Introduction

In the fast-paced world of manufacturing, the significance of production inspection cannot be overstated. It serves as a critical checkpoint in ensuring that products meet predetermined quality standards before they reach consumers. By integrating effective quality assurance practices, manufacturers can enhance their reputation and minimize costly errors.

Understanding Production Inspection Importance

Production inspection is essential for maintaining product integrity and customer satisfaction. Without it, manufacturers risk delivering subpar goods that could lead to returns, recalls, and damage to their brand image. This underscores why a robust approach to quality assurance is necessary; it not only safeguards the end product but also streamlines production processes.

Key Components of Quality Assurance

Quality assurance consists of various components that work in harmony to ensure consistent results throughout the manufacturing cycle. These elements include thorough documentation, employee training, and adherence to industry standards—all aimed at enhancing overall quality assurance quality. By focusing on these key components, organizations can create a solid foundation for effective production inspection.

The Role of Quality Control in Manufacturing

Quality control acts as the gatekeeper in the manufacturing process, ensuring that each stage meets established benchmarks before moving forward. It involves systematic monitoring and evaluation of production outputs through various techniques and tools designed for effective quality control control. Ultimately, implementing rigorous quality control measures fosters a culture of excellence within the organization while minimizing defects during production inspection.

What is Production Inspection?

Production inspection is a critical process in manufacturing that ensures products meet specific quality standards before they reach consumers. This process involves assessing various aspects of production, from raw materials to finished goods, to guarantee that quality assurance practices are effectively implemented. By focusing on quality control, production inspection plays a vital role in maintaining the integrity of the manufacturing process.

Definition and Scope

Production inspection refers to the systematic evaluation of products at different stages of manufacturing to ensure they conform to established specifications and quality standards. The scope encompasses everything from initial material inspections to final product evaluations, which helps identify defects early in the production line. This proactive approach not only enhances quality assurance but also minimizes waste and reduces costs associated with poor-quality products.

Importance in the Manufacturing Process

The importance of production inspection cannot be overstated; it serves as a safeguard against defects that could compromise product integrity and safety. By implementing rigorous quality control measures throughout the manufacturing process, companies can detect issues before they escalate into larger problems that affect customer satisfaction and brand reputation. Ultimately, effective production inspection fosters trust with consumers by ensuring high-quality standards are consistently met.

Types of Production Inspections

There are several types of production inspections that cater to different stages and requirements within the manufacturing cycle. Incoming inspections focus on raw materials before they enter production, while in-process inspections evaluate products during various stages of assembly or fabrication. Finally, final inspections assess completed goods prior to shipment, ensuring that all aspects align with quality assurance metrics and expectations for product performance.

Quality Assurance: The Backbone of Production

Quality assurance (QA) is the unsung hero in the world of production, ensuring that products meet established standards before they hit the market. It encompasses a systematic approach to evaluating quality control and maintaining high-quality production inspection processes. Without robust quality assurance, manufacturers risk falling into a cycle of defects and customer dissatisfaction, which can be detrimental to their reputation and bottom line.

Defining Quality Assurance in Production

At its core, quality assurance in production refers to the proactive measures taken to guarantee that products are consistently produced at a high standard. This involves not only setting clear quality benchmarks but also implementing rigorous testing protocols throughout the manufacturing process. By fostering a culture of quality within organizations, businesses can enhance their overall production inspection efforts while minimizing errors and rework.

Strategies for Implementing Quality Assurance

Implementing effective quality assurance strategies requires a multifaceted approach that incorporates training, process optimization, and continuous improvement initiatives. One key strategy is to establish comprehensive training programs for employees on best practices in quality control and inspection techniques. Additionally, leveraging data analytics can help identify trends in production quality issues, allowing manufacturers to make informed decisions that enhance their overall QA processes.

Quality Assurance Quality: Ensuring Consistency

Achieving high-quality assurance quality involves creating standardized procedures that ensure consistency across all stages of production inspection. This includes regular audits and feedback loops that help identify areas for improvement within both processes and personnel performance. By focusing on maintaining consistency through diligent application of QA principles, businesses can build trust with customers while enhancing their reputation for delivering reliable products.

Diving into Quality Control Techniques

Quality control is the unsung hero of the manufacturing world, ensuring that products meet specified standards before they reach consumers. By implementing robust quality control practices, companies can significantly reduce defects and enhance customer satisfaction. This section will explore an overview of quality control practices, effective tools for quality control, and how to seamlessly integrate these techniques into production processes.

Overview of Quality Control Practices

Quality control practices are essential for maintaining high standards in production inspection and overall product quality. They encompass a range of activities designed to monitor and evaluate the manufacturing process to ensure that products align with quality assurance expectations. By employing systematic approaches such as statistical process control (SPC) and regular inspections, organizations can identify issues early on and implement corrective actions swiftly.

The heart of any effective quality control strategy lies in its ability to adapt to various production environments while maintaining consistency in output. This adaptability allows businesses to tailor their quality assurance qc measures according to specific industry requirements or product types. Ultimately, a solid foundation in quality control not only enhances production efficiency but also builds consumer trust in the brand.

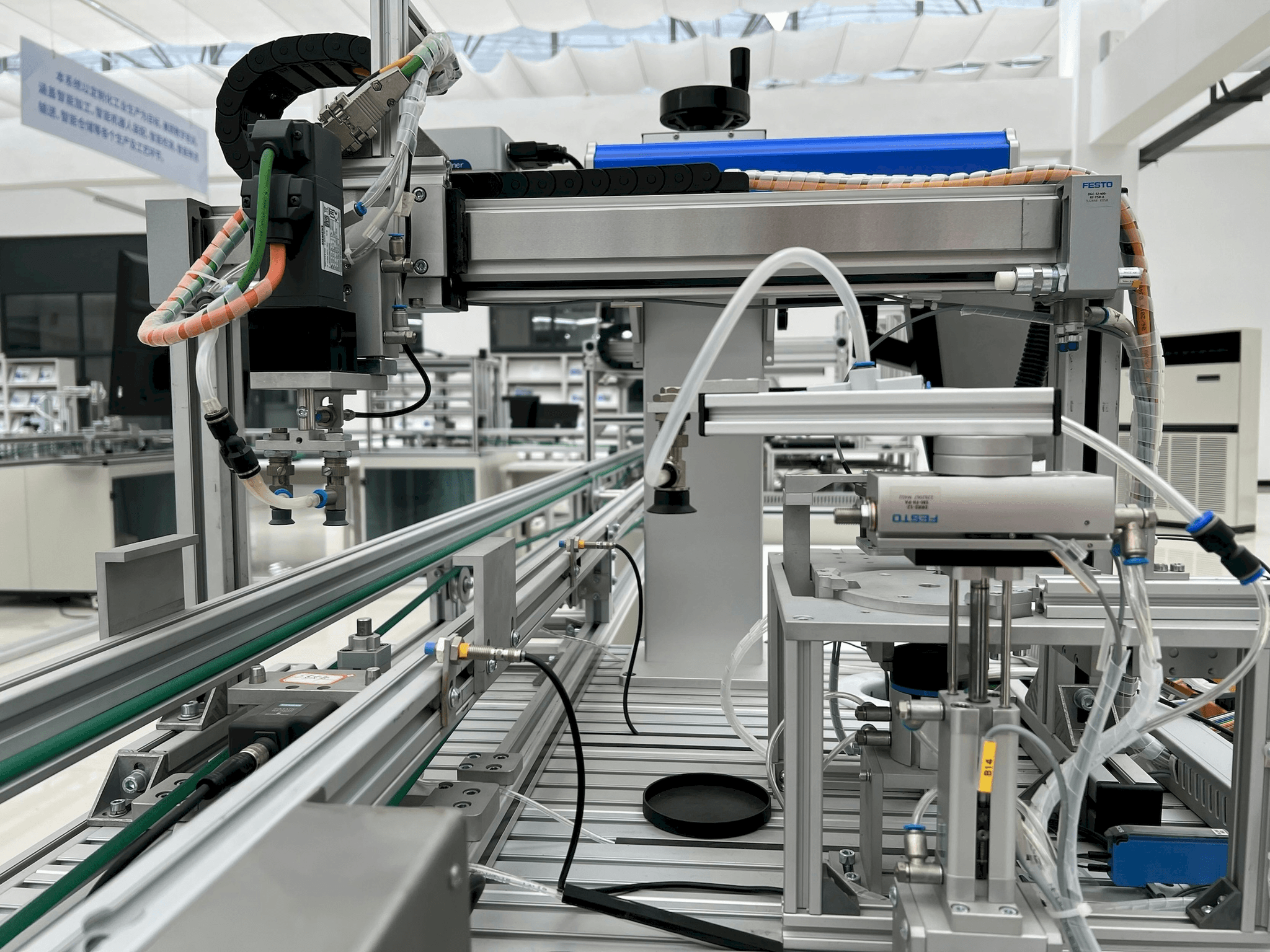

Tools for Effective Quality Control Control

In today's fast-paced manufacturing landscape, utilizing the right tools is crucial for effective quality control control. Various software solutions, such as enterprise resource planning (ERP) systems and specialized quality management software (QMS), help streamline processes by providing real-time data analytics and reporting capabilities. These tools empower teams to make informed decisions based on accurate metrics related to production inspection outcomes.

Additionally, traditional methods like checklists, flowcharts, and fishbone diagrams remain invaluable for visualizing problems within the production line. These tools foster collaboration among team members by enabling them to pinpoint areas needing improvement while reinforcing a culture focused on continuous enhancement of both quality assurance and quality inspection processes. Investing time in training personnel on these tools ensures that everyone is equipped with the knowledge needed for successful implementation.

Integrating Quality Control into Production Processes

Integrating quality control into production processes requires a strategic approach that aligns with overall business goals while emphasizing continuous improvement. Companies should establish clear protocols that outline how each step of the manufacturing process contributes to achieving desired levels of product excellence through rigorous production inspection methods. This integration fosters accountability among employees who understand their role in upholding both quality assurance standards and customer satisfaction.

Moreover, fostering a culture where feedback is encouraged can significantly enhance how effectively organizations implement their quality assurance qc strategies across departments. Regular training sessions can help employees stay updated on best practices related to both new technologies and established methodologies within their respective roles during production cycles. By creating an environment where everyone feels responsible for maintaining high-quality outputs through diligent inspections, businesses are more likely to achieve long-term success.

Quality Inspection Processes Explained

In the realm of manufacturing, quality inspection is a critical component that ensures products meet established standards before they reach consumers. This process involves systematic evaluations at various stages of production to identify defects and maintain quality assurance quality. By adhering to robust quality inspection processes, companies can mitigate risks and enhance overall customer satisfaction.

Steps Involved in Quality Inspection

The steps involved in quality inspection typically begin with defining the criteria for acceptable quality levels, which serve as benchmarks for assessing product integrity. Following this, inspections are carried out at different stages of production; this includes initial material assessments, in-process checks, and final product evaluations. Each step is designed to catch any deviations from quality standards early on, thereby reducing waste and ensuring that only products meeting the highest standards are delivered.

After identifying any issues during these inspections, corrective actions must be implemented promptly to address the root causes of defects. These actions often involve re-inspections or adjustments in the production process itself—an integral part of maintaining effective quality control control. Ultimately, a well-structured series of steps in production inspection not only enhances product reliability but also reinforces the company’s commitment to quality assurance.

Differentiating Quality Inspection from Quality Assurance

While both quality inspection and quality assurance play pivotal roles in manufacturing, they serve distinct functions within the broader framework of production processes. Quality inspection is primarily concerned with evaluating finished products against predefined criteria; it acts as a checkpoint to ensure compliance with specifications. In contrast, quality assurance focuses on establishing systematic processes that prevent defects throughout production—essentially laying down a foundation for consistent output.

Quality assurance encompasses proactive measures such as training employees on best practices and implementing standardized operating procedures aimed at fostering an environment where high-quality products can thrive. On the other hand, while conducting routine inspections may uncover issues post-production, it doesn’t necessarily prevent them from occurring initially—a key distinction between these two essential components of manufacturing success. Understanding this difference helps organizations allocate resources effectively towards both prevention (quality assurance) and detection (quality inspection).

Role of Technology in Modern Quality Inspection

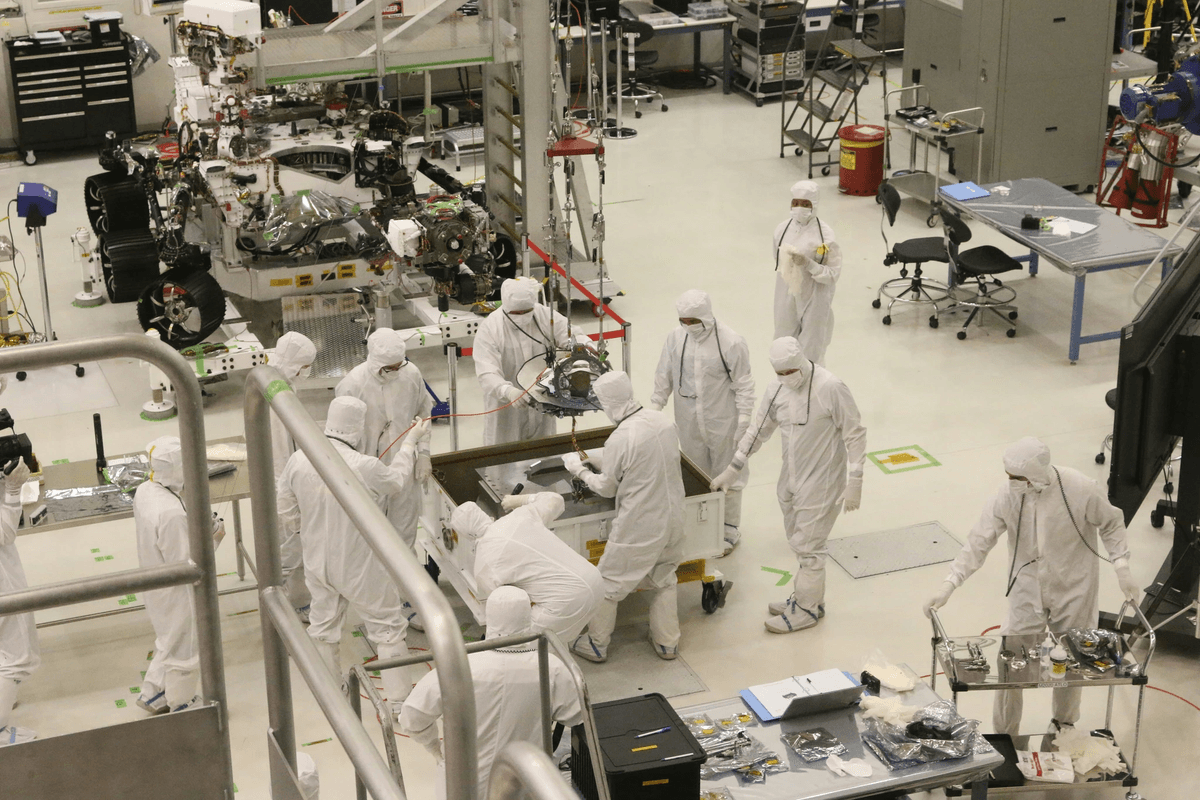

In today’s fast-paced manufacturing landscape, technology plays an increasingly vital role in enhancing efficiency and accuracy within production inspection processes. Advanced tools such as automated visual inspections using artificial intelligence can significantly reduce human error while increasing throughput rates during inspections—making them indispensable for maintaining high-quality standards across various industries. Moreover, data analytics allows companies to track performance metrics over time and identify trends that inform future improvements in both their quality control strategies and overall operational efficiency.

Technological integration also facilitates real-time monitoring through IoT devices connected throughout the supply chain; this ensures immediate feedback loops where potential issues can be addressed swiftly before they escalate into larger problems requiring extensive corrective measures later on down the line. Additionally, software solutions designed specifically for managing quality assurance qc allow businesses to streamline documentation processes related to compliance audits or certifications required by regulatory agencies—all while keeping everyone informed about ongoing projects’ statuses regarding their respective qualities.

Ultimately, leveraging technology not only enhances traditional methods used during production inspection but also empowers organizations striving toward excellence by providing them with actionable insights needed for continuous improvement initiatives aimed at achieving superior outcomes consistently.

Case Studies in Production Inspection Success

In the realm of production inspection, real-world examples illuminate the path to effective quality assurance and control. By examining successful case studies, we can glean valuable insights into how quality inspection practices can enhance manufacturing processes. These stories not only highlight the importance of quality assurance but also demonstrate the tangible benefits it brings to businesses.

China Inspection Pro: A Quality Inspection Leader

China Inspection Pro stands out as a leader in the field of production inspection, providing comprehensive quality assurance services across various industries. Their commitment to quality control is evident through their rigorous standards and advanced methodologies that ensure products meet both local and international regulations. With a focus on quality assurance qc, they have successfully helped numerous companies minimize defects and improve overall product reliability.

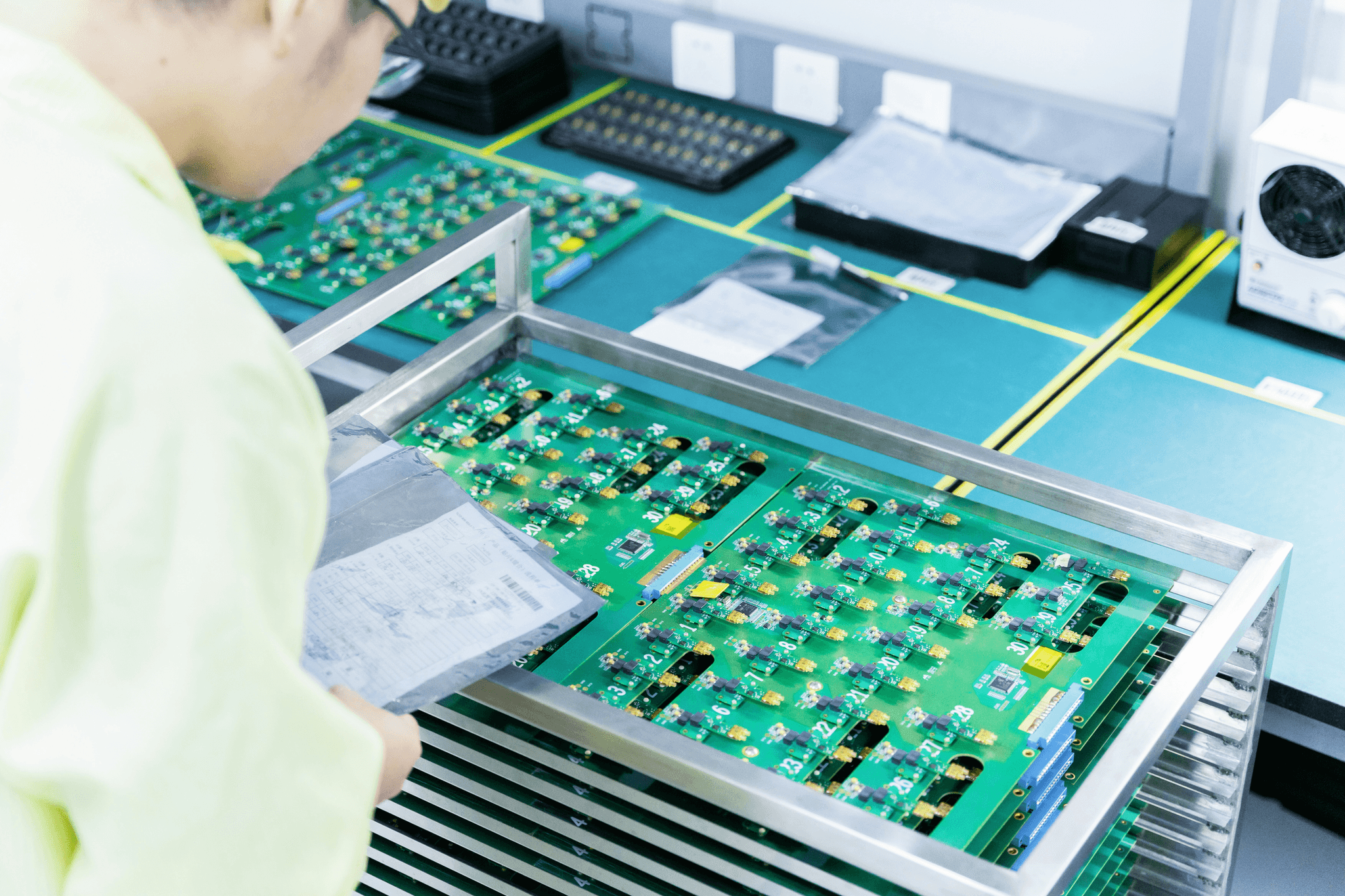

One notable success story involves a major electronics manufacturer that faced challenges with product consistency due to varying supplier standards. By partnering with China Inspection Pro for regular quality inspections, they were able to implement robust quality control measures that significantly reduced defect rates by over 30%. This partnership not only enhanced their production inspection processes but also fostered stronger relationships with suppliers who adapted to meet the new standards.

Real-World Examples of Production Inspection Benefits

The benefits of effective production inspection extend far beyond immediate defect detection; they fundamentally transform operational efficiency and customer satisfaction. For instance, a clothing manufacturer implemented systematic quality inspections at various stages of their production line, resulting in a remarkable decrease in returns due to defects. This proactive approach emphasized the critical role of quality assurance in maintaining brand reputation while simultaneously boosting profitability through reduced waste.

Another compelling example comes from an automotive parts supplier that adopted stringent quality control measures after experiencing significant losses from defective components reaching customers. By integrating comprehensive production inspections into their workflow, they achieved a 40% reduction in warranty claims within just one fiscal year. These real-world examples showcase how prioritizing quality inspection can lead to substantial financial gains while reinforcing trust between manufacturers and consumers.

Lessons Learned from Quality Control Failures

While success stories are inspiring, learning from failures is equally crucial in refining production inspection practices. One infamous case involved a well-known toy manufacturer that faced massive recalls due to safety violations attributed to inadequate quality control measures during production inspections. This incident underscored the importance of establishing thorough protocols for both quality assurance and ongoing monitoring throughout the manufacturing process.

Another lesson emerged from an electronics company that neglected proper training for staff responsible for conducting internal audits on production lines. The oversight led to missed defects and ultimately resulted in significant reputational damage when faulty products reached consumers' hands. Such failures highlight the need for consistent training programs focused on enhancing employees' understanding of both quality control control techniques and effective implementation strategies for ongoing improvement.

In conclusion, these case studies reflect how embracing best practices in production inspection can yield significant advantages while simultaneously illustrating pitfalls that must be avoided through diligent attention to detail and continuous improvement efforts.

Conclusion

In wrapping up our exploration of production inspection, it's clear that quality assurance and quality control are not just industry buzzwords—they're essential frameworks that drive success in manufacturing. As we look ahead, the future trends in quality assurance are set to evolve, focusing on more integrated approaches and advanced technologies. By embracing these changes, manufacturers can enhance their quality assurance quality and ensure robust production processes.

Future Trends in Quality Assurance

One of the most exciting future trends in quality assurance is the integration of AI and machine learning into quality control systems. These technologies promise to revolutionize how we approach production inspection by enabling real-time data analysis and predictive maintenance strategies. With a keen focus on improving overall efficiency, companies can expect a significant boost in their ability to maintain high-quality standards throughout the manufacturing process.

Another trend gaining traction is the emphasis on sustainability within quality assurance practices. Manufacturers are increasingly recognizing that maintaining high-quality products goes hand-in-hand with environmental responsibility. This shift not only enhances brand reputation but also aligns with consumer demand for sustainable practices, ultimately leading to improved quality control outcomes.

Lastly, collaboration between departments—such as engineering, production, and supply chain—will become more pronounced in future quality assurance initiatives. By fostering a culture of teamwork where everyone shares responsibility for maintaining product integrity, organizations will see enhanced communication and fewer discrepancies during production inspection processes.

Enhancing Quality Control Methods

To enhance existing quality control methods, businesses must prioritize continuous training for their teams on the latest techniques and tools available for effective quality inspection. This commitment to education ensures that employees remain informed about best practices while also cultivating an environment where innovation thrives. When staff members are equipped with the knowledge they need to excel at their roles, it translates directly into higher standards of product output.

Moreover, leveraging technology such as automated inspection systems can significantly improve both accuracy and efficiency during production inspections. These tools allow for consistent monitoring of product specifications while reducing human error—a win-win scenario for any manufacturer invested in maintaining high-quality products through rigorous quality control measures. The combination of skilled personnel and advanced technology paves the way for elevated standards across all aspects of manufacturing.

Finally, establishing clear metrics for evaluating performance within your quality control framework is essential for ongoing improvement efforts. By regularly assessing these metrics against established benchmarks or industry standards, companies can identify areas needing attention while also celebrating successes along their journey toward achieving excellence in production inspection.

Achieving Excellence in Production Inspection

Achieving excellence in production inspection requires a holistic approach that encompasses both proactive measures and reactive strategies when issues arise within manufacturing processes. Companies must cultivate a mindset geared toward continuous improvement by actively seeking feedback from various stakeholders involved—from suppliers to end-users—to refine their operations continuously. This dedication ensures that every aspect of product development meets or exceeds established expectations related to both safety and functionality.

Furthermore, fostering an organizational culture centered around accountability plays a pivotal role in ensuring consistent adherence to stringent guidelines surrounding both quality assurance qc practices as well as broader operational protocols across departments involved within each stage of production inspection workflows—ultimately leading towards superior outcomes overall!

In conclusion, thriving amidst today's competitive landscape demands an unwavering commitment towards integrating effective strategies rooted deeply within sound principles governing both Quality Assurance & Quality Control methodologies alike; thereby empowering organizations towards realizing unparalleled success through exceptional products delivered consistently over time!