Introduction

In today's competitive manufacturing landscape, visual quality inspection has emerged as a cornerstone of effective quality assurance. As businesses strive to meet ever-increasing customer expectations, the integration of robust QA practices becomes essential. By investing in QA quality assurance measures, companies can not only enhance product reliability but also build a reputation for excellence.

Understanding Visual Quality Inspection

Visual quality inspection refers to the systematic process of examining products for defects or deviations from specified standards using human observation and technology. This method is crucial in identifying issues early in the production cycle, thereby minimizing waste and ensuring that only top-quality products reach customers. The importance of visual quality inspection cannot be overstated; it serves as a frontline defense against defects that could tarnish a brand’s reputation.

The Role of Quality Assurance in Manufacturing

Quality assurance plays an integral role in manufacturing by establishing processes that ensure products meet predetermined standards throughout their lifecycle. It encompasses various methodologies, including visual quality inspection, which helps maintain consistency and reliability across production lines. By prioritizing QA quality practices, manufacturers can significantly reduce errors and enhance overall operational efficiency.

Why Invest in QA Quality Practices

Investing in QA quality practices is not just about compliance; it's about fostering a culture of excellence within an organization. Companies that prioritize visual quality inspection and other QA assurance methods often experience lower defect rates and increased customer satisfaction. Ultimately, this investment translates into long-term financial benefits, making it a smart move for any manufacturer aiming for success.

The Basics of Visual Quality Inspection

Visual quality inspection is a critical aspect of quality assurance in manufacturing and production processes. It involves the careful examination of products or components to ensure they meet specified standards and requirements. By implementing effective visual quality inspection practices, companies can enhance their overall qa quality assurance efforts, leading to reduced defects and improved customer satisfaction.

Definition and Importance

Visual quality inspection refers to the process of evaluating products by sight to identify any defects or deviations from established standards. This practice is essential because it serves as the first line of defense against poor-quality goods reaching consumers, which can harm a brand's reputation. In the realm of qa assurance, effective visual inspections contribute significantly to maintaining high-quality standards and ensuring compliance with industry regulations.

Key Techniques for Effective Inspection

There are several techniques that can enhance the effectiveness of visual quality inspection in various industries. One popular method is the use of standardized checklists that help inspectors systematically evaluate each product against specific criteria. Additionally, employing techniques such as controlled lighting conditions and magnification tools can significantly improve defect detection during inspections, making them more reliable for quality assurance purposes.

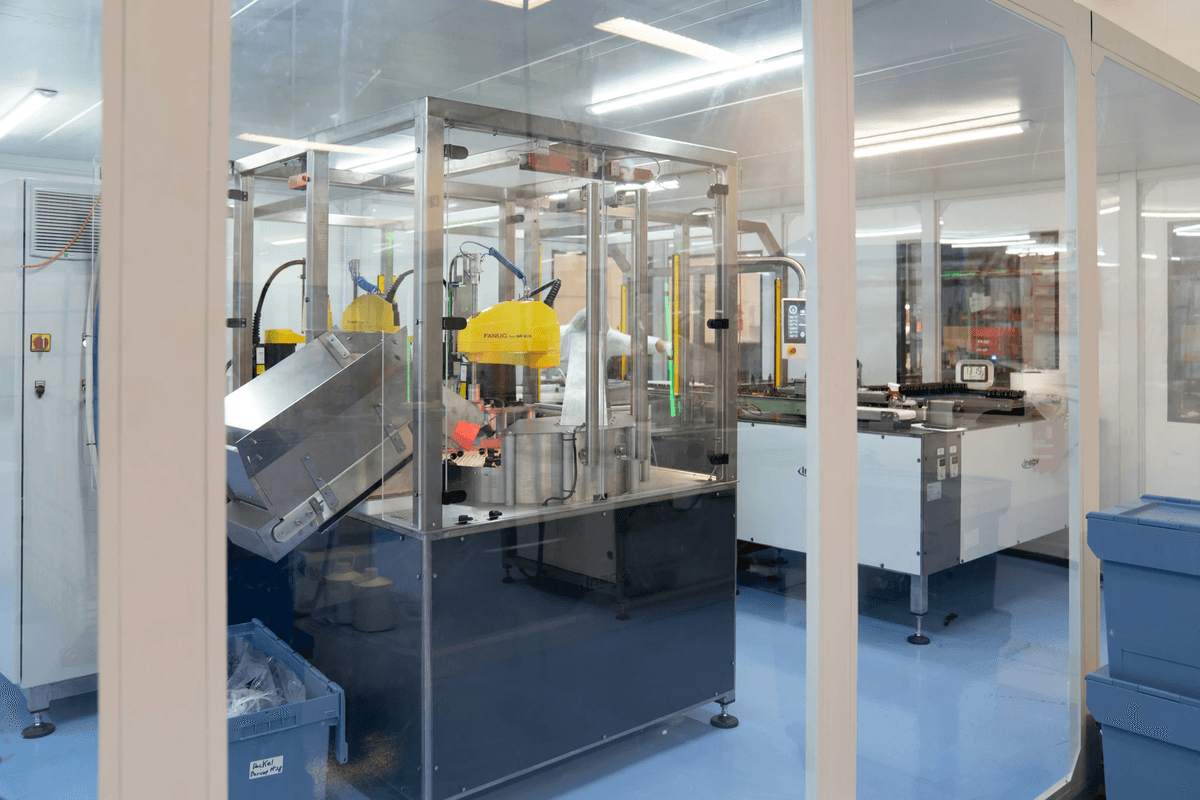

Common Tools and Technologies

The landscape of visual quality inspection has evolved with advancements in technology, leading to a variety of tools designed to streamline this process. Common tools include magnifying lenses, digital cameras for detailed imaging, and specialized lighting setups that highlight imperfections on surfaces. Moreover, integrating software solutions into qa quality processes allows teams to track inspection results efficiently while ensuring consistent adherence to qa quality standards.

Integrating Technology into Visual Inspection

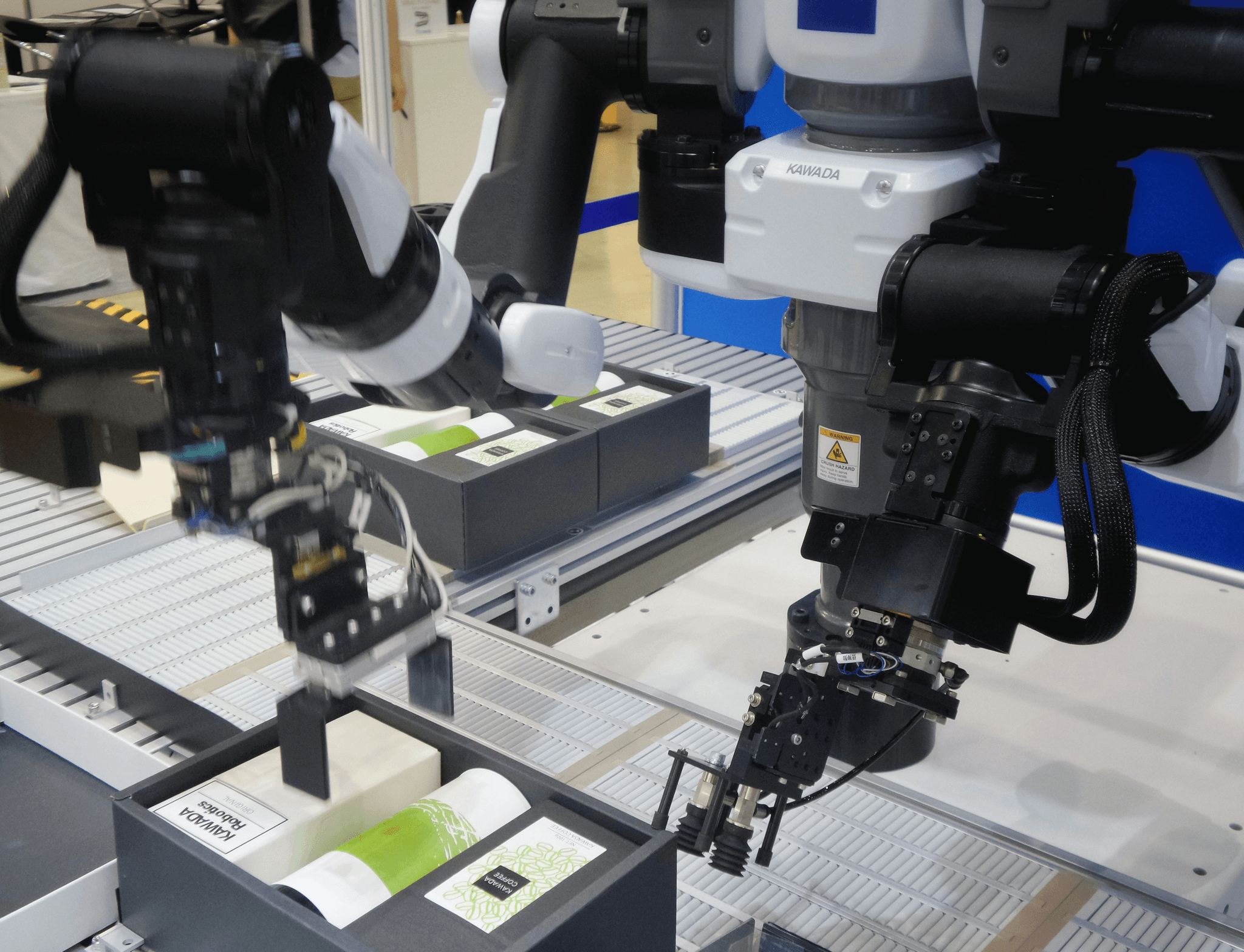

In today's fast-paced manufacturing environment, integrating technology into visual quality inspection processes is not just a luxury—it's a necessity. Automated inspection systems are revolutionizing the way quality assurance (QA) is approached, enhancing both efficiency and accuracy. By leveraging cutting-edge technologies, manufacturers can ensure that their QA quality assurance practices meet the highest standards.

Benefits of Automated Inspection Systems

Automated inspection systems provide numerous benefits that significantly enhance visual quality inspection efforts. First and foremost, they deliver consistent results by eliminating human error, which can often lead to oversight in manual inspections. Furthermore, these systems operate at high speeds, allowing for increased throughput without sacrificing the quality and assurance required in manufacturing.

Another key advantage is data collection; automated systems continuously gather data during inspections, providing valuable insights into production trends and potential issues. This data-driven approach supports ongoing improvements in QA quality practices over time. Ultimately, investing in automation not only boosts productivity but also reinforces a culture focused on maintaining high-quality standards.

Case Studies of Successful Implementations

Several companies have successfully integrated automated inspection technology into their visual quality inspection processes, yielding impressive results. For instance, a leading automotive manufacturer adopted an advanced vision system to monitor assembly line components for defects. This implementation reduced inspection times by 50%, while also enhancing detection rates for critical flaws—demonstrating a clear win for both efficiency and quality assurance.

In another example, a consumer electronics company utilized machine learning algorithms within their QA quality assurance framework to analyze product defects in real-time. By doing so, they were able to identify recurring issues much faster than traditional methods allowed. These case studies highlight how embracing technology can lead to significant improvements in overall product quality and operational efficiency.

How to Choose the Right Technology

Selecting the right technology for visual quality inspection requires careful consideration of several factors related to your specific needs and production environment. First and foremost, assess your current QA quality practices; understanding where improvements are needed will guide you toward suitable solutions that align with your goals for both efficiency and effectiveness in inspections.

Next, consider scalability; as your production demands evolve or expand over time, the chosen system should be adaptable enough to accommodate growth without requiring complete overhauls of existing infrastructure or processes. Finally, don't overlook user-friendliness; ensuring that your team can easily operate new technologies will facilitate smoother integration into existing workflows while maximizing the benefits of automation within your QA assurance efforts.

Building a Quality Assurance Culture

Creating a robust quality assurance culture is essential for any organization focused on visual quality inspection. This culture not only strengthens the foundation of QA practices but also empowers employees to take ownership of their roles in ensuring quality and assurance. By fostering an environment where quality is prioritized, companies can significantly enhance their overall performance.

Training Your Team on QA Quality Standards

Training your team on QA quality standards is the cornerstone of effective visual quality inspection. Regular training sessions ensure that all employees understand the critical aspects of quality assurance, from identifying defects to adhering to established protocols. Moreover, well-trained staff are more likely to embrace QA practices and contribute positively to the overall culture of continuous improvement.

Implementing hands-on workshops can further reinforce these standards, allowing team members to practice real-life scenarios in a controlled setting. This practical approach not only builds confidence but also encourages collaboration among team members as they learn from one another's experiences. Ultimately, investing in training pays off by reducing errors and enhancing product reliability through diligent adherence to QA principles.

Encouraging a Quality-First Mindset

To truly embed a culture of quality assurance within your organization, it’s crucial to cultivate a quality-first mindset among all employees involved in visual quality inspection. This mindset should encourage everyone—from management down to frontline workers—to prioritize quality over speed or cost-cutting measures. When employees recognize that their contributions directly impact both customer satisfaction and company reputation, they become more engaged and motivated.

Promoting open discussions about the importance of QA practices helps reinforce this mindset further, allowing team members to share insights and challenges they face during inspections. Additionally, incorporating regular feedback sessions can provide valuable insights into potential areas for improvement while celebrating successes fosters camaraderie among staff members committed to excellence in quality assurance. Emphasizing this cultural shift ensures that every employee feels responsible for maintaining high-quality standards.

Recognizing and Rewarding Quality Achievements

Recognizing and rewarding achievements related to visual quality inspection is vital for sustaining motivation within your QA teams. When individuals or teams reach specific milestones or demonstrate exceptional commitment to qa assurance practices, acknowledging their efforts reinforces the importance of maintaining high-quality standards across the board. Celebrating these achievements—whether through formal awards or informal shout-outs—creates an atmosphere where excellence becomes contagious.

Implementing a recognition program tailored specifically for qa quality accomplishments allows organizations not only to highlight individual efforts but also promotes healthy competition among teams striving for superior results in their inspections. Furthermore, sharing success stories within the organization can inspire others while demonstrating tangible benefits derived from prioritizing qa quality assurance initiatives effectively throughout operations.

In conclusion, building a strong culture around visual inspection requires comprehensive training programs alongside encouragement towards adopting a proactive approach towards ensuring consistent levels of excellence across all aspects related directly back into qa processes themselves—resulting ultimately in better products delivered reliably time after time!

Enhancing Communication for Quality Assurance

Effective communication is the bedrock of successful quality assurance practices, particularly in visual quality inspection. Clear reporting not only ensures that everyone is on the same page but also helps to identify issues before they escalate into more significant problems. When teams prioritize transparency in their QA quality assurance processes, they cultivate an environment where quality and assurance thrive.

The Importance of Clear Reporting

In the realm of visual quality inspection, clear reporting is crucial for tracking performance and identifying trends over time. Reports should be concise yet comprehensive, detailing inspection results while highlighting areas needing improvement within the QA quality framework. When stakeholders receive well-structured reports, they can make informed decisions that enhance overall product quality and ensure compliance with industry standards.

Moreover, clear reporting fosters accountability among team members involved in QA assurance activities. When everyone understands their roles and responsibilities through detailed documentation, it minimizes misunderstandings and promotes a culture of ownership regarding quality outcomes. As a result, organizations can drive continuous improvement initiatives more effectively by leveraging insights gained from accurate reporting.

Incorporating Feedback Loops

Integrating feedback loops into your visual quality inspection process can significantly enhance your overall QA quality performance. By establishing mechanisms for collecting input from various stakeholders—such as inspectors, production staff, and management—you create opportunities for ongoing dialogue about what works and what doesn’t in your QA assurance practices. This two-way communication not only empowers employees but also encourages a proactive approach to problem-solving.

Feedback loops help identify patterns or recurring issues that may otherwise go unnoticed without regular input from those directly involved in the inspection process. By addressing these concerns promptly, teams can implement corrective actions swiftly to improve product quality continuously. Furthermore, fostering an environment where feedback is valued cultivates trust within the organization—a vital component of any effective QA culture.

Collaborative Tools for QA Teams

The right collaborative tools can revolutionize how teams approach visual quality inspection and overall QA processes. Utilizing platforms designed for real-time communication allows team members to share insights quickly and efficiently while streamlining documentation related to inspections and findings within their QA assurance strategies. These tools not only facilitate better collaboration but also ensure that all relevant information regarding product quality is readily accessible.

Additionally, many modern collaborative tools offer features such as data visualization dashboards or integration with automated systems used during inspections—making it easier than ever to analyze trends in your QA efforts over time. By harnessing technology effectively within your team’s workflow, you create an agile environment where rapid responses to emerging issues become second nature rather than a chore requiring extra effort or resources. Ultimately, investing in these collaborative solutions enhances both individual accountability and collective responsibility toward maintaining high standards of visual quality inspection.

Leveraging Data for Continuous Improvement

In the realm of visual quality inspection, data is a goldmine waiting to be tapped. By meticulously analyzing inspection results, organizations can identify trends, pinpoint recurring issues, and enhance their overall quality assurance processes. This data-driven approach not only elevates the standards of QA quality assurance but also fosters a culture of continuous improvement that is essential in today’s competitive manufacturing landscape.

Analyzing Inspection Results

Analyzing inspection results involves more than just reviewing numbers; it’s about uncovering insights that can drive quality and assurance initiatives forward. By employing statistical tools and methodologies, teams can dissect visual quality inspection outcomes to understand where defects are occurring and why. This deep dive into data allows for targeted interventions that improve both the efficiency and effectiveness of QA quality practices.

Moreover, regular analysis helps establish benchmarks for performance, enabling teams to measure their progress over time. By continuously monitoring these metrics, organizations can adapt their QA assurance strategies to address emerging challenges in real-time. Ultimately, this proactive approach ensures that quality remains at the forefront of manufacturing operations.

Using Data to Drive Quality Assurance Strategies

Once inspection results are analyzed, the next step is leveraging this information to inform strategic decisions within QA quality assurance frameworks. Data-driven strategies empower organizations to allocate resources more effectively, streamline operations, and reduce waste—all while maintaining high standards of visual quality inspection. The integration of real-time data analytics into decision-making processes ensures that every action taken is backed by solid evidence.

Furthermore, utilizing predictive analytics allows companies to foresee potential issues before they arise—essentially turning reactive measures into proactive solutions. By understanding patterns in defect occurrences through historical data analysis, businesses can implement preventive measures that significantly enhance their overall quality assurance efforts. Thus, using data not only optimizes current practices but also lays a robust foundation for future innovations in qa quality management.

Success Stories from Industry Leaders

Numerous industry leaders have harnessed the power of data in their visual quality inspection processes with remarkable success stories showcasing tangible benefits from effective QA practices. For instance, a leading automotive manufacturer integrated advanced analytics into its production line inspections and reported a 30% reduction in defect rates within six months—transforming its approach to qa assurance entirely. This shift not only improved product reliability but also enhanced customer satisfaction significantly.

Another example comes from an electronics company that utilized machine learning algorithms on its visual inspection systems; they were able to identify defects at unprecedented speeds while simultaneously reducing human error rates by over 40%. These success stories highlight how leveraging data effectively can revolutionize traditional approaches within QA quality environments and lead to substantial improvements across various sectors.

In conclusion, embracing a culture centered around leveraging data for continuous improvement is vital for any organization committed to excellence in visual quality inspection and overall qa assurance practices.

Conclusion

In wrapping up our discussion on visual quality inspection, it's clear that the integration of robust quality assurance practices is not just beneficial but essential for manufacturing success. The emphasis on qa quality assurance ensures that products meet the highest standards, minimizing defects and enhancing customer satisfaction. By understanding the nuances of quality and assurance, organizations can foster a culture of excellence that permeates every level of their operations.

Key Takeaways for Visual Inspection Success

The key takeaways from our exploration of visual quality inspection highlight the importance of embracing both technology and a proactive mindset in qa quality practices. Effective visual inspection techniques, combined with automated systems, can significantly reduce human error and increase efficiency in production lines. Additionally, fostering a culture where quality is prioritized encourages employees to take ownership of their work, leading to continuous improvement in overall product quality.

The Future of Quality Assurance Practices

Looking ahead, the future of qa assurance is poised for exciting advancements driven by technology and data analytics. With the rise of artificial intelligence and machine learning in visual inspection processes, manufacturers can expect more accurate assessments and quicker turnaround times. This evolution will not only streamline operations but also redefine what we consider to be best practices in quality assurance across various industries.

Partnering with Experts like China Inspection Pro

To truly excel in visual quality inspection and ensure top-notch qa quality standards, partnering with experts like China Inspection Pro can be a game-changer for businesses. Their wealth of experience in implementing effective qa quality assurance strategies allows companies to leverage best practices tailored to their unique needs. Collaborating with such specialists ensures that your organization remains competitive while maintaining rigorous standards for product integrity.