Introduction

Navigating the labyrinth of LFGB Testing Requirements can feel like trying to solve a Rubik's cube blindfolded. However, understanding these requirements is crucial for anyone looking to ensure their products meet the necessary standards for safety and compliance in the German market. With growing consumer awareness and regulatory scrutiny, compliance with LFGB is not just a box to tick—it's a pathway to market success.

Understanding LFGB Testing Requirements

At its core, LFGB, or the Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch, establishes testing requirements that safeguard public health by ensuring that products are free from harmful substances. Familiarity with these testing requirements is essential for manufacturers and importers alike, as they dictate how products are assessed before reaching consumers. By grasping what is required under LFGB, businesses can streamline their processes and avoid costly non-compliance penalties.

Importance of LFGB Compliance

The importance of LFGB compliance cannot be overstated; it acts as a critical gatekeeper for product safety in the European market. Non-compliance can lead to severe repercussions such as product recalls, legal action, and irreparable damage to brand reputation. Therefore, adhering to LFGB standards not only protects consumers but also fortifies businesses' standing in a competitive landscape.

Overview of LFGB and Its Scope

LFGB covers an extensive range of products aimed at ensuring food safety and consumer protection. From kitchenware to tableware, understanding which products fall under this regulation is vital for compliance efforts. Moreover, recognizing the broader scope of LFGB helps companies anticipate changes in regulatory landscapes across different markets while preparing them for potential challenges ahead.

What is LFGB?

Understanding LFGB is crucial for manufacturers and importers looking to navigate the European market successfully. The German Food and Feed Code, commonly referred to as LFGB, sets forth stringent regulations aimed at ensuring consumer safety regarding food contact materials. This section will delve into the definition and purpose of LFGB, its historical context, and the key regulatory bodies involved in its enforcement.

Definition and Purpose of LFGB

The LFGB (Lebensmittel- und Futtermittelgesetzbuch) serves as Germany's primary legislation governing food safety and hygiene standards. Its main purpose is to safeguard public health by regulating materials that come into contact with food, including kitchenware and tableware. By adhering to LFGB testing requirements, manufacturers can ensure their products are safe for consumer use while also enjoying access to the European market.

Historical Context of LFGB Regulations

LFGB regulations have evolved significantly since their inception in the early 20th century, reflecting growing concerns about food safety and material toxicity. Originally established to address public health issues related to contaminated food supplies, these regulations have expanded over time to encompass a wider array of products that interact with food. Understanding this historical context helps illustrate why compliance with LFGB testing requirements is not just a bureaucratic hurdle but a vital aspect of consumer protection.

Key Regulatory Bodies Involved

Several key regulatory bodies oversee the implementation and enforcement of LFGB regulations in Germany and across Europe. The Federal Ministry of Food and Agriculture (BMEL) plays a pivotal role in shaping policies related to food safety standards under the LFGB framework. Additionally, various regional authorities conduct inspections and testing procedures to ensure compliance with these stringent standards—making it essential for businesses to understand which products does LFGB cover thoroughly.

Which Products Does LFGB Cover?

When it comes to LFGB testing requirements, understanding which products fall under its purview is essential for manufacturers and retailers alike. The LFGB, or the German Food and Feed Code, establishes rigorous safety standards that ensure consumer protection in various product categories. Compliance with these standards not only meets legal obligations but also enhances marketability by demonstrating a commitment to quality and safety.

Common Product Categories Under LFGB

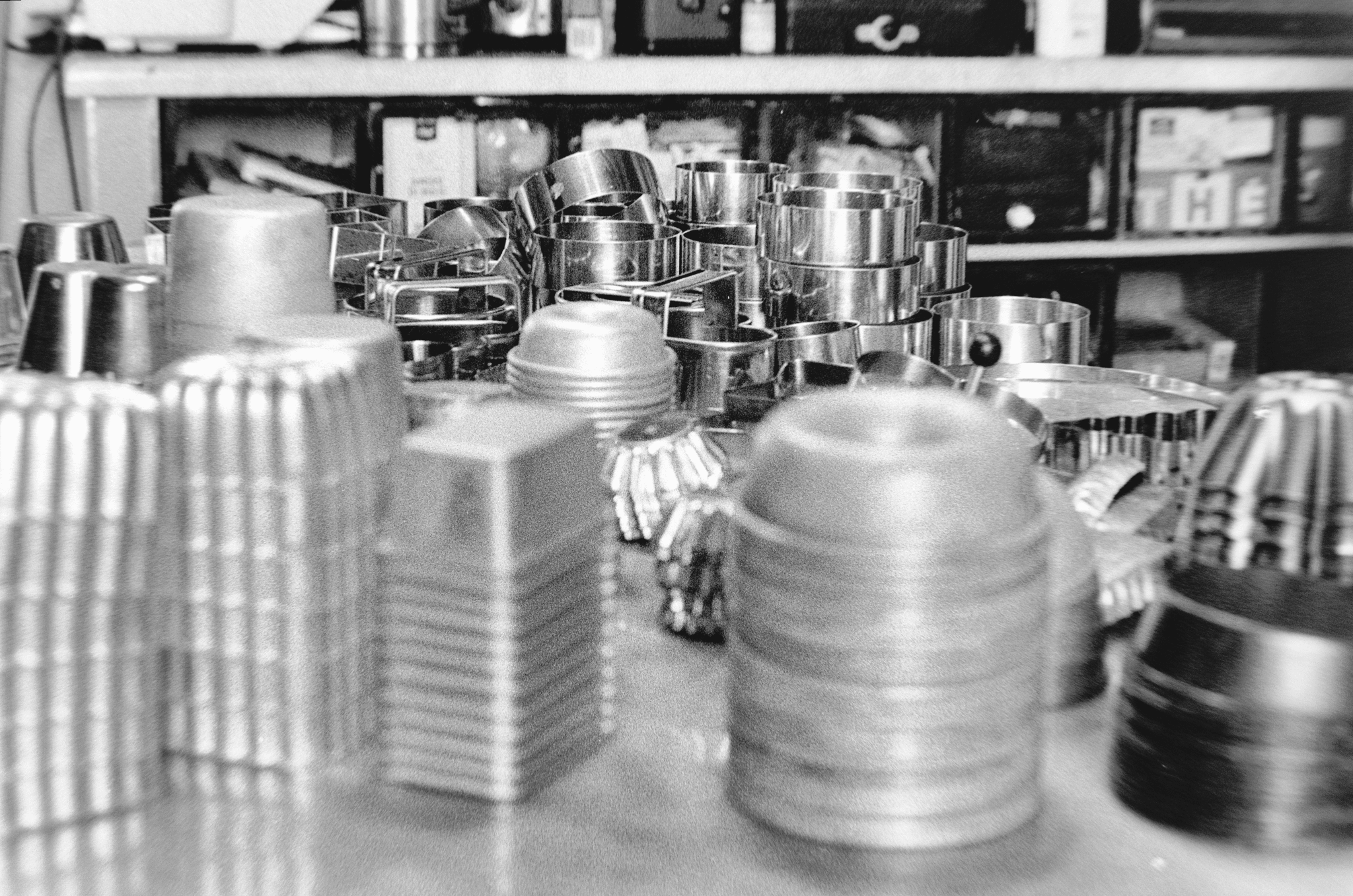

The LFGB covers a broad spectrum of product categories, primarily focusing on items that come into direct contact with food. This includes kitchenware, tableware, and food storage containers that are used in households and restaurants alike. Each of these categories is scrutinized under strict testing requirements to ensure they do not leach harmful substances into food or beverages.

Moreover, the scope of LFGB extends beyond just traditional kitchen items; it also includes utensils made from plastics, ceramics, glass, and metals. Each material type has specific guidelines regarding its safety and suitability for food contact applications. By adhering to these regulations within common product categories under LFGB, manufacturers can confidently market their goods while ensuring consumer safety.

Specifics on Kitchenware and Tableware

Kitchenware and tableware are perhaps the most scrutinized product types under the LFGB framework due to their direct interaction with food consumption. Items such as pots, pans, plates, cutlery, and serving utensils must meet stringent chemical migration limits set forth by the regulations. These specifics are crucial because they help prevent potential health risks associated with toxic substances leaching from materials used in manufacturing these items.

In addition to chemical safety concerns, kitchenware must also demonstrate durability and resistance to wear over time—factors that can affect overall performance during everyday use. Manufacturers must conduct thorough testing procedures as part of their compliance efforts for products like non-stick cookware or melamine dinner sets under the LFGB guidelines. Understanding what is required for kitchenware compliance helps businesses avoid pitfalls associated with non-compliance while ensuring customer satisfaction.

Importance of Material Safety in Product Categories

Material safety plays a pivotal role in determining whether products comply with the LFGB regulations effectively. The focus on safe materials ensures that consumers are protected from harmful chemicals that could potentially migrate into their food during cooking or serving processes. This aspect becomes increasingly important as consumers grow more aware of health risks associated with certain materials commonly used in kitchen products.

By prioritizing material safety within various product categories covered by the LFGB framework—including plastics free from BPA or lead-free ceramics—manufacturers can build trust among consumers who prioritize health-conscious choices when selecting kitchen items. In light of this emphasis on material integrity, businesses should consider partnering with China Inspection Pro to ensure compliance testing meets all necessary standards before launching products into the market.

In conclusion, understanding which products does LFGB cover—and why material safety matters—is vital for any business looking to thrive in markets where compliance is not just recommended but required by law.

LFGB vs. FDA: Understanding the Differences

When it comes to ensuring product safety, understanding the nuances between LFGB and FDA regulations is crucial for manufacturers and importers alike. Both frameworks aim to protect consumers but do so through different methodologies and criteria. This section will delve into how these two regulatory giants stack up against each other.

Comparing LFGB and FDA Regulations

LFGB, or the German Food and Feed Code, is primarily focused on food safety in Germany and the European Union, while the FDA (Food and Drug Administration) oversees food safety in the United States. One of the key differences lies in their approach to compliance; LFGB emphasizes rigorous testing of materials that come into contact with food, whereas FDA regulations may allow for broader interpretations based on existing safety data. Additionally, LFGB has specific provisions for various product categories under its scope, which can lead to more stringent requirements compared to general FDA guidelines.

Distinct Compliance Standards and Testing Procedures

The testing requirements for LFGB compliance are notably detailed and often require third-party certification from accredited laboratories. In contrast, while FDA regulations also necessitate testing, they may not always demand independent verification as stringently as LFGB does. This distinction means that manufacturers must be particularly vigilant about meeting LFGB testing requirements if they wish to market their products in Europe.

Implications of Non-Compliance in Different Markets

Non-compliance with LFGB can lead to severe repercussions such as product recalls, fines, or even bans on selling products within EU markets—an outcome that could severely damage a brand’s reputation globally. On the other hand, non-compliance with FDA regulations can result in similar penalties but may also affect a company's ability to enter or compete effectively within the U.S. market. Therefore, understanding Which Products Does LFGB Cover? is essential for businesses aiming for success across both regions without running afoul of either regulatory body.

Testing Requirements for LFGB Compliance

When it comes to LFGB Testing Requirements, understanding the specific protocols is crucial for manufacturers and importers aiming for compliance. The testing process not only ensures that products meet safety standards but also helps businesses avoid costly recalls or legal issues. With various testing requirements in place, it's essential to navigate this landscape effectively.

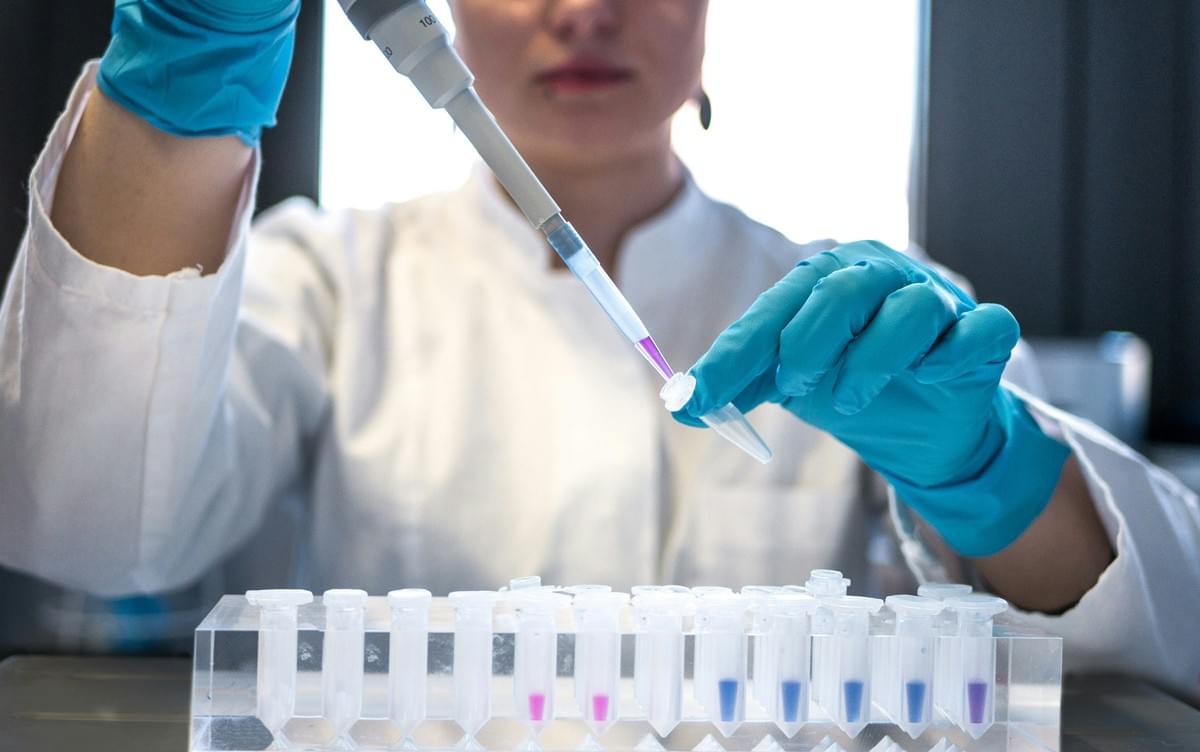

Overview of Testing Protocols

The testing protocols under LFGB are designed to assess the safety and suitability of materials used in kitchenware and tableware products. These protocols typically involve a series of tests that evaluate factors such as migration of harmful substances, mechanical stability, and overall durability. By adhering to these established protocols, companies can ensure their products align with what is LFGB? standards, thus reinforcing consumer trust.

In addition to standard testing methods, the LFGB regulations may require additional assessments depending on the product category. For example, items made from plastics may undergo specific tests targeting chemical leaching, while ceramics might focus on thermal shock resistance. Understanding these nuances is vital for businesses looking to thrive in markets where compliance with LFGB is non-negotiable.

Importance of Material Testing and Certification

Material testing and certification are at the heart of LFGB compliance—without them, your products could be destined for disaster! Ensuring that materials used in production meet stringent safety criteria protects consumers from potential health risks associated with unsafe materials. Moreover, certified products often enjoy better market acceptance and can command higher prices due to their proven safety credentials.

LFGB mandates rigorous material testing because even minor lapses can lead to significant repercussions—both legally and financially. Manufacturers must recognize that investing in thorough material testing is not just about ticking boxes; it's about fostering a reputation for quality and safety within the industry. This commitment ultimately translates into long-term success in competitive markets.

The Role of Compliance Testing Labs

Compliance testing labs play a pivotal role in helping businesses meet LFGB Testing Requirements efficiently and effectively. These specialized facilities conduct comprehensive assessments based on established protocols tailored specifically for various product categories covered under LFGB regulations. By partnering with reputable labs, companies can streamline their compliance processes while ensuring accurate results.

Testing labs not only provide certifications but also offer valuable insights into potential areas of improvement within product designs or materials used—an invaluable resource for manufacturers striving to enhance quality control measures continuously. Additionally, these partnerships enable businesses to stay updated on evolving regulations related to which products does LFGB cover? This proactive approach minimizes risks associated with non-compliance while maximizing market opportunities.

If you’re serious about navigating the complexities surrounding LFGB compliance smoothly, consider collaborating with experts like China Inspection Pro! Their professional inspection services simplify the process by providing guidance through every step—from initial assessments through final certification—making your journey toward compliance as seamless as possible.

Partner with China Inspection Pro to Ensure LFGB Compliance

Navigating the labyrinth of LFGB Testing Requirements can be daunting, but partnering with a professional inspection service like China Inspection Pro can make the journey smoother. By leveraging their expertise, you can ensure that your products meet all necessary standards and regulations. This partnership not only enhances product safety but also boosts your brand's reputation in a competitive market.

Benefits of Professional Inspection Services

These experts have in-depth knowledge of LFGB Testing Requirements and can guide you through the complexities of compliance. With their help, businesses can avoid costly mistakes and ensure that their products align with both local and international standards.

Additionally, professional inspectors provide thorough assessments that cover various aspects of compliance, including material safety and testing protocols. They are well-versed in which products does LFGB cover, ensuring that no stone is left unturned in your quest for compliance. Ultimately, this reduces the risk of non-compliance issues down the line.

Streamlined Processes for Testing and Compliance

The streamlined processes offered by China Inspection Pro simplify the often convoluted journey to achieving LFGB compliance. Their approach ensures that all necessary testing requirements for LFGB compliance are met efficiently, saving you time and resources. From initial consultations to final certification, every step is designed to be as straightforward as possible.

Moreover, these professionals utilize advanced technology and methodologies to expedite testing procedures without compromising quality. Their expertise allows businesses to focus on product development while ensuring they meet both LFGB and FDA regulations seamlessly. This efficiency translates into faster time-to-market for compliant products.

Success Stories from China Inspection Pro Clients

China Inspection Pro has an impressive track record of helping clients navigate the intricate landscape of LFGB vs. FDA: Understanding the Differences in regulatory requirements. Many companies have successfully launched their products after partnering with them for comprehensive inspections and testing services tailored specifically around LFGB Testing Requirements.

One notable success story involves a kitchenware manufacturer who faced challenges meeting stringent material safety standards before working with China Inspection Pro. After thorough evaluations and precise adjustments based on expert feedback, they achieved full compliance under LFGB regulations—leading to increased sales across European markets! These stories highlight how essential it is to partner with knowledgeable professionals when aiming for seamless compliance.

Conclusion

Navigating the labyrinth of LFGB Testing Requirements can seem daunting, but with the right approach and knowledge, it becomes manageable. Understanding what is LFGB? and how it impacts your products is crucial for ensuring compliance. By familiarizing yourself with which products does LFGB cover? you can streamline your path to market entry in Germany and beyond.

Navigating LFGB Testing Without Hassle

This will help you determine the necessary testing protocols and avoid potential pitfalls in compliance that could delay your product launch or lead to costly rework.

Partnering with professionals who specialize in LFGB compliance, such as China Inspection Pro, can significantly ease this process. They provide valuable insights into testing requirements for LFGB compliance and guide you through each step of the journey. With their expertise, navigating these waters becomes less of a chore and more of a streamlined experience.

The Impact of Compliance on Market Success

Compliance with LFGB regulations isn't just a box-ticking exercise; it's essential for market success. Products that meet these standards are more likely to gain consumer trust, leading to increased sales and brand loyalty. In contrast, non-compliance can lead to serious repercussions not only in terms of regulatory fines but also damage to reputation.

Understanding the differences between LFGB vs. FDA regulations further emphasizes this point; while both aim for safety, their approaches vary significantly. This means that businesses targeting multiple markets must be diligent about adhering to each set of standards accordingly. Ultimately, successful navigation through these regulations translates into a competitive edge in the marketplace.

Final Thoughts on LFGB and Product Safety

In conclusion, prioritizing understanding what is LFGB? along with its associated testing requirements is paramount for any business involved in food contact materials or kitchenware production. The significance of material safety cannot be overstated; it serves as the cornerstone for consumer confidence and brand integrity within various markets.

As you embark on your journey toward compliance, remember that partnering with China Inspection Pro ensures you're not alone in this endeavor—expert guidance is just around the corner! Emphasizing thorough testing requirements for LFGB compliance will ultimately pave the way for safer products that resonate well with consumers' expectations.