Introduction

In the fast-paced world of electronics, the testing of electronic components is not just a step in the process; it’s a critical phase that ensures reliability and safety. With the increasing complexity of electronic devices, effective quality control practices have become essential to maintain performance standards and customer satisfaction. By employing rigorous testing methods, manufacturers can identify defects early, thereby reducing costs and enhancing product longevity.

Importance of Testing Electronic Components

The testing of electronic components serves as the backbone for quality assurance in any manufacturing process. It helps to verify that each component meets specific performance criteria before it is integrated into larger systems. By ensuring that only high-quality parts are used, companies can minimize failures in the field, which ultimately protects their brand reputation and consumer trust.

Overview of Quality Control Practices

Quality control practices encompass various strategies designed to monitor and maintain product quality throughout production processes. Different types of inspections play a pivotal role in these practices, ranging from initial material checks to final product evaluations. Understanding what is a quality check is vital for anyone involved in manufacturing, as it lays down the foundation for effective oversight and compliance with industry standards.

Essential Tools for Efficient Testing

To streamline the testing process, certain tools are indispensable in ensuring accurate results and efficiency. The table AQL (Acceptable Quality Level) provides a systematic approach to sampling inspection, helping teams determine acceptable defect levels based on statistical methods. Additionally, regular calibration and maintenance of testing equipment are crucial to ensure reliable measurements and uphold quality management principles across various sectors like construction projects or even quality control in food industry settings.

Understanding the Testing Process

Testing electronic components is a critical aspect of ensuring that devices function correctly and meet industry standards. It involves various methods and inspections to assess the reliability and performance of these components before they are deployed in real-world applications. By understanding the testing process, organizations can enhance their quality control practices and minimize defects.

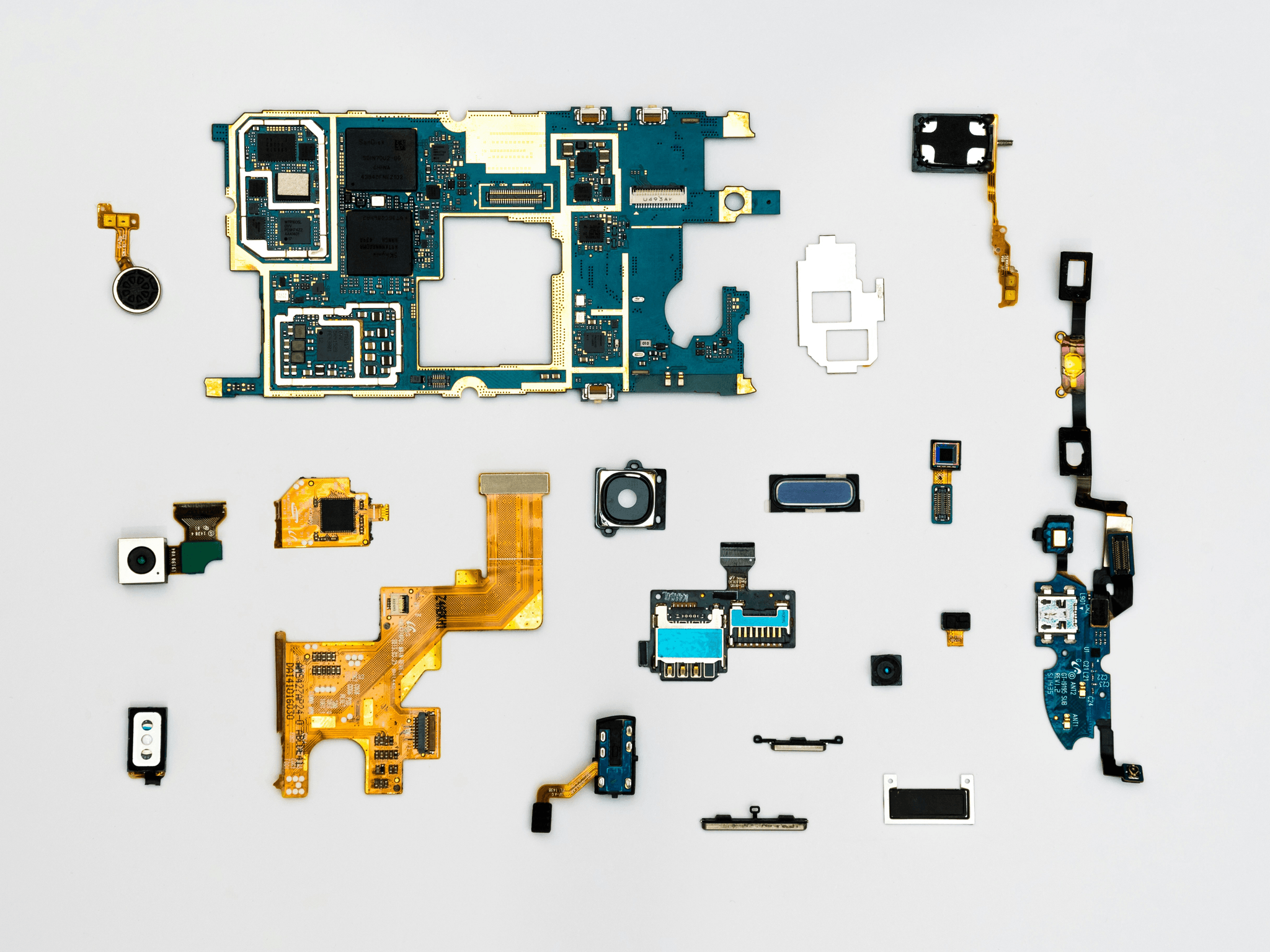

Definition of Testing of Electronic Components

The testing of electronic components refers to a systematic evaluation process aimed at verifying that each component meets specified requirements and functions as intended. This includes assessing electrical characteristics, durability, and overall performance under different conditions. Proper testing not only helps in identifying faulty components but also plays a significant role in maintaining acceptable quality levels across production lines.

Different Types of Inspections Explained

When it comes to inspections, there are several different types that can be utilized throughout the testing process. Visual inspection is often the first line of defense, where inspectors look for physical defects or inconsistencies in electronic components. Other types include functional tests that measure performance against established benchmarks, as well as environmental tests that evaluate how components behave under extreme conditions—both essential for quality management in construction projects and beyond.

Role of Inspectors in the Testing Process

Inspectors play a vital role in the testing process by ensuring compliance with established standards and protocols. They are typically classified into various types based on their expertise; for example, some may specialize in electrical testing while others focus on environmental assessments or visual inspections. Their insights not only facilitate effective quality checks but also help organizations maintain an acceptable quality level formula (AQL), ultimately enhancing product reliability across industries like food production where quality control is paramount.

Quality Control Techniques

Quality control techniques are the backbone of ensuring that electronic components meet industry standards and customer expectations. By implementing effective strategies, organizations can minimize defects and maximize reliability. In this section, we will explore the effective use of the Table AQL, define what constitutes a quality check, and discuss quality management in construction projects.

Effective Use of the Table AQL

The Table AQL (Acceptable Quality Level) is a vital tool in the testing of electronic components, providing manufacturers with a benchmark for acceptable defect rates. This table helps determine how many items should be inspected from a batch to ensure that quality standards are met without excessive costs or time delays. Utilizing the acceptable quality level formula allows companies to balance efficiency with thoroughness, ensuring that they maintain high-quality output while managing resources wisely.

By understanding how to effectively apply the Table AQL, inspectors can categorize different types of inspections based on risk levels associated with each component type. For example, critical components may require more stringent inspection criteria compared to non-critical ones. This strategic approach not only enhances product reliability but also fosters trust among stakeholders who rely on consistent quality.

What is a Quality Check?

A quality check refers to systematic assessments conducted at various stages during the production process to ensure that products meet specified requirements and standards. In essence, it serves as a checkpoint for identifying defects before products reach consumers or clients, thereby reducing potential recalls or dissatisfaction down the line. Understanding what is a quality check is crucial for anyone involved in manufacturing or assembly processes involving electronic components.

Different types of inspections fall under this umbrella term; these include visual checks for physical defects and functional tests that evaluate performance under specific conditions. By integrating routine quality checks into their workflow, organizations can significantly improve their overall production outcomes while adhering to industry regulations like those seen in food industry standards for safety and hygiene practices. This proactive stance not only mitigates risks but also enhances brand reputation.

Quality Management in Construction Projects

Quality management in construction projects shares similarities with practices found in other industries but comes with its unique set of challenges due to varying site conditions and project scopes. Implementing robust testing protocols ensures that all materials and processes align with regulatory requirements while meeting client expectations regarding safety and durability—especially when dealing with electronic components embedded within structures like smart buildings or automated systems.

Type of inspectors involved in construction projects includes civil engineers who assess structural integrity as well as specialized inspectors focused on electrical systems—ensuring compliance with both safety codes and performance benchmarks throughout all phases of development. Regular audits alongside rigorous documentation practices form part of an effective strategy for maintaining high-quality standards across all project elements while minimizing costly errors or rework later on.

In conclusion, mastering these quality control techniques—from utilizing the Table AQL effectively to conducting thorough quality checks—will significantly enhance reliability across various sectors including electronics manufacturing and construction alike.

Standard Testing Equipment

In the realm of **testing of electronic components**, having the right tools can make all the difference between a successful inspection and a costly oversight. The equipment used not only aids in identifying defects but also ensures compliance with industry standards. It's essential to stay informed about recommended tools, as they evolve alongside technology and testing methodologies.

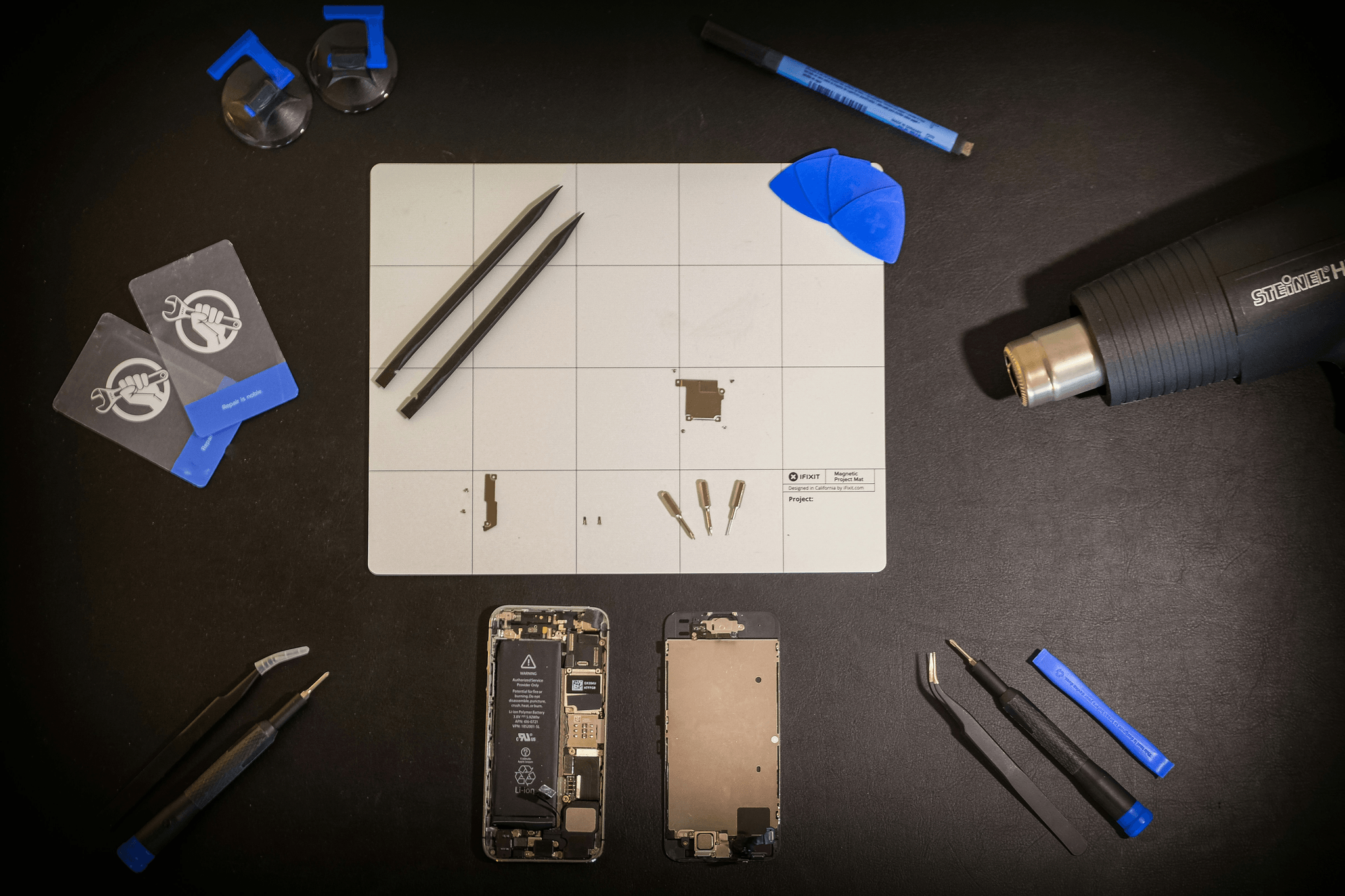

Recommended Tools for Electronic Testing

When it comes to **testing of electronic components**, several tools stand out as indispensable. Multimeters are critical for measuring voltage, current, and resistance, while oscilloscopes allow for detailed waveform analysis. Additionally, spectrum analyzers help in assessing signal quality, making them vital for ensuring that electronic components meet their specifications.

For inspectors engaged in different types of inspections, having a well-equipped toolkit enhances efficiency and accuracy. Each tool serves a unique purpose; thus, understanding their functions is crucial for effective quality checks. Moreover, integrating these tools into quality management in construction projects can streamline workflows and improve overall outcomes.

Importance of Calibration and Maintenance

Calibration is paramount in the **testing of electronic components** to ensure that results are accurate and reliable over time. Regular maintenance prevents equipment from becoming outdated or malfunctioning, which could lead to incorrect assessments during inspections. In fact, neglecting calibration can skew results beyond acceptable quality level formulas like the table AQL.

For type of inspectors working across various industries—including those involved in quality control in the food industry—maintaining calibrated instruments is essential for compliance with safety regulations. A well-calibrated tool not only enhances precision but also instills confidence among stakeholders regarding testing processes. Continuous monitoring ensures that every measurement taken reflects true performance levels.

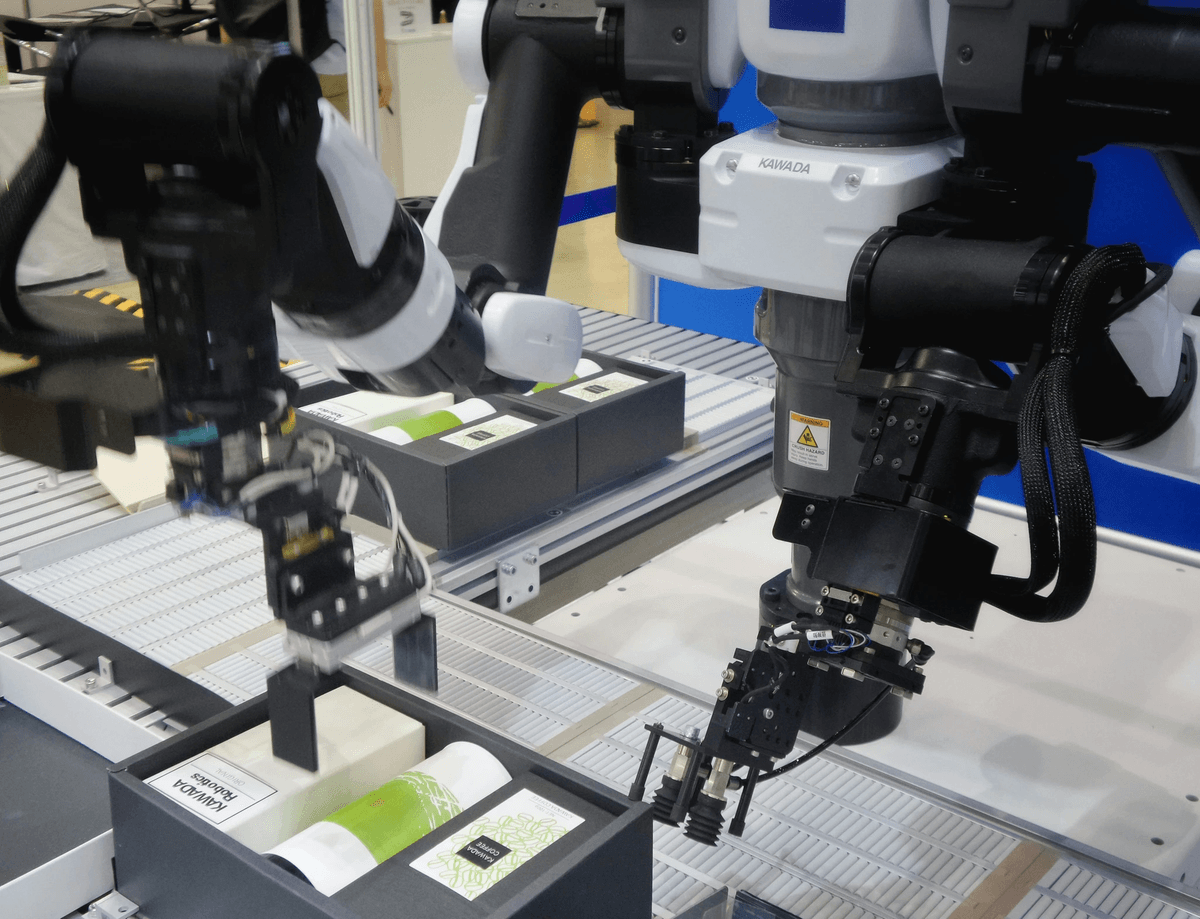

Emerging Technologies in Component Testing

As technology advances at breakneck speed, so too do innovative solutions for **testing of electronic components** emerge on the scene. Automated testing systems are becoming increasingly popular due to their ability to perform complex tests with minimal human intervention while maintaining high accuracy levels—perfect for meeting rigorous industry standards! These systems can significantly reduce inspection times while enhancing reliability.

Moreover, artificial intelligence (AI) is beginning to play a pivotal role by analyzing data patterns from past inspections to predict potential failures before they occur—a game-changer for proactive quality management in construction projects! With AI's capabilities extending into real-time monitoring during production processes, manufacturers can adjust parameters instantly based on immediate feedback from testing results.

The future looks promising with developments such as non-destructive testing methods gaining traction; these techniques allow inspectors to evaluate component integrity without damaging them—ideal for sensitive applications across various sectors including electronics manufacturing and even food safety assessments!

Common Testing Methods

When it comes to the testing of electronic components, employing a variety of methods ensures that each aspect of quality is covered. Different types of inspections can be applied depending on the component and its intended use, making it essential to understand which method fits best for your needs. This section will delve into visual inspection techniques, electrical testing approaches, and environmental testing considerations.

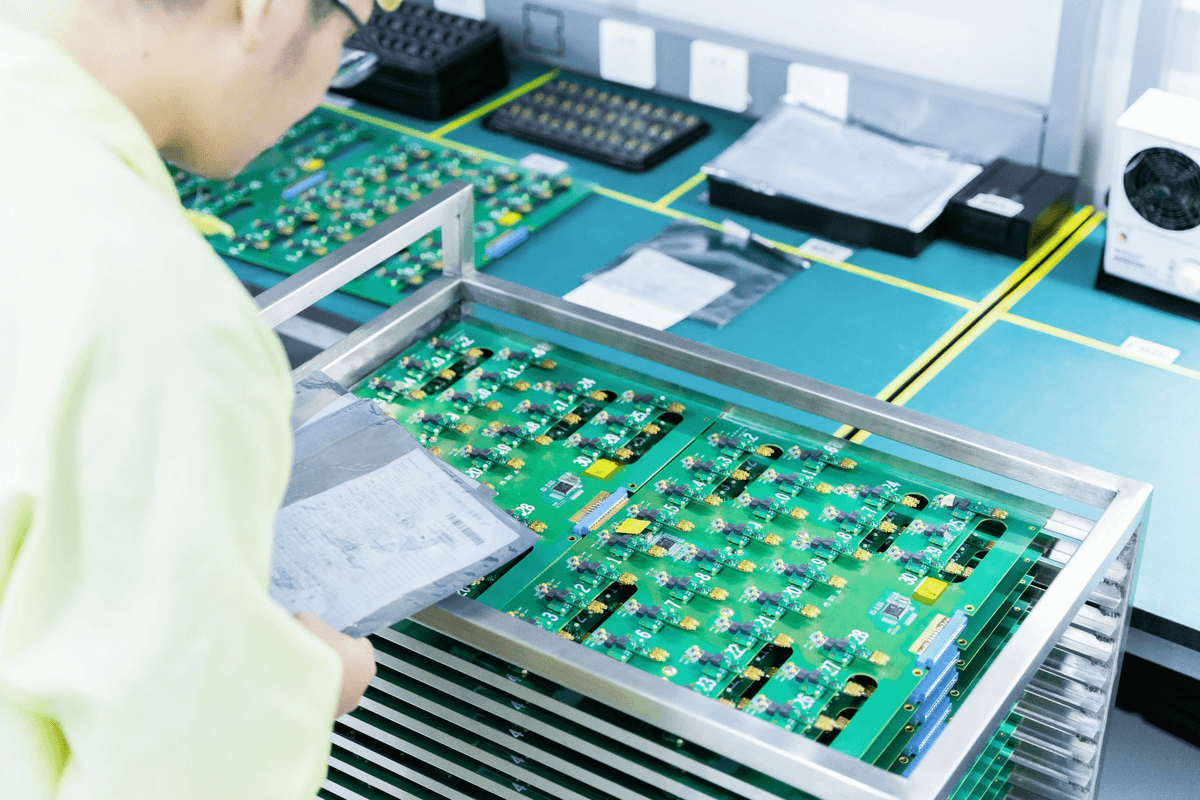

Visual Inspection Techniques

Visual inspection techniques are often the first line of defense in the testing of electronic components. Inspectors utilize their keen eyes to spot defects such as cracks, soldering issues, or misalignments that might not be visible during other tests. This method is not only cost-effective but also efficient; however, it requires skilled type of inspectors who can accurately assess quality based on their experience.

Incorporating tools like magnifying glasses and digital microscopes can enhance the effectiveness of visual inspections. These tools allow inspectors to examine intricate details that could compromise performance later on. Moreover, maintaining a consistent approach with an acceptable quality level formula helps determine what constitutes an acceptable product—essential for quality management in construction projects as well.

Electrical Testing Approaches

Electrical testing approaches are pivotal in ensuring that electronic components perform as intended under operational conditions. Techniques such as continuity tests, insulation resistance tests, and functional tests are commonly used to verify electrical characteristics and detect failures early in the production process. These methods not only help identify defective components but also ensure compliance with industry standards—a crucial aspect when considering quality control in food industry applications where safety is paramount.

Utilizing automated test equipment (ATE) can streamline these processes significantly by providing precise measurements rapidly compared to manual methods. Additionally, integrating statistical process control (SPC) alongside these tests allows manufacturers to monitor trends over time effectively—ensuring continuous improvement in their production lines while adhering to established benchmarks like table AQL standards.

Environmental Testing Considerations

Environmental testing considers how electronic components will withstand various external conditions throughout their lifecycle. Factors such as temperature fluctuations, humidity levels, and exposure to dust or chemicals must be evaluated rigorously through controlled experiments simulating real-world environments. This level of scrutiny is especially important for sectors like automotive or aerospace where reliability is non-negotiable.

The role of different types of inspections becomes evident here; specialized inspectors conduct environmental stress screenings (ESS) to uncover potential weaknesses before products hit the market. By implementing rigorous environmental assessments alongside other quality checks—like those defined by what is a quality check?—manufacturers can ensure robust performance even under extreme conditions while safeguarding consumer trust.

Real-World Applications

Quality control isn't just a buzzword; it's a lifeline in various industries, ensuring that products meet rigorous standards before reaching consumers. In this section, we will explore how the testing of electronic components and quality management practices are applied across different sectors, including food and manufacturing. We’ll also highlight inspiring success stories that showcase effective quality control measures.

Case Study: Quality Control in the Food Industry

The food industry exemplifies the critical importance of quality checks to ensure safety and compliance with health regulations. In this sector, different types of inspections are employed to assess everything from ingredient sourcing to final product packaging. For instance, implementing the table AQL helps determine acceptable quality levels—allowing inspectors to identify defects while maintaining efficiency.

One notable example is a large-scale food manufacturer that adopted rigorous testing of electronic components used in their processing equipment. By conducting regular inspections and utilizing an acceptable quality level formula, they were able to significantly reduce spoilage rates and enhance product safety. This case illustrates how effective quality management can lead to both consumer trust and operational excellence.

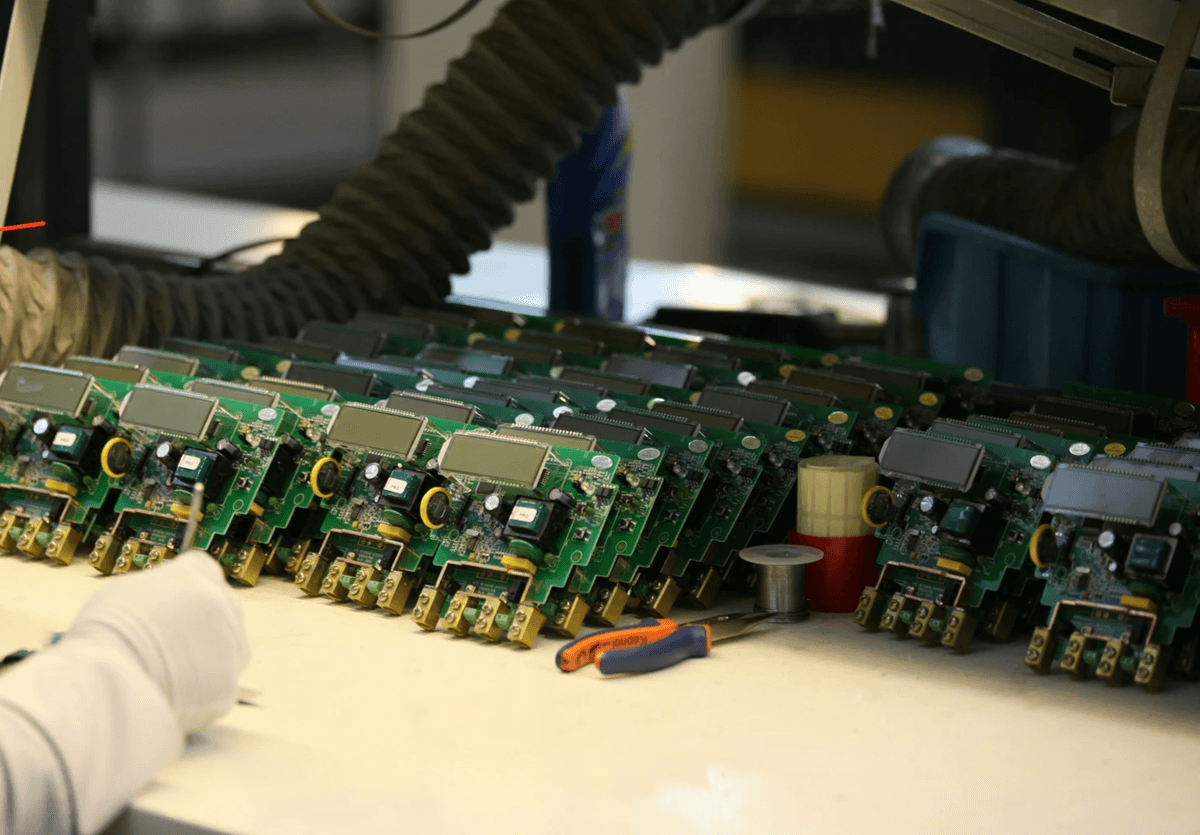

Implementation in Manufacturing Processes

In manufacturing processes, the integration of systematic testing protocols is vital for ensuring product reliability and performance. Quality checks are not only about meeting specifications but also about preventing costly recalls or failures down the line. Employing various types of inspectors—ranging from those who focus on visual inspections to those specializing in electrical testing—ensures comprehensive coverage throughout production.

For instance, an automotive parts manufacturer implemented a robust framework for testing electronic components that included regular calibration of equipment and adherence to strict inspection schedules. This proactive approach helped them identify potential failures early on, thus maintaining high-quality standards while minimizing waste. The result? A streamlined production process that consistently meets customer expectations.

Success Stories from China Inspection Pro

China Inspection Pro has made significant strides in promoting effective quality control across diverse industries by leveraging advanced technologies and methodologies for testing electronic components. Their success stories often highlight how they’ve utilized innovative techniques alongside traditional inspection methods to achieve remarkable results for clients worldwide. For example, their application of environmental testing considerations has proven invaluable in industries where component durability is paramount.

One standout achievement involved collaborating with a tech firm facing challenges with defective electronic parts due to inadequate oversight during production phases. By employing a combination of different types of inspections—including visual assessments paired with electrical performance tests—they were able to rectify issues swiftly while adhering to established standards like the table AQL for acceptable quality levels. This collaboration not only salvaged client relationships but also reinforced China Inspection Pro's reputation as a leader in quality management solutions.

Conclusion

In the realm of electronic components, effective testing is not just a best practice; it's a necessity. The meticulous approach to the testing of electronic components ensures that products meet safety and performance standards, leading to enhanced reliability and customer satisfaction. By implementing robust quality control measures, including various types of inspections and using tools like the table AQL, organizations can significantly mitigate risks associated with defects.

Key Takeaways for Effective Testing

One of the most important takeaways from our exploration is that understanding different types of inspections is crucial for effective testing. Different inspectors bring unique skills to the table; some may specialize in visual inspection techniques while others excel in electrical testing approaches. Additionally, knowing how to apply the acceptable quality level formula can help organizations set realistic expectations for their quality checks.

Importance of Continuous Improvement

Continuous improvement should be at the heart of any quality management strategy, particularly in sectors like construction projects where stakes are high. Regularly revisiting processes allows teams to identify areas needing enhancement, whether it’s refining inspection methods or adopting new technologies for better accuracy in testing electronic components. In industries such as food production, ongoing improvements can lead to significant advancements in quality control practices that benefit both producers and consumers alike.

Resources for Further Learning on Quality Control

To deepen your understanding of quality control practices, numerous resources are available online and through industry publications. Websites dedicated to engineering and manufacturing often feature articles on topics like what is a quality check or detailed guides on implementing effective table AQL strategies. Additionally, professional organizations offer workshops and certifications focused on quality management in construction projects and other fields that emphasize excellence in product reliability.