Introduction

In today’s fast-paced manufacturing landscape, the significance of quality assurance cannot be overstated. Quality assurance is not just a buzzword; it’s a vital framework that ensures products meet stringent standards before they reach consumers. By implementing robust quality control measures, businesses can enhance their reputation and customer satisfaction, ultimately leading to increased sales and loyalty.

The Importance of Quality Assurance

Quality assurance plays a pivotal role in maintaining product integrity throughout the production process. It establishes systematic processes that prevent defects, thereby ensuring that every item produced meets predetermined criteria. When companies prioritize quality assurance, they not only protect their brand image but also foster a culture of excellence within their teams.

Understanding During Production Inspections

During production inspections are essential checkpoints that allow for real-time assessment of product quality while manufacturing is ongoing. These inspections help identify potential issues before they escalate into costly problems, making them an invaluable part of any quality control strategy. By integrating during production inspection into the workflow, companies can ensure compliance with industry standards and maintain consistent product reliability.

How Inspections Enhance Product Quality

Quality inspections serve as the backbone of effective quality control by systematically evaluating products at various stages of production. Through thorough assessments, these inspections can pinpoint deviations from desired specifications early in the process, allowing for timely corrections. Ultimately, regular quality inspections lead to superior product outcomes and reinforce customer trust in the brand's commitment to excellence.

The Role of Quality Control

Quality control is a cornerstone of effective production processes, ensuring that products meet established standards before they reach consumers. It encompasses various activities aimed at monitoring and maintaining quality throughout the production cycle, particularly during production inspections. By implementing robust quality control measures, businesses can enhance their reputation and build customer loyalty.

Defining Quality Control in Production

Quality control in production refers to systematic processes designed to ensure that products are manufactured to specified standards and requirements. This involves regular assessments during production inspections to identify any deviations from quality benchmarks. By integrating quality assurance into the manufacturing process, companies can minimize waste and optimize efficiency.

Quality Control Inspector Responsibilities

Quality control inspectors play a critical role in maintaining product integrity by conducting thorough evaluations at various stages of production. Their responsibilities include performing detailed inspections, documenting findings, and communicating any issues related to quality control and quality assurance with the production team. These inspectors are the frontline defenders against defects, ensuring compliance with industry regulations and company policies.

Ensuring Compliance Through Quality Control

Ensuring compliance through quality control is essential for meeting both customer expectations and legal requirements. Effective inspection services facilitate adherence to established standards by providing real-time feedback during production inspections. This proactive approach not only helps prevent costly recalls but also reinforces a company's commitment to delivering high-quality products consistently.

Benefits of During Production Inspection

When it comes to maintaining high standards in manufacturing, during production inspection plays a pivotal role. Quality assurance is not just a buzzword; it's a necessity that ensures products meet the required specifications before they reach the customer. By integrating effective quality control measures, businesses can significantly enhance their product reliability and overall market reputation.

Early Detection of Defects

One of the prime benefits of during production inspection is the early detection of defects, which can save time and resources down the line. Quality control inspectors are trained to identify issues at various stages of production, allowing for immediate corrective actions before problems escalate. This proactive approach not only minimizes waste but also ensures that only products meeting stringent quality assurance standards make it to consumers.

Cost Savings Through Proactive Measures

Implementing robust quality control practices through during production inspection can lead to substantial cost savings for manufacturers. By catching defects early on, companies can avoid costly recalls or reworks that arise from poor-quality products reaching the market. Moreover, investing in quality inspection services reduces long-term expenses associated with customer dissatisfaction and brand damage—because let’s face it, nobody wants to deal with an angry customer!

Building Customer Trust with Quality Assurance

Quality assurance is crucial for building trust with customers who expect nothing less than perfection from their purchases. When businesses consistently utilize effective quality control methods during production inspection, they establish a reputation for reliability and excellence in their offerings. This trust translates into repeat business and positive word-of-mouth referrals—key components for sustained success in any competitive market.

Quality Inspection Techniques

When it comes to ensuring product excellence, quality inspection techniques are the backbone of effective quality control and quality assurance strategies. These methods not only help in identifying defects early but also play a crucial role in maintaining compliance with industry standards. By employing a mix of traditional and modern inspection techniques, companies can significantly enhance their during production inspection processes.

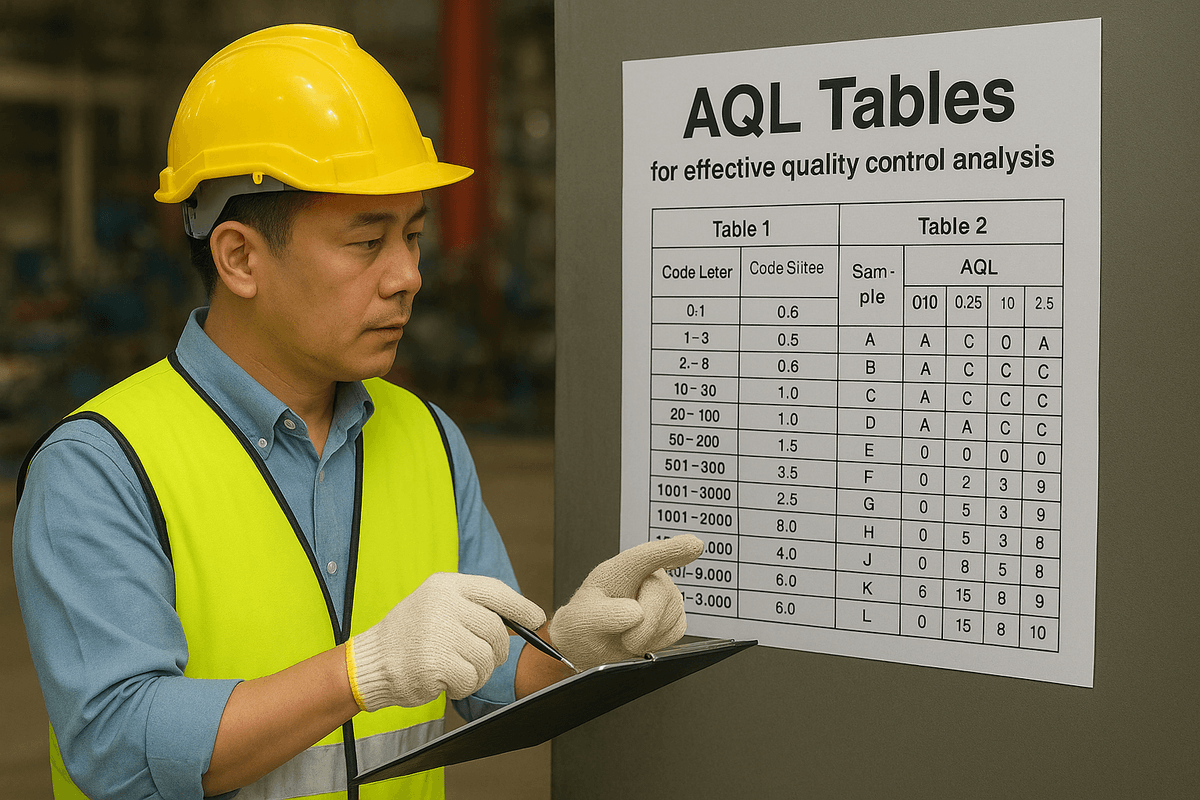

Visual Inspections and Sampling

Visual inspections remain a staple in the realm of quality control, allowing inspectors to catch defects that might elude more automated systems. During production inspections, trained quality control inspectors use their keen eyes to assess products for inconsistencies, damage, or deviations from specifications. Sampling further enhances this process by allowing inspectors to evaluate a representative subset of products rather than examining each item individually, saving time while still ensuring robust quality assurance.

Sampling techniques can vary from random sampling to systematic approaches depending on the production scale and product type. This flexibility ensures that even with limited resources, companies can maintain high standards of quality control without compromising on thoroughness. Ultimately, visual inspections combined with sampling create a solid foundation for identifying potential issues before they escalate into larger problems.

Advanced Inspection Technologies

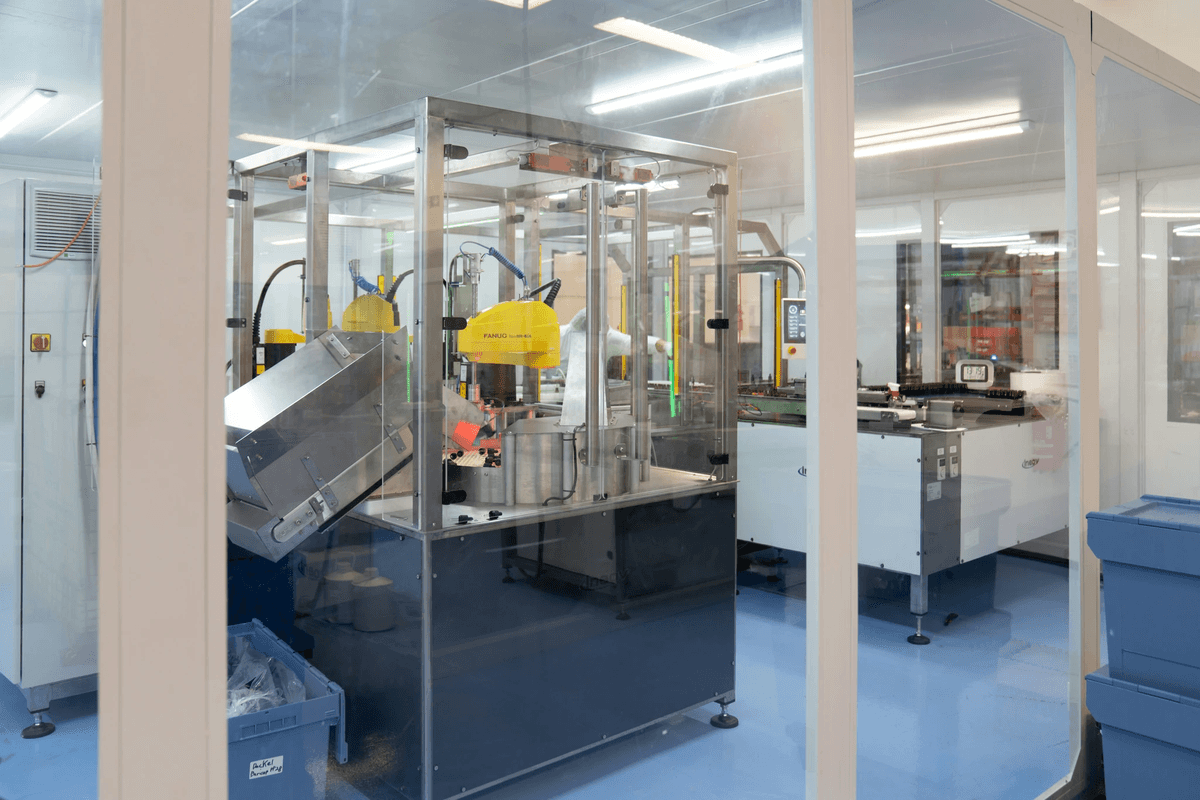

In today's fast-paced manufacturing environment, relying solely on traditional methods may not suffice; hence the rise of advanced inspection technologies has transformed how we approach quality assurance. Techniques such as X-ray imaging, ultrasonic testing, and machine vision systems provide deeper insights into product integrity that visual inspections alone cannot offer. These technologies enable real-time detection of defects during production inspections, enhancing overall efficiency while ensuring compliance with strict quality control standards.

Moreover, automation in inspection processes reduces human error and boosts consistency across batches—making it easier for companies to uphold rigorous quality assurance practices. The integration of these advanced technologies empowers organizations to adapt quickly to changing market demands while maintaining high-quality output throughout their supply chains.

Real-Time Monitoring for Quality Control

Real-time monitoring is revolutionizing how businesses approach both quality control and during production inspections by providing immediate feedback on product performance at every stage of manufacturing. With sensors and IoT devices embedded within production lines, data is continuously collected and analyzed for any anomalies or variations from established benchmarks. This proactive approach allows companies to address issues as they arise rather than waiting until the end of the production cycle.

By implementing real-time monitoring systems as part of their overall inspection services strategy, organizations can significantly reduce waste and improve operational efficiencies—ultimately leading to enhanced customer satisfaction through superior product offerings. The ability to swiftly identify trends or recurring issues also fosters an environment where continuous improvement becomes part of the company culture.

Choosing the Right Inspection Services

Selecting the right inspection services is crucial for maintaining high standards of quality assurance and quality control in production. With a multitude of options available, it can be overwhelming to determine which inspection service will best meet your needs. By focusing on key factors and evaluating potential companies, you can ensure that your during production inspections are thorough and effective.

Key Factors in Selecting an Inspector

When it comes to choosing a quality control inspector, several factors should guide your decision-making process. First, consider their experience in your specific industry; familiarity with your product type can significantly enhance the effectiveness of inspections. Additionally, assess their qualifications and certifications to ensure they adhere to established quality control standards and practices.

Another critical factor is the inspector's ability to communicate findings clearly and promptly. Effective communication helps translate complex inspection data into actionable insights that can drive improvements in quality assurance processes. Finally, look for inspectors who utilize advanced technology during their inspections—this not only increases accuracy but also streamlines the overall quality inspection process.

Evaluating Quality Inspection Companies

Evaluating potential quality inspection companies involves a careful assessment of their reputation, reliability, and track record in delivering consistent results. Start by seeking recommendations from industry peers or conducting online research to gauge customer satisfaction levels with their services. A company’s history of managing during production inspections effectively showcases its commitment to maintaining high standards of quality control.

Next, review case studies or testimonials that demonstrate how these companies have successfully identified defects or improved product quality for other clients. This evidence will provide insight into their capabilities and reliability as partners in your quality assurance journey. Lastly, consider the range of services offered by each company; a comprehensive suite indicates versatility and expertise across various aspects of quality control.

How China Inspection Pro Stands Out

China Inspection Pro distinguishes itself from competitors through its unwavering commitment to excellence in both during production inspection and overall service delivery. With a team of highly trained inspectors who bring extensive industry experience, they ensure rigorous adherence to international quality standards while tailoring solutions specifically for each client’s needs. Their proactive approach not only identifies defects early on but also implements actionable recommendations that enhance long-term product reliability.

Moreover, China Inspection Pro leverages advanced technologies such as real-time monitoring systems that provide up-to-the-minute insights into production processes—this level of transparency is invaluable for effective decision-making regarding quality control measures. Their strong emphasis on customer collaboration fosters trust and opens communication channels that further elevate the standard of service provided.

In summary, when selecting an inspection service provider like China Inspection Pro, you are not just opting for routine checks; you are investing in a partner dedicated to elevating your brand's reputation through impeccable product quality assurance.

Transforming Findings into Actionable Insights

In the realm of quality assurance, transforming findings from inspections into actionable insights is a crucial step toward improving product quality. During production inspection reports often reveal critical information that can influence manufacturing processes and enhance overall quality control. By effectively analyzing these reports, companies can identify trends, pinpoint recurring issues, and streamline their operations for better outcomes.

Analyzing Inspection Reports

Analyzing inspection reports involves diving deep into the data collected during quality inspections to uncover meaningful patterns and insights. Quality control inspectors play a vital role in this process by meticulously reviewing findings and categorizing defects according to severity and frequency. This analysis not only helps in understanding the current state of production but also aids in forecasting potential future challenges that may arise if corrective actions are not taken.

Furthermore, leveraging advanced analytics tools can enhance the efficiency of this analysis, allowing for quicker identification of root causes behind defects observed during production inspection. By breaking down complex data sets into understandable visuals or summaries, teams can make informed decisions that drive improvements in quality control practices. Ultimately, thorough analysis empowers organizations to prioritize their efforts where they matter most.

Implementing Quality Control Recommendations

Once analysis is complete, implementing quality control recommendations becomes paramount for driving change within production environments. These recommendations often stem from both inspection findings and industry best practices aimed at mitigating identified risks or enhancing processes. Ensuring that all stakeholders are on board with these changes is essential; effective communication regarding the importance of adhering to these new protocols fosters a culture of accountability around quality assurance.

Training sessions may be necessary to ensure that employees understand how to implement new procedures resulting from inspection services feedback effectively. Additionally, integrating these recommendations into daily operations requires careful planning and monitoring to gauge their impact on overall product quality continuously. The goal here is not just compliance but fostering an environment where continuous improvement becomes second nature.

Continuous Improvement through Feedback

Continuous improvement hinges on establishing a robust feedback loop between inspection services and production teams—a cycle that encourages ongoing refinement of processes based on real-time data gathered during production inspections. Regularly revisiting inspection reports allows teams to assess whether implemented changes yield desired results or if further adjustments are needed for optimal performance in quality control.

Encouraging open dialogue about successes and setbacks fosters an atmosphere where employees feel empowered to share insights gleaned from their experiences with quality assurance practices. This collaborative spirit leads to innovative solutions tailored specifically for unique challenges faced during production runs while enhancing overall product reliability over time. As organizations embrace this iterative approach towards improvement, they position themselves favorably within competitive markets driven by consumer demand for high-quality products.

Conclusion

In conclusion, the significance of quality control in manufacturing cannot be overstated. By implementing rigorous during production inspection processes, companies can elevate their standards and ensure that every product meets the highest quality assurance benchmarks. This commitment to quality not only enhances customer satisfaction but also strengthens brand reputation in a competitive marketplace.

Elevating Standards with Quality Control

Elevating standards with quality control starts with a proactive approach to quality assurance throughout the production process. During production inspections serve as a crucial checkpoint, allowing manufacturers to identify potential defects before they escalate into costly problems. By prioritizing these inspections, businesses can foster a culture of excellence that resonates through every aspect of their operations.

The Future of Quality Assurance Practices

The future of quality assurance practices lies in embracing innovation and advanced technologies that enhance traditional methods like visual inspections and sampling. With the rise of automation and real-time monitoring systems, companies can expect more efficient quality control measures that provide deeper insights into production processes. As industries evolve, integrating these advancements will be essential for maintaining high-quality standards and staying ahead of competitors.

Partnering with Experts for Success

Partnering with experts for success is key to achieving effective quality control and assurance strategies. Engaging professional inspection services ensures that your products undergo thorough evaluations by experienced quality control inspectors who understand industry standards inside out. This collaboration not only streamlines the inspection process but also provides invaluable insights that drive continuous improvement in product quality.