Introduction

In today's fast-paced manufacturing landscape, understanding AQL 2.5 in inspections is essential for maintaining high standards of quality control. AQL, or Acceptable Quality Level, serves as a crucial benchmark that helps businesses determine the maximum number of defective items permissible in a sample batch. By implementing AQL sampling techniques, companies can effectively balance cost and quality while ensuring their products meet customer expectations.

Understanding AQL 2.5 in Inspections

AQL 2.5 specifically refers to an acceptable quality level where the maximum allowable defect rate is set at 2.5%. This means that for every 100 items inspected, up to two or three defects may be accepted without triggering further action. Quality inspection services utilize this standard to streamline their processes and provide reliable assessments of product quality.

Importance of Quality Control

Quality control is not just a checkbox on a production list; it’s the backbone of any successful manufacturing operation. With effective quality control measures in place, businesses can reduce waste, enhance customer satisfaction, and ultimately improve their bottom line. The role of a quality control inspector becomes pivotal here as they ensure adherence to standards like AQL 2.5 throughout the inspection process.

Key Concepts in AQL Standards

Understanding key concepts within AQL standards can significantly impact how companies approach their quality inspection strategies. Terms like acceptance number, sample size, and defect classification are fundamental when using tools such as an AQL calculator for determining acceptable levels of defects during inspections. By grasping these concepts, organizations can make informed decisions that bolster their overall product integrity while navigating the complexities of modern manufacturing demands.

What is AQL 2.5?

AQL 2.5, or Acceptable Quality Level at 2.5%, is a critical standard in quality control that helps businesses determine the maximum number of defective items considered acceptable during random sampling inspections. This level strikes a balance between maintaining product quality and minimizing costs associated with over-inspection. By implementing AQL 2.5, companies can ensure that their products meet customer expectations while efficiently managing resources.

Definition and Purpose

AQL 2.5 serves as a guideline for quality control inspectors when assessing the acceptability of a batch of products based on predetermined criteria. The primary purpose of this standard is to provide a clear, quantifiable measure of quality that can be applied consistently across various industries during quality inspections. By utilizing an AQL calculator, businesses can easily determine how many items to sample from a lot and what defect rate is permissible, thus simplifying the inspection process.

Differences from Other AQL Levels

While there are several AQL levels—such as 1.0, 1.5, and others—AQL 2.5 offers a middle ground that balances risk and cost more effectively than its counterparts. For instance, an AQL level of 1.0 would allow for fewer defects in the same sample size compared to AQL 2.5, which could lead to increased inspection costs without significantly improving product quality assurance outcomes. This makes AQL 2.5 particularly appealing for industries where maintaining competitive pricing while ensuring adequate quality control is essential.

Applications in Quality Inspections

AQL 2.5 finds its applications across various sectors including electronics manufacturing, textiles, and food safety inspections among others—all areas where product quality directly impacts consumer satisfaction and safety standards compliance. In these industries, effective use of AQL sampling allows businesses to maintain high-quality products without incurring excessive costs associated with stringent inspection processes or rework due to defects identified post-production by a quality control inspector or through inspection services like China Inspection Pro's offerings.

How AQL 2.5 Works

When it comes to maintaining high standards in quality control, AQL 2.5 is a game-changer. This standard provides a structured approach to quality inspections, ensuring that products meet specified criteria before they reach consumers. By understanding how AQL 2.5 works, businesses can significantly improve their quality control processes and enhance overall product reliability.

The Sampling Process Explained

The sampling process is at the heart of AQL 2.5, allowing quality control inspectors to evaluate a portion of the total production batch rather than inspecting every single item. In this method, an aql calculator helps determine the sample size and the acceptance number based on the desired quality level of 2.5%. This means that if the number of defective items in the sample exceeds a predetermined limit, the entire batch fails inspection, prompting necessary corrective actions.

This strategic approach saves time and resources while still providing reliable insights into product quality. It’s essential for manufacturers to grasp this sampling process as it directly influences their ability to maintain compliance with industry standards and customer expectations. Ultimately, effective use of AQL sampling ensures that only products meeting stringent quality control measures make it to market.

Understanding Acceptable Quality Levels

Acceptable Quality Levels (AQL) are benchmarks that define what constitutes an acceptable number of defects in a given sample size during inspections. With AQL 2.5 specifically targeting a maximum defect rate of 2.5%, businesses can set clear expectations for product quality across various industries—be it electronics or textiles. Understanding these levels allows companies to balance cost efficiency and product integrity effectively.

Quality control inspectors play a crucial role in interpreting these levels during inspections, ensuring that any deviations from standards are promptly addressed before products reach consumers' hands. By utilizing tools like an aql calculator during this phase, manufacturers can streamline their evaluation process and minimize risks associated with poor-quality goods reaching the market. Familiarity with acceptable quality levels thus empowers organizations to uphold their reputation while fostering customer trust.

Benefits of Using AQL 2.5

Implementing AQL 2.5 offers numerous benefits for companies focused on enhancing their overall quality control strategies through rigorous inspection services and practices. First off, it provides clarity on acceptable defect rates—helping businesses identify areas needing improvement without overwhelming them with excessive scrutiny over every single item produced.

Moreover, utilizing AQL 2.5 fosters better communication between stakeholders regarding product expectations—ultimately leading to improved collaboration among teams involved in production and inspection processes alike! Finally, by adhering to established standards like AQL 2.5, organizations not only boost customer satisfaction but also position themselves competitively within their respective markets.

Industry Applications of AQL 2.5

AQL 2.5 has become a cornerstone in various industries, particularly where product quality is paramount. From electronics to textiles and food safety, the application of AQL standards ensures that products meet customer expectations while adhering to regulatory requirements. By implementing effective quality control measures through AQL sampling, businesses can enhance their reputation and reduce returns.

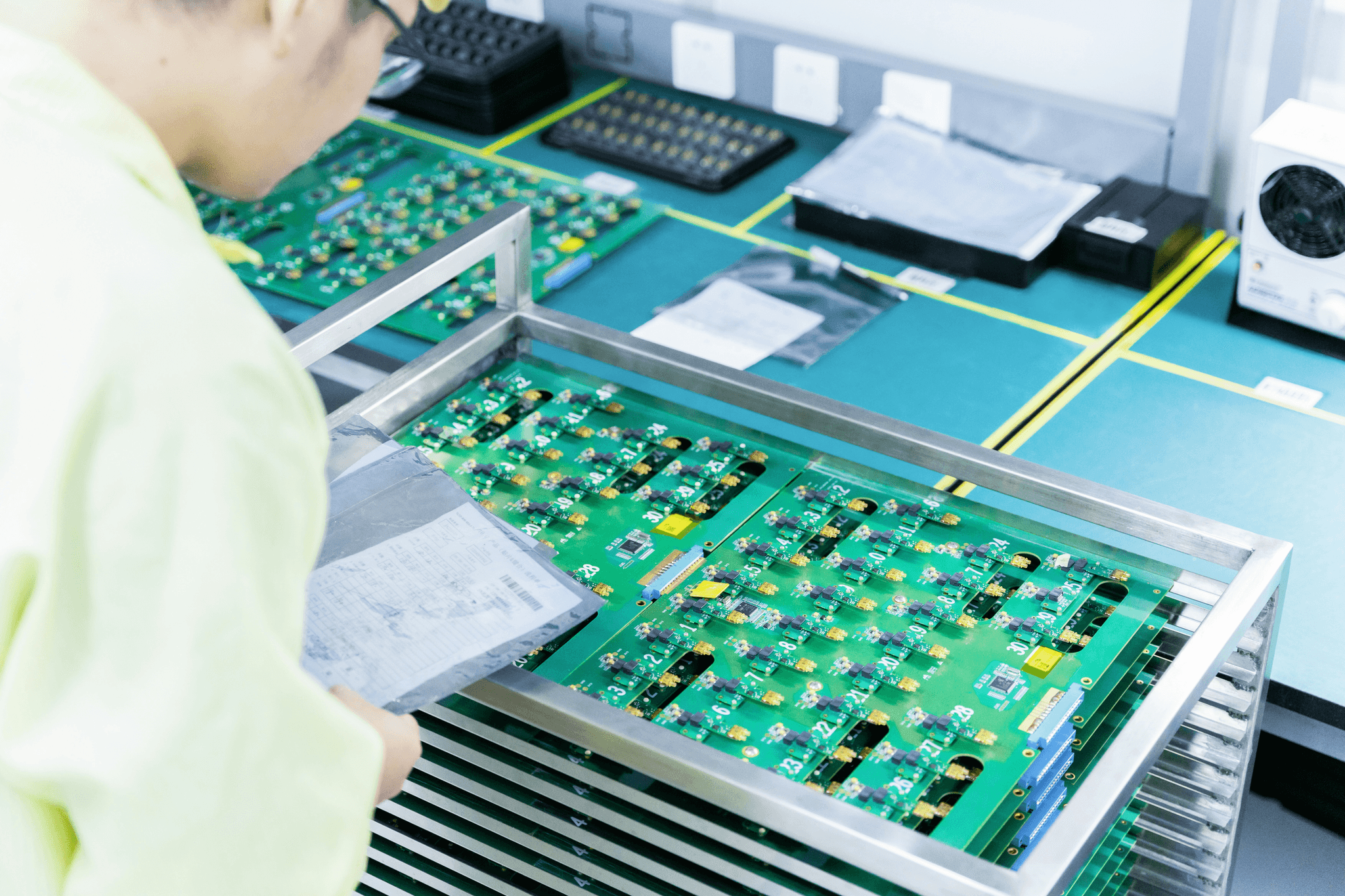

Electronics Manufacturing Case Study

In the fast-paced world of electronics manufacturing, maintaining high-quality standards is crucial for success. A case study involving a major electronics manufacturer revealed that using an AQL 2.5 approach significantly reduced defects in their production line. By employing skilled quality control inspectors and utilizing an AQL calculator for precise sampling, they improved overall product reliability while minimizing costs associated with rework and returns.

This manufacturer adopted rigorous quality inspection services to identify issues early in the production process, ensuring that only products meeting the AQL 2.5 criteria reached consumers. The results were impressive: a notable decrease in warranty claims and an increase in customer satisfaction ratings. Ultimately, this case illustrates how integrating AQL 2.5 into quality control practices can lead to enhanced operational efficiency and brand loyalty.

Textiles and Apparel Examples

The textile industry also heavily relies on AQL 2.5 standards to guarantee product consistency and safety across various garments and fabrics. For instance, a renowned apparel brand implemented these guidelines during its production processes to address common issues related to stitching defects and fabric flaws effectively. By employing professional inspection services at multiple stages of production, they ensured compliance with quality control measures that met or exceeded industry expectations.

Quality control inspectors utilized specific methodologies based on AQL sampling techniques to evaluate batches before shipment, allowing them to catch potential defects early on. This proactive approach resulted not only in better-quality products but also in reduced waste during manufacturing—an essential factor given today’s sustainability focus within the fashion industry. As such, brands using AQL 2.5 have seen improved market positioning due to their commitment to delivering high-quality apparel.

Food Safety Inspections

In food safety inspections, maintaining strict adherence to quality standards is non-negotiable; here too, AQL 2.5 plays a pivotal role in ensuring consumer safety and satisfaction. Food manufacturers often face challenges related to contamination or spoilage; however, by applying the principles of AQL 2.5 during their inspection processes, they can significantly mitigate these risks before products reach shelves.

Quality control inspectors conduct thorough assessments based on predefined acceptable quality levels defined by the standard—ensuring every batch meets stringent health regulations before distribution occurs through meticulous inspection services tailored for food safety compliance checks as part of their overall strategy for risk management practices within the supply chain framework . This method not only enhances consumer trust but also aligns with regulatory requirements set forth by governing bodies overseeing food safety protocols globally.

Role of Quality Inspection Services

In today's competitive marketplace, the role of quality inspection services cannot be overstated. Professional inspections are crucial for maintaining high standards in production and ensuring that products meet the required specifications. By employing a quality control inspector, businesses can identify potential defects early in the process, thereby minimizing costly recalls and enhancing customer satisfaction.

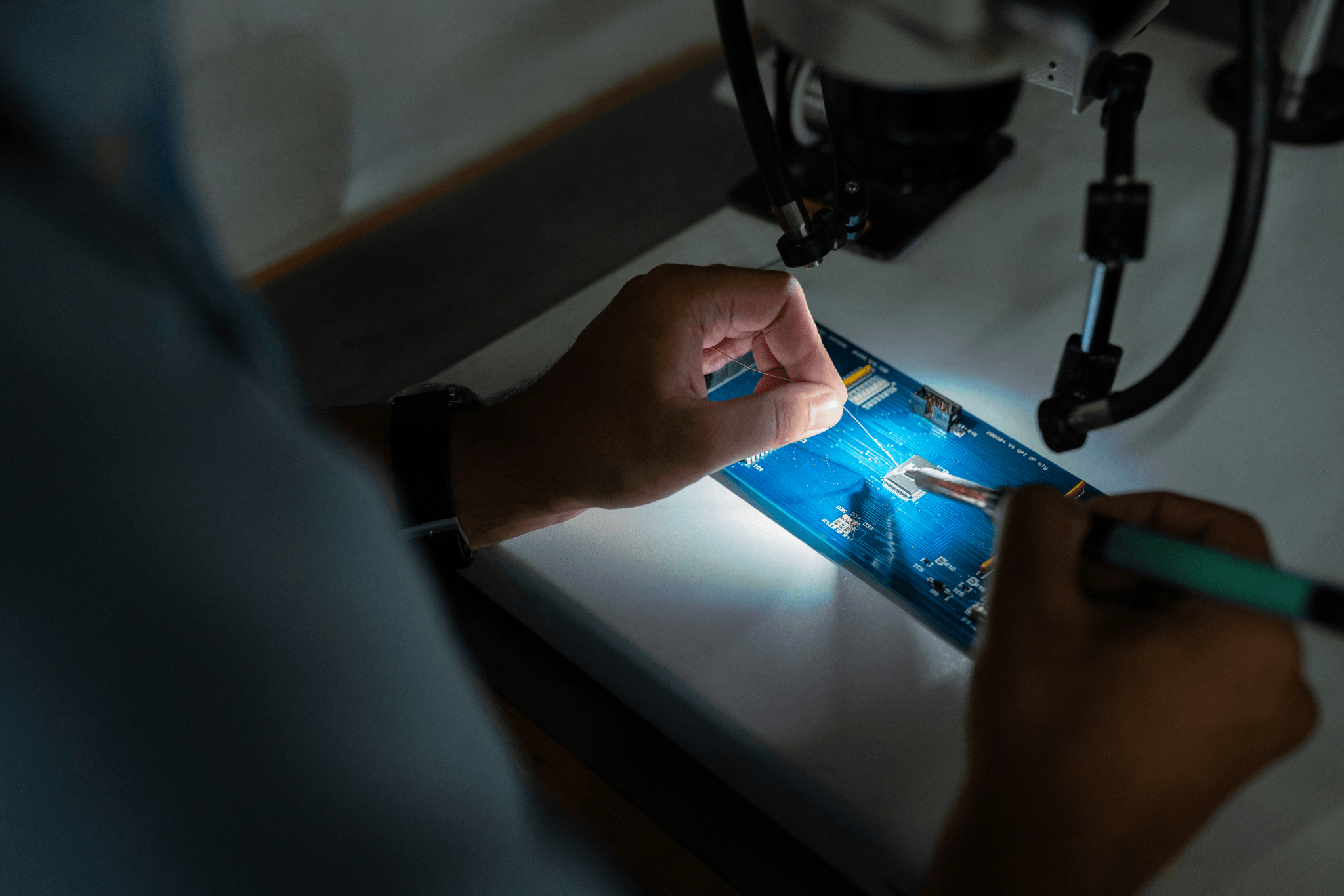

The Importance of Professional Inspections

Professional inspections play a vital role in quality control by providing an unbiased evaluation of products before they reach consumers. Utilizing AQL 2.5 sampling methods allows inspectors to determine acceptable quality levels efficiently and effectively, ensuring that any defects are caught before mass distribution. This level of scrutiny not only protects brand reputation but also fosters trust between manufacturers and consumers, leading to long-term business success.

How China Inspection Pro Can Help

China Inspection Pro stands out as a leader in providing comprehensive inspection services tailored to various industries. With expertise in AQL sampling techniques and a deep understanding of quality control standards, their team helps clients navigate the complexities of product inspections with ease. By leveraging an AQL calculator, businesses can make informed decisions about their production processes and maintain compliance with industry regulations.

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards is critical for any manufacturer looking to thrive in today's global market. Quality inspection services facilitate adherence to these standards by employing rigorous testing protocols based on established AQL levels like 2.5. By integrating professional inspections into their workflow, companies can enhance their quality control measures while simultaneously reducing risks associated with non-compliance.

Challenges in Implementing AQL 2.5

Implementing AQL 2.5 can be a daunting task for many organizations, primarily due to misunderstandings and operational hurdles that arise during the process. Quality control is not merely a checkbox exercise; it requires a cultural shift within the organization to prioritize quality at every level. As companies navigate this transition, they often encounter challenges that can derail their quality inspection efforts.

Common Misconceptions

One of the most prevalent misconceptions about AQL 2.5 is that it guarantees perfect quality in products inspected under this standard. In reality, while AQL sampling provides a statistical basis for assessing quality, it does not eliminate defects entirely; rather, it allows for an acceptable level of defects based on risk tolerance and production capabilities. Additionally, some believe that employing an AQL calculator alone will suffice for effective quality control; however, without trained quality control inspectors and robust processes in place, reliance solely on numbers can lead to significant oversights.

Another misconception is that AQL 2.5 applies uniformly across all industries or product types. The truth is that different sectors may require tailored approaches to meet their unique challenges and standards effectively. Understanding these nuances is critical for organizations looking to implement AQL 2.5 successfully.

Addressing Quality Control Issues

Quality control issues often stem from inadequate training or lack of understanding among staff regarding the importance of inspections and adherence to standards like AQL 2.5. Companies must invest in training programs that emphasize the significance of quality inspection services and equip employees with the necessary skills to identify defects accurately during production processes. This proactive approach not only mitigates risks but also fosters an organizational culture where quality becomes everyone's responsibility.

Moreover, communication gaps between teams involved in production and those handling inspections can lead to misunderstandings regarding expectations around product quality levels defined by AQL 2.5 standards. Establishing clear channels of communication helps ensure everyone is aligned on goals related to quality assurance while facilitating timely feedback loops when issues arise.

Strategies for Effective Implementation

To effectively implement AQL 2.5 within any organization, it’s crucial first to establish comprehensive procedures tailored specifically for your products and industry requirements—this includes defining how you’ll utilize your aql calculator effectively throughout the inspection process! Engaging professional inspection services early on can provide invaluable insights into best practices tailored toward achieving compliance with industry standards while also identifying potential pitfalls before they escalate into larger problems.

Additionally, developing a continuous improvement plan ensures ongoing evaluation of your processes against established benchmarks allows organizations to adapt as necessary over time—this means regularly reviewing data collected from inspections performed by qualified quality control inspectors! By doing so, businesses can refine their approaches continually while enhancing overall product integrity through informed decision-making based on real-time performance metrics derived from rigorous application of aql sampling techniques.

Conclusion

In wrapping up our exploration of AQL 2.5, it's clear that this standard plays a crucial role in the realm of quality control. By establishing a systematic approach to inspections, AQL 2.5 helps businesses maintain high-quality products while minimizing defects. This not only fosters customer satisfaction but also enhances brand reputation and trust in the marketplace.

Summarizing AQL 2.5 Benefits

AQL 2.5 offers several benefits that make it an essential tool for any quality control inspector. First and foremost, it provides a balanced framework for determining acceptable quality levels through effective aql sampling methods, ensuring that businesses can detect defects without excessive costs or delays. Additionally, the use of an aql calculator simplifies the process of evaluating samples, allowing companies to make informed decisions quickly and efficiently.

Enhancing Product Quality Assurance

The implementation of AQL 2.5 significantly enhances product quality assurance by establishing clear criteria for inspections and reducing variability in manufacturing processes. By adhering to these standards, businesses can improve their overall quality control measures and ensure that their products meet both internal specifications and external regulations consistently. Furthermore, regular quality inspections through professional inspection services help identify potential issues before they escalate into costly problems.

Taking Action with Quality Inspections

To truly harness the power of AQL 2.5, companies must take proactive steps towards integrating effective quality inspection practices into their operations. This involves not only training staff on best practices but also collaborating with experienced inspection services to ensure compliance with industry standards consistently. Ultimately, taking action now will lead to improved product reliability and customer satisfaction in the long run.