic devices. A single flaw in a circuit card assembly can lead to malfunctions that not only affect performance but can also result in costly recalls or repairs. By implementing robust quality control measures, manufacturers can enhance product reliability, boost customer satisfaction, and ultimately secure their position in a competitive market.

Key Challenges in PCB Manufacturing

Despite its importance, PCB manufacturing faces numerous challenges that complicate the quality control process. From intricate designs to varying material properties, each aspect introduces potential pitfalls that can compromise product integrity during assembly. Additionally, maintaining consistency across production batches while adhering to evolving industry standards adds another layer of complexity for manufacturers striving for excellence in their PCB assembly board processes.

Overview of Effective Strategies

To navigate these challenges successfully, manufacturers must adopt effective strategies tailored to their specific needs. Implementing rigorous testing standards and utilizing advanced optical inspection technologies are just two approaches that can significantly enhance PCB quality control efforts. Furthermore, fostering a culture of continuous improvement and investing in skilled labor through training programs will ensure that teams are well-equipped to tackle emerging issues within circuit card assembly processes.

Implementing Rigorous Testing Standards

In the world of PCB quality control, rigorous testing standards are not just a recommendation; they are essential for ensuring the reliability and functionality of electronic devices. By adhering to established guidelines, manufacturers can significantly reduce defects in printed circuit assembly and enhance overall product quality. This section delves into the role of IPC standards, various testing techniques, and effective documentation practices that form the backbone of a robust quality control system.

The Role of IPC Standards

IPC standards serve as the gold standard in PCB quality control, providing critical benchmarks for manufacturing processes. These guidelines cover everything from design specifications to assembly procedures, ensuring that each circuit board meets industry requirements for performance and reliability. By aligning with IPC standards, companies can streamline their printed board assembly processes while also minimizing errors during circuit card assembly.

Moreover, adhering to these standards fosters a culture of quality within organizations. It encourages teams to prioritize best practices throughout the entire production lifecycle—from initial design through final inspection—ultimately leading to higher customer satisfaction and trust in their electronic devices. In a rapidly evolving market where technology is constantly advancing, staying compliant with IPC standards is not just beneficial; it’s imperative for long-term success.

Testing Techniques in PCB Quality Control

Testing techniques play a crucial role in maintaining high levels of PCB quality control throughout the manufacturing process. Various methods such as functional testing, in-circuit testing (ICT), and automated optical inspection (AOI) help identify defects early on before they escalate into costly issues down the line. Each technique has its strengths; for instance, AOI excels at detecting surface-level imperfections while ICT tests component functionality directly on the circuit board.

Integrating these diverse testing approaches ensures comprehensive coverage of potential failure points within printed circuit assemblies. Regularly employing these techniques helps manufacturers achieve consistent performance across all electronic devices produced while also enhancing their reputation in an increasingly competitive marketplace. Furthermore, incorporating advanced technologies like machine learning into these testing methods can lead to even greater efficiencies and accuracy.

Effective Documentation Practices

Effective documentation practices are often overlooked but are vital components of successful PCB quality control systems. Properly documenting every stage—from design modifications to test results—provides a clear audit trail that can be invaluable during troubleshooting or regulatory inspections related to printed board assembly processes. This level of detail ensures that any issues encountered during circuit card assembly can be traced back to their source quickly and efficiently.

Additionally, thorough documentation promotes accountability among team members by clearly outlining responsibilities and expectations at each phase of production. It also facilitates knowledge transfer within organizations by creating a repository of best practices and lessons learned over time—essential for ongoing improvement efforts in PCB assembly boards manufacturing processes. Ultimately, strong documentation supports continuous improvement initiatives while reinforcing commitment to excellence across all aspects of electronic device production.

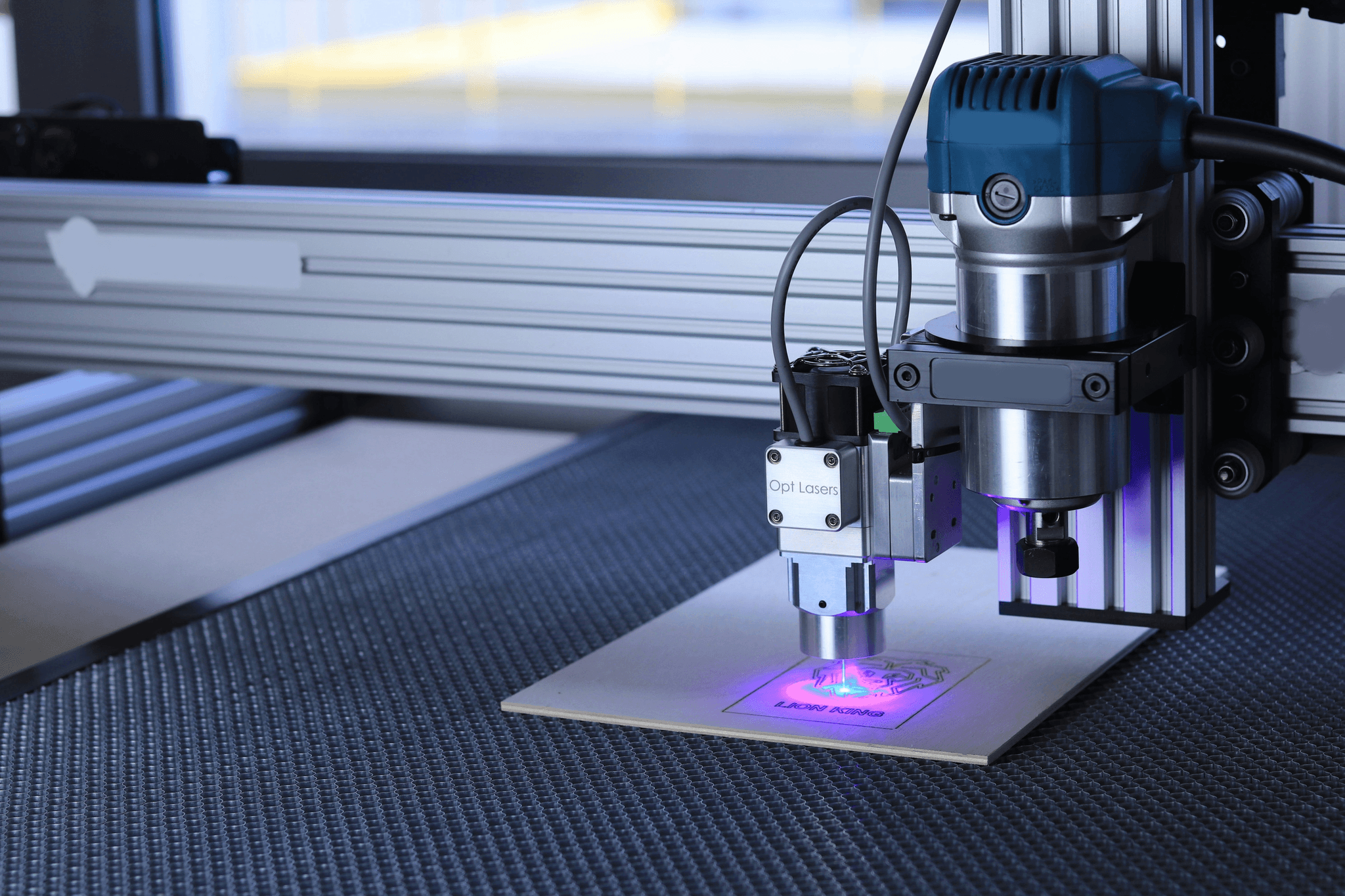

Utilizing Advanced Optical Inspection

In the realm of PCB quality control, advanced optical inspection technology is a game-changer. This innovative approach enhances the accuracy and efficiency of inspecting printed circuit assembly, ensuring that defects are identified and addressed before they escalate into costly issues. As electronic devices become more complex, the need for precise and reliable inspection methods has never been greater.

Benefits of Optical Inspection Technology

Optical inspection technology provides numerous benefits that significantly enhance PCB quality control processes. Firstly, it allows for high-resolution imaging of circuit board features, enabling inspectors to detect even the smallest defects in printed board assembly. Additionally, this technology can operate at high speeds, which is essential for meeting the demands of modern manufacturing environments where time is money.

Moreover, optical inspection systems reduce human error by automating the detection process. By utilizing advanced algorithms and machine learning techniques, these systems can learn from past inspections and improve their accuracy over time. This not only enhances quality assurance but also boosts overall productivity in circuit card assembly operations.

Comparative Analysis of Inspection Systems

When considering various optical inspection systems available on the market, it's crucial to evaluate their capabilities against specific PCB quality control requirements. Some systems focus on 2D imaging while others offer 3D capabilities that provide a more comprehensive view of the printed circuit assembly's structure. The choice between these options often depends on the complexity of the circuit board being inspected.

Additionally, factors such as speed, resolution, and integration with existing workflows must be considered when selecting an optical inspection system. For instance, some systems may excel in detecting surface defects but may lack in-depth analysis for solder joint integrity—critical aspects in ensuring robust electronic devices performance. Therefore, conducting a thorough comparative analysis will help manufacturers choose an optimal solution tailored to their specific needs.

Integration with Automated Processes

Integrating optical inspection technology with automated processes is pivotal for enhancing PCB quality control in modern manufacturing settings. By incorporating these systems into automated production lines, manufacturers can achieve real-time monitoring and feedback loops that drastically reduce defect rates during printed board assembly operations. Such integration ensures that any issues are caught early on without slowing down production.

Furthermore, automation allows for seamless data collection from each inspection cycle; this data can then be analyzed to identify trends or recurring issues within circuit card assembly processes. With insights gained from this data analysis, manufacturers can implement targeted improvements that lead to sustained quality enhancements over time. Ultimately, integrating optical inspection with automation not only streamlines operations but also fortifies overall product reliability.

Ensuring Quality in Printed Circuit Assembly

In the realm of electronic devices, ensuring quality in printed circuit assembly (PCA) is paramount. The integrity of a circuit board directly impacts the performance and reliability of the final product. By adhering to best practices, manufacturers can enhance their pcb quality control measures while minimizing defects during the assembly process.

Best Practices in PCB Assembly Board

Implementing best practices in pcb assembly board is essential for producing high-quality printed board assemblies. One key practice involves meticulous design reviews, ensuring that every aspect of the layout adheres to industry standards and IPC guidelines. Additionally, investing in advanced optical inspection technologies can significantly reduce errors by identifying potential issues before they escalate into costly defects.

Another crucial aspect is maintaining a clean and organized workspace to prevent contamination during assembly. Regular training sessions for technicians on handling sensitive components and following standard operating procedures also contribute to better outcomes. Ultimately, these best practices not only improve efficiency but also bolster overall pcb quality control efforts.

Common Defects in Circuit Card Assembly

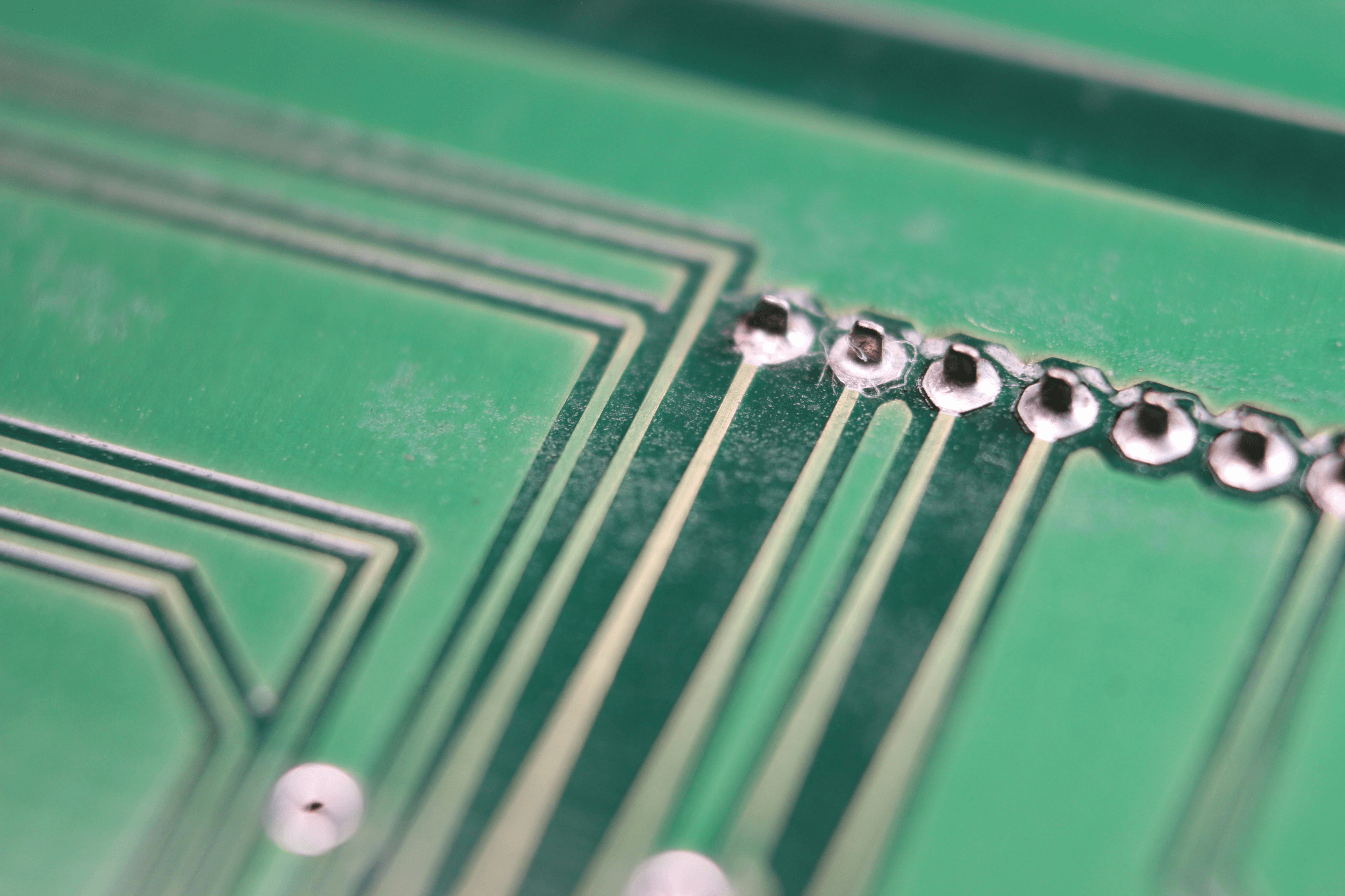

Despite rigorous efforts, common defects can still occur during circuit card assembly that threaten product reliability. Issues such as solder bridging, misaligned components, and insufficient solder joints are frequent culprits that can lead to malfunctioning electronic devices. Identifying these defects early through thorough inspections—especially utilizing optical inspection methods—can save manufacturers from incurring significant rework costs.

Moreover, environmental factors like temperature fluctuations and humidity can exacerbate defect rates if not properly managed during the assembly process. Awareness of these common pitfalls allows teams to implement corrective measures proactively rather than reactively addressing problems after they arise. This approach not only improves pcb quality control but also enhances customer satisfaction with reliable products.

Continuous Improvement Methods

To maintain excellence in printed circuit assembly, continuous improvement methods must be an integral part of the manufacturing process. Employing methodologies such as Six Sigma or Lean Manufacturing helps identify inefficiencies within production lines while fostering a culture of quality among employees involved in pcb quality control processes. Regularly scheduled audits and feedback loops ensure that lessons learned are documented and applied moving forward.

Incorporating data analytics into production workflows also enables teams to monitor performance metrics effectively over time, allowing for timely adjustments when necessary. Engaging employees through training programs focused on new technologies ensures that staff remain competent amidst evolving industry standards related to printed board assemblies and circuit card assemblies alike. Ultimately, continuous improvement fosters innovation while securing long-term success for manufacturers in an increasingly competitive market.

Training and Development for Quality Control

In the realm of PCB quality control, the importance of skilled labor cannot be overstated. Skilled workers are essential in ensuring that every step of the printed circuit assembly process meets stringent quality standards. Their expertise not only enhances the overall reliability of electronic devices but also minimizes defects in circuit card assembly, ultimately leading to better product performance.

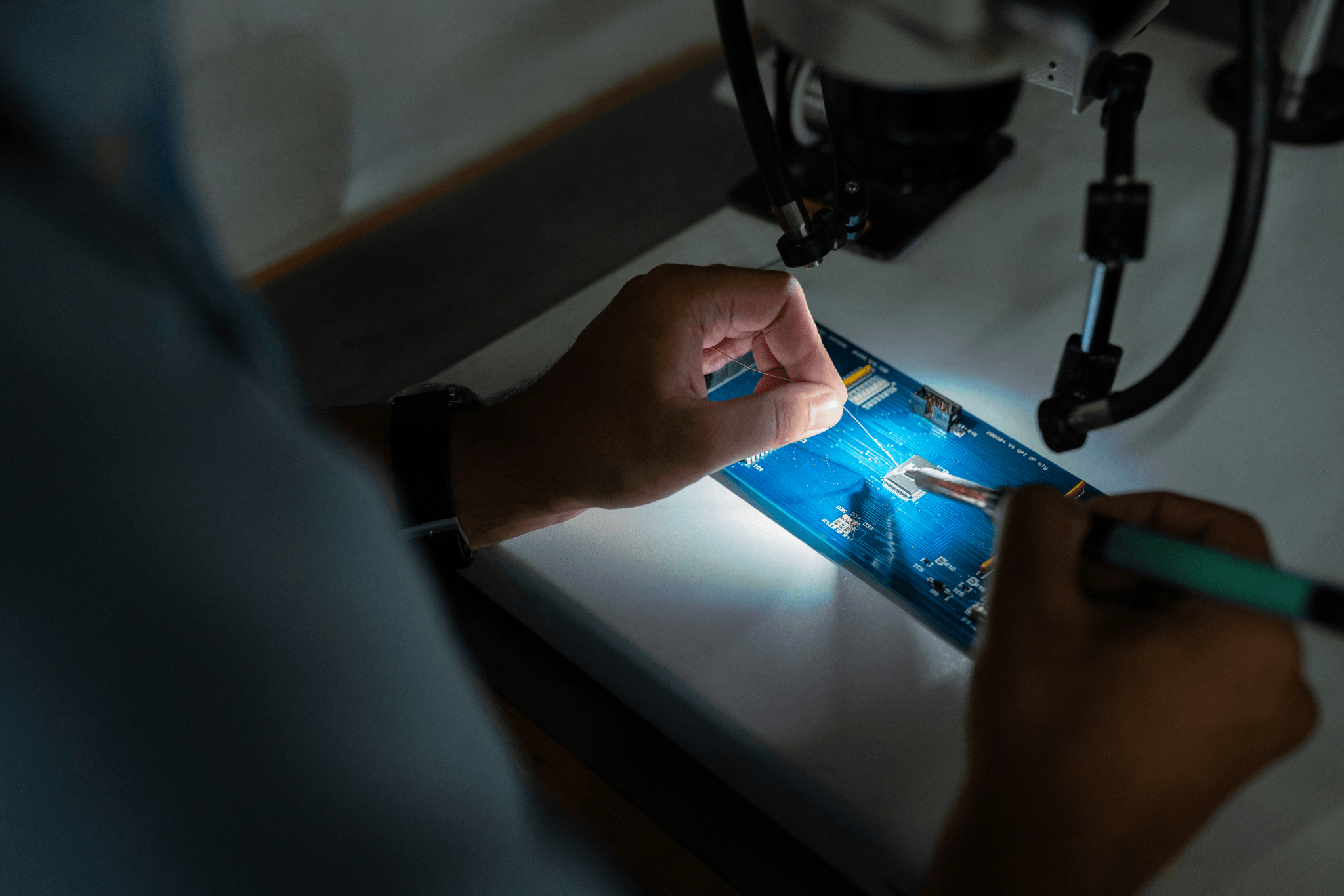

Importance of Skilled Labor

The backbone of effective PCB quality control lies in a well-trained workforce. Skilled labor ensures that each technician understands the complexities involved in printed board assembly, from initial design to final inspection. With a deep understanding of processes like optical inspection, these professionals can swiftly identify and rectify potential issues before they escalate into costly problems.

Moreover, their familiarity with industry standards and best practices allows them to maintain high-quality benchmarks throughout production. This directly correlates with reduced error rates during circuit card assembly, resulting in a more efficient manufacturing process. Thus, investing in skilled labor is not merely an operational choice; it’s a strategic imperative for any organization aiming for excellence in PCB quality control.

Training Programs from Expert Institutions

To cultivate such skilled labor, companies should seek training programs offered by expert institutions specializing in electronics and manufacturing processes. These programs often cover essential topics like advanced optical inspection techniques and updated methodologies for printed circuit assembly. By enrolling employees in these courses, businesses can ensure their workforce remains adept at handling modern challenges associated with PCB quality control.

Institutions often provide hands-on training that simulates real-world scenarios encountered during circuit card assembly processes. This practical approach equips workers with valuable experience while reinforcing theoretical knowledge about electronic devices' intricacies. As they gain proficiency through these programs, employees become more capable of contributing to continuous improvement efforts within their organizations.

Additionally, many institutions offer certifications that validate an employee's skills and knowledge base within the industry—a significant advantage when competing for top talent or securing contracts requiring compliance with specific standards. Thus, leveraging expert training programs is crucial for developing a competent workforce dedicated to achieving high-quality outcomes.

Ongoing Education in Technology Advances

In an ever-evolving technological landscape, ongoing education is vital for maintaining competitive edge within PCB quality control practices. As new advancements emerge—be it innovative materials or cutting-edge inspection technologies—workers must stay informed about these changes to enhance their proficiency effectively. Regular workshops and seminars focused on developments related to printed board assembly can empower employees to adopt new techniques seamlessly into existing workflows.

Furthermore, as electronic devices continue to grow more complex, understanding how these innovations impact both design and manufacturing becomes increasingly important for all personnel involved in circuit card assembly operations. Continuous learning fosters a culture where team members actively engage with emerging trends rather than becoming complacent with outdated methods or tools.

Investing time and resources into ongoing education not only benefits individual employees but also strengthens the overall company culture surrounding PCB quality control initiatives—leading to sustained improvements across all levels of production activities.

Partnering with Reliable Quality Inspection Services

In the intricate world of PCB manufacturing, partnering with reliable quality inspection services is essential for ensuring top-notch standards. These partnerships not only enhance the effectiveness of PCB quality control but also streamline processes in printed circuit assembly and circuit card assembly. By leveraging the expertise of specialized inspection services, manufacturers can significantly mitigate risks associated with defects in electronic devices.

The Value of China Inspection Pro

China Inspection Pro stands out as a premier choice for businesses aiming to elevate their PCB quality control measures. With extensive experience in inspecting printed board assembly and circuit board integrity, they provide tailored solutions that meet diverse industry needs. Their rigorous protocols ensure that every aspect of the PCB assembly board is scrutinized, from initial design to final product delivery.

How Professional Services Enhance Quality

Professional inspection services play a pivotal role in enhancing overall quality by implementing advanced optical inspection techniques and thorough testing processes. By employing state-of-the-art technology and methodologies, these services identify potential issues before they escalate into costly problems during production runs. Furthermore, their ability to provide detailed reports helps manufacturers understand defect patterns, enabling continuous improvement in both printed circuit assembly and circuit card assembly practices.

Building Long-Term Partnerships for Success

Establishing long-term partnerships with reliable quality inspection services fosters a culture of excellence within organizations focused on PCB quality control. Such collaborations promote consistent communication and feedback loops that are crucial for refining processes over time. Ultimately, these enduring relationships not only lead to superior product outcomes but also cultivate trust among stakeholders involved in the electronics supply chain.

Conclusion

In the rapidly evolving world of electronics, the importance of PCB quality control cannot be overstated. As electronic devices become more sophisticated, ensuring the integrity and functionality of printed circuit assembly (PCA) is crucial for manufacturers striving to meet consumer demands. The future will likely see even greater integration of technology and processes that enhance quality assurance in circuit card assembly.

The Future of PCB Quality Control

The future of PCB quality control is poised for transformation with advancements in automation and artificial intelligence. These technologies will enable more precise optical inspection methods, allowing for quicker detection of defects in circuit boards during production. As we look ahead, embracing these innovations will be essential for maintaining high standards in printed board assembly.

Strategies for Sustained Improvement

To achieve sustained improvement in PCB quality control, manufacturers must adopt a proactive approach that includes regular training and development programs for their workforce. By investing in skilled labor who are well-versed in the latest techniques and technologies, companies can significantly reduce errors in circuit card assembly processes. Continuous feedback loops and data analysis will also play a pivotal role in refining practices and ensuring ongoing excellence.

Final Thoughts on Quality Excellence

Quality excellence is not just a goal; it’s a commitment to delivering reliable electronic devices that consumers can trust. By prioritizing effective strategies such as rigorous testing standards and advanced optical inspection, businesses can elevate their PCB assembly board processes to new heights. Ultimately, fostering a culture of quality within organizations ensures that they remain competitive while meeting the ever-increasing expectations from customers.