Introduction

In the fast-paced world of electronics, maintaining high standards in PCB Quality Control is paramount. Printed Circuit Boards (PCBs) are the backbone of modern technology, and any lapse in quality can lead to significant operational failures. Therefore, rigorous quality control processes are essential to ensure that these components meet industry requirements and customer expectations.

Importance of PCB Quality Control

PCB Quality Control encompasses various aspects, including Quantity Verification, Craftsmanship Evaluation, and an assessment of Aesthetics such as Colour and Documentation. These elements contribute not only to the functionality of the final product but also to its visual appeal and reliability. By prioritizing PCB Quality Control, manufacturers minimize defects and enhance overall product performance.

The Role of Third-Party Inspections

Third-party inspections play a crucial role in validating PCB Quality Control processes by providing an independent assessment that adds credibility to manufacturing claims. These inspections focus on critical areas such as Field Testing and Precision Measurements, ensuring that every aspect meets stringent industry standards. Engaging third-party experts helps manufacturers identify potential issues early on—before shipping marks and packaging become a concern.

Overview of the Inspection Process

The inspection process for PCBs is thorough and multi-faceted, beginning with initial evaluations that check for compliance with specifications. This includes detailed assessments of craftsmanship, aesthetics like colour consistency, and comprehensive documentation review. Following this initial phase are rigorous field testing and precision measurements designed to catch any defects before products reach customers—ultimately safeguarding both quality and brand reputation.

Understanding PCB Quality Control

In the dynamic world of electronics, PCB Quality Control is not just a checkbox on a manufacturing list; it’s the backbone of reliable performance. This process ensures that each printed circuit board meets stringent standards before it reaches the market. By maintaining high-quality benchmarks, manufacturers can prevent costly failures and enhance customer satisfaction.

Definition and Significance

PCB Quality Control refers to the systematic process of ensuring that printed circuit boards are manufactured to meet specific quality standards and customer expectations. This involves various activities like Quantity Verification, Craftsmanship Evaluation, and Aesthetics assessment to ensure that every unit is up to par. The significance lies in its ability to prevent defects and ensure functionality, which ultimately protects the reputation of manufacturers and satisfies end-users.

Key Components of Quality Control

Quality control in PCB manufacturing encompasses several key components that work together to guarantee excellence. These include Quantity Verification, which confirms that the correct number of boards are produced; Craftsmanship Evaluation, assessing the precision in soldering and assembly; and Aesthetics checks for Colour consistency and overall appearance. Additionally, thorough Documentation is essential for tracking quality metrics throughout production, ensuring transparency and accountability.

Industry Standards and Compliance

Adhering to industry standards is crucial for effective PCB Quality Control as it establishes a baseline for quality assurance practices across the board (pun intended!). Compliance with recognized guidelines such as IPC-A-600 or ISO 9001 helps manufacturers maintain high-quality levels while also meeting regulatory requirements. These standards often dictate everything from Field Testing procedures to Precision Measurements, ensuring that products not only look good but function reliably under various conditions—right down to Shipping Marks and Packaging specifications necessary for safe transport.

Why Opt for Third-Party Inspections

When it comes to ensuring top-notch PCB Quality Control, third-party inspections are a game changer. These independent evaluations provide an unbiased look at your products, verifying not just the quantity but also the quality of your printed circuit boards. By leveraging external expertise, companies can enhance their reputation and trustworthiness in a competitive market.

Benefits of Independent Verification

Independent verification through third-party inspections offers a plethora of benefits that go beyond mere compliance checks. For starters, it ensures that craftsmanship evaluation is performed with an objective lens, highlighting any areas needing improvement without bias. Additionally, these inspections often include assessments of aesthetics and colour consistency, which are crucial for maintaining brand integrity and customer satisfaction.

Moreover, third-party inspectors bring seasoned experience to the table, employing rigorous field testing and precision measurements that might be overlooked internally. This level of diligence not only enhances PCB Quality Control but also helps in identifying defects early in the production process—saving time and money in the long run. Ultimately, independent verification fosters confidence among stakeholders by guaranteeing that every product meets established standards before reaching customers.

Case Studies of Inspection Success

Real-world examples showcase how third-party inspections have transformed operations for various companies dealing with PCBs. One notable case involved a manufacturer facing persistent issues with shipping marks and packaging inconsistencies that were damaging their reputation. After engaging a third-party inspection service, they conducted thorough evaluations focusing on quantity verification and craftsmanship evaluation—resulting in significant improvements across production lines.

Another success story involves a company specializing in high-end electronics who struggled with aesthetic defects impacting their product appeal. The introduction of independent inspections allowed them to address colour mismatches effectively and refine their overall design quality. This case illustrates how comprehensive documentation from these inspections can serve as valuable feedback for continuous improvement initiatives.

These case studies underscore the tangible benefits derived from opting for third-party inspections—showing that when it comes to PCB Quality Control, investing in external expertise pays off handsomely.

Risk Mitigation through Third-Party Expertise

Risk mitigation is another compelling reason to engage third-party inspectors during the PCB manufacturing process. With their specialized knowledge and experience in identifying potential pitfalls early on, these experts play a crucial role in safeguarding your investment against costly errors or recalls down the line. By emphasizing rigorous field testing and precision measurements throughout each stage of production, they ensure adherence to industry standards while minimizing risks associated with non-compliance.

Furthermore, an independent inspection can serve as an additional layer of protection against supplier discrepancies or unintentional oversights within your own teams—particularly important when dealing with complex designs or large quantities of PCBs where mistakes can easily occur unnoticed. When shipping marks and packaging are scrutinized by seasoned professionals before dispatching products globally, businesses can avoid logistical nightmares caused by incorrect labels or inadequate packing materials.

In essence, partnering with third-party inspection services not only enhances PCB Quality Control but also significantly reduces operational risks—making it an essential component for any serious manufacturer looking to thrive in today’s competitive landscape.

The Inspection Process Explained

When it comes to PCB Quality Control, the inspection process is a crucial element that ensures products meet rigorous standards before they reach the market. This process not only verifies quantity but also evaluates craftsmanship, aesthetics, and overall functionality. By systematically assessing each component, manufacturers can identify potential issues early on, reducing risks associated with defects and ensuring customer satisfaction.

Step-by-Step Overview

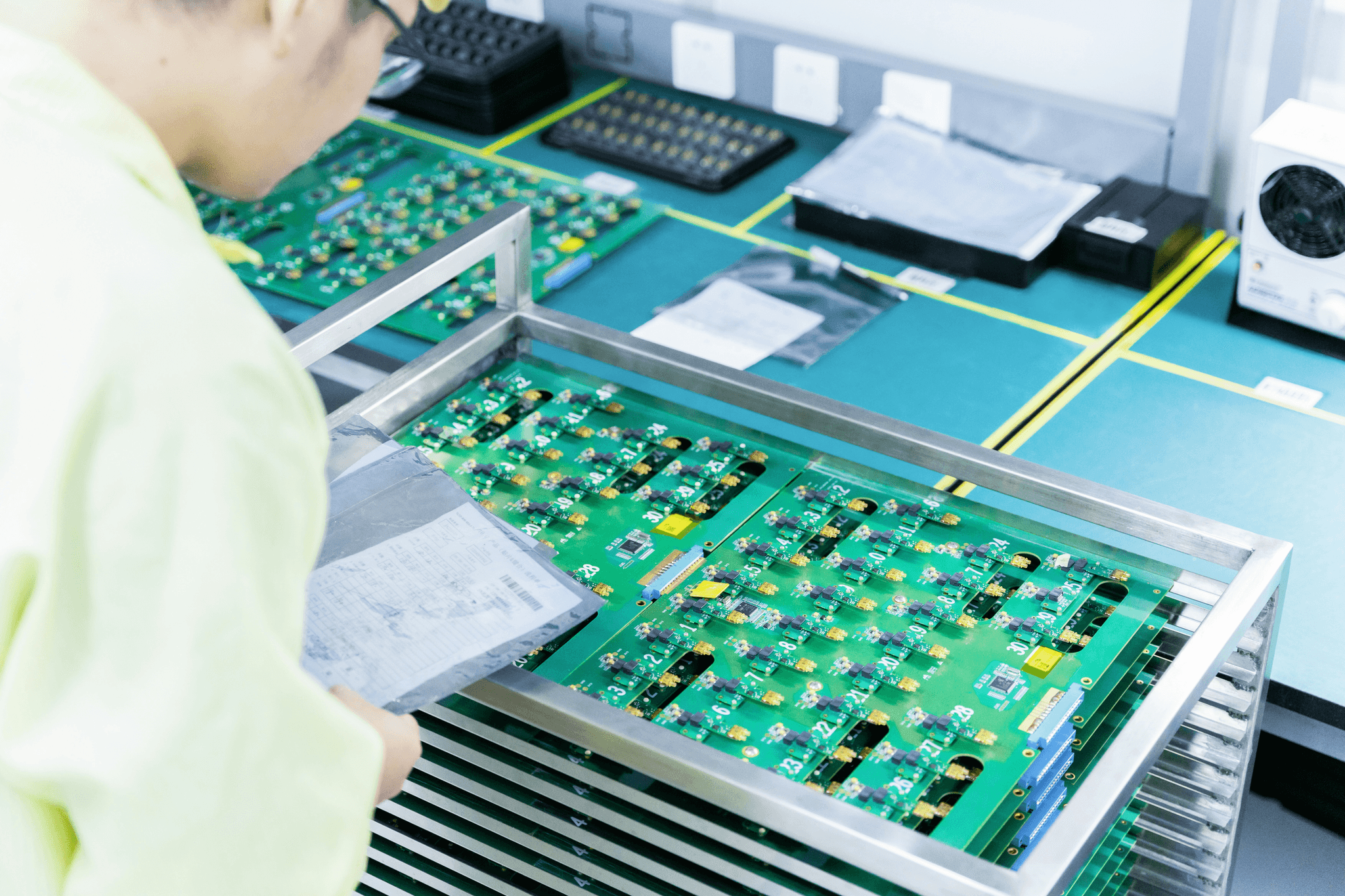

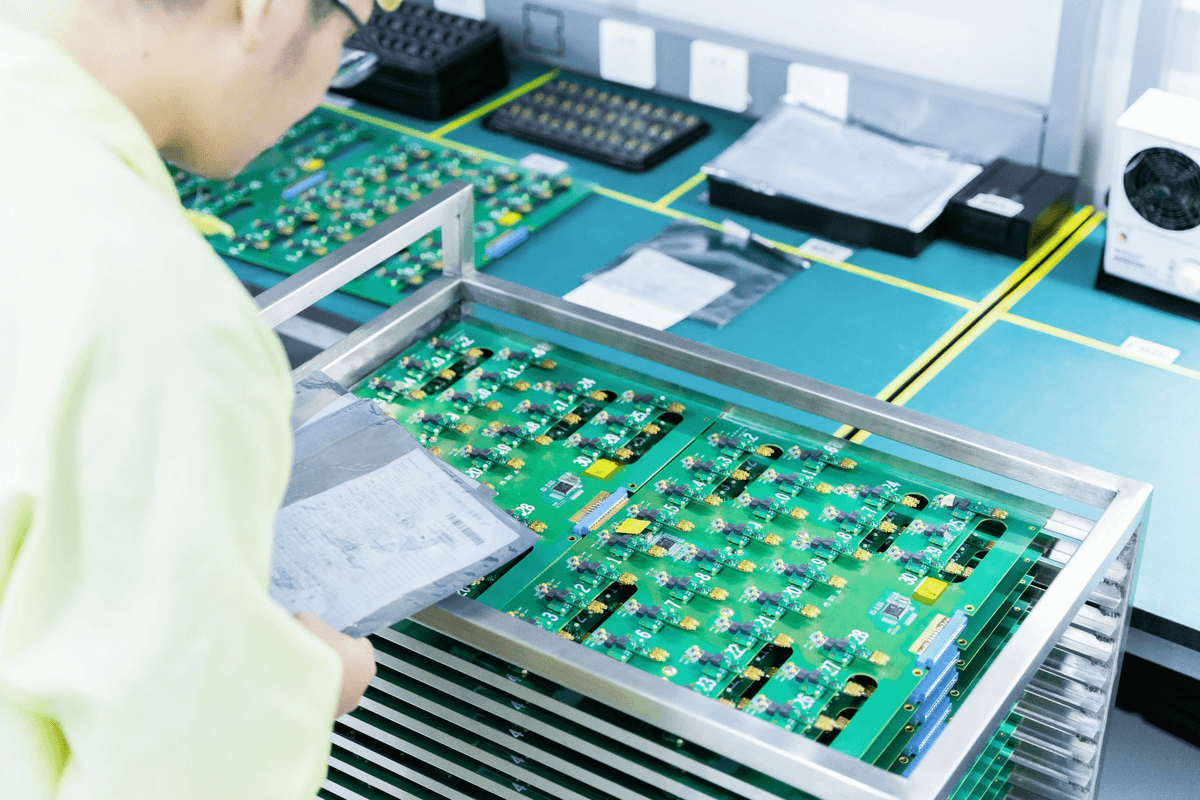

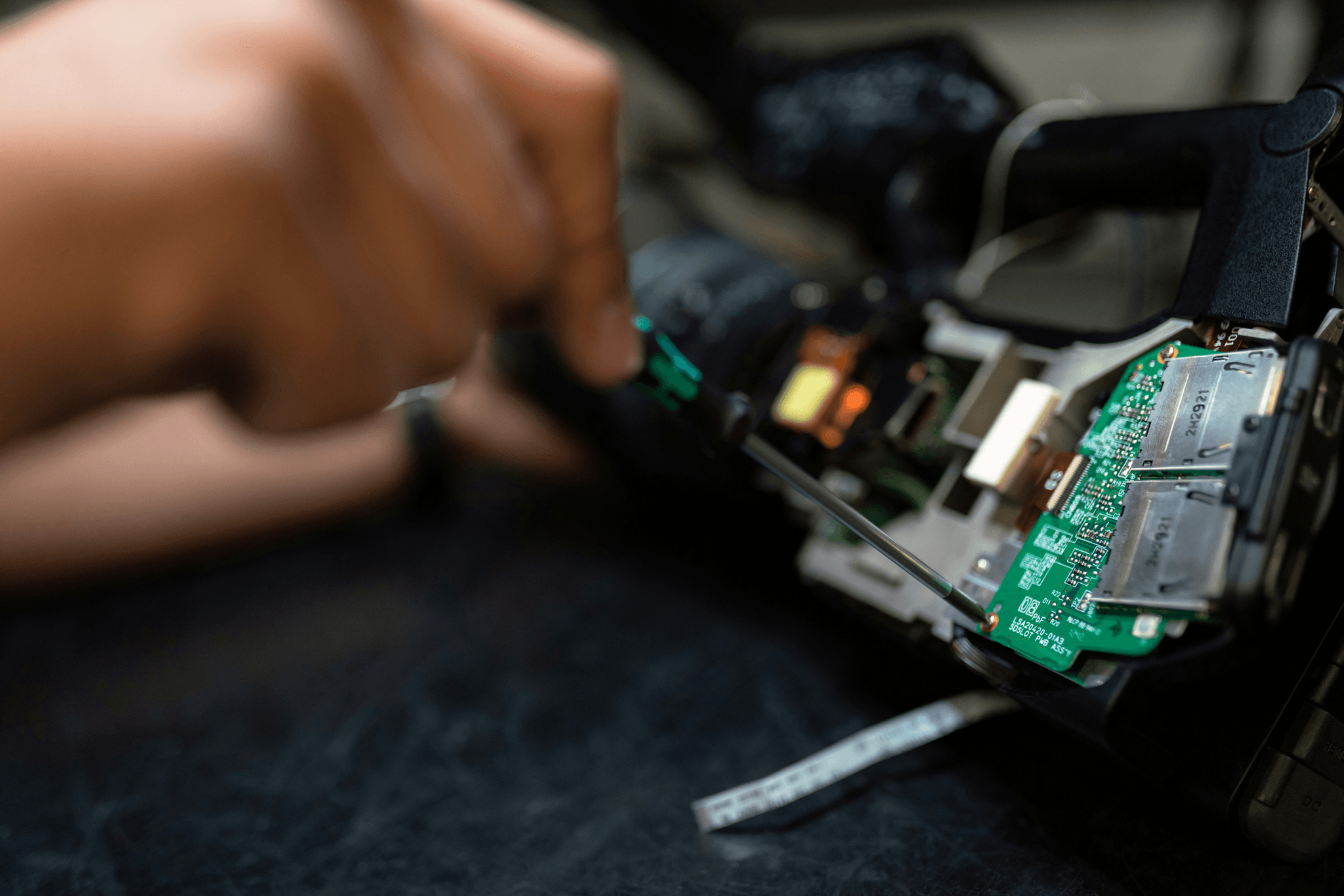

The inspection process begins with a comprehensive review of documentation, which includes specifications, design files, and manufacturing records. Following this initial review, inspectors conduct quantity verification to ensure that the number of produced units matches what was ordered. Next comes the hands-on evaluation phase where craftsmanship evaluation takes center stage—inspectors meticulously check solder joints and component placements for precision.

Once these initial checks are complete, inspectors move on to field testing and precision measurements using advanced tools that gauge performance under various conditions. After field testing is done, aesthetics come into play; inspectors assess color consistency and visual appeal to ensure that the final product aligns with brand expectations. Finally, shipping marks and packaging are reviewed to confirm they meet regulatory requirements before products are cleared for dispatch.

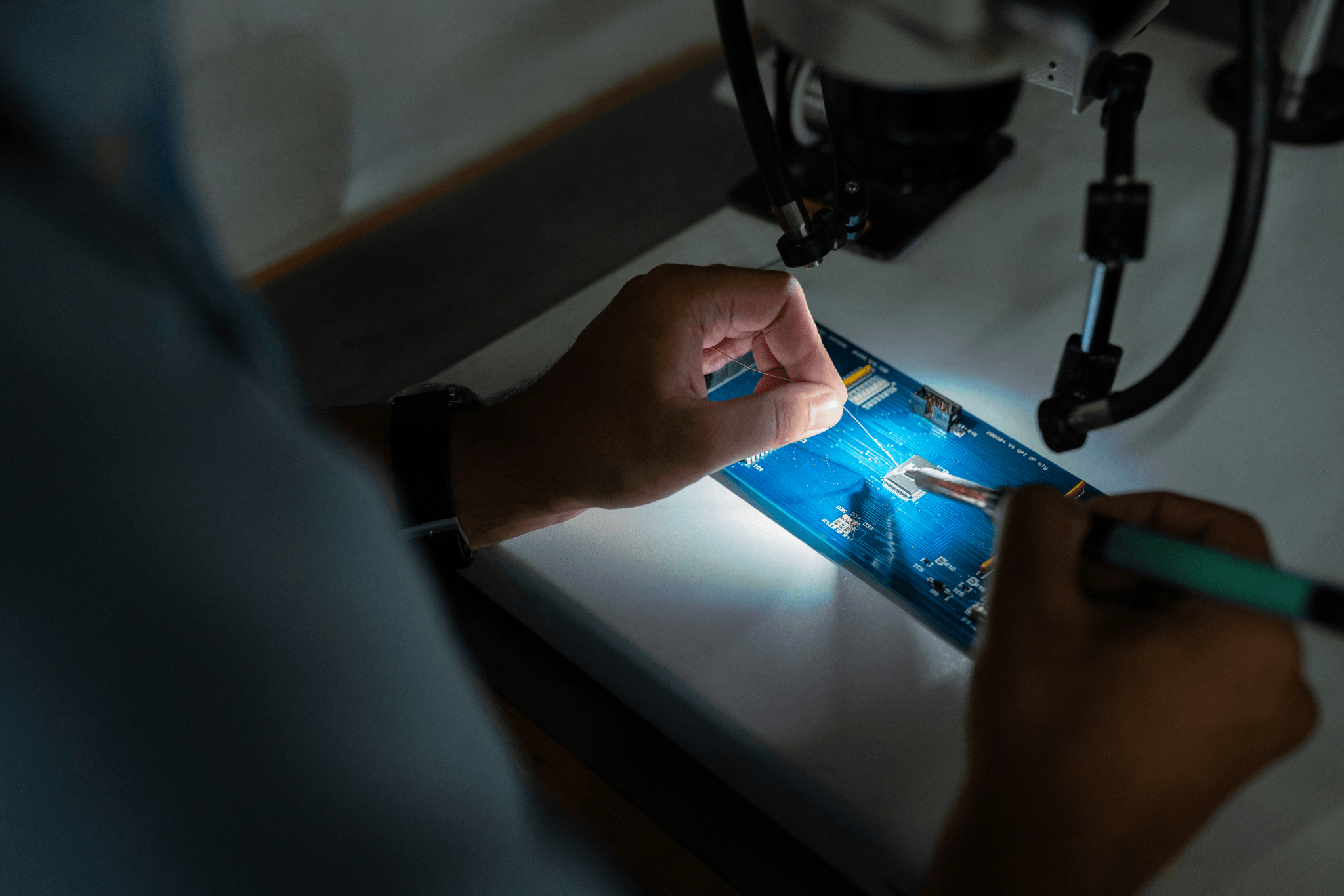

Tools and Technologies Used

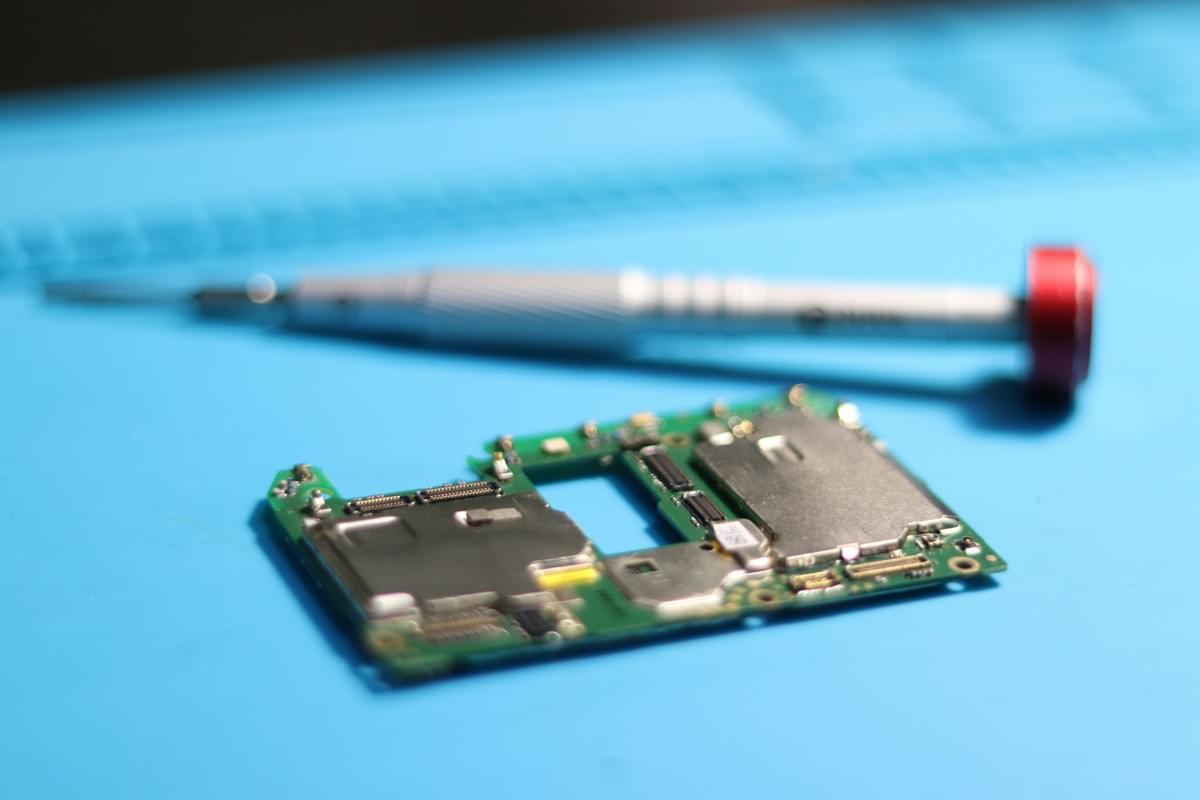

To conduct thorough inspections in PCB Quality Control, a variety of tools and technologies are employed throughout the process. Automated Optical Inspection (AOI) systems serve as a first line of defense by quickly scanning PCBs for visible defects such as misaligned components or soldering issues—speeding up both quantity verification and craftsmanship evaluation significantly. Additionally, X-ray machines can be utilized to inspect hidden connections within multilayer boards without damaging them.

Field testing may involve sophisticated equipment like oscilloscopes or signal analyzers that measure electrical performance under real-world conditions; this step is essential for validating functionality beyond mere visual inspections. For aesthetics assessments, colorimeters can accurately measure color consistency across batches—ensuring products not only perform well but also look good while doing so! The combination of these tools allows inspectors to provide detailed feedback on every aspect of quality control.

Common Defects Identified

Throughout the inspection process in PCB Quality Control, several common defects can be identified that could jeopardize product integrity or functionality if left unchecked. One frequent issue is insufficient solder coverage at joints leading to unreliable electrical connections—a defect often caught during craftsmanship evaluations or AOI scans. Additionally, misalignment of components during assembly can cause significant operational failures; this is why meticulous quantity verification steps are essential.

Another area where defects commonly arise is in aesthetics; variations in color or finish can affect consumer perception even if the board functions correctly—hence why aesthetic evaluations hold weight in inspections too! Packaging flaws such as incorrect shipping marks may also lead to logistical issues down the line; therefore inspectors pay close attention here as well during their final reviews before shipment approval. Addressing these common defects early through rigorous inspections ultimately safeguards against larger problems later on.

Leading Companies in PCB Inspections

In the evolving landscape of PCB Quality Control, various companies have emerged as leaders in providing comprehensive inspection services. These firms not only ensure adherence to industry standards but also enhance the overall quality of printed circuit boards through meticulous evaluations. By focusing on quantity verification, craftsmanship evaluation, and aesthetics, these companies play a pivotal role in maintaining high production standards.

Spotlight on China Inspection Pro

China Inspection Pro has established itself as a frontrunner in the PCB Quality Control arena, offering a range of services tailored to meet diverse client needs. Their expertise extends beyond basic inspections; they delve into quantity verification and craftsmanship evaluation, ensuring that each batch meets stringent specifications. Additionally, their attention to detail regarding aesthetics—such as colour consistency and documentation accuracy—sets them apart from competitors.

The company's commitment to field testing and precision measurements ensures that every product is rigorously evaluated before it reaches the market. With advanced tools at their disposal, they can identify even minute defects that could compromise performance or reliability. This dedication not only enhances product quality but also builds trust with manufacturers who rely on their insights for decision-making.

Comparison of Major Players

When comparing major players in PCB inspections, it’s essential to consider factors such as service offerings and industry reputation. Companies like China Inspection Pro stand out for their comprehensive approach that includes quantity verification and detailed craftsmanship evaluation alongside aesthetic assessments like colour uniformity. Other firms may excel in specific areas but often lack the holistic perspective necessary for thorough PCB Quality Control.

Furthermore, shipping marks and packaging are critical elements that some companies overlook during inspections; however, leading firms prioritize this aspect to ensure products are delivered safely and correctly labeled. The ability to provide detailed documentation is another hallmark of top-tier inspectors; this transparency fosters better communication between manufacturers and clients regarding quality expectations and outcomes. Ultimately, selecting an inspection partner should involve evaluating how well they address all facets of quality assurance.

What to Look for in a Quality Inspector

Choosing the right quality inspector requires careful consideration of several key factors related to PCB Quality Control processes. First and foremost, look for inspectors who offer robust quantity verification methods; this ensures you receive exactly what you ordered without any unwelcome surprises down the line. Additionally, craftsmanship evaluation should be prioritized—inspectors must assess not just functionality but also visual aspects such as aesthetics and colour fidelity.

Documentation plays a vital role too; effective inspectors provide clear reports detailing findings from field testing and precision measurements along with recommendations for improvement when necessary. Moreover, consider their experience with shipping marks and packaging practices—this can save time during logistics while preventing costly errors post-inspection. In summary, seek out inspectors who combine technical expertise with a keen eye for detail across all aspects of PCB evaluations.

Interpreting Inspection Reports

Understanding inspection reports is crucial for maintaining high standards in PCB Quality Control. These documents encapsulate the findings from third-party inspections, offering insights into various aspects of the boards, including craftsmanship evaluation, quantity verification, and overall aesthetics. By breaking down these reports methodically, manufacturers can ensure that their products not only meet industry standards but also satisfy customer expectations.

Key Metrics and Findings

When diving into inspection reports, several key metrics stand out that relate directly to PCB Quality Control. Quantity verification is essential; it confirms that the number of boards produced matches what was ordered. Additionally, craftsmanship evaluation focuses on the quality of work—are solder joints clean? Are there any visible defects? Aesthetics also play a role; factors like colour consistency and surface finish are assessed to ensure they align with design specifications.

Documentation is another critical aspect highlighted in these reports. Properly maintained records provide a trail of compliance with industry standards and can be invaluable during audits or future inspections. Field testing and precision measurements are often included as well, ensuring that the boards perform as intended under real-world conditions.

Making Informed Decisions

Interpreting inspection reports allows manufacturers to make informed decisions about their production processes. By analyzing findings related to quantity verification and craftsmanship evaluation, companies can identify specific areas requiring improvement or adjustment in their manufacturing practices. For instance, if multiple boards show issues with aesthetics or colour discrepancies, it may indicate a need for better quality control measures during production.

Moreover, understanding metrics related to shipping marks and packaging can help streamline logistics operations while ensuring product integrity during transit. If packaging fails to meet specifications outlined in the report, it could lead to damage or loss—a risk no manufacturer wants to take! Thus, making decisions based on these insights not only enhances product quality but also protects brand reputation.

Turning Reports into Actionable Insights

Turning inspection report findings into actionable insights is where the real magic happens in PCB Quality Control. After identifying key metrics such as craftsmanship evaluation and aesthetic concerns like colour matching, companies should develop targeted action plans aimed at addressing these issues promptly. This might involve retraining staff on best practices or investing in new technology for enhanced precision measurements.

Additionally, regular reviews of documentation related to past inspections can help establish trends over time—allowing companies to proactively address recurring problems before they escalate into larger issues affecting production quality or customer satisfaction. Shipping marks and packaging should also be revisited regularly; ensuring that all products leave the facility securely packaged minimizes risks associated with transportation.

By embedding these insights into daily operations and fostering a culture focused on continuous improvement based on third-party feedback, organizations will enhance their overall PCB Quality Control efforts significantly.

Conclusion

In the fast-paced world of electronics, ensuring high standards of PCB Quality Control is not just a luxury; it's a necessity. Inspections play a pivotal role in enhancing product quality, as they provide an independent verification of craftsmanship evaluation while ensuring that every detail—from aesthetics to quantity verification—is meticulously examined. By incorporating thorough checks and balances, manufacturers can significantly reduce defects and improve overall reliability.

Enhancing Product Quality with Inspections

The process of PCB Quality Control involves rigorous inspections that focus on various aspects such as craftsmanship evaluation and aesthetics, including colour consistency and finish quality. Such meticulous attention to detail guarantees that products not only function well but also meet visual expectations in the market. Furthermore, proper documentation during inspections plays a crucial role in tracking quality over time, helping companies maintain high standards.

Building Trust with Third-Party Validators

Third-party validators are essential for building trust between manufacturers and consumers by providing objective assessments of PCB Quality Control processes. Their expertise in quantity verification and field testing ensures that products meet industry benchmarks before reaching the market. This transparency fosters confidence among clients who rely on these independent evaluations to validate the integrity of their supply chain.

Future Trends in PCB Quality Control

As technology evolves, so too will the methodologies employed in PCB Quality Control, especially concerning shipping marks and packaging standards. Advanced tools for precision measurements are set to revolutionize how inspections are conducted, making them more efficient and accurate than ever before. Embracing these trends will not only enhance product quality but will also ensure that manufacturers remain competitive in an increasingly demanding marketplace.