Introduction

In today's fast-paced global market, the significance of Factory Inspections cannot be overstated. With businesses increasingly relying on overseas suppliers, understanding the nuances of these inspections is vital for maintaining quality and mitigating risks. This introduction sets the stage for exploring why Factory Inspections are essential, particularly when placing large orders.

Understanding Factory Inspections

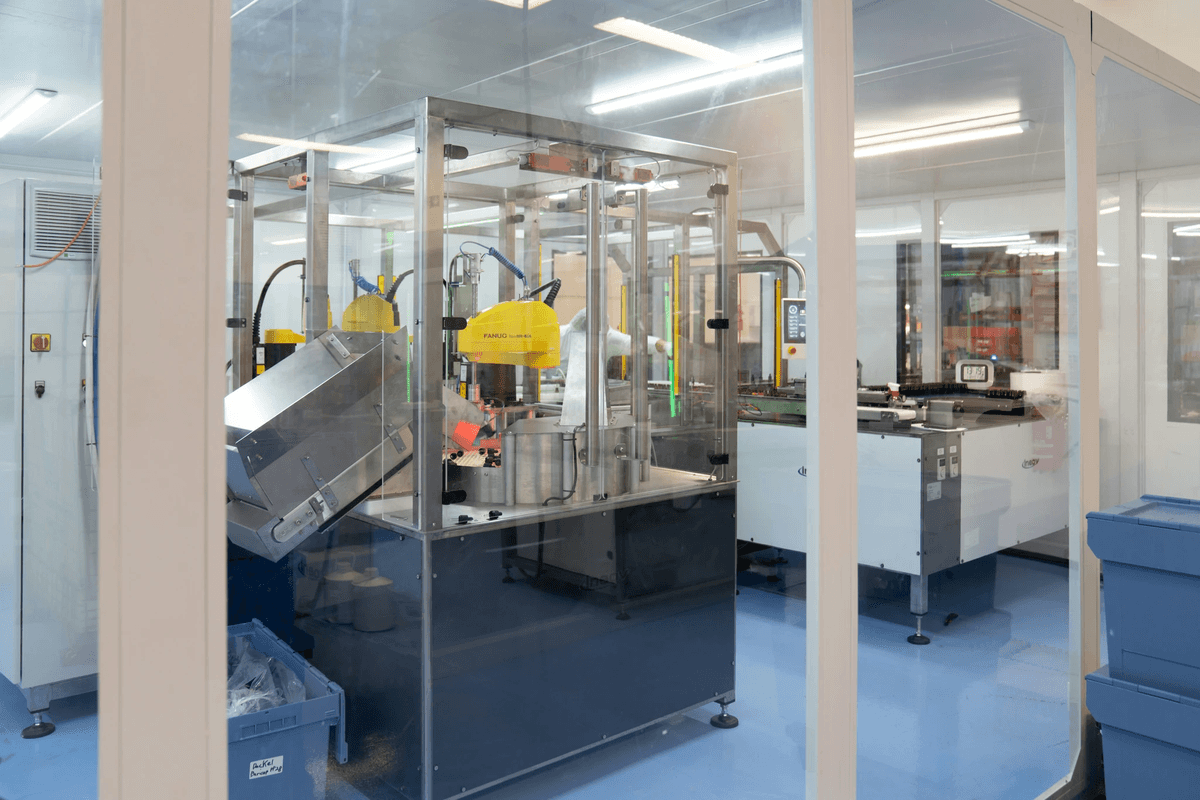

Factory Inspections serve as a critical checkpoint in the manufacturing process, ensuring that products meet required standards before they reach consumers. These inspections typically involve a thorough examination of production facilities, processes, and quality control measures. By understanding what Factory Inspections entail, companies can better appreciate their role in safeguarding product integrity.

The Importance of Quality in Production

Quality is not just a buzzword; it's a cornerstone of successful production strategies. When businesses prioritize quality through rigorous Factory Inspections, they reduce the likelihood of defects that could lead to costly recalls or dissatisfied customers. Ultimately, focusing on quality helps build brand loyalty and enhances overall market competitiveness.

Overview of Common Inspection Practices

Common inspection practices include pre-production checks, during-production inspections, and final random inspections—each designed to catch potential issues at different stages of manufacturing. These practices allow companies to assess compliance with specifications while identifying areas for improvement before large orders are fulfilled. By familiarizing themselves with these common practices, businesses can make informed decisions about implementing effective inspection protocols tailored to their needs.

The Risks of Placing Large Orders Without a Factory Inspection

When businesses decide to place large orders without conducting Factory Inspections, they often underestimate the potential risks involved. These risks can lead to significant financial losses, tarnished brand reputations, and disrupted supply chains. Understanding these dangers is crucial for any company aiming to maintain quality and reliability in their production processes.

Financial Implications of Poor Quality

Placing large orders without a proper Factory Inspection can result in severe financial implications due to poor-quality products. If the goods received do not meet the required standards, companies may face costly returns, refunds, or even legal disputes. Moreover, reworking or replacing defective products can drain budgets and resources that could have been better utilized elsewhere.

The financial impact doesn’t stop at immediate costs; it can also affect long-term profitability. Brands that rely on subpar products may find themselves investing heavily in marketing campaigns to recover from negative customer experiences caused by quality issues. Ultimately, the lack of thorough inspections before placing large orders can lead to a downward spiral of escalating expenses and dwindling profits.

Impact on Brand Reputation

In today's fast-paced market, brand reputation is everything—and nothing damages it quite like poor-quality products. When consumers receive items that don’t meet their expectations due to inadequate oversight during production, they are quick to voice their dissatisfaction online and through word-of-mouth. This negative feedback can spread like wildfire, severely damaging a brand's image.

Factory Inspections serve as a safeguard against such reputation-damaging incidents by ensuring product quality before goods reach consumers' hands. Companies that prioritize inspections demonstrate commitment to excellence and customer satisfaction—qualities that resonate positively with buyers. Conversely, neglecting this critical step when placing large orders can leave brands scrambling to rebuild trust after experiencing public backlash.

Supply Chain Disruptions

Another major risk associated with placing large orders without conducting Factory Inspections is the potential for supply chain disruptions. If products fail quality checks after shipment or are found defective upon arrival, it creates chaos within the supply chain process—leading to delays in distribution and fulfillment timelines. Such disruptions not only frustrate customers but also strain relationships with suppliers who may be held accountable for delivering unsatisfactory goods.

Additionally, these interruptions can ripple through an organization’s operations as teams scramble to address unexpected challenges while trying to maintain service levels amid growing demand pressures. Efficient management relies heavily on predictable supply chains; thus ignoring necessary inspections compromises this vital aspect of business continuity when handling large orders. By understanding Why Factory Inspections Matter for Large Orders upfront, businesses can avoid these pitfalls and ensure smoother operations overall.

Why Factory Inspections Matter for Large Orders

When it comes to large orders, the stakes are high, and so are the potential pitfalls. Factory inspections serve as a critical safeguard against the myriad risks that can arise from placing substantial orders without proper oversight. By understanding why factory inspections matter for large orders, businesses can protect their investments and ensure a smoother production process.

Ensuring Compliance with Standards

One of the primary reasons factory inspections matter is to ensure compliance with industry standards and regulations. Manufacturers must adhere to specific guidelines that govern quality, safety, and environmental impact; factory inspections verify that these standards are met consistently. Without this oversight, companies risk receiving subpar products that may not only fail quality checks but could also lead to costly recalls or legal issues.

Furthermore, ensuring compliance through thorough factory inspections helps businesses maintain their credibility in the market. Customers today are more discerning than ever; they expect products that meet certain quality benchmarks and ethical production practices. By prioritizing factory inspections, companies can confidently assure their clients of adherence to these essential standards.

Mitigating Risks in Production

The risks associated with placing large orders without a factory inspection can be staggering. From defective products to production delays, these issues can spiral into significant financial losses and tarnish a brand’s reputation overnight. Factory inspections play a pivotal role in identifying potential problems early on in the manufacturing process, allowing businesses to address them before they escalate.

Moreover, effective factory inspections help mitigate risks by evaluating production capabilities and processes comprehensively. This proactive approach not only safeguards against immediate concerns but also fosters continuous improvement within manufacturing operations. Ultimately, mitigating risks through diligent factory inspections translates into better-quality products delivered on time—an invaluable combination for any business.

Building Strong Supplier Relationships

Investing in regular factory inspections is not merely about safeguarding your own interests; it’s also about nurturing strong supplier relationships over time. When manufacturers know they will be held accountable through regular audits and evaluations, they’re likely to prioritize quality control measures more seriously. This shared commitment enhances collaboration between suppliers and buyers while fostering an environment of trust.

Additionally, open communication during the inspection process allows both parties to discuss challenges and opportunities for improvement candidly. This dialogue contributes significantly to building long-term partnerships based on mutual respect rather than transactional exchanges alone. In essence, robust supplier relationships cultivated through consistent factory inspections lead to smoother operations and enhanced product quality across the board.

What a Factory Inspection (Audit) Covers

When it comes to ensuring the integrity of production, understanding what a factory inspection covers is crucial. Factory inspections serve as a comprehensive assessment tool that evaluates various aspects of manufacturing, quality control, and worker safety. By delving into these areas, businesses can mitigate the risks associated with placing large orders without proper oversight.

Verifying Manufacturing Processes

Verifying manufacturing processes is at the heart of effective factory inspections. This involves scrutinizing every step of production to ensure that established protocols are followed and that products are made according to specifications. When companies overlook this critical aspect, they expose themselves to substantial risks associated with poor quality and compliance failures.

During factory inspections, auditors will check for adherence to industry standards and best practices in manufacturing processes. They assess everything from equipment maintenance to workflow efficiency, ensuring that all elements align with quality expectations. Ultimately, verifying these processes not only safeguards product integrity but also reinforces why factory inspections matter for large orders.

Assessing Quality Control Measures

Quality control measures are another vital component covered during factory inspections. These measures determine how well a company can maintain consistent product quality throughout the production cycle. Without thorough assessments in this area, businesses risk encountering significant financial implications stemming from defective products or subpar materials.

Inspectors evaluate various methodologies used by factories to monitor quality at different stages of production. This includes examining testing protocols, inspection routines, and corrective actions taken when issues arise. By conducting these assessments as part of factory inspections, companies can better understand their suppliers' commitment to maintaining high standards—a key factor in mitigating risks when placing large orders without prior evaluations.

Evaluating Worker Safety Conditions

Evaluating worker safety conditions is not just an ethical obligation; it's also essential for maintaining operational integrity within factories. During a factory inspection, auditors will thoroughly assess the environment where workers operate—checking for hazards that could compromise safety or productivity levels. This evaluation is crucial because unsafe working conditions can lead not only to legal ramifications but also disruptions in supply chains if incidents occur.

Inspectors look at everything from personal protective equipment (PPE) usage to emergency preparedness plans during their evaluations of worker safety conditions. Ensuring compliance with health and safety regulations helps foster a positive workplace culture while simultaneously protecting brand reputation—an important consideration when contemplating why factory inspections matter for large orders. After all, no one wants their business associated with unsafe practices or poor labor conditions.

The Role of China Inspection Pro in Factory Inspections

When it comes to ensuring quality in production, China Inspection Pro stands out as a vital partner for businesses looking to mitigate risks. Their comprehensive approach to factory inspections not only safeguards your investment but also enhances the overall quality of your products. With a focus on delivering actionable insights, they help you navigate the complexities of global sourcing with confidence.

Professional Services for Quality Assurance

China Inspection Pro offers a suite of professional services designed specifically for quality assurance during factory inspections. These services encompass everything from pre-production assessments to final product evaluations, ensuring that every aspect of the manufacturing process meets established standards. By engaging with their team, businesses can significantly reduce the risks associated with placing large orders without a factory inspection and ensure compliance with industry regulations.

The importance of these professional services cannot be overstated; they provide an essential layer of protection against potential pitfalls that can arise during production. Whether it’s verifying materials or assessing production capabilities, China Inspection Pro’s expertise ensures that companies are well-informed before making significant investments. This proactive approach is crucial when considering why factory inspections matter for large orders.

Deep Experience in Global Markets

With years of experience navigating diverse global markets, China Inspection Pro understands the nuances that come with international sourcing and manufacturing. Their deep knowledge allows them to effectively address the unique challenges faced by companies when conducting factory inspections abroad. This expertise is particularly beneficial for businesses looking to expand their operations and maintain high-quality standards across different regions.

Furthermore, their familiarity with various industries enables them to tailor inspection processes according to specific needs and compliance requirements. This adaptability ensures that clients receive relevant insights into what a factory inspection (audit) covers based on their unique context and product specifications. As companies grapple with the risks of placing large orders without thorough evaluations, having an experienced partner like China Inspection Pro can make all the difference.

Actionable Recommendations for Improvement

One of the standout features of working with China Inspection Pro is their commitment to providing actionable recommendations following each factory inspection. After evaluating manufacturing processes and quality control measures, they offer tailored guidance aimed at enhancing overall production efficiency and product quality. These insights empower businesses not only to rectify immediate issues but also to implement long-term improvements that foster better supplier relationships.

By focusing on continuous improvement, organizations can significantly reduce future risks associated with large orders while enhancing brand reputation through consistent quality delivery. The recommendations provided serve as a roadmap for addressing weaknesses identified during inspections, ultimately leading to stronger partnerships within supply chains worldwide. In today’s competitive market landscape, understanding what a factory inspection (audit) covers is essential for those seeking sustained success through meticulous evaluation practices.

The Steps to Conducting an Effective Factory Inspection

Conducting a successful factory inspection is crucial for ensuring product quality and mitigating the risks associated with placing large orders without proper oversight. This process involves careful preparation, effective engagement with inspectors, and diligent follow-up after the inspection. By understanding these steps, businesses can enhance their approach to factory inspections and safeguard their interests.

Preparing for the Inspection

Preparation is key when it comes to effective factory inspections. Before the inspection date, it's essential to gather all relevant documentation about manufacturing processes, quality control measures, and any previous audit reports that highlight potential issues. This groundwork not only streamlines the inspection but also helps in identifying specific areas of concern related to why factory inspections matter for large orders.

Additionally, establishing clear objectives for what you want to achieve during the inspection will guide both your team and the inspectors in focusing on critical aspects of production quality. Consider creating a checklist that outlines what a factory inspection (audit) covers—this will ensure no stone is left unturned during the evaluation process. Ultimately, thorough preparation sets a solid foundation for a successful inspection that can significantly reduce financial risks associated with poor-quality products.

Engaging with Inspectors

Engagement during factory inspections plays a pivotal role in obtaining accurate assessments of manufacturing practices. Building rapport with inspectors can lead to more open communication about any potential issues or concerns they may uncover regarding compliance or safety standards—both of which are critical when considering why factory inspections matter for large orders. A collaborative approach fosters an environment where inspectors feel comfortable sharing actionable insights that could prevent supply chain disruptions down the line.

Moreover, actively participating in discussions during the inspection allows you to learn firsthand about what’s working well and what needs improvement within your production processes. It’s also beneficial to ask questions; this not only clarifies any uncertainties but also demonstrates your commitment to upholding high standards of quality assurance through regular factory inspections. Remember, engaging effectively with inspectors can transform an ordinary audit into an invaluable learning experience.

Post-Inspection Follow-Up

Once the dust settles after a factory inspection, it’s time for some serious reflection and action planning based on findings from what a factory inspection (audit) covers. Reviewing the inspector's report thoroughly is vital; identify key areas where improvements are needed and prioritize them based on urgency and impact on product quality or compliance standards—after all, understanding The Risks of Placing Large Orders Without a Factory Inspection is crucial for long-term success.

Following up means not just addressing immediate concerns but also developing strategies for ongoing monitoring and continuous improvement within your supply chain operations. Establishing regular check-ins with suppliers post-inspection ensures that any recommendations made are implemented effectively over time—and reinforces strong supplier relationships built on trust and accountability regarding quality assurance practices through consistent factory inspections.

Lastly, don’t forget to celebrate successes! If improvements have been made based on previous audits or if compliance has increased since last evaluated, acknowledge these achievements as part of fostering an organizational culture committed to excellence in production quality.

Conclusion

In the world of manufacturing, the significance of Factory Inspections cannot be overstated. By investing in thorough evaluations before placing large orders, businesses can significantly minimize risks associated with poor quality products. The Risks of Placing Large Orders Without a Factory Inspection can lead to financial losses, damage to brand reputation, and disruptions in the supply chain that may take years to resolve.

Minimizing Risks with Factory Inspections

Factory Inspections serve as a crucial safeguard against potential pitfalls in production. They provide an opportunity to identify issues early on, ensuring that companies adhere to necessary standards and regulations. By understanding Why Factory Inspections Matter for Large Orders, businesses can proactively address concerns before they escalate into costly problems.

Enhancing Product Quality for Success

Quality is paramount in today's competitive market, and Factory Inspections play an essential role in achieving it. Comprehensive audits allow companies to assess What a Factory Inspection (Audit) Covers, including manufacturing processes and quality control measures. This commitment to quality not only enhances product reliability but also fosters customer trust and loyalty—key ingredients for long-term success.

Long-Term Benefits of Thorough Evaluations

The advantages of conducting diligent Factory Inspections extend far beyond immediate risk mitigation; they build a foundation for sustainable business practices. Establishing strong supplier relationships through regular inspections leads to improved communication and collaboration over time. Ultimately, by prioritizing thorough evaluations, companies position themselves for ongoing success in an ever-evolving marketplace.