Introduction

In the world of industrial operations, the significance of a comprehensive piping inspection cannot be overstated. It serves as a crucial safeguard against potential hazards, ensuring that systems remain efficient and reliable. Regular inspections are not just a regulatory requirement; they are vital for maintaining the integrity of piping systems across various sectors, including construction and food production.

Importance of a Comprehensive Piping Inspection

A thorough piping inspection checklist is essential for identifying wear, corrosion, or any other issues that could compromise safety. Ignoring these inspections can lead to catastrophic failures, resulting in costly downtime and potential harm to personnel. By implementing a robust inspection process, organizations can proactively address problems before they escalate into serious threats.

Ensuring Safety and Compliance

Regular inspections help ensure compliance with health regulations while safeguarding public health by maintaining high-quality production standards. This level of diligence not only protects consumers but also enhances an organization's reputation and trustworthiness.

Key Elements of Quality Control

Quality management in construction projects hinges on effective inspection strategies that encompass different types of inspections tailored to specific needs. From visual checks to non-destructive testing methods, each approach plays a critical role in assessing the condition of piping systems and ensuring they meet stringent quality benchmarks. Moreover, having qualified inspectors who understand the nuances of these techniques is indispensable for achieving optimal results.

Understanding Different Types of Inspections

Each method has its own strengths and applications, tailored to meet specific needs in quality management in construction projects or specialized industries like food production. By familiarizing yourself with these techniques, you can enhance your piping inspection checklist and ensure compliance with industry standards.

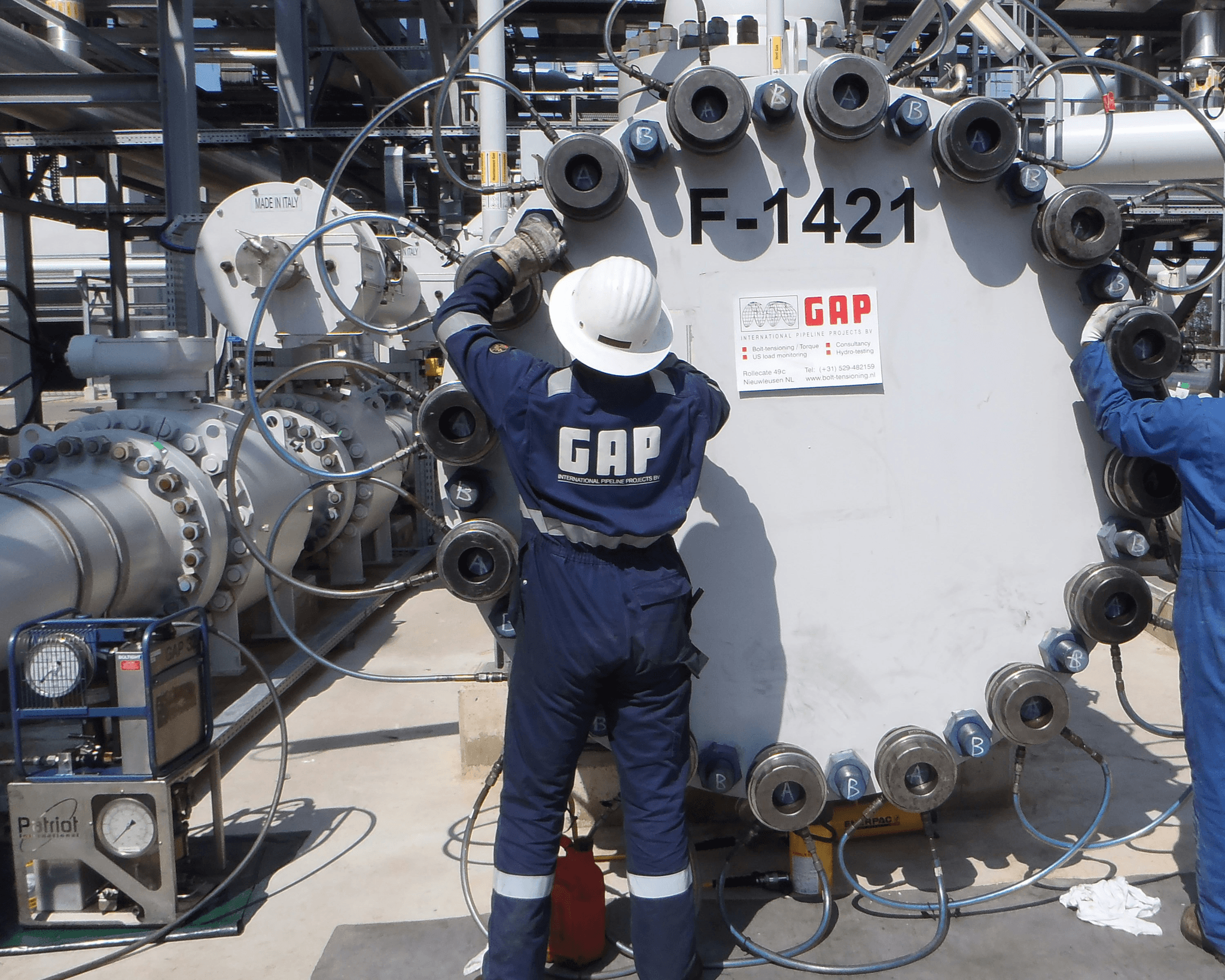

Visual Inspection Techniques

Visual inspection techniques are often the first line of defense in identifying potential issues within piping systems. Inspectors use their keen eyes to spot signs of wear, corrosion, leaks, or other anomalies that could compromise safety and efficiency. This straightforward approach is vital for maintaining quality control in the food industry, where even minor defects can lead to significant compliance issues.

Incorporating visual inspections into your routine can help streamline your piping inspection checklist by providing immediate feedback on system conditions. Inspectors trained in this method can quickly assess a pipeline's integrity without needing complex equipment—making it both time-efficient and cost-effective. However, while visual inspections are valuable, they should be complemented by other testing methods for a comprehensive evaluation.

Non-Destructive Testing Methods

Non-destructive testing (NDT) methods take inspection a step further by allowing inspectors to evaluate materials without causing harm or damage. Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing are commonly used to detect flaws that may not be visible through visual inspection alone. These methods are essential for ensuring that components meet stringent quality standards—especially critical in sectors like construction where structural integrity is paramount.

The use of NDT enhances the reliability of your piping inspection checklist by providing deeper insights into material conditions and potential weaknesses. Moreover, these tests help ensure compliance with regulatory requirements across various industries—including the food sector—where product safety hinges on robust quality control measures. By employing NDT techniques alongside traditional inspections, you create a more comprehensive strategy for assessing piping systems.

Functional Testing Procedures

Functional testing procedures evaluate how well a piping system operates under normal conditions or specific stress scenarios. This type of inspection ensures that all components function correctly together—something that's particularly important when you're producing quality goods and services in any industry setting. By simulating operational environments during these tests, inspectors can identify issues related to pressure drops or flow restrictions before they escalate into larger problems.

Integrating functional tests into your overall quality management strategy not only enhances your piping inspection checklist but also supports proactive maintenance efforts across various sectors—including construction projects where delays can be costly. These procedures help verify that all elements meet performance specifications while complying with health regulations essential in food production contexts as well. Ultimately, functional testing serves as a critical component in safeguarding both product integrity and operational efficiency.

Crafting Your Piping Inspection Checklist

Creating an effective piping inspection checklist is essential for maintaining quality control in the food industry and other sectors. A well-structured checklist not only ensures compliance with safety regulations but also enhances the overall quality management in construction projects. By incorporating various inspection techniques and standards, you can streamline your operations and promote the production of quality goods and services.

Essential Components to Include

When developing a piping inspection checklist, it's crucial to include essential components that address different types of inspections. Start with a section for visual inspections, where inspectors can note any visible signs of wear or damage on pipes and fittings. Additionally, include sections for non-destructive testing methods and functional testing procedures to ensure comprehensive coverage of all potential issues that could impact safety or performance.

Don't forget to incorporate specific criteria relevant to each type of inspectors involved in the process; their expertise will guide what needs special attention during inspections. This tailored approach ensures that your piping inspection checklist is both thorough and efficient, allowing for quick identification of potential problems while adhering to industry standards.

Frequency and Timing of Inspections

The frequency and timing of inspections are vital elements in any piping inspection checklist, especially when considering quality control in the food industry. Regularly scheduled inspections help identify issues before they escalate into costly repairs or safety hazards. Depending on factors such as the type of materials used, environmental conditions, and previous inspection findings, you might opt for weekly, monthly, or quarterly checks.

Moreover, certain situations may call for unscheduled inspections—such as after extreme weather events or following maintenance work—ensuring that any changes are promptly addressed. Establishing a clear timeline not only aids inspectors but also fosters a culture of proactive maintenance within your organization.

Documentation and Reporting Standards

Documentation is a critical aspect of any effective piping inspection checklist; it provides a record that can be referenced later for compliance audits or quality management in construction projects. Establish standardized reporting formats so that findings from different types of inspections are consistently documented across various teams—this promotes clarity and accountability among all involved parties.

In addition to documenting results, it's important to outline how these findings will be communicated within your organization; timely sharing allows stakeholders to make informed decisions regarding necessary actions based on the inspection results. By adhering to robust documentation practices, you create an invaluable resource that supports continuous improvement efforts across all aspects related to your operations.

The Role of Inspectors in Piping Safety

When it comes to ensuring the integrity and safety of piping systems, inspectors play a pivotal role. They are the gatekeepers who ensure that all operations meet stringent standards and regulations. Their expertise not only helps in maintaining compliance but also significantly contributes to the quality management in construction projects and other industries.

Types of Inspectors and Their Expertise

There are various types of inspectors, each specializing in different aspects of piping safety. Some focus on visual inspections, while others utilize advanced techniques such as non-destructive testing methods to assess structural integrity. In specialized sectors like the food industry, inspectors are trained to address unique challenges that arise during production processes, ensuring that every piping inspection checklist is meticulously followed.

The diversity in inspector expertise means that organizations can rely on professionals who understand the specific requirements of their industry. For instance, those involved in the testing of electronic components may have a different skill set compared to those inspecting pipelines for food processing facilities. This specialization ensures that all inspections align with best practices and regulatory standards.

Importance of Certification and Training

Certification and training are crucial for inspectors to perform their roles effectively and confidently. Accredited programs ensure that inspectors are well-versed in current regulations, safety protocols, and inspection methodologies relevant to their field. As industries evolve—especially with innovations impacting quality control in the food industry—ongoing education becomes vital for maintaining high standards.

A certified inspector brings credibility to any inspection process; they not only follow a comprehensive piping inspection checklist but also understand how to adapt it based on specific project needs or regulatory changes. Furthermore, proper training equips them with skills necessary for identifying potential hazards before they escalate into serious issues, thus safeguarding both personnel and products.

Collaboration with Quality Control Teams

Effective collaboration between inspectors and quality control teams is essential for achieving optimal results in any project involving piping systems. By working together closely, these professionals can develop tailored inspection strategies that align with overall project goals while adhering to compliance requirements. This integration fosters a culture where quality management in construction projects becomes seamless.

Quality control teams benefit from having inspectors onboard during critical phases as they can provide real-time insights into the effectiveness of processes being implemented—whether it's related to production of quality goods or services or ensuring safe operational conditions within facilities like food processing plants. Such teamwork enhances overall efficiency by minimizing errors during inspections while maximizing adherence to established standards through comprehensive documentation practices.

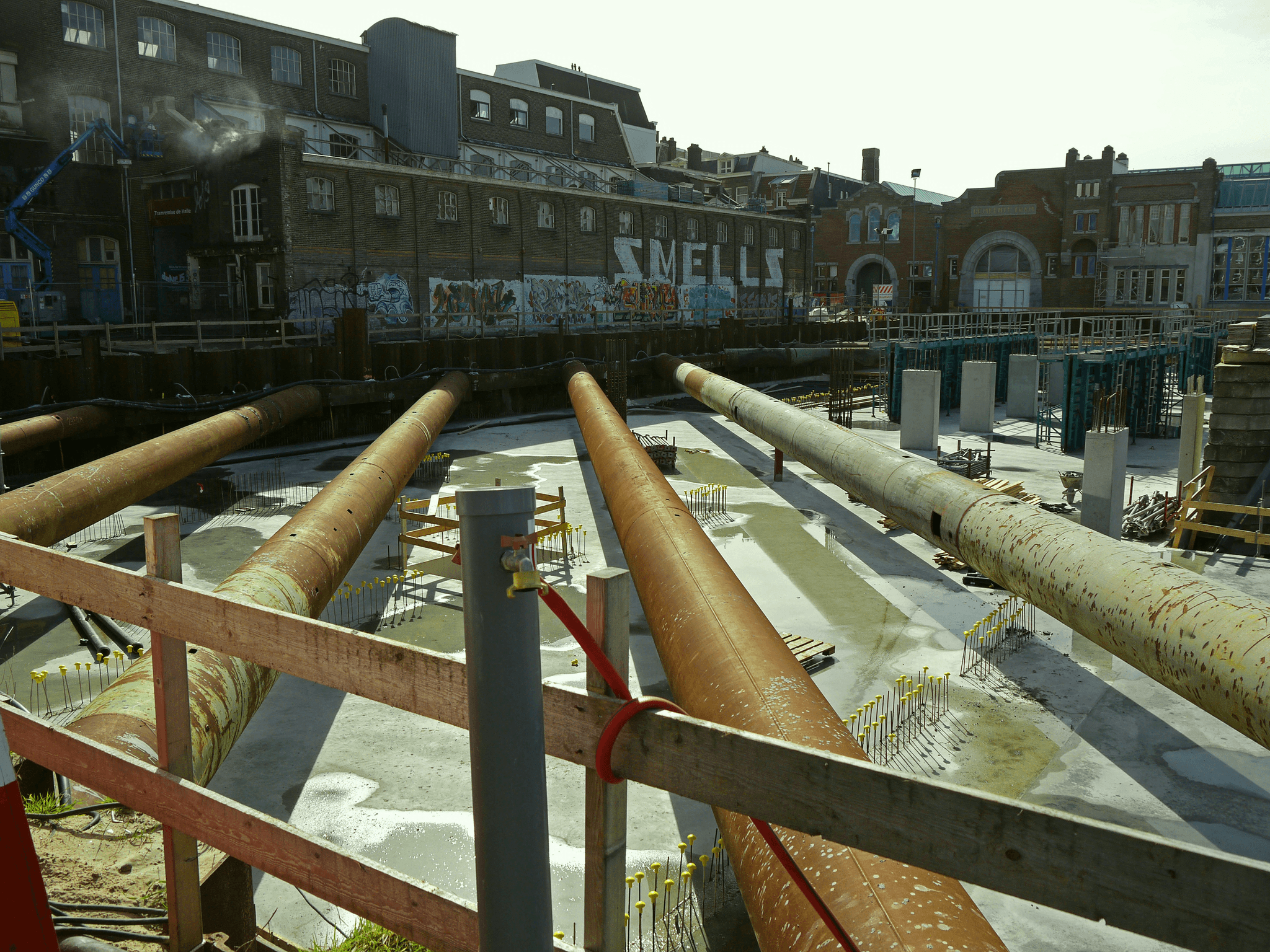

Quality Management in Construction Projects

Quality management in construction projects is not just a box to check; it’s the backbone of delivering reliable and efficient outcomes. Integrating inspections into the workflow ensures that every phase of construction adheres to standards, mitigating risks associated with poor quality. This seamless integration allows for timely identification of issues, ensuring that the end product meets both safety and regulatory requirements.

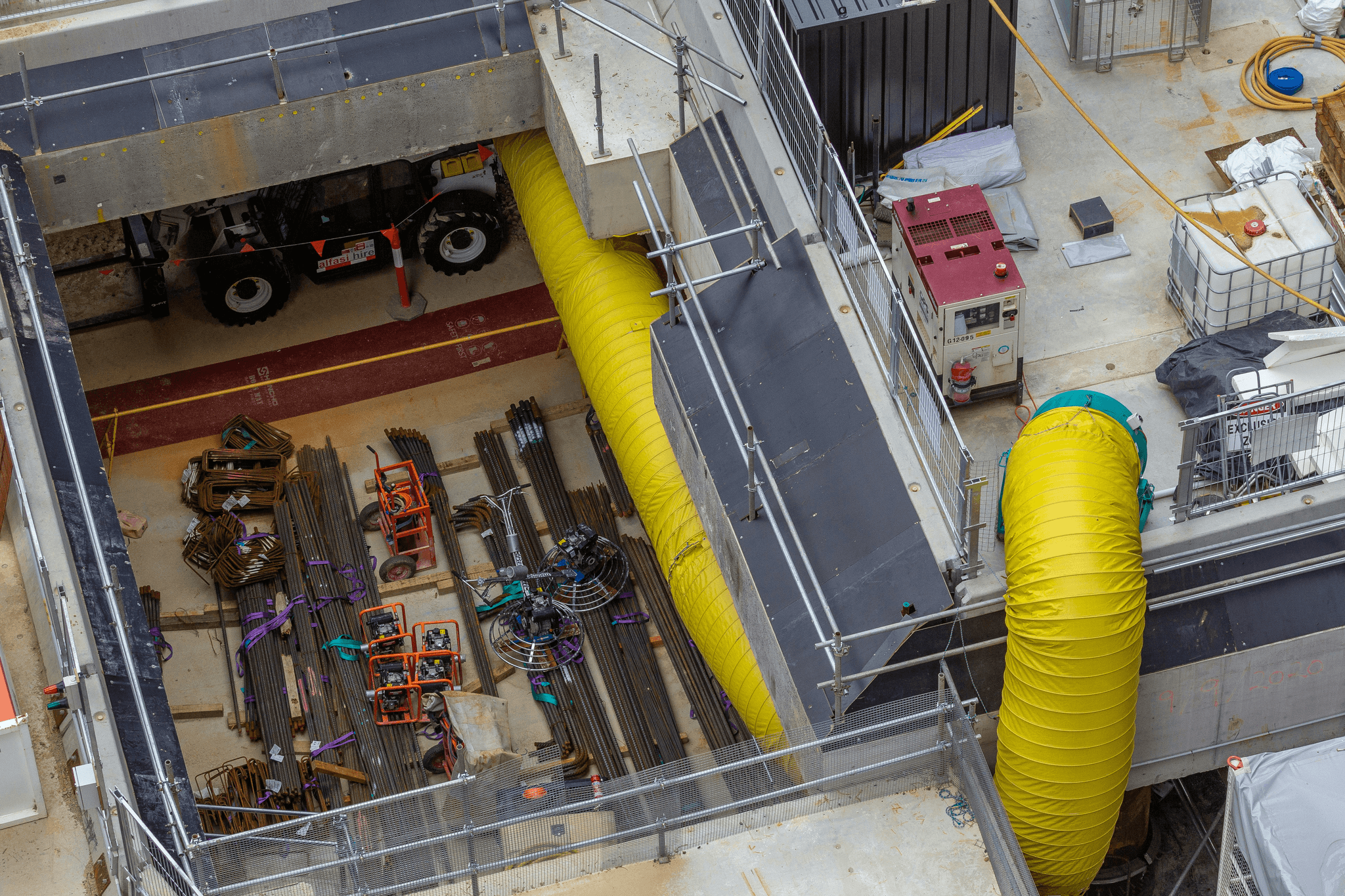

Integrating Inspections into Project Workflow

Integrating a piping inspection checklist into project workflows is crucial for maintaining high standards throughout the construction process. By scheduling inspections at key milestones, teams can catch potential defects early, reducing costly rework down the line. This proactive approach not only enhances quality control but also fosters accountability among team members who are responsible for different types of inspections.

Moreover, collaboration between various stakeholders—including engineers, contractors, and inspectors—ensures that everyone is on the same page regarding quality expectations. Regular meetings can help discuss findings from inspections and adjust workflows accordingly to address any identified concerns. Ultimately, this integration leads to a smoother project flow and higher quality outcomes in construction.

Strategies for Enhancing Quality Control

To elevate quality control in construction projects, employing diverse strategies is essential. First off, implementing a robust training program for different types of inspectors ensures they are well-versed in current standards and practices. This investment in human resources pays dividends as trained inspectors can better identify issues during their assessments.

Another effective strategy involves utilizing technology to streamline inspection processes. Digital tools can help create detailed piping inspection checklists that are easy to update and share among team members—keeping everyone informed about compliance requirements at all times. Additionally, leveraging data analytics allows teams to track performance over time and make informed decisions based on empirical evidence.

Finally, fostering a culture of continuous improvement within teams encourages everyone involved in production of quality goods and services to actively seek out ways to enhance processes further. Regular feedback loops help identify areas ripe for improvement while celebrating successes reinforces positive behaviors across the board.

Case Studies of Successful Quality Management

Examining case studies reveals how effective quality management has transformed construction projects across various industries. One notable example involves a large-scale infrastructure project where integrating inspections into the workflow led to a 30% reduction in defects discovered post-construction compared to previous projects without such measures in place. This significant improvement was largely attributed to comprehensive training programs for inspectors focused on non-destructive testing methods relevant to piping systems.

Another case highlights how one company adopted an innovative approach by combining traditional inspection techniques with advanced testing of electronic components used within their structures—resulting in enhanced reliability and safety measures being implemented from day one of construction activities onward. The success here underscores how embracing diverse strategies contributes directly toward achieving excellence in quality control across all aspects of production.

Lastly, a food industry project showcased how tailored piping inspection checklists addressed unique challenges by ensuring compliance with stringent health regulations while also improving overall efficiency during operations—a win-win situation! Such examples illustrate that when organizations prioritize quality management effectively through strategic planning and execution processes like these—they reap tangible benefits long after completion too!

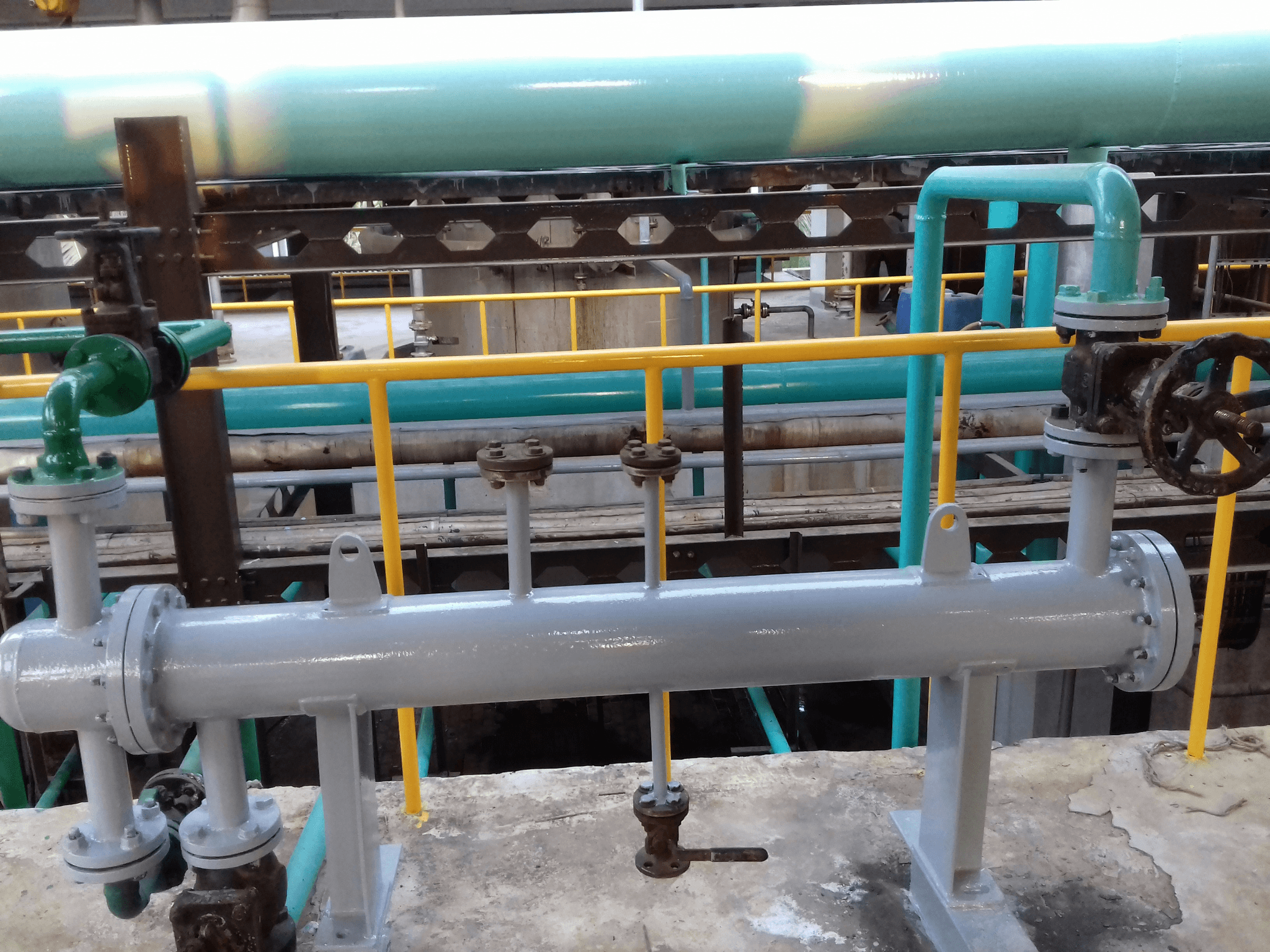

Specialized Inspections in the Food Industry

The food industry presents unique challenges when it comes to piping inspections, primarily due to the stringent quality control standards required for food safety. The complexity of food production processes often involves various types of inspections to ensure that all components meet health regulations and operational efficiency. A well-structured piping inspection checklist can help navigate these challenges, ensuring that every aspect of the production line maintains integrity and adherence to safety protocols.

Unique Challenges in Food Production

In food production, maintaining a clean and safe environment is paramount, which makes piping inspection particularly critical. The presence of contaminants can lead to significant health risks, making it essential for inspectors to be vigilant about every detail during their evaluations. Different types of inspections, such as visual checks and non-destructive testing methods, are employed to identify potential issues before they escalate into larger problems.

Moreover, the fast-paced nature of food production means that any downtime can result in financial losses and compromised product quality. This urgency underscores the need for an efficient piping inspection checklist tailored specifically for this industry’s unique requirements. Inspectors must be equipped with the knowledge and tools necessary to conduct thorough assessments quickly while adhering to strict quality management in construction projects related to food facilities.

Compliance with Health and Safety Regulations

Compliance with health and safety regulations is non-negotiable in the food industry; failure to meet these standards can lead not only to legal repercussions but also harm consumer trust. Inspectors play a vital role in ensuring that all aspects of production comply with local and international safety guidelines through rigorous testing protocols. By utilizing a comprehensive piping inspection checklist, organizations can systematically verify compliance across all areas involved in food processing.

Regular inspections help identify any deviations from established standards early on, allowing businesses to take corrective actions swiftly—essentially preventing costly recalls or shutdowns later down the line. Furthermore, training programs focused on certification are crucial for inspectors who specialize in this field; their expertise ensures that they are well-versed in both regulatory demands and effective inspection techniques tailored for food applications.

The Value of a Tailored Piping Inspection Checklist

A tailored piping inspection checklist is invaluable as it directly addresses specific concerns within the food industry while enhancing overall quality control measures. Such checklists should encompass various elements including material compatibility, cleanliness requirements, and maintenance schedules—all critical factors influencing product quality during manufacturing processes. By customizing these checklists based on individual facility needs or particular types of inspectors involved in assessments, organizations can significantly improve their operational outcomes.

Additionally, having a structured approach allows teams engaged in quality management within construction projects related to new facilities or renovations to maintain consistency across different stages of development. This ensures that all electronic components involved are tested adequately before being put into service; after all, even minor oversights could lead not only to malfunctioning equipment but also compromise product integrity during production cycles. Ultimately, investing time into developing an effective piping inspection checklist will pay dividends by bolstering consumer confidence through consistently high-quality goods and services.

Conclusion

In the world of piping systems, inspections are not just a box to check; they are essential for maximizing efficiency and ensuring that operations run smoothly. A thorough piping inspection checklist is vital for identifying potential issues before they escalate into costly problems. By integrating various types of inspections into your workflow, you can significantly enhance the quality management in construction projects, ultimately leading to the production of quality goods and services.

Maximizing Efficiency Through Inspections

Efficiency in any operation hinges on proactive measures, and inspections play a pivotal role in this process. By utilizing a comprehensive piping inspection checklist, businesses can pinpoint weaknesses in their systems early on and address them promptly. This not only saves time but also minimizes downtime, ensuring that production lines remain operational and efficient.

Essential Takeaways for Better Quality Control

Quality control is paramount across industries, particularly in the food industry where safety regulations are stringent. Implementing different types of inspections—such as visual techniques and non-destructive testing—ensures compliance with health standards while maintaining high-quality outputs. Remember that a well-structured piping inspection checklist can serve as your roadmap to achieving better quality control, making it easier to track compliance and performance over time.

Partnering with Experts like China Inspection Pro

When it comes to navigating the complexities of inspection processes, partnering with experts like China Inspection Pro can be invaluable. Their knowledge about the various types of inspectors ensures that you have access to qualified professionals who understand your industry's unique challenges, especially regarding quality control in the food industry. With their support, you’ll streamline your inspections and elevate your overall quality management practices.