Introduction

Visual inspections play a crucial role in various industries, serving as a primary method for assessing the quality and integrity of products, structures, and systems. By employing a visual inspection procedure, organizations can identify potential issues before they escalate into significant problems. This proactive approach not only enhances safety but also contributes to overall operational efficiency.

Understanding Visual Inspections

At its core, a visual inspection involves examining an object or environment with the naked eye or through optical aids to detect defects or irregularities. This straightforward yet effective method is essential in ensuring compliance with industry standards and regulations. By understanding how visual inspections function, stakeholders can better appreciate their significance across different sectors.

Importance of Visual Inspection Procedures

The importance of implementing robust visual inspection procedures cannot be overstated; they are vital for maintaining quality control and ensuring safety in various settings. These procedures help mitigate risks associated with faulty products or unsafe conditions, ultimately protecting both consumers and companies alike. Furthermore, a well-defined visual inspection procedure fosters accountability within teams, ensuring that everyone is on the same page regarding quality expectations.

Overview of Inspection Types

Visual inspections come in various forms, tailored to meet the specific needs of different industries. From routine checks in manufacturing to specialized assessments in healthcare settings, each type serves its unique purpose while adhering to established protocols. Additionally, advancements such as Remote Visual Inspection (RVI) have emerged as innovative solutions that enhance traditional methods by incorporating technology into the inspection process.

What is a Visual Inspection Procedure?

Visual inspection procedures are systematic approaches used to assess the condition of materials, components, or systems through direct observation. These procedures serve the essential purpose of identifying defects, irregularities, or deviations from established standards without causing damage to the inspected items. In essence, a visual inspection procedure acts as the first line of defense in quality assurance across various industries.

Definition and Purpose

At its core, a visual inspection procedure involves examining an object or environment using the naked eye or optical aids like magnifying glasses and borescopes. The primary purpose is to detect any visible faults that could compromise functionality or safety. By establishing clear criteria for what constitutes acceptable conditions, these procedures help ensure compliance with industry regulations and maintain product integrity.

Key Elements of a Visual Inspection

Several key elements define an effective visual inspection procedure. Firstly, it requires well-defined standards for what inspectors should look for—these can include dimensions, surface finishes, and any signs of wear or damage. Secondly, proper training for inspectors is crucial; they must be equipped with knowledge about potential failure modes relevant to their specific industries—be it manufacturing or healthcare—to make informed judgments during inspections.

Benefits of Visual Inspection Procedures

The benefits of implementing robust visual inspection procedures are manifold and impactful across various sectors. One significant advantage is cost-effectiveness; by catching issues early in the production process or before equipment use, organizations can avoid expensive repairs down the line. Additionally, these procedures enhance safety by ensuring that any potential hazards are identified before they escalate into serious problems—especially critical in industries like aerospace and healthcare where precision is paramount.

Which Industries Use Visual Inspections?

Visual inspection procedures are vital across a multitude of industries, ensuring quality and safety standards are met. From manufacturing to healthcare, the impact of visual inspections is profound and far-reaching. Each sector employs these procedures uniquely, adapting them to suit specific needs and regulatory requirements.

Manufacturing and Quality Control

In manufacturing, visual inspection procedures serve as the first line of defense against defects in products. Quality control teams meticulously examine items for any signs of non-conformance, ensuring that only the best products reach consumers. This process not only helps maintain brand reputation but also reduces waste and enhances overall efficiency.

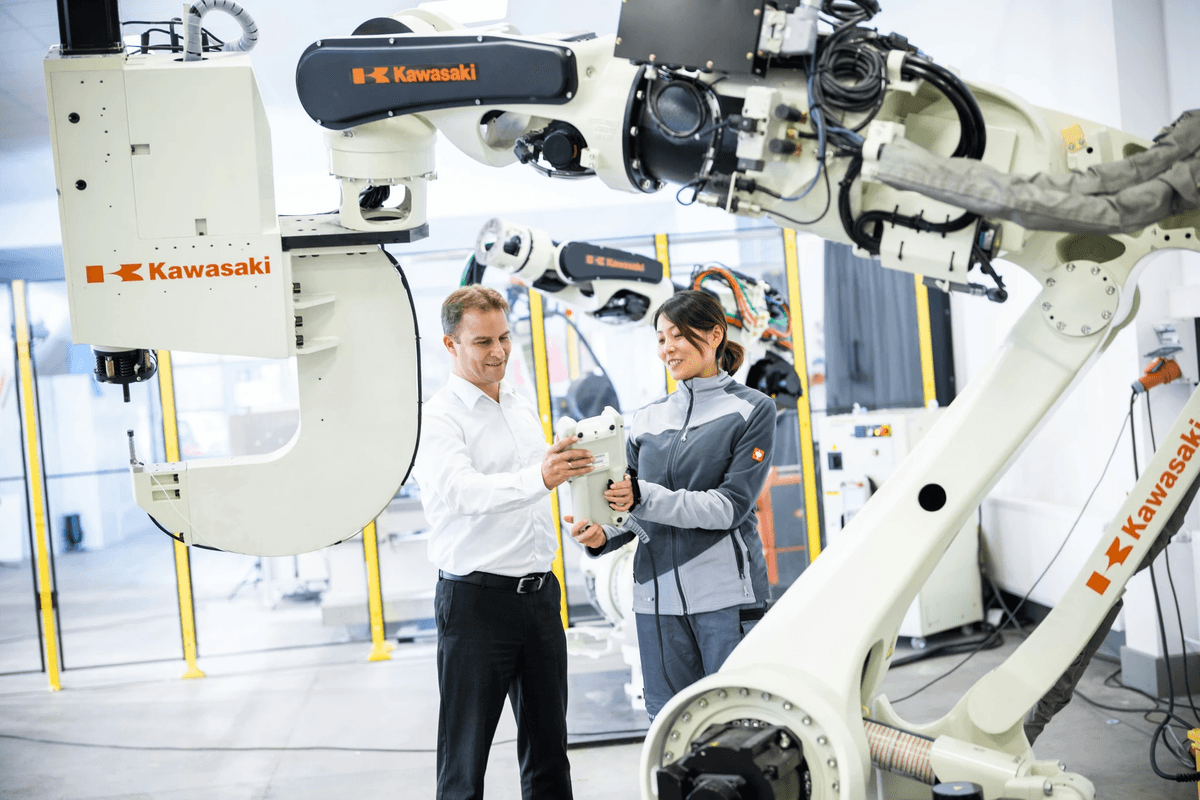

Visual inspections in manufacturing often involve checking dimensions, surface finishes, and assembly integrity using various tools like magnifying glasses or cameras. These checks can be performed manually or through automated systems that leverage technology for better accuracy. The integration of Remote Visual Inspection (RVI) techniques is also becoming increasingly popular in this sector, allowing inspectors to assess hard-to-reach areas without interrupting production flow.

Aerospace and Aviation Standards

The aerospace industry places an extraordinary emphasis on safety and precision, making visual inspection procedures indispensable. Inspectors meticulously examine aircraft components to ensure they meet stringent aviation standards before takeoff. Any oversight could lead to catastrophic consequences; thus, thorough visual inspections are critical for maintaining airworthiness.

Aerospace inspections often require specialized training due to the complexity of systems involved—ranging from engines to navigational instruments. Inspectors utilize advanced technologies alongside traditional methods during these assessments; RVI tools enable them to inspect confined spaces without disassembly. Consequently, these practices not only enhance safety but also streamline maintenance processes within the industry.

Healthcare and Surgical Applications

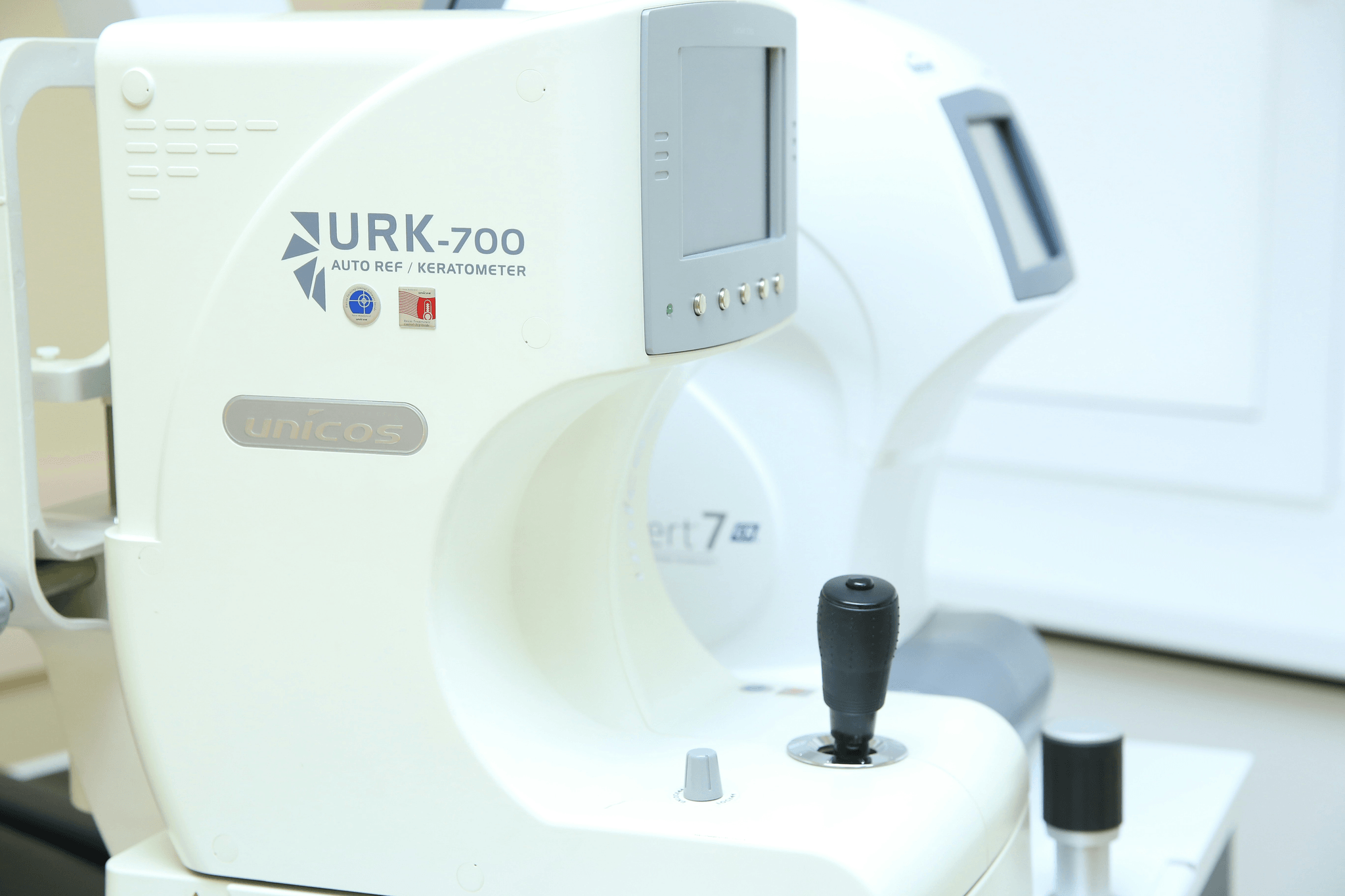

In healthcare settings, visual inspection procedures play a crucial role in ensuring patient safety and surgical success rates. Surgeons rely on their keen observational skills during operations to identify any abnormalities or complications that may arise in real-time. Moreover, equipment used in surgical environments undergoes rigorous visual inspections before use to prevent any potential hazards.

Healthcare facilities implement strict protocols that mandate regular checks on medical devices and equipment through detailed visual inspections. This ensures compliance with health regulations while safeguarding patients from unnecessary risks associated with faulty instruments or devices. As with other industries mentioned earlier, Remote Visual Inspection (RVI) has also made its way into healthcare—enabling remote assessments while minimizing contamination risks during surgeries or sterile environments.

Other Kinds of Inspections

While visual inspection procedures are essential in many industries, they are far from the only means of ensuring quality and safety. Various other kinds of inspections complement visual methods, each with its unique advantages and applications. Understanding these alternatives can provide valuable insights into comprehensive inspection strategies.

Non-Destructive Testing Techniques

Non-destructive testing (NDT) techniques are critical for evaluating materials and components without causing any damage. These methods include ultrasonic testing, radiographic testing, and magnetic particle testing, all designed to identify flaws that a simple visual inspection procedure might miss. By employing NDT, industries can maintain the integrity of their products while ensuring compliance with safety standards.

The beauty of non-destructive testing lies in its versatility; it is widely used across various sectors such as manufacturing, aerospace, and construction. For instance, aerospace engineers rely on NDT to ensure that aircraft components are free from defects before flight. Ultimately, incorporating NDT into a quality control strategy enhances reliability and extends the lifespan of critical assets.

In-Situ Testing Methods

In-situ testing methods offer another layer of scrutiny by assessing materials or systems directly at their operational site. These tests often involve specialized equipment to measure factors like soil stability or structural integrity without removing samples for analysis elsewhere. In many cases, combining in-situ tests with traditional visual inspection procedures provides a more comprehensive understanding of an asset's condition.

This approach is particularly beneficial in construction projects where immediate feedback can prevent costly delays or safety issues down the line. For example, geotechnical engineers may perform in-situ tests on soil conditions before laying foundations to ensure stability and safety—an invaluable step that could save time and resources later on. The integration of in-situ methods within broader inspection protocols helps organizations make informed decisions based on real-time data.

Safety Inspections in Construction

Safety inspections play a pivotal role in maintaining workplace safety standards within the construction industry—a sector known for its inherent risks. While visual inspection procedures help identify visible hazards like loose scaffolding or unguarded edges, regular safety inspections delve deeper into compliance with regulations and best practices. This proactive approach not only protects workers but also mitigates legal liabilities for companies.

These inspections often encompass various aspects such as equipment checks, hazard assessments, and employee training evaluations—all crucial for fostering a culture of safety on-site. Additionally, integrating technology like Remote Visual Inspection (RVI) can enhance these efforts by allowing inspectors to assess hard-to-reach areas without compromising worker safety or project timelines. By prioritizing rigorous safety inspections alongside traditional visual methods, construction firms can create safer environments while adhering to industry standards.

Remote Visual Inspection (RVI) Explained

In an era where efficiency is paramount, Remote Visual Inspection (RVI) has emerged as a game changer in the realm of visual inspection procedures. Utilizing advanced technologies such as drones, robotic cameras, and fiber optic systems, RVI allows inspectors to assess hard-to-reach areas without the need for physical presence. This not only enhances safety but also streamlines the inspection process across various industries.

Technology Behind Remote Visual Inspection

The backbone of Remote Visual Inspection lies in its cutting-edge technology that enables real-time data transmission and high-resolution imagery. Devices like drones equipped with high-definition cameras can capture intricate details from elevations or confined spaces that traditional methods might miss. Additionally, advancements in software allow for immediate analysis and reporting, making it easier to incorporate RVI into existing visual inspection procedures.

Advantages of RVI in Modern Inspections

One of the standout advantages of Remote Visual Inspection is its ability to save time and reduce costs associated with manual inspections. By eliminating the need for scaffolding or other access equipment, organizations can conduct thorough inspections more quickly and safely. Furthermore, RVI minimizes downtime in critical operations—an essential factor in industries like manufacturing and healthcare where efficiency is key.

Applications of RVI Across Industries

Remote Visual Inspection has found its niche across a variety of sectors due to its versatility and effectiveness. In manufacturing, it helps ensure quality control by inspecting machinery without halting production lines; meanwhile, aerospace leverages RVI for compliance with stringent safety regulations during aircraft inspections. Healthcare facilities also benefit from RVI when assessing surgical instruments or complex equipment without compromising operational flow.

Best Practices in Visual Inspections

Visual inspections are a critical part of many industries, ensuring that products and processes meet required standards. To maximize the effectiveness of a visual inspection procedure, it’s essential to follow best practices that enhance accuracy and reliability. This section will delve into the essential tools and equipment needed, common pitfalls to avoid, and effective documentation techniques.

Essential Tools and Equipment

The right tools can make or break a visual inspection procedure. Basic tools such as magnifying glasses, borescopes, and high-definition cameras are indispensable for capturing details that might otherwise go unnoticed. Additionally, having proper lighting equipment is crucial; good visibility can significantly improve the quality of your inspections across various industries.

For more complex environments like aerospace or healthcare, specialized equipment may be necessary to comply with stringent regulations. Using Remote Visual Inspection (RVI) technology allows inspectors to assess hard-to-reach areas without compromising safety or integrity. Integrating these essential tools ensures that your visual inspection procedures are thorough and reliable.

Common Pitfalls to Avoid

While conducting visual inspections may seem straightforward, several common pitfalls can undermine their effectiveness. One major issue is rushing through the process; even seasoned inspectors can miss critical defects if they don’t take their time to thoroughly examine each component. It’s vital to maintain focus during inspections and avoid distractions that could lead to oversights.

Another pitfall is neglecting proper training for personnel involved in visual inspections—especially when utilizing advanced techniques like Remote Visual Inspection (RVI). Without adequate training on using specific tools or understanding what constitutes a defect, staff may misinterpret findings or overlook issues entirely. Establishing clear guidelines for what constitutes acceptable versus unacceptable conditions can mitigate this risk significantly.

Documentation and Reporting Techniques

Effective documentation is an often-overlooked aspect of any visual inspection procedure but is crucial for maintaining quality control across industries. Accurate records not only provide evidence of compliance but also serve as valuable references for future inspections or audits. Utilizing standardized reporting templates helps ensure consistency while making it easier to track trends over time.

Incorporating digital solutions into your documentation process can streamline reporting significantly—think mobile apps that allow real-time data entry during inspections! This approach not only saves time but also reduces errors associated with manual data entry later on. As industries increasingly embrace digital transformation, integrating technology into your inspection processes will keep you ahead of the curve.

[Image description=inspector using a borescope in an industrial setting, bright lighting illuminating equipment details, focused expression on inspector's face, clipboard nearby with notes], Image name=inspector_using_borescope_industry, Alt tag=visual inspection procedure in action with inspector using RVI technology

Conclusion

Visual inspections are a cornerstone of quality assurance across various industries, ensuring that products and services meet established standards. The visual inspection procedure is not just about looking; it’s about understanding what to look for and why it matters. By implementing effective visual inspection procedures, organizations can significantly reduce errors, enhance safety, and improve overall operational efficiency.

Recap of Visual Inspection Importance

The importance of a robust visual inspection procedure cannot be overstated. In sectors such as manufacturing and healthcare, the stakes are high—one oversight can lead to catastrophic results. By employing systematic visual inspections, companies can catch defects early, ensuring that they maintain high-quality standards while safeguarding their reputation.

The Impact of Quality Inspections

Quality inspections serve as the backbone for trust in any industry that employs them. The meticulous nature of visual inspection procedures helps prevent costly recalls and enhances customer satisfaction by delivering reliable products and services. Moreover, when organizations prioritize quality inspections—including remote visual inspection (RVI)—they foster a culture of accountability that resonates throughout their workforce.

Future Trends in Visual Inspection Technology

Looking ahead, the future of visual inspection technology is set to be both exciting and transformative. Innovations like artificial intelligence (AI) are beginning to play a pivotal role in enhancing traditional methods—including remote visual inspection (RVI)—by automating routine checks and providing real-time analytics. As industries continue to adopt these advanced technologies, we can expect even more refined processes that ensure safety and quality across all sectors reliant on effective visual inspections.