Introduction

In today's fast-paced world, the significance of quality control inspections cannot be overstated. Quality control is essential for ensuring that products meet established standards and customer expectations, ultimately safeguarding a company's reputation and profitability. As industries become increasingly competitive, the role of quality assurance specialists has never been more critical in maintaining high standards of quality and control.

The Importance of Quality Control

Quality control serves as the backbone of product development and manufacturing processes. By implementing rigorous quality control inspections, businesses can identify defects early in production, reducing waste and minimizing costs associated with returns or rework. Moreover, effective quality assurance not only enhances customer satisfaction but also fosters brand loyalty, making it an indispensable aspect of any successful organization.

Key Components of Quality Inspections

Quality inspections encompass various elements that contribute to overall product excellence. These include systematic evaluation processes that assess materials, components, and finished goods against predefined specifications. By employing tools such as checklists and statistical methods during these inspections, organizations can ensure that every aspect of their products adheres to the highest standards of quality.

The Role of Quality Assurance Specialists

Quality assurance specialists are the guardians of product integrity within an organization. Their expertise lies in developing inspection protocols, conducting audits, and analyzing data to identify trends related to quality control jobs. These professionals play a vital role in fostering a culture of continuous improvement by training employees on best practices in quality inspection and ensuring compliance with industry regulations.

Understanding Quality Control Inspections

Quality control inspections are the backbone of any successful production process, ensuring that products meet established standards before reaching consumers. The essence of quality control lies in its ability to catch defects early, saving companies from costly recalls and reputational damage. By implementing rigorous quality control measures, businesses can enhance customer satisfaction and maintain a competitive edge.

Defining Quality Control

Quality control is a systematic approach aimed at maintaining the desired level of quality in products or services through various processes and inspections. It encompasses all activities related to the planning, assurance, and monitoring of product quality throughout its lifecycle. In essence, quality control is about establishing benchmarks and ensuring compliance with those standards to deliver exceptional value to customers.

The Process of Quality Inspections

The process of quality inspections typically begins with defining the criteria for acceptable quality levels based on industry standards or customer expectations. Inspectors then carry out assessments at different stages of production, employing various techniques to evaluate products against these benchmarks. This ongoing evaluation not only helps identify defects but also fosters continuous improvement within manufacturing processes by highlighting areas for enhancement.

Tools Used in Quality Control

Quality control relies on a variety of tools designed to facilitate accurate inspections and assessments. Commonly used instruments include calipers, micrometers, gauges, and software systems that track data over time for analysis. These tools help ensure that every aspect of production adheres to strict quality standards while enabling quality assurance specialists to make informed decisions regarding product adjustments or rejections.

The Impact of Quality Assurance Jobs

Quality assurance jobs play a pivotal role in maintaining the integrity of products and services across various industries. These positions not only ensure compliance with industry standards but also enhance customer satisfaction by guaranteeing that quality control inspections are thorough and effective. As organizations increasingly prioritize quality, the demand for skilled quality assurance specialists continues to rise, making this field both rewarding and essential.

Types of Quality Assurance Roles

The landscape of quality assurance encompasses a variety of roles tailored to different sectors and functions. From quality control inspectors who conduct on-site evaluations to quality assurance managers who oversee entire teams, each position contributes uniquely to the overarching goal of maintaining high standards in production processes. Other roles include auditors who assess compliance with regulations and analysts who utilize data to identify trends in quality control, ensuring that every aspect of product development is scrutinized.

Skills Required for Quality Assurance Specialists

To thrive in quality assurance jobs, specialists must possess a diverse skill set that combines technical knowledge with analytical prowess. Critical thinking is essential for identifying potential issues during quality inspections, while attention to detail ensures that no defect goes unnoticed. Additionally, strong communication skills are vital for collaborating with cross-functional teams and effectively conveying findings from quality control inspections to stakeholders.

Career Advancement in Quality Control Jobs

Career advancement in quality control jobs often hinges on continuous learning and professional development. Many professionals start as entry-level inspectors or technicians before progressing into supervisory or managerial roles as they gain experience and expertise in quality control processes. Networking within industry circles, pursuing certifications related to quality management systems, and staying updated on emerging trends can significantly enhance career prospects for those aiming to excel as a quality assurance specialist.

Quality Inspection in Various Industries

Quality inspections are the backbone of numerous industries, ensuring that products meet required standards and specifications. Across various sectors, quality control inspections play a pivotal role in safeguarding consumer trust and maintaining brand integrity. Let’s explore how different industries implement quality control and the unique challenges they face.

Manufacturing Sector Insights

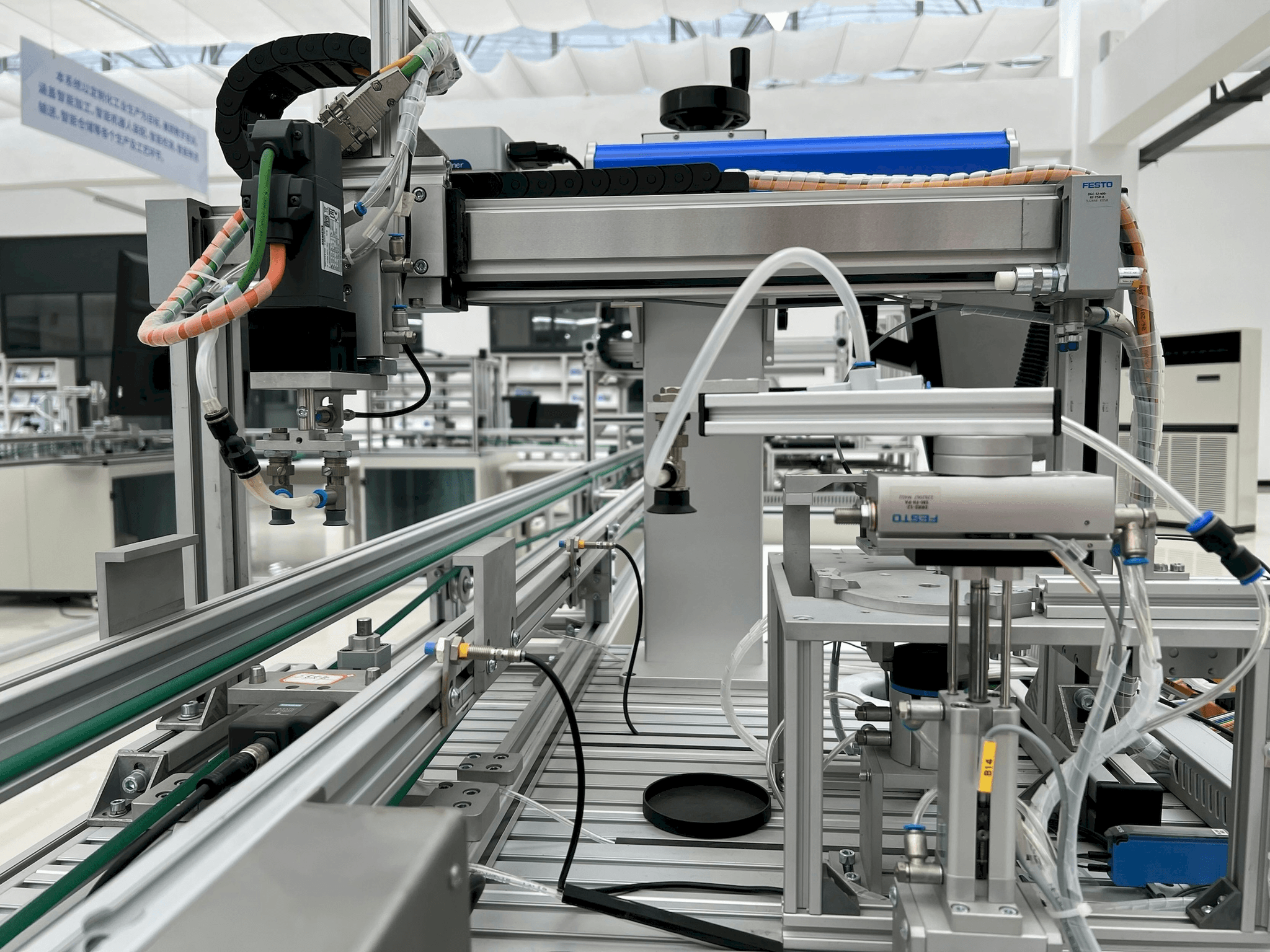

In the manufacturing sector, quality control is paramount to ensure that products are safe, reliable, and meet customer expectations. Quality inspections here often involve rigorous testing processes that assess everything from raw materials to finished goods. The integration of technology, such as automated inspection systems, has revolutionized quality control jobs by enhancing accuracy and efficiency in detecting defects.

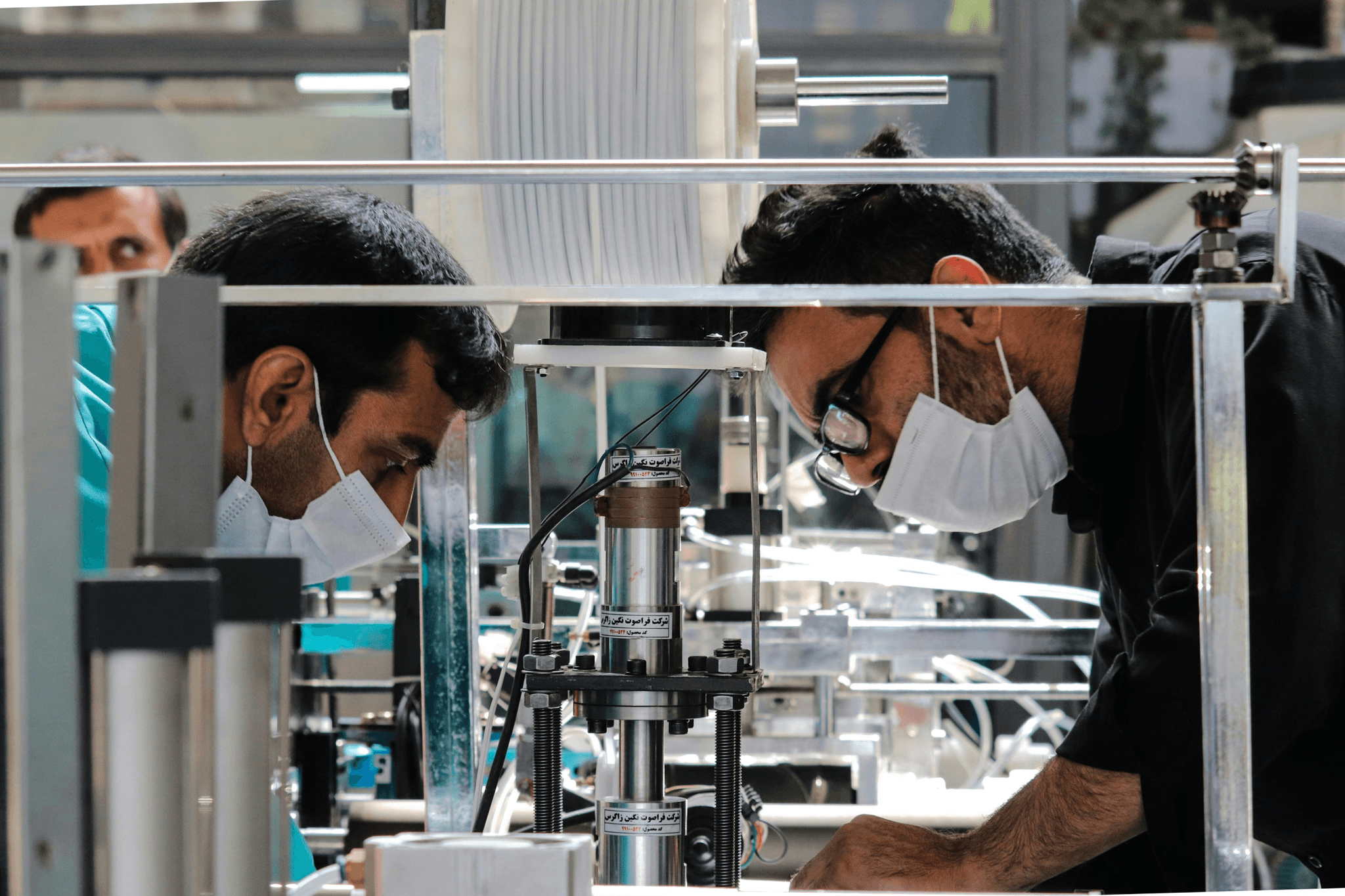

Manufacturers rely heavily on quality assurance specialists who are trained to identify issues early in the production process. These professionals utilize a variety of tools to conduct thorough quality inspections, ensuring compliance with industry standards. By investing in robust quality control measures, manufacturers not only reduce waste but also improve their overall productivity.

The manufacturing landscape is continually evolving with new techniques and technologies aimed at improving product quality. As competition intensifies globally, companies must prioritize effective quality control strategies to maintain their market position. Ultimately, a commitment to excellence through consistent quality inspections can lead manufacturers toward sustained growth and customer loyalty.

Food Safety and Quality Control

Food safety is an area where stringent quality control is non-negotiable; consumers expect nothing less than perfection when it comes to what they eat. Quality inspections in this sector involve checking for contaminants and ensuring compliance with health regulations at every stage of food production—from farm to table. Quality assurance specialists play a critical role by implementing food safety protocols that protect public health.

In addition to regulatory compliance, effective quality control practices help food companies build trust with consumers who demand transparency about their food sources. Regular audits and sampling are essential components of maintaining high-quality standards within the industry. By employing advanced technologies like blockchain for traceability or AI for anomaly detection, companies can further enhance their food safety measures.

The consequences of failing to adhere to strict food safety standards can be severe—ranging from product recalls to legal ramifications—making it imperative for businesses in this sector to focus on comprehensive quality inspections regularly. As the demand for organic and sustainably sourced foods rises, so does the need for enhanced monitoring systems within these supply chains. Emphasizing rigorous quality control not only safeguards consumers but also boosts a company’s reputation in an increasingly competitive market.

Electronics and Quality Assurance

In the fast-paced electronics industry, where innovation meets consumer demand head-on, maintaining high-quality standards through meticulous inspections is crucial. The complexity of electronic components necessitates thorough testing procedures during both manufacturing and assembly stages; even minor defects can lead to significant operational failures later on. This makes skilled professionals specializing in quality assurance jobs indispensable within this field.

Quality inspection processes often include functional testing, visual examinations, and reliability assessments designed specifically for electronic devices—ensuring each product meets rigorous performance criteria before reaching consumers’ hands. The use of automated inspection tools has become increasingly prevalent as they offer speed without compromising accuracy during these critical evaluations of components like circuit boards or semiconductors.

As technology advances rapidly within electronics manufacturing—from smart devices to IoT solutions—the importance of continuous improvement in quality control cannot be overstated. Companies must adapt their strategies accordingly while investing heavily into training programs for their workforce focused on emerging trends related directly back into effective practices around ongoing product evaluations through regular audits or feedback loops from end-users themselves! With strong emphasis placed upon excellence derived from thoroughness seen throughout all levels involved ensures success across this dynamic landscape!

Challenges in Quality Control

Quality control inspections are crucial for ensuring that products meet the desired standards of quality and compliance. However, the path to effective quality control is often fraught with challenges that can hinder the overall process. Understanding these challenges is essential for quality assurance specialists and organizations aiming to maintain high standards in their operations.

Common Issues Faced

One of the most prevalent issues in quality control is inconsistency in inspection processes, which can lead to varying results and unreliable data. This inconsistency often arises from a lack of standardized procedures or insufficient training among quality assurance specialists. Additionally, communication gaps between teams can exacerbate problems, resulting in misunderstandings about quality requirements and expectations.

Another common challenge is the rapid pace of production, which can pressure teams to overlook critical quality control inspections. When deadlines loom large, there's a temptation to cut corners, potentially compromising product integrity and safety. Moreover, evolving customer expectations mean that what was once considered acceptable might no longer meet current market demands.

Lastly, regulatory compliance remains a significant hurdle for many organizations engaged in quality control jobs. Navigating complex regulations requires constant vigilance and up-to-date knowledge about industry standards, which can be overwhelming for even seasoned professionals. Without proper adherence to these regulations, companies risk facing penalties or damage to their reputation.

Strategies for Overcoming Quality Challenges

To tackle these common issues effectively, organizations must establish clear protocols for conducting quality inspections consistently across all departments. Implementing standardized checklists and training programs ensures that every team member understands their role in maintaining product quality throughout the inspection process. Regular audits also help identify areas needing improvement while fostering a culture of accountability within teams.

Investing in advanced technology can significantly enhance efficiency during production without sacrificing thoroughness in quality control inspections. Automation tools assist in streamlining repetitive tasks while providing precise measurements that reduce human error during inspections. By integrating data analytics into their operations, companies can gain valuable insights into trends affecting product performance and make informed decisions accordingly.

Furthermore, fostering open communication between departments promotes collaboration and helps address potential issues before they escalate into major problems. Regular meetings focused on sharing feedback regarding inspection outcomes enable teams to learn from one another's experiences while aligning on best practices related to both quality assurance jobs and overall production goals.

The Importance of Compliance and Regulations

Compliance with industry regulations is paramount when it comes to maintaining trust among consumers and stakeholders alike; non-compliance could lead not only to financial penalties but also reputational damage that might take years to repair! Quality control inspections must adhere strictly not just internally but also externally by following guidelines set forth by governing bodies relevant within each sector—be it manufacturing or food safety.

Understanding these regulations empowers quality assurance specialists as they navigate complex landscapes filled with ever-changing rules governing product safety standards worldwide! Continuous education on compliance updates will ensure your organization remains ahead of potential pitfalls associated with non-compliance risks while enhancing its credibility within respective markets over time!

In summation: prioritizing compliance isn’t merely about avoiding fines—it’s an investment toward building long-lasting relationships founded on trustworthiness through consistent delivery of high-quality products backed by rigorous oversight via effective implementation strategies tailored specifically around robust frameworks surrounding both “quality” AND “control”.

The Future of Quality Control

Quality control is undergoing a significant transformation, driven by technological advancements and evolving industry standards. As businesses strive for excellence, quality control inspections are becoming more sophisticated, utilizing cutting-edge tools to ensure top-notch products. This shift not only enhances product reliability but also streamlines the quality assurance jobs landscape, making it an exciting field for aspiring professionals.

Emerging Technologies in Quality Inspections

The integration of emerging technologies is reshaping the way quality control inspections are conducted. Innovations such as artificial intelligence (AI), machine learning, and automation are enabling real-time monitoring and analysis of production processes. These advancements allow quality assurance specialists to identify defects earlier than ever before, reducing waste and improving overall efficiency in quality control.

Moreover, technologies like drones and 3D scanning are revolutionizing how inspections are performed across various industries. With these tools at their disposal, professionals can conduct thorough quality inspections without compromising safety or efficiency. As a result, the future of quality control looks promising, with technology paving the way for more precise and effective practices.

Trends in Quality Assurance and Control

As we look ahead, several trends are shaping the landscape of quality assurance and control. One notable trend is the increasing emphasis on data-driven decision-making within organizations; companies now rely heavily on analytics to inform their quality strategies. This shift means that those pursuing careers in quality control jobs will need to develop strong analytical skills alongside traditional inspection techniques.

Another trend is the growing importance of sustainability in quality management practices; businesses are recognizing that maintaining high-quality standards must also align with environmental responsibilities. Consequently, many organizations are adopting eco-friendly practices as part of their overall commitment to product excellence while ensuring compliance with regulations related to environmental impact. This evolution not only enhances brand reputation but also opens new avenues for career advancement in the field.

The Role of China Inspection Pro in Modern Quality Control

China Inspection Pro has emerged as a key player in modernizing quality control inspections within various industries globally. By providing comprehensive services tailored to meet diverse client needs, they ensure that products adhere to international standards while maintaining rigorous inspection protocols throughout the supply chain process. Their expertise helps businesses navigate complex regulations while enhancing product reliability through meticulous evaluations.

Furthermore, China Inspection Pro leverages innovative technology solutions that complement traditional inspection methods—offering clients real-time insights into their production processes and potential risks associated with poor-quality products. By bridging gaps between manufacturers and consumers through transparent communication channels, they play an essential role in fostering trust within global markets reliant on stringent quality assurance measures.

In conclusion, as we embrace emerging technologies and adapt to changing trends within the realm of quality assurance jobs, organizations like China Inspection Pro will continue leading efforts toward elevating industry standards through effective collaboration between stakeholders involved in ensuring exceptional product outcomes.

Conclusion

Quality control is the backbone of any successful production process, ensuring that products meet established standards and specifications. Without rigorous quality control inspections, businesses risk delivering subpar products that can tarnish their reputation and lead to financial losses. By prioritizing quality and control, companies not only enhance customer satisfaction but also foster loyalty and trust in their brand.

Ensuring Product Excellence Through Quality Control

To achieve product excellence, organizations must implement a robust quality control system that encompasses every stage of production. Quality control inspections play a crucial role in identifying defects early on, allowing for timely interventions before products reach the market. This proactive approach not only saves costs associated with returns and recalls but also strengthens the overall integrity of the product.

The Vital Role of Quality Inspections

Quality inspections are essential in various industries to maintain high standards and ensure compliance with regulations. These inspections serve as checkpoints, verifying that processes are followed correctly and that end products meet specified criteria. The diligent work of quality assurance specialists during these inspections helps prevent costly errors, making them invaluable assets in any organization focused on maintaining excellence.

Building a Career in Quality Assurance

A career in quality assurance offers numerous opportunities for growth and development as industries increasingly recognize the importance of quality control jobs. Aspiring professionals can find roles ranging from entry-level positions to senior quality assurance specialist roles, each requiring a unique set of skills such as attention to detail, analytical thinking, and problem-solving abilities. As businesses continue to prioritize quality assurance jobs, those who invest time in honing their skills will find themselves well-positioned for advancement within this dynamic field.