Introduction

In the realm of product quality, AQL—Acceptable Quality Level—stands as a pivotal concept that shapes how businesses approach quality control. Understanding AQL and its importance is essential for anyone involved in quality inspections, as it provides a framework for determining acceptable defect rates in products. By effectively utilizing table AQL, companies can ensure that their products meet the required standards before reaching consumers, thus safeguarding their reputation and minimizing losses.

Understanding AQL and Its Importance

AQL serves as a critical benchmark in quality inspection, allowing businesses to balance cost-efficiency with product reliability. It helps organizations define the maximum number of defects considered acceptable during a random sampling of products, which is crucial for maintaining customer satisfaction. Without an understanding of AQL, companies might struggle to implement effective quality checks, leading to potential issues down the line.

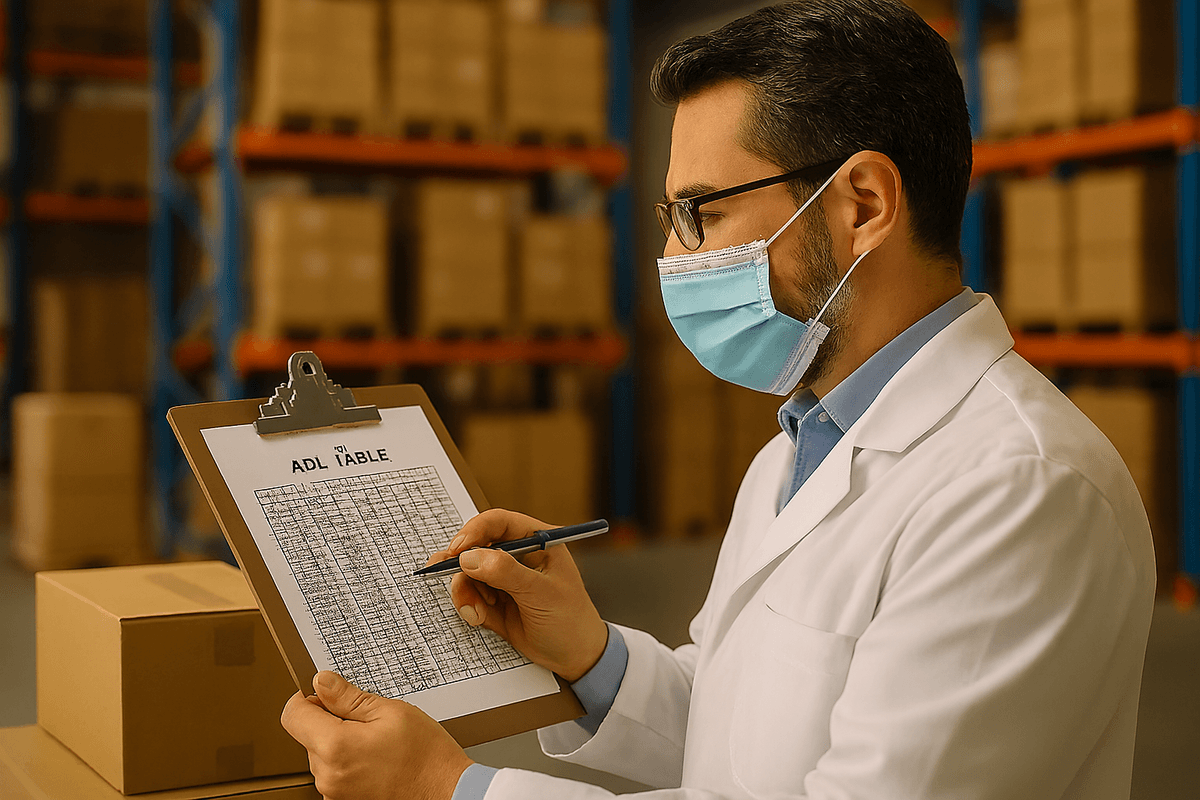

The Role of Quality Control in Inspections

Quality control plays a fundamental role in ensuring that products meet industry standards through systematic inspections and testing. Quality control companies employ trained quality control inspectors who utilize various methodologies—including AQL sampling—to assess product integrity before shipment. This proactive approach not only identifies defects early but also fosters continuous improvement within manufacturing processes.

Key Terminology in Quality Inspection

To navigate the world of quality inspection effectively, it's vital to familiarize oneself with key terminology related to AQL and its application. Terms such as defect rate, sampling plan, and acceptance criteria are integral to understanding how inspections are conducted and analyzed by quality inspection companies. Mastery of these concepts allows businesses to communicate more efficiently with their quality control teams and make informed decisions based on inspection results.

Defining AQL and Its Levels

Understanding Acceptable Quality Level (AQL) is crucial for any quality control process. AQL serves as a statistical measurement that defines the maximum number of defective items considered acceptable in a sample set during a quality inspection. This concept helps businesses balance product quality with cost-effectiveness, ensuring they meet customer expectations without overspending on unnecessary scrutiny.

Explanation of AQL Basics

At its core, AQL is a standard used in quality inspections to determine the level of defects permissible in a batch of products. It provides a clear guideline for quality control inspectors on how many defects can be tolerated before rejecting an entire shipment. By utilizing AQL sampling methods, companies can efficiently assess product quality while minimizing waste and maintaining operational efficiency.

The importance of understanding AQL basics cannot be overstated; it lays the foundation for effective quality checks across various industries. Knowing how to interpret these levels allows businesses to make informed decisions about their products and suppliers. Ultimately, this knowledge leads to enhanced relationships with quality control companies that specialize in inspections.

Types of AQL Levels: General vs. Special

AQL levels are generally categorized into two main types: general and special. General AQL applies to most production processes and is suitable for assessing typical defects that may occur during manufacturing or handling. On the other hand, special AQL is tailored for specific characteristics or critical items that require more stringent inspection criteria due to their importance or potential impact on safety.

Quality inspection companies often use both types of AQL levels when conducting assessments, depending on the nature of the product being inspected. Understanding these distinctions helps businesses select appropriate standards based on their specific needs and risk factors associated with their goods. This differentiation also aids quality control inspectors in focusing their efforts where they matter most.

Importance of Table AQL in Inspections

The table AQL is an essential tool in the arsenal of any quality control inspector, providing quick access to predefined acceptable limits based on sample sizes and inspection levels. This table outlines various combinations of lot size and allowable defect rates, making it easier for inspectors to determine whether a batch passes or fails during inspections. By using this resource effectively, companies can streamline their quality check processes while ensuring compliance with industry standards.

Moreover, leveraging table AQL enhances communication between manufacturers and their chosen quality control companies by establishing clear expectations upfront regarding defect tolerance levels. This clarity not only reduces misunderstandings but also fosters trust between parties involved in the production process—ultimately leading to better outcomes for all stakeholders involved in product delivery and satisfaction.

In conclusion, defining AQL and its various levels plays a pivotal role in establishing robust frameworks for effective inspections across industries—ensuring products meet required standards while optimizing resources used during evaluations.

Choosing the Right AQL for Your Product

Selecting the appropriate Acceptable Quality Level (AQL) is a crucial step in ensuring that your product meets quality standards without breaking the bank. It’s like finding that sweet spot between perfection and practicality, balancing customer satisfaction with cost-effectiveness. The right AQL not only helps in maintaining quality control but also plays a significant role in the overall success of your quality inspection process.

Factors Influencing AQL Selection

Several factors come into play when deciding on the appropriate AQL for your product, including industry standards, customer expectations, and production capabilities. For instance, if you’re dealing with high-stakes products like medical devices, you might opt for a stricter AQL to minimize risks. Conversely, for less critical items such as promotional merchandise, a more lenient AQL could suffice without jeopardizing overall quality control.

Another important consideration is the historical data from previous quality checks; if past inspections indicate recurring issues, it may be wise to lower your AQL to address those concerns effectively. Additionally, understanding your target market's tolerance for defects can guide you toward an acceptable level of quality that meets their needs while keeping costs manageable. Ultimately, selecting the right AQL involves a careful assessment of these factors to ensure optimal outcomes in your quality inspection efforts.

Common AQL Standards Across Industries

Different industries have established their own common standards when it comes to Acceptable Quality Levels (AQL). For example, in electronics manufacturing, an AQL of 0.65% might be standard due to the precise nature of components involved; any defect could lead to significant failures down the line. In contrast, textile industries often work with higher AQLs—typically around 2.5%—reflecting variations that are more acceptable given fabric tolerances.

The automotive industry also showcases varying levels of stringency depending on component criticality; safety-related parts usually demand an even stricter approach than non-critical components do. By familiarizing yourself with these industry-specific norms and table AQL references available through various quality control companies, you can make informed decisions about which levels best suit your products and customers alike.

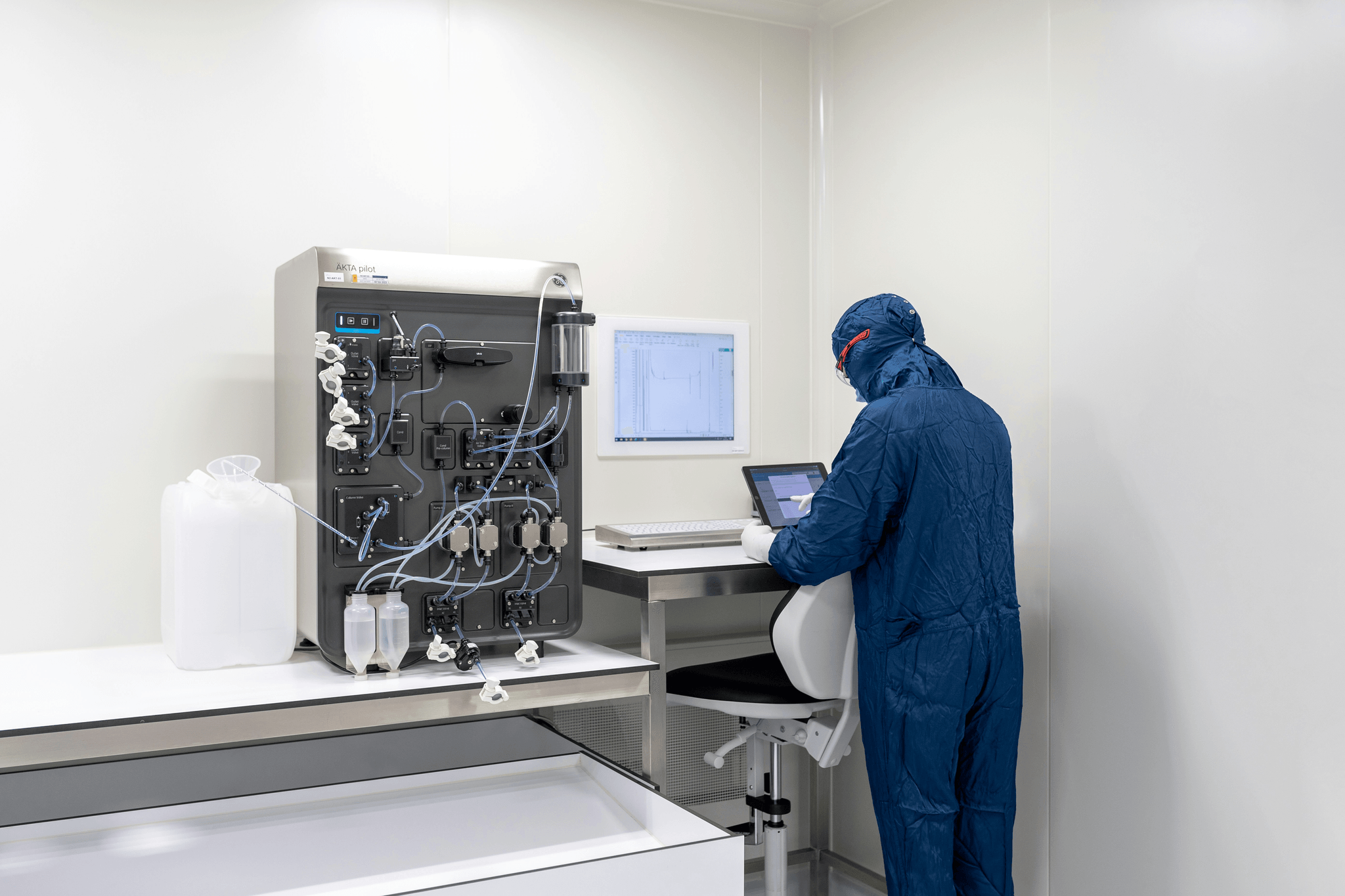

AQL in Relation to Quality Control Companies

Quality control companies play an essential role in helping businesses navigate the complexities of Acceptable Quality Levels (AQL). They provide expertise in selecting appropriate sampling techniques tailored specifically for each product type and industry requirement while also offering valuable insights into common pitfalls during inspections. By collaborating with experienced quality inspection companies, businesses can ensure they’re making educated choices about their AQL settings.

Moreover, these companies often utilize comprehensive table AQL resources that help clarify which levels are most suitable based on specific criteria such as lot size or defect types encountered during previous inspections. This partnership allows manufacturers to maintain rigorous standards while optimizing their processes through effective training programs for quality control inspectors focused on implementing best practices within inspections efficiently.

By leveraging these resources and relationships with reputable quality control companies, businesses can achieve better outcomes from their sampling strategies while minimizing risks associated with poor-quality products reaching consumers.

AQL Sampling Techniques

When it comes to ensuring product quality, AQL sampling techniques play a pivotal role in the quality inspection process. These methods allow quality control inspectors to evaluate a representative sample of products rather than examining every single item, which can be time-consuming and impractical. By employing effective AQL sampling strategies, businesses can maintain high standards while optimizing their resources.

Overview of AQL Sampling Methods

A variety of AQL sampling methods exist, each tailored to meet specific needs in quality checks. The most common techniques include random sampling, stratified sampling, and systematic sampling. Random sampling involves selecting items from a lot at random, while stratified sampling divides the lot into subgroups to ensure representation across different categories; systematic sampling follows a fixed interval approach for selection.

Quality control companies often utilize these methods in conjunction with table AQL to determine sample sizes and acceptance criteria based on the desired level of quality assurance. The choice of method can significantly impact the effectiveness of inspections and ultimately the satisfaction of customers. Understanding these techniques is crucial for any quality control inspector aiming to implement robust inspection processes.

Benefits of AQL Sampling in Quality Checks

The benefits of using AQL sampling techniques in quality checks are manifold and can lead to significant improvements in product reliability. First and foremost, these methods save time and resources by allowing inspectors to focus on a smaller subset rather than conducting exhaustive checks on every item produced. This efficiency not only reduces operational costs but also accelerates the overall inspection process.

Moreover, utilizing table AQL ensures that inspections are statistically sound, helping quality control companies make informed decisions about product acceptance or rejection based on empirical data rather than guesswork. Additionally, effective AQL sampling fosters continuous improvement by identifying trends or recurring issues within batches that may require further scrutiny or corrective action from manufacturers.

Case Studies from Quality Inspection Companies

Several notable case studies illustrate the successful application of AQL sampling techniques by leading quality inspection companies. For instance, one prominent firm implemented random sampling across its electronics manufacturing clients using table AQL as their guiding framework; this resulted in a 30% reduction in defective units reaching customers compared to previous practices without structured inspections.

In another example, a textile manufacturer partnered with a quality control company that adopted stratified sampling for its diverse range of fabrics; this approach allowed them to pinpoint specific flaws related to different fabric types efficiently while maintaining compliance with industry standards for each category. These cases highlight how strategic use of AQL sampling not only enhances product integrity but also boosts customer confidence through reliable quality checks.

Implementing AQL in Your Inspection Process

Integrating AQL into your quality inspection process is not just a step; it's a leap toward ensuring consistent product quality. By following a structured approach, you can seamlessly incorporate AQL sampling techniques into your existing quality control framework. This integration will enhance the effectiveness of inspections and foster better relationships with quality control companies.

Steps to Integrate AQL into Quality Inspections

The first step in integrating AQL into your quality inspection is to understand the specific requirements of your product and industry standards. Once you’ve established these parameters, you can select the appropriate table AQL that aligns with your quality check goals. Follow this by developing clear procedures for inspectors, detailing how they should utilize AQL sampling during their inspections to ensure accuracy and consistency.

Next, it’s essential to communicate these procedures across all levels of your organization, so everyone involved understands their role in maintaining high-quality standards. Regularly reviewing and updating these processes based on feedback from quality control inspectors will help keep them relevant and effective. Finally, consider implementing software solutions that assist in tracking inspection data against the defined AQL levels to streamline reporting and analysis.

Training Your Quality Control Inspector

Training is crucial for ensuring that your quality control inspector fully grasps the nuances of AQL sampling techniques. Start with comprehensive workshops that cover fundamental concepts like table AQL, types of defects, and how to interpret inspection results effectively. By providing hands-on training sessions with real-world scenarios from reputable quality inspection companies, you’ll help inspectors develop practical skills.

Encourage ongoing education by sharing resources about industry best practices related to quality checks and inspections using AQL methods. Regular refresher courses can also keep inspectors updated on any changes in standards or technologies relevant to their roles. Ultimately, a well-trained inspector not only improves the reliability of inspections but also enhances overall product quality.

Real-World Applications of AQL in Inspections

A variety of industries have successfully implemented AQL methodologies within their inspection processes, showcasing its versatility across different contexts. For example, electronics manufacturers often rely on table AQL during production runs to ensure components meet stringent specifications without incurring excessive costs associated with over-inspection or rework. These real-world applications illustrate how effective use of AQL can lead to both improved product reliability and customer satisfaction.

In another instance, textile companies utilize tailored sampling plans based on specific defect categories identified through previous inspections—this allows them to focus resources where they’re most needed while adhering strictly to established tolerances defined by table AQL standards. Such targeted approaches not only streamline operations but also enhance collaboration between manufacturers and their chosen quality control companies.

As more organizations recognize the value derived from adopting structured methodologies like AQL sampling techniques within their inspection protocols, it becomes increasingly evident that this practice leads directly towards achieving continuous improvement goals across various sectors.

Analyzing AQL Inspection Results

Analyzing the results from AQL inspections is crucial for ensuring that products meet quality standards and customer expectations. By effectively interpreting findings, businesses can make informed decisions that enhance their overall quality control processes. This section will delve into how to interpret AQL tables, leverage data for continuous improvement, and explore successful strategies from reputable quality inspection companies like China Inspection Pro.

Interpreting Findings with AQL Tables

Interpreting findings using table AQL is essential for any quality control inspector aiming to assess product quality accurately. These tables provide a clear framework for determining acceptance or rejection based on sample sizes and defect levels, guiding inspectors through the decision-making process. By understanding how to read these tables, companies can ensure their quality checks are both efficient and effective, ultimately leading to better product outcomes.

When analyzing results from an inspection, it’s important to consider both the number of defects found and the acceptable limits set by the chosen AQL level. For instance, if a company opts for a stricter AQL standard, even a small number of defects may lead to rejection during quality inspections. This nuanced understanding helps businesses align their production processes with customer expectations while maintaining robust relationships with quality control companies.

Using Data for Continuous Improvement

Data collected during AQL sampling should not be viewed as mere numbers; rather, they represent opportunities for continuous improvement within manufacturing processes. Quality inspection companies often emphasize the importance of analyzing trends in defect rates over time to identify underlying issues in production or supply chain management. By leveraging this data effectively, organizations can implement targeted changes that reduce defects and enhance overall product consistency.

Utilizing statistical analysis tools alongside table AQL results allows teams to pinpoint specific areas needing attention—whether it's machinery calibration or employee training related to quality checks. Moreover, regular reviews of inspection data can foster a culture of accountability among team members responsible for maintaining product standards. Ultimately, this proactive approach leads not only to improved product quality but also boosts customer satisfaction and loyalty.

Successful Strategies from China Inspection Pro

China Inspection Pro has implemented numerous successful strategies in analyzing AQL inspection results that other quality control companies can learn from. One key tactic is their commitment to real-time data collection during inspections; this enables immediate feedback loops between inspectors and production staff regarding any identified issues or trends in defects observed through table AQL evaluations. Such timely communication ensures that problems are addressed promptly before they escalate into larger concerns.

Another noteworthy strategy involves conducting regular training sessions for their quality control inspectors focused on interpreting data effectively and applying insights gained from past inspections towards future improvements in processes or materials used in production lines. This ongoing education fosters an environment where continuous improvement becomes part of everyday operations rather than just an afterthought following inspections.

Lastly, China Inspection Pro emphasizes collaboration across departments when analyzing inspection results—bringing together insights from design engineers, production managers, and sales teams allows them not only to understand why certain defects occur but also how those issues affect customer satisfaction levels directly linked back through rigorous application of table AQL methodologies during various stages of manufacturing cycles.

Conclusion

In the ever-evolving landscape of quality control, AQL (Acceptable Quality Level) continues to play a pivotal role in ensuring products meet the necessary standards before they reach consumers. As industries grow and diversify, the importance of effective quality inspection becomes increasingly evident. Embracing AQL not only enhances product reliability but also fosters trust between businesses and their customers.

The Future of AQL in Quality Control

Looking ahead, the future of AQL in quality control appears bright, with advancements in technology enhancing its application across various sectors. Innovations such as AI-driven quality checks and real-time data analysis are set to revolutionize how quality inspection companies approach their processes. As these technologies develop, we can expect more precise table AQL assessments that will streamline inspections and reduce errors.

Building Relationships with Quality Control Companies

Developing strong partnerships with quality control companies is essential for businesses aiming to maintain high-quality standards. These relationships facilitate better communication about expectations, leading to more effective quality checks that align with specific industry requirements. When companies collaborate closely with experienced quality control inspectors, they can leverage expertise that enhances their own internal processes while ensuring compliance with established AQL levels.

Taking Action: Transforming Inspection Results

To truly transform inspection results, businesses must take proactive steps toward implementing robust AQL sampling techniques within their operations. This involves not only training your team effectively but also fostering a culture of continuous improvement based on data-driven insights from past inspections. By utilizing findings from table AQL assessments and embracing feedback loops, organizations can significantly enhance product quality while reducing waste and costs associated with defective items.