Introduction

In today's competitive landscape, the importance of a quality company cannot be overstated. Companies that prioritize quality not only enhance their reputation but also foster customer loyalty and satisfaction. As consumers become more discerning, businesses must adapt to meet these expectations, making quality control an essential element of their operations.

Importance of a Quality Company

A quality company stands out in the marketplace by consistently delivering products and services that meet or exceed customer expectations. This commitment to excellence is often reflected in robust quality control processes, including the use of advanced quality control monitoring equipment. By investing in these tools, companies can ensure that they maintain high standards throughout production and quality assurance.

The Rising Demand for Quality Control

With globalization and technological advancements reshaping industries, the demand for effective quality control has surged. Businesses are increasingly recognizing that rigorous supplier audits and comprehensive types of quality inspection are crucial for maintaining product integrity. As a result, there is a growing emphasis on implementing strategies like AQL C=0 to minimize defects and ensure compliance with industry standards.

Challenges in Production and Quality

Despite the clear benefits of prioritizing quality, many companies face significant challenges in production and maintaining high-quality standards. Issues such as inconsistent supplier performance and inadequate factory audit checklists can lead to costly mistakes and product recalls. To navigate these hurdles successfully, organizations must adopt a proactive approach to quality management that encompasses thorough inspections and continuous improvement initiatives.

Understanding Quality Control Monitoring Equipment

In today's fast-paced manufacturing landscape, the significance of quality control monitoring equipment cannot be overstated. A quality company recognizes that investing in advanced technology is crucial for maintaining high production and quality standards. As consumer expectations rise, so does the need for effective tools that ensure every product meets rigorous quality benchmarks.

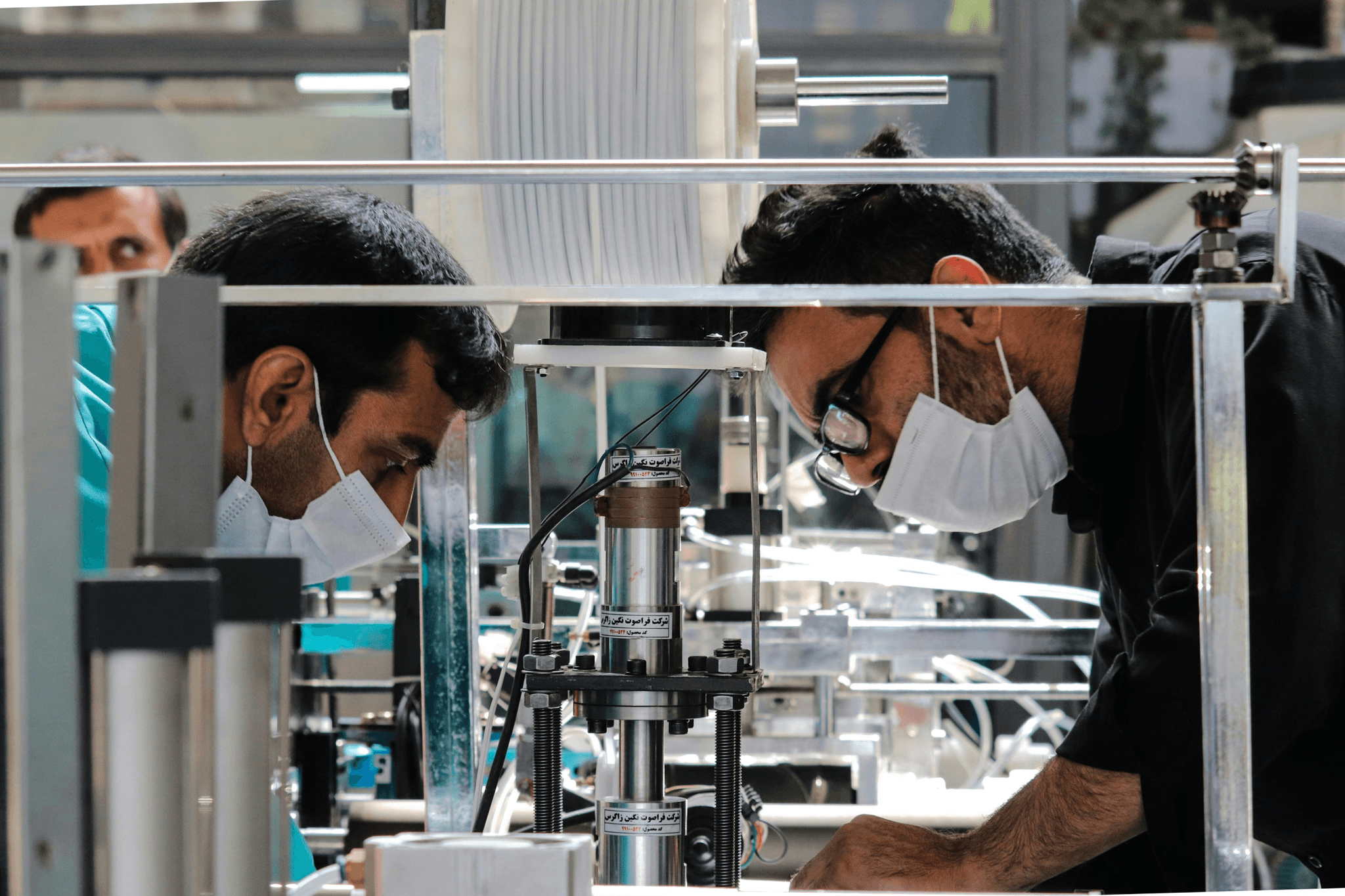

The Role of Technology in Quality Assurance

Technology plays a pivotal role in enhancing quality assurance processes across various industries. By utilizing state-of-the-art quality control monitoring equipment, businesses can automate inspections and streamline workflows, resulting in improved efficiency and accuracy. Moreover, real-time data collection allows companies to identify issues promptly, reducing the risk of defective products reaching consumers.

Key Features of Effective Monitoring Tools

Effective monitoring tools come equipped with several key features that set them apart from basic alternatives. These include user-friendly interfaces, advanced analytics capabilities, and integration options with existing systems—essential for any quality company striving to maintain high standards. Additionally, flexibility in handling different types of quality inspection methods ensures that manufacturers can adapt to diverse production needs without compromising on quality.

Impact on Production and Quality

The impact of robust quality control monitoring equipment on production and quality is profound. With reliable systems in place, companies can minimize waste and enhance productivity while ensuring compliance with standards like AQL C=0 during inspections. Ultimately, this leads to a more efficient operation where suppliers are held accountable through thorough supplier audits based on precise data collected from these monitoring tools.

Supplier Audits: A Crucial Step

In the quest for maintaining high production and quality, conducting supplier audits emerges as a pivotal strategy. These audits serve as a quality control monitoring equipment in the broader sense, ensuring that suppliers adhere to the standards expected of a quality company. By evaluating suppliers systematically, businesses can mitigate risks and enhance overall product integrity.

The Benefits of Conducting Supplier Audits

Supplier audits offer numerous benefits that extend beyond mere compliance checks. First and foremost, they provide insights into the operational practices of suppliers, helping to identify potential weaknesses in their processes that could impact production and quality. Additionally, these audits can foster stronger relationships between companies and their suppliers by promoting transparency and collaboration.

Moreover, conducting regular supplier audits can lead to significant cost savings over time. By identifying inefficiencies or non-compliance early on, companies can avoid costly recalls or rework later in the production cycle. Ultimately, these audits not only enhance trust but also ensure that all parties are aligned with the company’s standards for quality control monitoring equipment.

How to Effectively Evaluate Suppliers

Evaluating suppliers effectively requires a structured approach that incorporates various types of quality inspection methods tailored to specific needs. Start by developing clear criteria based on your company’s unique requirements; this could include aspects like production capabilities, adherence to safety standards, or previous audit results. Utilizing tools such as a factory audit checklist can streamline this process by ensuring all critical areas are assessed thoroughly.

Next, engage in direct observation during site visits or inspections to gather firsthand information about their operations. This hands-on approach allows you to assess not just what is documented but also how processes are executed in real-time—a crucial element when considering factors like AQL C=0 standards for product acceptance levels. Remember, effective communication during evaluations is key; it helps clarify expectations while building rapport with supplier representatives.

Finally, involve cross-functional teams within your organization during evaluations for a holistic perspective on each supplier’s capabilities and risks associated with them. This collaboration ensures that insights from various departments—such as production and quality assurance—are factored into decision-making processes regarding supplier selection.

Integrating Audit Findings into Procurement

Once you have gathered data from your supplier audits, integrating those findings into procurement strategies is essential for driving continuous improvement within your supply chain management process. Start by analyzing audit results alongside existing performance metrics; this will help identify trends or recurring issues that need addressing across different suppliers involved in your production line.

Additionally, leverage audit findings to refine your criteria for future supplier selection; this will ensure you’re partnering with those who meet the rigorous demands of being classified as a quality company committed to excellence in production and quality controls. Moreover, communicating these findings back to suppliers fosters accountability while encouraging them to align more closely with your expectations moving forward.

Lastly, consider implementing regular follow-ups or re-audits based on previous findings—especially if certain areas were flagged during initial assessments using types of quality inspections like visual checks or functional testing methods related to AQL C=0 compliance levels. By doing so, you create an ongoing dialogue about performance improvements while reinforcing the importance of maintaining high-quality standards throughout your supply chain.

Exploring Types of Quality Inspection

Quality inspection is a cornerstone of ensuring that a quality company meets the standards expected by consumers and regulatory bodies alike. With various types of quality inspection available, understanding the nuances can significantly impact production and quality outcomes. By leveraging effective quality control monitoring equipment, businesses can enhance their inspection processes, leading to more reliable products.

Different Methods of Quality Inspection Explained

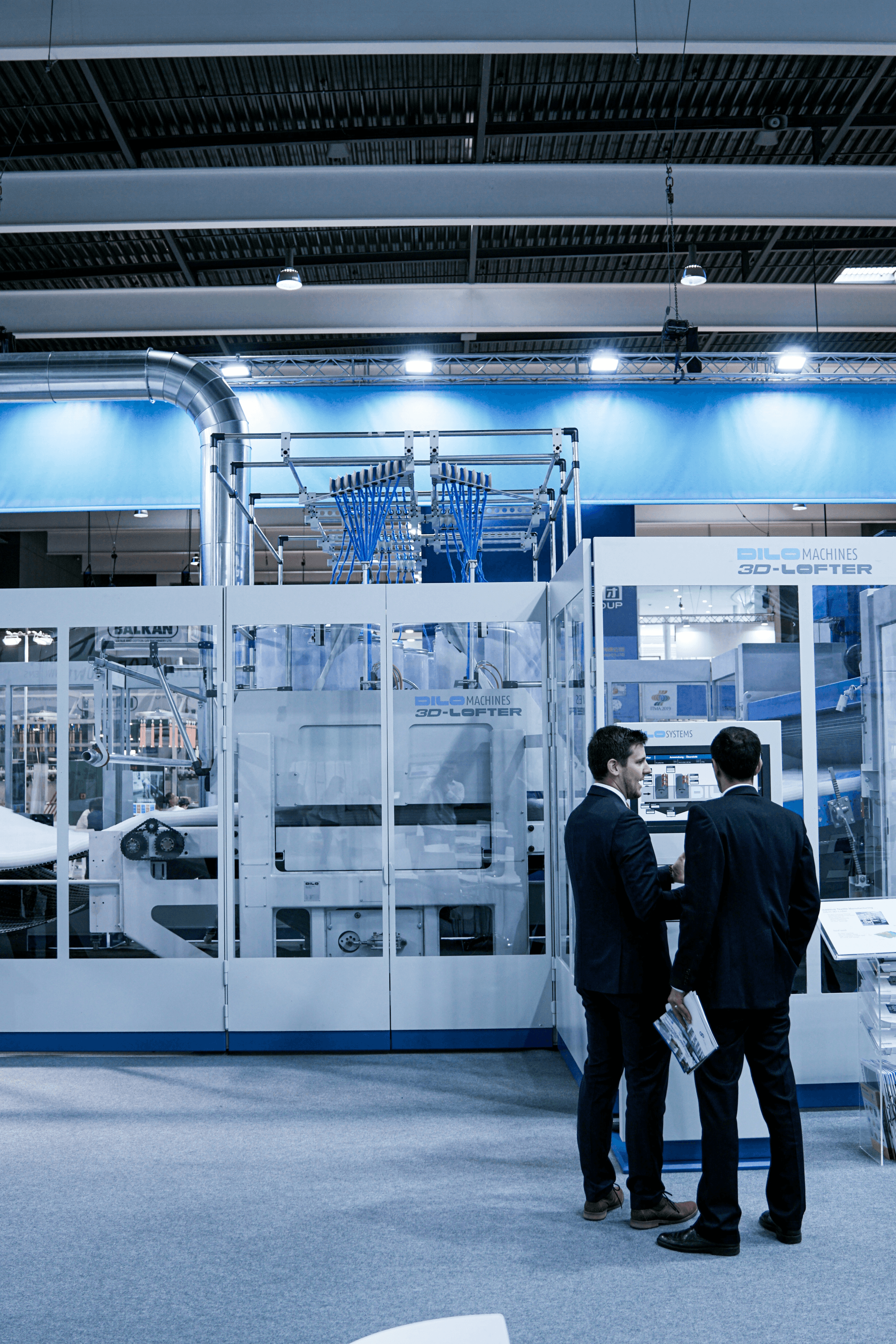

There are several methods to conduct quality inspections, each tailored to specific needs and contexts within production and quality management. Visual inspections involve checking products for visible defects, while measurement-based inspections utilize tools to ensure items conform to specified dimensions or tolerances. Destructive testing is another method where samples are tested until failure, providing insights into material durability but at the cost of losing those samples.

In addition to these traditional methods, automated inspections using advanced technology have emerged as game-changers in the industry. Quality control monitoring equipment such as cameras and sensors can quickly assess products on assembly lines without human intervention, improving efficiency and accuracy. Ultimately, selecting the right method depends on your specific requirements, product type, and the level of risk you're willing to accept.

Selecting the Right Type for Your Needs

Choosing the appropriate type of quality inspection is vital for any quality company aiming for excellence in production and quality assurance. Factors such as product complexity, volume produced, and potential risks associated with defects should guide your decision-making process. For instance, if you're dealing with high-stakes items like medical devices or aerospace components, more rigorous types like AQL C=0 inspections may be warranted.

On the other hand, for less critical products where minor defects won't lead to significant issues or safety concerns, simpler visual inspections might suffice. It's essential to balance thoroughness with practicality; over-inspecting can lead to increased costs without proportional benefits. By carefully analyzing your needs against available inspection types—like supplier audits or factory audit checklists—you can optimize both efficiency and effectiveness.

Real-World Examples of Quality Inspections

Real-world applications illustrate how different types of quality inspection play out in various industries today—often with impressive results! In electronics manufacturing, companies frequently use automated optical inspection (AOI) systems that rapidly scan circuit boards for defects before they proceed further down the line—saving time while ensuring high-quality outputs. This approach demonstrates how integrating technology into your processes can elevate overall product integrity.

Similarly, in food production environments where safety is paramount, regular supplier audits coupled with stringent hygiene checks ensure compliance with health regulations while maintaining product standards. These proactive measures not only safeguard consumers but also bolster a company's reputation as a reliable provider within its market sector—a true hallmark of a quality company! Lastly, implementing AQL C=0 standards has proven successful in textile manufacturing by reducing returns due to defects significantly.

The AQL C=0 Standard Explained

In the realm of quality control, understanding the Acceptance Quality Limit (AQL) is crucial for any quality company striving to maintain high standards. AQL defines the maximum number of defective items considered acceptable in a sample batch, ensuring that production and quality meet customer expectations. Among various AQL standards, C=0 is particularly noteworthy as it mandates zero defects, pushing companies to achieve impeccable quality.

Understanding Acceptance Quality Limit (AQL)

Acceptance Quality Limit (AQL) serves as a benchmark that helps organizations gauge the level of defects permissible in their products without compromising overall quality. This statistical measurement allows businesses to balance risk and cost while ensuring that their products meet required specifications. By implementing effective quality control monitoring equipment aligned with AQL principles, companies can enhance their inspection processes and reduce the likelihood of defective goods reaching consumers.

Importance of AQL C=0 in Quality Control

The significance of the AQL C=0 standard cannot be overstated; it represents a commitment to excellence by demanding that no defects are allowed in production batches. For a quality company, adhering to this stringent standard not only enhances brand reputation but also fosters customer trust and loyalty. Moreover, integrating this approach into supplier audits ensures that all partners align with the same uncompromising standards, thereby elevating overall production and quality across the supply chain.

Success Stories of Implementing AQL

Numerous organizations have reaped substantial benefits from implementing the AQL C=0 standard within their operations. For instance, a leading electronics manufacturer adopted this strict approach during its supplier audits and witnessed a dramatic reduction in product returns due to defects—an impressive feat for any quality company. Similarly, a prominent automotive firm leveraged types of quality inspection rooted in AQL principles, resulting in enhanced safety ratings and increased consumer satisfaction.

Factory Audit Checklist Essentials

When it comes to ensuring that a quality company meets production and quality standards, a well-structured factory audit checklist is essential. This checklist serves as a roadmap for auditors, guiding them through the critical areas of assessment to verify compliance with quality control monitoring equipment and procedures. By having a comprehensive checklist in place, organizations can streamline their audits and avoid overlooking vital components.

Key Components of a Comprehensive Checklist

A thorough factory audit checklist should encompass several key components that reflect the operational realities of the facility being assessed. First, it should include sections dedicated to evaluating supplier audits, focusing on documentation accuracy, adherence to specifications, and overall performance metrics. Additionally, it must address types of quality inspection relevant to the production process—whether visual checks or more sophisticated testing methods are employed—to ensure all aspects of quality control are monitored effectively.

Another crucial element is assessing compliance with standards like AQL C=0, which directly impacts how products are accepted or rejected based on their defect rates. The checklist should also cover equipment maintenance records related to quality control monitoring equipment and employee training protocols to guarantee that staff are well-versed in maintaining high-quality standards throughout production cycles. By integrating these elements into the checklist, companies can achieve a holistic view of their operations.

How to Prepare for a Factory Audit

Preparation is half the battle when it comes to conducting a successful factory audit. First and foremost, ensure that all team members involved understand the goals of the audit and what specific areas will be evaluated according to your factory audit checklist. This includes familiarizing them with any relevant regulations or standards related to production and quality so everyone is on the same page regarding expectations.

Next, gather all necessary documentation beforehand—this includes previous audit reports, supplier contracts, records relating to types of quality inspection conducted in past audits, and maintenance logs for any quality control monitoring equipment used in production processes. Having this information readily available not only expedites the auditing process but also demonstrates transparency and commitment to maintaining high-quality standards.

Finally, conduct mock audits if possible; this practice will help identify potential weaknesses before the actual evaluation takes place. It’s an excellent way for teams to familiarize themselves with both the factory audit checklist components and any specific requirements tied into AQL C=0 standards or other regulatory benchmarks.

Common Pitfalls and How to Avoid Them

Even with careful planning, pitfalls can arise during factory audits that may compromise their effectiveness. One common issue is failing to involve key stakeholders from various departments early in the process; this oversight can lead to incomplete assessments or missed opportunities for improvement regarding supplier audits or types of quality inspection needed for certain products. Engaging cross-functional teams ensures diverse perspectives contribute toward achieving comprehensive evaluations.

Another frequent mistake is neglecting follow-up actions after an audit has been completed; simply checking items off your factory audit checklist without addressing identified issues undermines its purpose entirely! Establishing clear action plans based on findings—including timelines for resolution—can help maintain momentum toward continuous improvement in production processes while adhering strictly to established AQL C=0 criteria.

Lastly, don’t underestimate human error! Ensure that personnel responsible for conducting inspections using your quality control monitoring equipment receive adequate training so they’re equipped with skills necessary not just during audits but throughout regular operations too! With these preventive measures in mind—and by utilizing an effective factory audit checklist—you’ll be better positioned against challenges ahead!

Conclusion

In the ever-evolving landscape of production and quality, investing in a quality company is no longer just an option; it's a necessity. Companies that prioritize quality control monitoring equipment and rigorous supplier audits are better positioned to meet consumer demands while minimizing risks. By embracing these practices, businesses can enhance their reputation and secure a competitive edge.

Why Quality Companies Are Worth the Investment

Quality companies understand that the foundation of success lies in maintaining high standards throughout their operations. This commitment not only fosters customer loyalty but also translates into tangible financial benefits over time. By implementing effective types of quality inspection and adhering to standards like AQL C=0, these companies ensure that every product meets stringent requirements, ultimately leading to fewer returns and higher satisfaction rates.

The Long-Term Benefits of Quality Control

The long-term benefits of robust quality control cannot be overstated; they extend far beyond immediate gains. Consistent use of quality control monitoring equipment helps identify issues before they escalate, saving time and resources in the production process. Moreover, by regularly conducting supplier audits, organizations can build stronger relationships with vendors who share their commitment to excellence, creating a ripple effect that enhances overall production and quality.

Making Informed Choices in Supplier Selection

Making informed choices in supplier selection is crucial for maintaining high-quality standards within any business model. Utilizing a comprehensive factory audit checklist ensures that potential suppliers align with your organization's values regarding quality assurance and reliability. By focusing on suppliers who prioritize types of quality inspection and adhere to AQL C=0 standards, companies can cultivate partnerships that bolster their reputation as leaders in their respective industries.