Introduction

In the world of manufacturing and production, ensuring quality is not just a checkbox on a list; it's a vital component that can make or break a business. One of the most effective tools in this quest for excellence is the AQL table, which provides a systematic way to evaluate product quality through statistical sampling. Understanding how to use this table effectively is crucial for anyone involved in quality control and inspection processes.

Understanding the AQL Table

The AQL table, or Acceptable Quality Level table, serves as a guide for determining the maximum number of defective items allowed in a sample size during quality inspections. This tool is essential for quality control inspectors who aim to maintain high standards while also being mindful of production costs and timelines. By familiarizing oneself with the intricacies of the AQL table, businesses can better navigate their quality assurance processes and enhance overall product reliability.

Importance of Quality Control

Quality control is not merely an operational necessity; it’s an integral part of building brand reputation and customer satisfaction. Effective quality control inspections help identify defects early in the production process, thereby reducing waste and preventing costly recalls down the line. Moreover, implementing robust quality check systems fosters trust between manufacturers and suppliers, leading to more fruitful business relationships.

The Role of China Inspection Pro

Enter China Inspection Pro—a key player in facilitating seamless quality control inspections throughout your supply chain process. With their expertise in utilizing tools like the AQL table, they provide invaluable support to businesses looking to uphold stringent quality standards while navigating complex international markets. By partnering with professionals like China Inspection Pro, companies can ensure that their products meet both local regulations and global expectations without compromising on quality.

What is the AQL Table?

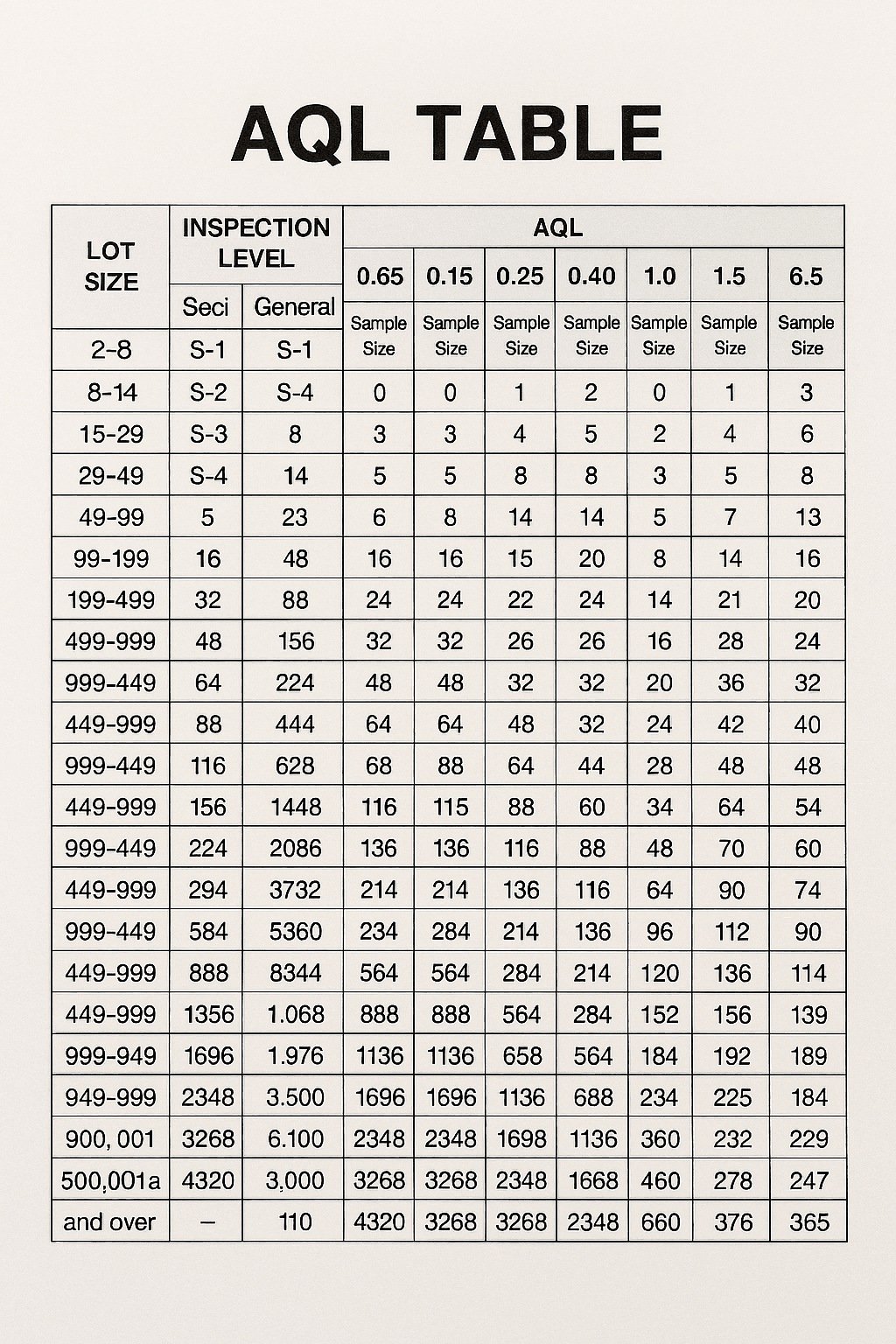

The AQL table, or Acceptable Quality Level table, is a crucial tool in the realm of quality control and inspection. It provides a systematic approach to assessing product quality by defining acceptable limits for defects in a batch of goods. By utilizing the AQL table, businesses can streamline their quality check processes while ensuring that products meet established standards.

Definition and Applications

At its core, the AQL table serves as a guideline that outlines the maximum number of defective items considered acceptable during a quality control inspection. This framework is widely applied across various industries, including manufacturing, textiles, and electronics. The primary application of the AQL table lies in determining sample sizes for inspections and establishing criteria for product acceptance or rejection based on defect rates.

Quality assurance inspectors rely heavily on the AQL table to make informed decisions during quality checks. By referencing this tool, they can efficiently assess whether batches meet predefined quality standards without having to inspect every single item. This not only saves time but also resources, making it an invaluable asset in any quality control program.

AQL in Quality Control Inspections

In practice, the AQL plays a pivotal role in quality control inspections by providing a standardized method for evaluating product consistency and reliability. Inspectors utilize this tool to determine how many items should be sampled from a production lot based on its size and desired confidence level regarding product integrity. This structured approach minimizes variability and helps maintain high-quality standards across all inspected products.

The use of an AQL table ensures that companies can effectively balance cost management with quality assurance efforts during inspections. By setting acceptable limits on defects, businesses can avoid excessive rework or returns while still delivering satisfactory products to customers. Consequently, implementing an effective quality control inspection process using the AQL framework ultimately enhances customer satisfaction.

Different Types of AQL

There are several types of Acceptable Quality Levels (AQL) that organizations may choose from depending on their specific needs and industry requirements. Commonly used types include general inspection levels such as Level I (for normal inspection), Level II (for tightened inspection), and Level III (for reduced inspection). Each type corresponds to varying degrees of scrutiny based on factors like production volume or risk tolerance.

Moreover, there are different defect categories within the context of an AQL framework: critical defects (which could pose safety hazards), major defects (which affect usability), and minor defects (which do not significantly impact function). Understanding these distinctions allows quality control inspectors to prioritize their focus during inspections effectively while ensuring compliance with industry standards.

By leveraging these various types of AQLs tailored to specific situations, organizations can enhance their overall quality management practices while minimizing costs associated with poor-quality products or services.

How to Use the AQL Table

Navigating the AQL table can feel like deciphering a secret code, but once you understand its structure, it becomes an invaluable tool for quality control. The AQL table provides a systematic approach to quality inspection, enabling quality control inspectors to determine acceptable levels of defects in a batch of products. By using this guide, you’ll be well-equipped to implement effective quality checks and ensure your products meet the required standards.

Step-by-Step Guide

To effectively use the AQL table, start by defining your acceptable quality level (AQL), which is typically expressed as a percentage. Next, determine your lot size—the total number of items in the batch you're inspecting. Once you have these figures, consult the AQL table to find the corresponding sample size and acceptance number based on your chosen AQL level.

After selecting your sample size, conduct a thorough quality control inspection on that subset of items. Count any defects found during this inspection and compare this number against the acceptance number from the AQL table. If the number of defects is below or equal to this threshold, congratulations—you've passed your quality check!

Common Pitfalls to Avoid

One common pitfall when using the AQL table is misunderstanding what constitutes a defect versus a non-defect item; not all imperfections affect product functionality or safety equally. Quality assurance inspectors should be clear about which defects are critical and which are minor before starting their inspections—this clarity helps avoid unnecessary rejections and streamlines processes. Additionally, failing to consider sample size can lead to skewed results; always ensure that you're sampling enough items for an accurate representation.

Another mistake is neglecting documentation throughout the inspection process; keeping detailed records helps in identifying trends over time and supports better decision-making for future orders. Lastly, overlooking proper training for quality control inspectors can lead to inconsistent interpretation of results—investing in training ensures everyone understands how to use the AQL table effectively.

Real-World Examples

Consider a company that manufactures electronic gadgets with an acceptable defect rate set at 2% (AQL). For a shipment containing 1,000 units, they refer to their AQL table and find they need to inspect 80 units with an acceptance number of 3 defects allowed for passing inspection. After conducting their quality control inspection on those 80 units, they discover only 2 defective items—success! Their products meet standards thanks to effective use of the AQL table.

In another scenario involving textiles where an organization sets its AQL at 1%, they must inspect 125 garments from a lot size of 12,500 pieces according to their relevant sampling plans outlined in their AQL chart. During their inspections conducted by skilled quality control inspectors trained specifically on fabric flaws, they identify no more than one defect per batch checked—a clear pass! This illustrates how applying structured methods through careful sampling leads directly toward maintaining high-quality standards.

AQL Sampling Methods Explained

Understanding AQL sampling methods is essential for effective quality control inspections. The AQL table provides a framework that helps determine the acceptability of samples during quality checks. By mastering these sampling methods, quality control inspectors can ensure that products meet the required standards without unnecessary waste.

Single versus Double Sampling

When it comes to AQL sampling, one of the primary decisions is whether to use single or double sampling plans. Single sampling involves taking one sample from a lot and determining its acceptability based on the results, while double sampling allows for a second chance if the first sample falls within a gray area—think of it as a safety net for your quality assurance inspector. Each method has its pros and cons; single sampling is simpler and quicker, but double sampling can provide more confidence in your quality control inspection results by allowing for additional verification.

Importance of Sample Size

The size of your sample plays a crucial role in the effectiveness of your AQL sampling strategy. Too small a sample may lead to misleading conclusions about product quality, while an excessively large sample could waste time and resources during inspections. Striking the right balance ensures that quality checks are both efficient and reliable, allowing quality control inspectors to make informed decisions based on solid data derived from the AQL table.

Sampling Plans and Strategies

Developing effective sampling plans is key to successful quality control inspections, especially when using the AQL table as your guide. Different strategies can be employed depending on factors like production volume, risk tolerance, and historical data on defect rates—all vital considerations for any diligent quality assurance inspector. By tailoring your approach with smart planning and strategic thinking, you’ll not only enhance product quality but also build stronger relationships with suppliers through consistent reliability in your processes.

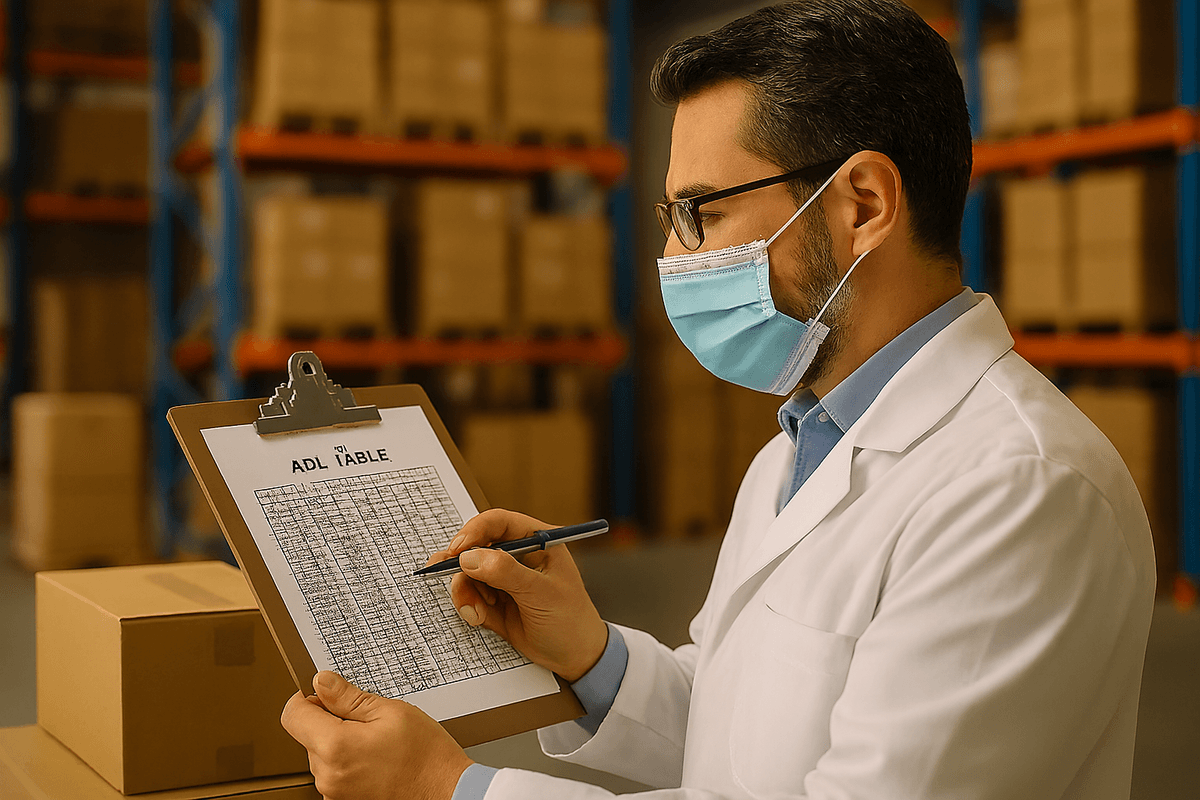

The Role of Quality Inspectors

Quality inspectors are the unsung heroes in the realm of manufacturing and production, ensuring that products meet established standards before they reach consumers. Their role is pivotal in maintaining the integrity of quality control processes, and they serve as the frontline defenders against defects and inconsistencies. In this section, we will explore the duties of a quality control inspector, the skills required for effective inspections, and how these professionals utilize the AQL table to enhance their work.

Duties of a Quality Control Inspector

The primary duty of a quality control inspector is to conduct thorough quality inspections throughout various stages of production. This includes performing detailed quality checks on raw materials, in-process items, and finished goods to ensure compliance with specifications. Additionally, they document their findings meticulously to provide actionable insights that can drive improvements in product quality and overall manufacturing processes.

Quality control inspectors also play an essential role in communicating with suppliers and production teams about any issues identified during inspections. They often recommend corrective actions when defects are found, fostering a culture of continuous improvement within organizations. By utilizing tools such as the AQL table during these assessments, inspectors can determine acceptable levels of defects and make informed decisions about product acceptance or rejection.

Skills Required for Effective Inspections

To excel as a quality control inspector, one must possess a unique blend of technical knowledge and interpersonal skills. Strong analytical skills are crucial for interpreting data from quality checks effectively; this includes understanding statistical methods related to AQL sampling techniques. Furthermore, attention to detail is paramount—inspectors must be able to spot even minor discrepancies that could indicate larger underlying issues.

Communication skills also play a vital role; inspectors must convey their findings clearly to both technical teams and non-technical stakeholders alike. Being adept at problem-solving allows them to propose practical solutions when faced with challenges during inspections. Additionally, familiarity with various inspection tools and methodologies enhances their ability to execute comprehensive quality control inspections efficiently.

How Quality Assurance Inspectors Utilize the AQL Table

Quality assurance inspectors leverage the AQL table as an essential tool in their daily operations for effective quality control inspections. By referencing this table during assessments, they can establish acceptable defect rates based on specific sample sizes—making it easier to determine whether batches meet predefined standards or require further scrutiny. The structured approach provided by the AQL table aids inspectors in making quick yet informed decisions regarding product acceptance.

Moreover, incorporating AQL sampling strategies into their workflow helps streamline inspection processes while minimizing unnecessary delays caused by excessive testing or rework efforts. Quality assurance inspectors often train their teams on how to interpret data from the AQL table accurately so that everyone involved understands what constitutes acceptable versus unacceptable levels of defects during production runs. This collaborative effort fosters greater accountability across departments while enhancing overall product quality.

Benefits of Using the AQL Table

When it comes to maintaining high standards in product quality, the AQL table serves as an invaluable tool. By providing a clear framework for quality control inspections, it helps ensure that products meet predefined criteria before they reach consumers. This not only enhances product quality but also streamlines the entire quality check process.

Enhancing Product Quality

Utilizing the AQL table significantly improves product quality by establishing specific benchmarks for acceptable defect rates during quality control inspections. Quality assurance inspectors rely on these benchmarks to identify and rectify issues early in the production process, preventing defective items from reaching the market. Moreover, consistent application of the AQL sampling methods fosters a culture of excellence among manufacturers, encouraging them to prioritize quality.

Reducing Costs and Risks

Implementing an effective AQL sampling strategy can lead to substantial cost savings by minimizing waste and reducing returns due to defects. By conducting thorough quality control inspections with the help of the AQL table, companies can catch potential issues before they escalate into costly problems down the line. Additionally, maintaining high-quality standards mitigates risks associated with brand reputation and customer dissatisfaction.

Building Trust with Suppliers

The transparency offered by using an AQL table fosters stronger relationships between businesses and their suppliers. When both parties understand and agree upon acceptable levels of defects through well-defined quality control inspection criteria, it builds mutual trust and accountability. This collaborative approach not only enhances communication but also encourages suppliers to uphold their end of the bargain regarding product quality.

Conclusion

In summary, the AQL table serves as a crucial tool in the realm of quality control, providing a systematic approach to evaluating product quality during inspections. By understanding its applications and integrating it into your quality control inspection processes, you can significantly enhance the reliability of your products. Quality assurance inspectors who effectively utilize the AQL table can streamline their quality checks and minimize risks associated with defective goods.

Key Takeaways on AQL and Quality Control

The AQL table is not just a set of numbers; it represents a framework for maintaining high standards in quality control. It helps businesses determine acceptable levels of defects, ensuring that products meet customer expectations while minimizing costs. Moreover, effective use of the AQL sampling method can lead to better decision-making during quality inspections and foster stronger relationships with suppliers.

Future Trends in Quality Inspection

As industries evolve, so too does the landscape of quality inspection. Future trends indicate an increased reliance on technology, such as automation and AI-driven analytics, to enhance the efficiency of quality control processes. Additionally, integrating real-time data analysis with traditional methods like the AQL table will likely become standard practice for quality assurance inspectors aiming to stay ahead in an increasingly competitive market.

How China Inspection Pro Can Help

China Inspection Pro stands out as a valuable partner for businesses seeking reliable quality control solutions. With expertise in utilizing tools like the AQL table effectively, their team of skilled inspectors ensures thorough assessments during every stage of production. By leveraging their services, companies can achieve enhanced product quality while building trust with suppliers through consistent and transparent quality checks.