Introduction

In today's fast-paced production environments, understanding the importance of sample checking is crucial for maintaining high-quality standards. Sample checks serve as a critical checkpoint in the quality control process, ensuring that products meet specified criteria before they reach consumers. By implementing effective sample checking practices, companies can enhance their overall quality assurance efforts and reduce costly errors.

Understanding Sample Checking Importance

What is sample checking? At its core, it involves inspecting a subset of products to gauge the quality of an entire batch without examining every single item. This method not only saves time and resources but also provides valuable insights into potential issues within production processes, making it an essential practice for businesses aiming for excellence.

Role of Sample Checking in Quality Control

The role of sample checking in quality control cannot be overstated; it acts as a safety net that catches defects before they escalate into larger problems. By routinely performing sample checks, organizations can identify trends and areas needing improvement, ultimately leading to enhanced product reliability. Moreover, effective sampling methods help ensure compliance with industry regulations and standards while fostering customer trust.

Overview of Key Checks in Sample Checking

When discussing key checks conducted during sample checking, several vital components come to mind: visual inspections, functional testing, and thorough documentation. Visual inspections allow teams to catch obvious defects at a glance, while functional testing ensures that products perform as intended under real-world conditions. Lastly, maintaining accurate documentation and traceability throughout the process not only supports accountability but also aids in continuous improvement efforts.

What is Sample Checking?

Sample checking is a crucial process in quality assurance that involves inspecting a subset of products or materials to ensure they meet predefined standards. This method allows organizations to evaluate the overall quality without the need for exhaustive testing of every single item produced. Essentially, it’s about being smart with resources while still maintaining high-quality outputs.

Definition and Purpose

At its core, sample checking refers to the practice of selecting a representative portion from a larger batch for inspection and analysis. The purpose is clear: by examining this smaller group, companies can infer the quality of the entire production lot without the time and cost associated with full inspections. This technique not only streamlines operations but also enhances efficiency in identifying defects early on, which is vital for maintaining customer satisfaction.

Historical Context in Quality Inspection

The roots of sample checking can be traced back to early industrial practices where mass production posed challenges in maintaining consistent quality. Initially, inspectors would check every item, leading to bottlenecks and inefficiencies; thus, sampling methods emerged as a solution during the 20th century. Over time, methodologies evolved alongside technological advancements, paving the way for more sophisticated sampling techniques that are widely used today across various industries.

Differences Between Sampling Methods

When discussing sample checking, it's essential to recognize that not all sampling methods are created equal; each comes with its own set of advantages and drawbacks. Random sampling ensures that every item has an equal chance of selection but may lead to variability if not enough samples are taken. On the other hand, systematic sampling follows a fixed interval approach which can provide more consistent results but might miss out on capturing anomalies present within specific segments of production.

Why Perform Sample Checking?

In the realm of quality assurance, sample checking is not just an optional practice; it’s a strategic necessity. By implementing effective sample checks, organizations can ensure that their products meet predefined standards and specifications before they reach consumers. This proactive approach helps in identifying defects early in the production process, thereby safeguarding brand reputation and customer satisfaction.

Benefits for Quality Assurance

One of the primary benefits of sample checking is its ability to enhance overall quality assurance efforts. By conducting regular sample checks, companies can systematically identify issues and rectify them before they escalate into larger problems. Furthermore, consistent application of key checks conducted during sample checking fosters a culture of continuous improvement within organizations, encouraging teams to strive for excellence.

Quality assurance through sample checking also builds consumer trust. When customers know that a company rigorously tests its products through systematic sampling methods, they are more likely to develop loyalty toward the brand. Ultimately, this commitment to quality not only protects consumers but also strengthens the business's market position.

Cost-Effectiveness in Production

Cost-effectiveness is another compelling reason why businesses should prioritize sample checking in their operations. Implementing a robust sampling strategy allows companies to detect faults early on, which can significantly reduce costs associated with recalls or rework later in the production cycle. In essence, investing time and resources into effective sample checks saves money by minimizing waste and maximizing productivity.

Moreover, when manufacturers perform regular sample checks instead of exhaustive inspections on every product unit, they can allocate resources more efficiently without compromising quality standards. This balance between thoroughness and efficiency leads to streamlined processes that ultimately benefit the bottom line. Therefore, embracing strategic sampling methods not only enhances product quality but also contributes positively to financial performance.

Risk Management and Compliance

Risk management is an essential aspect of any successful business strategy, making it crucial to understand why performing sample checking is vital for compliance purposes as well. Regulatory bodies often require companies to adhere to specific standards; failing to comply could result in hefty fines or reputational damage. By integrating systematic sampling into their quality control processes, businesses can demonstrate compliance while effectively managing risks associated with non-conformance.

Additionally, effective risk management involves anticipating potential issues before they arise—something that thorough sample checks excel at achieving. Companies that regularly conduct key checks during their sampling process are better equipped to navigate challenges such as supply chain disruptions or unexpected changes in consumer demand. In this way, sample checking serves as both a shield against risks and a tool for maintaining operational integrity.

Key Checks Conducted During Sample Checking

When it comes to ensuring quality, the checks conducted during sample checking play a pivotal role. These key checks not only determine the integrity of the products but also influence overall consumer satisfaction and brand reputation. By understanding what is sample checking and why perform sample checking, businesses can implement these checks effectively to uphold quality standards.

Visual Inspections and Measurements

Visual inspections are often the first line of defense in sample checking. Inspectors examine products for any obvious defects, such as scratches, discoloration, or misalignments that could affect functionality or aesthetics. Measurements are taken using calibrated tools to ensure that dimensions meet specified tolerances; this step is crucial because even minor deviations can lead to significant issues down the line.

In addition to identifying visible flaws, visual inspections help establish a baseline for quality assurance practices. They also serve as an educational opportunity for employees involved in production—highlighting common defects can foster a culture of continuous improvement. Ultimately, these checks contribute significantly to why perform sample checking: they catch problems early before they escalate into costly recalls or customer complaints.

Functional Testing of Products

Once visual inspections are complete, functional testing comes into play during sample checking to evaluate how well a product performs its intended function. This process involves simulating real-world usage scenarios to ensure that each item meets operational specifications and safety standards. For example, electronics might undergo stress tests while toys could be subjected to durability assessments.

Functional testing is essential because it provides insights into potential weaknesses in product design or manufacturing processes that might not be visible through visual inspection alone. By identifying these weaknesses early on, companies can make necessary adjustments before mass production begins—saving time and resources while enhancing customer satisfaction in the long run. Thus, when considering what is sample checking, functional testing emerges as a critical component that directly impacts product reliability.

Documentation and Traceability

Documentation is another key check conducted during sample checking that cannot be overlooked. Accurate records provide traceability throughout the supply chain—from raw materials to finished products—which is vital for compliance with industry regulations and standards. This documentation not only supports quality assurance efforts but also serves as evidence should any disputes arise regarding product safety or performance.

Traceability allows companies to pinpoint issues quickly if defects are discovered after distribution; they can track back through their processes to identify where things went wrong effectively. Moreover, proper documentation fosters transparency within organizations and builds trust with consumers who increasingly demand accountability from brands regarding their products' origins and safety measures taken during production processes. Therefore, understanding why perform sample checking includes recognizing its role in maintaining thorough documentation practices that enhance overall quality management systems.

Methods for Effective Sample Checking

In the world of quality control, effective sample checking is crucial for ensuring that products meet established standards. The methods employed can significantly impact the reliability and efficiency of the checks performed. By utilizing statistical techniques, advanced tools, and best practices, organizations can enhance their sample check processes.

Statistical Techniques Explained

When we talk about sample checking, statistical techniques are at the heart of effective quality assurance. These methods allow companies to make informed decisions based on data rather than guesswork. Techniques such as random sampling and stratified sampling help in understanding variations within a production batch, enabling businesses to identify defects early on and reduce waste.

Moreover, employing statistical process control (SPC) helps monitor production processes in real-time. By analyzing trends and patterns through control charts, organizations can detect anomalies that may indicate potential issues before they escalate. This proactive approach not only enhances product quality but also aligns with the broader question of Why perform sample checking?—it saves time and resources while ensuring compliance with industry standards.

Tools and Technology Utilized

The landscape of sample checking has evolved dramatically with technological advancements. Today’s quality inspectors have access to a plethora of tools designed to streamline their processes effectively. From digital calipers for precise measurements to sophisticated software that tracks inspection data in real-time, these innovations significantly improve the accuracy of key checks conducted during sample checking.

Automation plays a pivotal role as well; machines equipped with sensors can perform visual inspections much faster than human eyes ever could. Additionally, technologies like RFID (Radio Frequency Identification) enhance traceability throughout the supply chain, making it easier to track samples from production to delivery. The integration of these tools not only increases efficiency but also reinforces the importance of meticulous sampling techniques in maintaining product integrity.

Best Practices for Implementation

Implementing effective sample checking requires more than just good intentions; it demands adherence to best practices that maximize its benefits. First and foremost is establishing clear criteria for what constitutes an acceptable product—this clarity helps guide inspectors during their evaluations and ensures consistency across checks. Furthermore, regular training sessions keep staff updated on new techniques and technologies related to sample checks.

Another key practice involves maintaining comprehensive documentation throughout the inspection process; this fosters accountability while enhancing traceability should any issues arise later on. Additionally, fostering a culture where feedback is encouraged aids continuous improvement efforts within an organization’s quality assurance framework. Ultimately, by adhering to these best practices while asking “What is Sample Checking?” organizations can ensure they are not just meeting standards but exceeding them consistently.

Sample Checking in Different Industries

Sample checking plays a pivotal role across various industries, ensuring that products meet quality standards and consumer expectations. By tailoring sample checks to the specific needs of each sector, organizations can enhance their quality assurance processes effectively. Let’s dive into how sample checking is applied in manufacturing, retail, and food safety.

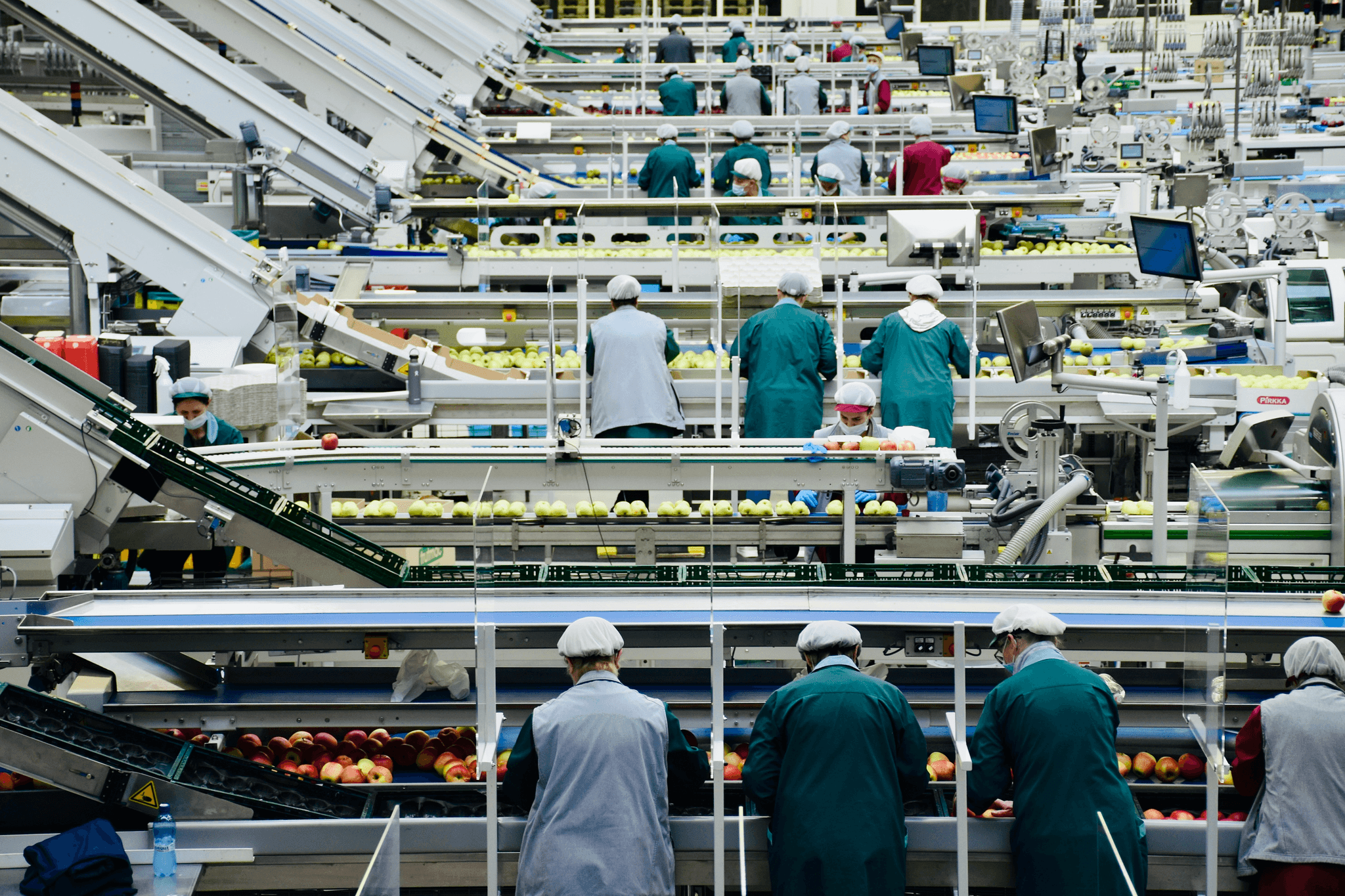

Manufacturing Sector Insights

In the manufacturing sector, sample checking is crucial for maintaining product quality and operational efficiency. What is sample checking? It refers to the process of inspecting a representative subset of products to ensure they meet predefined specifications. This method not only helps identify defects early but also streamlines production by reducing waste and rework.

Manufacturers often utilize key checks conducted during sample checking, such as visual inspections and functional testing of machinery components. These checks provide immediate feedback on production processes and help in fine-tuning operations for better output. Why perform sample checking? The answer lies in its ability to prevent costly recalls and maintain customer satisfaction through consistent product quality.

Moreover, with advancements in technology, manufacturers are adopting statistical techniques for effective sampling methods. This ensures that their sampling is both efficient and effective, allowing them to make informed decisions based on data-driven insights. In a competitive landscape where margins are tight, leveraging robust sample checks can be the difference between success and failure.

Retail and E-commerce Applications

The retail industry has seen a significant transformation with the rise of e-commerce, making effective sample checking more important than ever before. Retailers must ensure that products shipped to customers meet quality standards consistently; otherwise, they risk damaging their brand reputation. What is sample checking? In this context, it involves examining selected items from inventory before dispatching them to consumers.

Key checks conducted during sample checking in retail include visual inspections for packaging integrity and functional tests for electronics or appliances prior to sale. Why perform sample checking? It helps retailers mitigate returns due to defective products while enhancing customer trust through reliable service delivery. By implementing these practices effectively, retailers can boost customer loyalty while managing inventory costs efficiently.

Additionally, technology plays a significant role here; many retailers now employ automated systems that integrate real-time data analytics into their sampling processes. This allows them to adapt quickly based on consumer feedback or sales trends while ensuring compliance with industry regulations regarding product safety and quality assurance standards.

Food Safety and Pharmaceuticals

In sectors like food safety and pharmaceuticals where lives are at stake, the importance of rigorous sample checking cannot be overstated. What is sample checking? Here it means meticulously inspecting batches of goods before they reach consumers or healthcare providers to ensure safety standards are upheld without compromise.

Key checks conducted during sample checking in these industries often involve microbiological testing for food products or potency tests for pharmaceuticals—both critical elements in safeguarding public health. Why perform sample checking? The stakes are high; failing to identify issues can lead not only to regulatory penalties but also potential harm to consumers—a risk no company wants to take lightly.

Furthermore, adherence to strict guidelines necessitates comprehensive documentation throughout the process—ensuring traceability from production through distribution channels right up until consumption is vital for compliance audits as well as public confidence in product safety measures taken by companies involved in these sectors.

Conclusion

In wrapping up our exploration of sample checking, it’s clear that this process plays a pivotal role in ensuring quality across various industries. By understanding what is sample checking, we can appreciate its significance in maintaining standards and meeting customer expectations. The benefits of performing sample checking extend beyond mere compliance; they encompass enhanced product reliability and overall operational efficiency.

Recap of Sample Checking Benefits

Sample checking serves as a crucial mechanism for quality assurance by identifying defects early in the production process. When we ask ourselves why perform sample checking, the answers are compelling: it not only saves costs but also mitigates risks associated with faulty products reaching consumers. Additionally, the key checks conducted during sample checking—ranging from visual inspections to functional testing—help ensure that only the best products make it to market.

Choosing the Right Inspection Partner

Selecting an inspection partner is no small feat; it's about finding someone who understands your specific needs in relation to sample checks. Look for partners who have a proven track record in effective sample checking methods and can conduct thorough key checks tailored to your industry requirements. Remember, a reliable partner not only enhances your quality control process but also adds value through their expertise and technology adoption.

Future Trends in Quality Inspection

The landscape of quality inspection is continuously evolving, with innovations such as AI and machine learning redefining how we approach sample checks. As industries become more complex, understanding what is sample checking will be essential for adapting to these changes effectively. In the future, expect more emphasis on data-driven decision-making and automated processes that enhance the efficiency of key checks conducted during sample checking.