Introduction

In the ever-evolving landscape of business, quality control stands as a cornerstone of operational excellence. Understanding the various quality control types is crucial for organizations aiming to maintain high standards and meet customer expectations. By implementing effective quality management practices, businesses can not only enhance their products but also ensure a robust reputation in the marketplace.

The Importance of Quality Control

Quality control is not just a buzzword; it's an essential practice that ensures products meet specified requirements and standards. Without proper quality inspection, companies risk delivering subpar products that can damage customer trust and brand loyalty. In today's competitive environment, the significance of quality assurance cannot be overstated; it serves as a safety net that protects both consumers and businesses alike.

Distinguishing Quality Control Types

Navigating through the different quality control types can be daunting, yet it's vital for effective implementation. From statistical methods to total quality management strategies, each type plays a unique role in enhancing product integrity and performance. Understanding these distinctions equips organizations with the tools necessary to tailor their approach to fit specific industry needs.

How Quality Control Impacts Businesses

The impact of quality control on businesses extends far beyond mere compliance; it influences overall efficiency and profitability. A strong focus on quality management fosters innovation while minimizing waste—leading to significant cost reductions over time. Ultimately, embracing effective quality assurance practices not only satisfies customers but also drives long-term success in an increasingly demanding market.

What is Quality Control?

Quality control is the backbone of ensuring that products and services meet established standards and satisfy customer expectations. It encompasses a range of processes that help businesses maintain consistency in their offerings, ultimately leading to enhanced customer satisfaction. Understanding quality control meaning is essential for any organization aiming to thrive in a competitive market.

Defining Quality Control Meaning

At its core, quality control refers to the systematic approach taken by organizations to monitor and maintain the quality of their products or services. This includes various techniques and processes designed to identify defects or deviations from set standards before they reach the consumer. By focusing on quality management practices, businesses can ensure that their output aligns with both internal benchmarks and external regulations.

The Role of Quality Management

Quality management plays a crucial role in implementing effective quality control measures within an organization. It encompasses all activities aimed at improving product or service quality, including planning, assurance, and continuous improvement efforts. A robust quality management system not only facilitates better adherence to quality control types but also fosters a culture of excellence among employees.

Connection to Quality Assurance

Quality assurance is often confused with quality control; however, they serve distinct purposes within an organization's framework. While quality control focuses on identifying defects after production through inspections and testing, quality assurance aims to prevent such issues from occurring in the first place by establishing robust processes and standards. The synergy between these two concepts ensures comprehensive oversight over product integrity while enhancing overall operational efficiency.

The Different Quality Control Types

When it comes to quality control types, understanding the nuances can make all the difference in a business's success. Quality management is not just about maintaining standards; it’s about ensuring that every aspect of production and service delivery is optimized for excellence. Let’s dive into three primary quality control types: Statistical Quality Control, Conformance Quality Control, and Total Quality Management.

Statistical Quality Control

Statistical Quality Control (SQC) uses statistical methods to monitor and control processes, ensuring that they operate at their full potential. By analyzing data from quality inspections, businesses can identify variations and trends that may indicate issues before they escalate into significant problems. This proactive approach helps maintain high-quality standards while minimizing waste and reducing costs—key components of effective quality management.

SQC relies heavily on tools like control charts and process capability analysis to gauge performance against established benchmarks. These tools allow quality assurance specialists to visualize data trends over time, making it easier to spot deviations from desired outcomes. Ultimately, the goal of SQC is not just to react but to anticipate challenges in order to uphold product consistency across all quality control types.

Conformance Quality Control

Conformance Quality Control focuses on whether products meet specified standards and requirements set forth by industry regulations or company policies. This type emphasizes adherence to predefined specifications during production processes, which ensures that every item produced aligns with customer expectations for quality and assurance. When companies prioritize conformance, they build a solid reputation for reliability in their offerings.

The role of a quality assurance specialist is crucial in this context; they conduct regular audits and inspections throughout the manufacturing process. By doing so, they help ensure compliance with both internal guidelines and external regulatory demands—keeping businesses safe from costly recalls or reputational damage due to non-conforming products. With an emphasis on conformity, organizations can achieve streamlined operations while enhancing customer trust through consistent product delivery.

Total Quality Management

Total Quality Management (TQM) takes a holistic approach by integrating all members of an organization into the pursuit of continuous improvement in product quality and operational efficiency. TQM encourages a culture where every employee—from top management down—is responsible for maintaining high-quality standards across all facets of business operations. This inclusive strategy fosters collaboration among teams while emphasizing the importance of ongoing training related to various quality control types.

Incorporating principles like customer focus, process optimization, and employee involvement allows organizations practicing TQM to adapt swiftly to changing market demands while consistently delivering superior products or services. Moreover, TQM facilitates better communication between departments which can lead directly to improved performance metrics across various dimensions of quality management practices. By embracing this comprehensive framework, businesses position themselves for sustained success in an increasingly competitive landscape.

Quality Inspection: An Overview

Quality inspection is a critical component of quality management that ensures products meet established standards before reaching consumers. This process involves systematic examination and evaluation, allowing businesses to identify defects and areas for improvement in their production lines. By integrating various quality control types, organizations can maintain high levels of quality and assurance throughout their operations.

The Process of Quality Inspection

The process of quality inspection typically begins with defining specific criteria based on the quality control meaning relevant to the product or service being evaluated. Inspectors then perform checks at various stages of production, from raw materials to finished goods, ensuring adherence to these standards. This proactive approach not only helps catch issues early but also reinforces a culture of quality within the organization.

Tools and Techniques Used

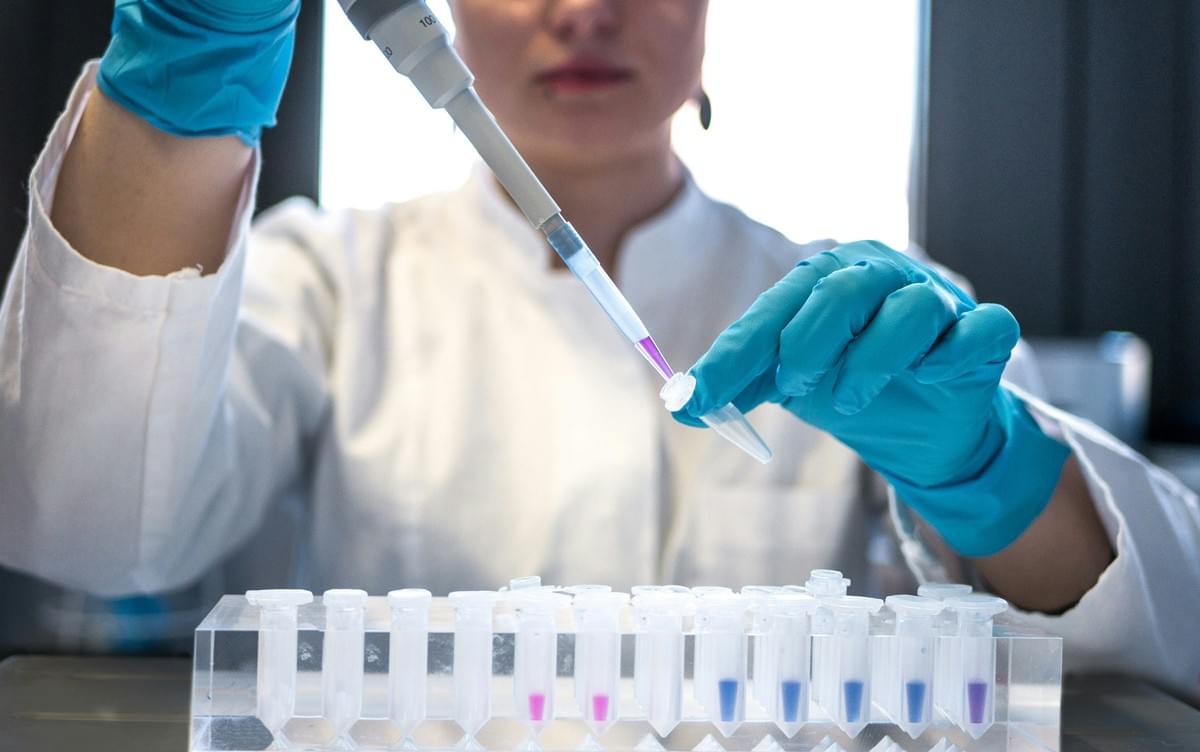

A variety of tools and techniques are employed during quality inspection to facilitate accurate assessments. Commonly used methods include statistical sampling, visual inspections, and automated testing systems that leverage technology for real-time data analysis. Each tool serves a unique purpose, enhancing the overall effectiveness of the inspection process while aligning with different quality control types.

Role of a Quality Assurance Specialist

A quality assurance specialist plays an essential role in overseeing the entire quality inspection process, ensuring that all aspects align with organizational goals and regulatory requirements. This professional is responsible for developing inspection protocols, training team members on best practices, and analyzing data collected during inspections to drive continuous improvement efforts in quality management. Their expertise not only supports compliance but also fosters trust among customers who rely on consistent product excellence.

Benefits of Quality Control

Quality control is more than just a buzzword; it’s a vital component of successful business operations. The benefits of implementing effective quality control types can be felt across the entire organization, from product development to customer satisfaction. By focusing on quality management and assurance, businesses can enhance their overall performance and reputation in the marketplace.

Enhancing Product Consistency

One of the primary benefits of quality control is the enhancement of product consistency. When organizations implement robust quality inspection processes, they ensure that every item produced meets specific standards, reducing variability. This consistency not only satisfies customer expectations but also streamlines production processes, leading to improved efficiency and reduced errors.

Moreover, maintaining consistent quality helps businesses build a strong brand identity, as customers come to recognize and trust their products. With various quality control types available, companies can choose methods that best align with their goals for consistency and excellence. Ultimately, achieving high levels of product consistency translates into increased customer loyalty and repeat business.

Reducing Costs and Waste

Another significant advantage of effective quality control is its ability to reduce costs and waste within an organization. By identifying defects early in the production process through diligent quality inspection practices, companies can minimize costly rework or recalls later on. This proactive approach not only saves money but also conserves valuable resources by reducing material waste.

Implementing various quality control types allows businesses to adopt strategies that focus on efficiency while ensuring high standards are met throughout production cycles. Additionally, fostering a culture centered around quality management encourages employees to take ownership of their work, leading to fewer errors and enhanced productivity overall. In turn, these cost savings can be reinvested into innovation or improving other areas of the business.

Building Customer Trust

Building customer trust is arguably one of the most crucial benefits tied to effective quality assurance practices. When consumers know that a company prioritizes quality control meaningfully—through rigorous testing and adherence to standards—they are more likely to feel confident in their purchases. This trust not only enhances customer satisfaction but also contributes significantly to brand loyalty over time.

Quality assurance specialists play a pivotal role in this process by ensuring that every product meets established criteria before reaching consumers’ hands. By consistently delivering high-quality products backed by solid assurances from reputable brands, businesses foster long-term relationships with their customers based on reliability and integrity. In today’s competitive market landscape, establishing such trust can set companies apart from competitors who may overlook these essential elements.

Quality Control in Various Industries

Quality control is a vital aspect across numerous industries, ensuring that products and services meet established standards. By implementing effective quality management strategies, businesses can enhance their operations and deliver superior results. This section will explore the role of quality control types in manufacturing, food safety, and technology.

Manufacturing Sector Strategies

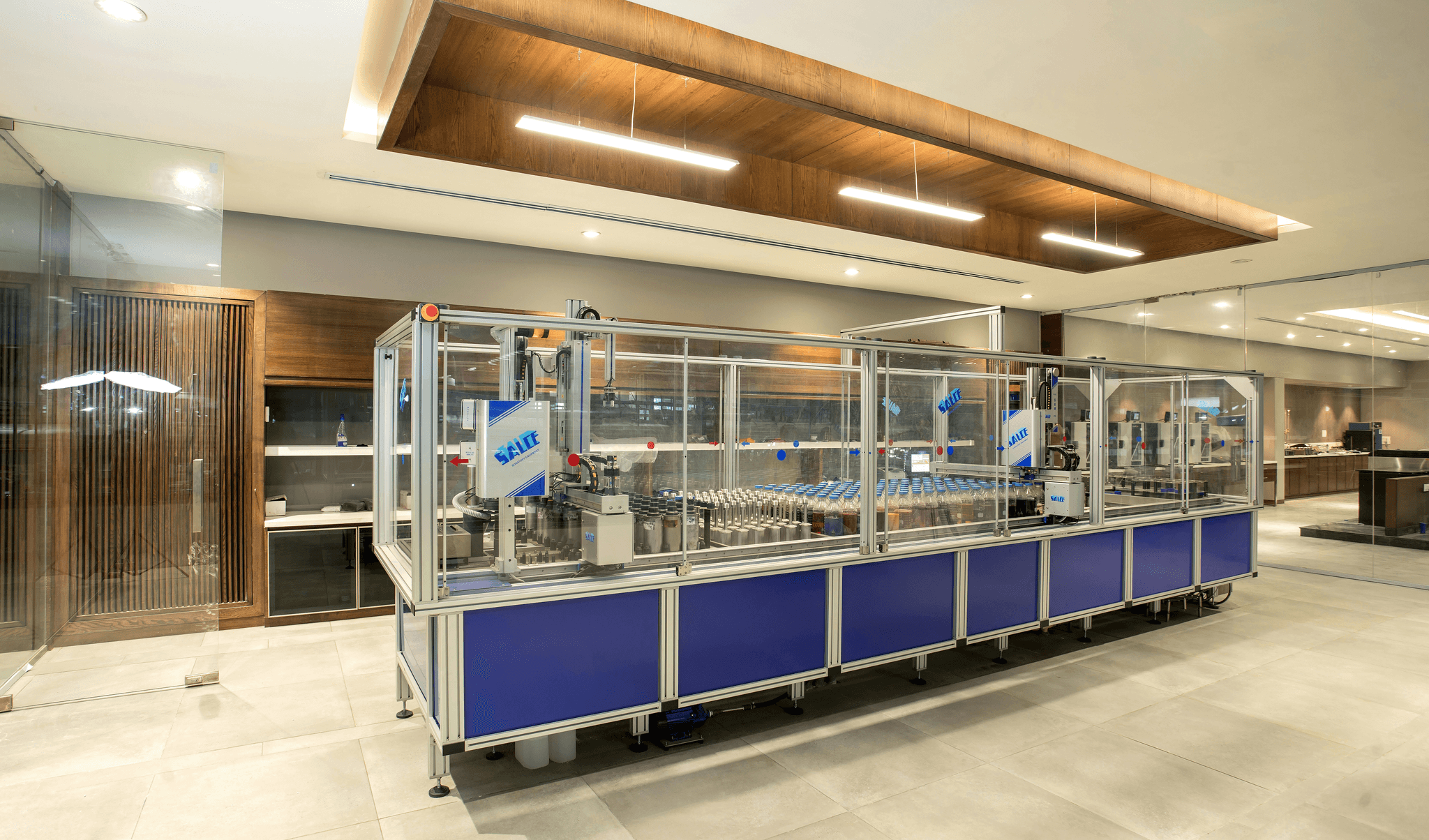

In the manufacturing sector, quality control types play a crucial role in maintaining product standards and efficiency. By employing statistical quality control methods, manufacturers can analyze production processes to identify defects early on. Additionally, quality inspection practices help ensure that every item produced aligns with the defined quality management criteria, reducing waste and enhancing overall productivity.

Quality assurance specialists are instrumental in this sector; they oversee the implementation of these strategies to ensure compliance with industry regulations. Their expertise allows for continuous improvement in production lines by identifying areas needing enhancement based on quality control meaning. Ultimately, robust quality management systems lead to increased customer satisfaction and loyalty.

The Importance in Food Safety

Food safety is another area where stringent quality control is paramount to protect consumers' health. The application of various quality control types ensures that food products are safe for consumption by monitoring everything from raw ingredients to final packaging. Quality inspection processes are critical here; they verify that hygiene standards are upheld throughout production.

Quality assurance specialists within the food industry conduct regular audits and inspections to maintain compliance with health regulations. Their work helps mitigate risks associated with contamination or spoilage while reinforcing consumer trust in brands committed to high-quality standards. In this way, effective quality management not only safeguards public health but also enhances brand reputation.

Quality Assurance in Technology

The technology sector faces unique challenges regarding product reliability and performance due to rapid advancements and consumer expectations. Quality control types such as total quality management (TQM) focus on integrating all organizational functions toward continuous improvement of products and services through effective processes. Here again, the role of a dedicated quality assurance specialist becomes invaluable—they ensure that software applications or hardware devices meet specific performance metrics before release.

Moreover, rigorous testing through various stages of development serves as a form of proactive risk management—catching potential issues before they reach end-users is key to maintaining brand integrity. As technology evolves rapidly, adhering strictly to established quality inspection protocols becomes essential for success in an increasingly competitive landscape where customers demand excellence at every turn.

Conclusion

In the realm of business, understanding quality control types is not just a luxury; it’s a necessity. The nuances of quality management and the interrelationship between quality and assurance play pivotal roles in maintaining high standards across various industries. As we’ve explored, effective quality inspection processes are essential in ensuring that products meet or exceed customer expectations.

Key Takeaways on Quality Control Types

Quality control meaning extends beyond mere checks and balances; it encapsulates a comprehensive approach to maintaining product integrity. From statistical quality control to total quality management, each type offers unique benefits tailored to specific operational needs. Emphasizing these different quality control types helps businesses streamline their processes, reduce waste, and ultimately enhance customer satisfaction.

The Future of Quality Management

The future of quality management is increasingly reliant on technology and data-driven decision-making. Innovations such as artificial intelligence and machine learning are set to revolutionize how we approach quality assurance, making it more efficient than ever before. As industries evolve, so too will the strategies employed by quality assurance specialists to ensure compliance with emerging standards and consumer expectations.

Embracing Quality Assurance for Success

To thrive in today’s competitive landscape, embracing robust quality assurance practices is crucial for any business aiming for long-term success. By prioritizing effective quality control measures alongside a culture of continuous improvement, organizations can build trust with their customers while minimizing costs associated with defects or failures. Ultimately, investing in comprehensive quality management strategies not only enhances product reliability but also paves the way for sustainable growth.