Introduction

In the world of lighting, LED technology has revolutionized how we illuminate our spaces, but not all LED lights are created equal. Understanding Quality Defects in LED Lights is crucial for consumers and manufacturers alike, as these defects can significantly impact performance and longevity. From Flickering Lights to Color Inconsistency, recognizing these issues early can save both time and money while enhancing the overall lighting experience.

Understanding Quality Defects in LED Lights

Quality defects in LED lights encompass a range of issues that may affect their functionality and durability. Common problems include Flickering Lights, which can be distracting and annoying, as well as Dimming Problems that might leave your space inadequately lit when you need it most. Additionally, factors like Buzzing Noise from faulty components or ineffective Heat Management can detract from the intended benefits of modern lighting solutions.

The Impact of Defects on Performance

The performance of LED lights is directly influenced by various quality defects that can arise during manufacturing or installation. For instance, Color Inconsistency not only hampers aesthetic appeal but also affects mood and productivity in workspaces or homes. Furthermore, issues like Lumen Depreciation—where the light output diminishes over time—can lead to increased energy costs and more frequent replacements than anticipated.

How to Spot Issues Early

Spotting quality defects early is essential for maintaining optimal performance in your lighting systems. Regular inspections can help identify problems such as Flickering at Low Temperatures or unexpected buzzing sounds before they escalate into major concerns. By being proactive and utilizing services like those offered by China Inspection Pro for thorough quality assessments, you ensure your investments yield long-lasting results while adhering to industry standards.

Common Quality Defects in LED Lights

When it comes to LED lighting, quality defects can significantly affect performance and user satisfaction. Understanding these common issues is essential for anyone looking to invest in reliable lighting solutions. In this section, we will explore flickering lights, color inconsistency, and dimming problems—three prevalent quality defects in LED lights that can disrupt your experience.

Flickering Lights: Causes and Solutions

Flickering lights are one of the most annoying quality defects in LED lights that can turn a cozy environment into a distracting nightmare. The primary culprits behind flickering often include incompatible dimmer switches and poor-quality drivers that can't regulate power effectively. Fortunately, solutions exist; upgrading to compatible dimmers or investing in high-quality drivers can alleviate this issue and ensure a smooth lighting experience.

Another important factor to consider is the electrical supply; fluctuations in voltage can also lead to flickering lights. Regularly monitoring your electrical system for stability can help identify underlying issues before they escalate into more significant problems. By addressing these concerns proactively, you can enjoy consistent lighting without interruptions.

Lastly, if you find yourself dealing with persistent flickering despite making adjustments, it might be time to consult professionals like China Inspection Pro for a thorough examination of your LED systems. Their expertise ensures that all components meet industry standards, thereby reducing the likelihood of encountering such quality defects in LED lights again.

Color Inconsistency: What to Look For

Color inconsistency is another frustrating quality defect that can leave spaces looking uneven or poorly lit. This issue arises when different batches of LEDs emit varying hues or brightness levels due to manufacturing discrepancies or subpar materials used during production. To spot this problem early on, pay attention to how well the light matches across fixtures within the same space—any noticeable differences should raise red flags.

One effective way to assess color consistency is by using color temperature meters or simply comparing similar bulbs side by side under controlled conditions. If you notice significant variations between products labeled as having the same color temperature (measured in Kelvin), it’s wise to reconsider your purchase decisions carefully. High-quality manufacturers typically adhere closely to specified standards, ensuring uniformity across their product lines.

If you do encounter color inconsistency after installation, consider reaching out for professional inspection services like those offered by China Inspection Pro. They specialize in identifying such quality defects in LED lights and provide actionable recommendations tailored for long-term satisfaction with your lighting choices.

Dimming Problems: When Less Is More

Dimming problems represent yet another challenge when dealing with quality defects in LED lights; they often manifest as inadequate light output or erratic behavior when attempting to adjust brightness levels. These issues typically arise from incompatible dimmer switches or low-quality bulbs that do not support smooth dimming functions properly—leaving users frustrated when trying to create their desired ambiance.

To tackle this problem effectively, ensure compatibility between your chosen LEDs and any existing dimmers before finalizing your purchase decision; look for products specifically labeled as dimmable. Additionally, opting for reputable brands known for their commitment to quality will likely result in fewer headaches down the line regarding dimming performance.

Should you find yourself grappling with persistent dimming problems despite taking precautions during installation? It may be time for an expert evaluation from China Inspection Pro—a team dedicated not only to inspecting but also providing insights on how best to enhance overall performance while minimizing potential quality defects in LED lights moving forward.

The Buzzing Noise Dilemma

Buzzing noises in LED lights can be more than just a minor annoyance; they are often an indicator of underlying quality defects in LED lights. While the flickering lights and color inconsistency may capture more attention, the persistent buzzing noise can disrupt your environment and lead to significant dimming problems. Understanding the source of this noise is crucial for ensuring a peaceful and pleasant lighting experience.

Identifying the Source of the Buzz

The buzzing noise typically originates from three main sources: driver circuits, incompatible dimmers, or even electromagnetic interference. Poor-quality drivers can cause fluctuations that result in audible buzzing, while certain dimmers may not be compatible with LED technology, leading to unwanted sounds. Identifying these sources early on can help you address quality defects in LED lights before they escalate into bigger issues.

How to Minimize Disruptive Sounds

To minimize disruptive sounds, consider investing in high-quality drivers designed specifically for LED applications; these generally provide better heat management and reduce buzzing significantly. Additionally, ensure that your dimmer switch is compatible with LEDs to prevent flickering and other annoyances associated with poor compatibility. Lastly, if you notice persistent buzzing from a particular fixture, it might be worth replacing it altogether to avoid ongoing quality defects in LED lights.

Products with Known Buzzing Issues

Certain products have gained notoriety for their buzzing issues due to subpar components or design flaws. Brands that have faced criticism often include lower-end models lacking proper heat management or those using outdated technology that doesn’t align well with modern LEDs. When shopping for new lighting solutions, always check reviews and product specifications to steer clear of known offenders—after all, nobody wants their cozy evening ambiance disrupted by an irritating buzz!

Effective Heat Management Strategies

Heat management is a crucial aspect of maintaining the quality and longevity of LED lights. Poor heat dissipation can lead to a range of quality defects in LED lights, including flickering lights, color inconsistency, and even dimming problems. Without effective heat management, LEDs can suffer from accelerated lumen depreciation, reducing their overall performance and lifespan.

Importance of Proper Heat Dissipation

Proper heat dissipation is essential for ensuring the reliability and efficiency of LED lighting systems. When LEDs generate heat without adequate ventilation or cooling mechanisms, they can experience performance issues such as flickering lights and buzzing noise that disrupts the user experience. Moreover, effective heat management minimizes lumen depreciation over time, allowing your LED lights to maintain consistent brightness levels throughout their lifespan.

Common Designs that Fail Heat Tests

Many common LED designs struggle with effective heat management due to inadequate thermal pathways or poorly designed housings. For instance, compact fixtures often trap heat within tight spaces, leading to overheating which manifests as flickering at low temperatures or color inconsistency in output. It's essential to recognize these design flaws early on; otherwise, you may find yourself dealing with a host of quality defects in LED lights that could have been avoided.

Solutions for Improved Thermal Management

To combat these issues effectively, several solutions can be implemented for improved thermal management in LED lighting products. Utilizing materials with high thermal conductivity helps dissipate heat more efficiently while incorporating larger heatsinks or fans can significantly reduce operating temperatures. Additionally, conducting thorough inspections through services like China Inspection Pro ensures that your products meet industry standards for thermal performance—essentially safeguarding against future problems such as dimming problems or buzzing noise that stem from inadequate heat management.

Understanding Lumen Depreciation

Lumen depreciation is a critical concept in the realm of LED lighting, directly impacting the overall quality and performance of these lights. As time progresses, LED lights lose their brightness, which can lead to various quality defects in LED lights that may go unnoticed until it’s too late. Understanding this phenomenon is essential for ensuring longevity and maintaining optimal illumination levels.

What Is Lumen Depreciation?

Lumen depreciation refers to the gradual reduction in light output that occurs as an LED light ages. Unlike traditional incandescent bulbs, LEDs experience a slow decline in brightness rather than a sudden failure, making it crucial for consumers and manufacturers alike to monitor this degradation closely. This decline can be influenced by several factors, including heat management issues and electrical fluctuations that may also contribute to flickering lights or color inconsistency.

Measuring Lumen Loss Over Time

To effectively measure lumen loss over time, one must utilize photometric testing methods that quantify light output at different intervals throughout the lifespan of an LED light source. Regular assessments allow users to track performance degradation and identify potential dimming problems before they become significant issues. By establishing baseline measurements at initial installation and conducting periodic evaluations, one can pinpoint trends that indicate when replacement may be necessary due to lumen depreciation.

Preventive Measures for Longevity

Preventive measures play a vital role in extending the life of LED lights and minimizing lumen depreciation. Implementing effective heat management strategies is paramount; excessive heat can significantly accelerate lumen loss while also causing buzzing noise or flickering at low temperatures. Additionally, selecting high-quality components from reputable manufacturers can mitigate risks associated with color inconsistency and other quality defects in LED lights, ensuring sustained brightness over time.

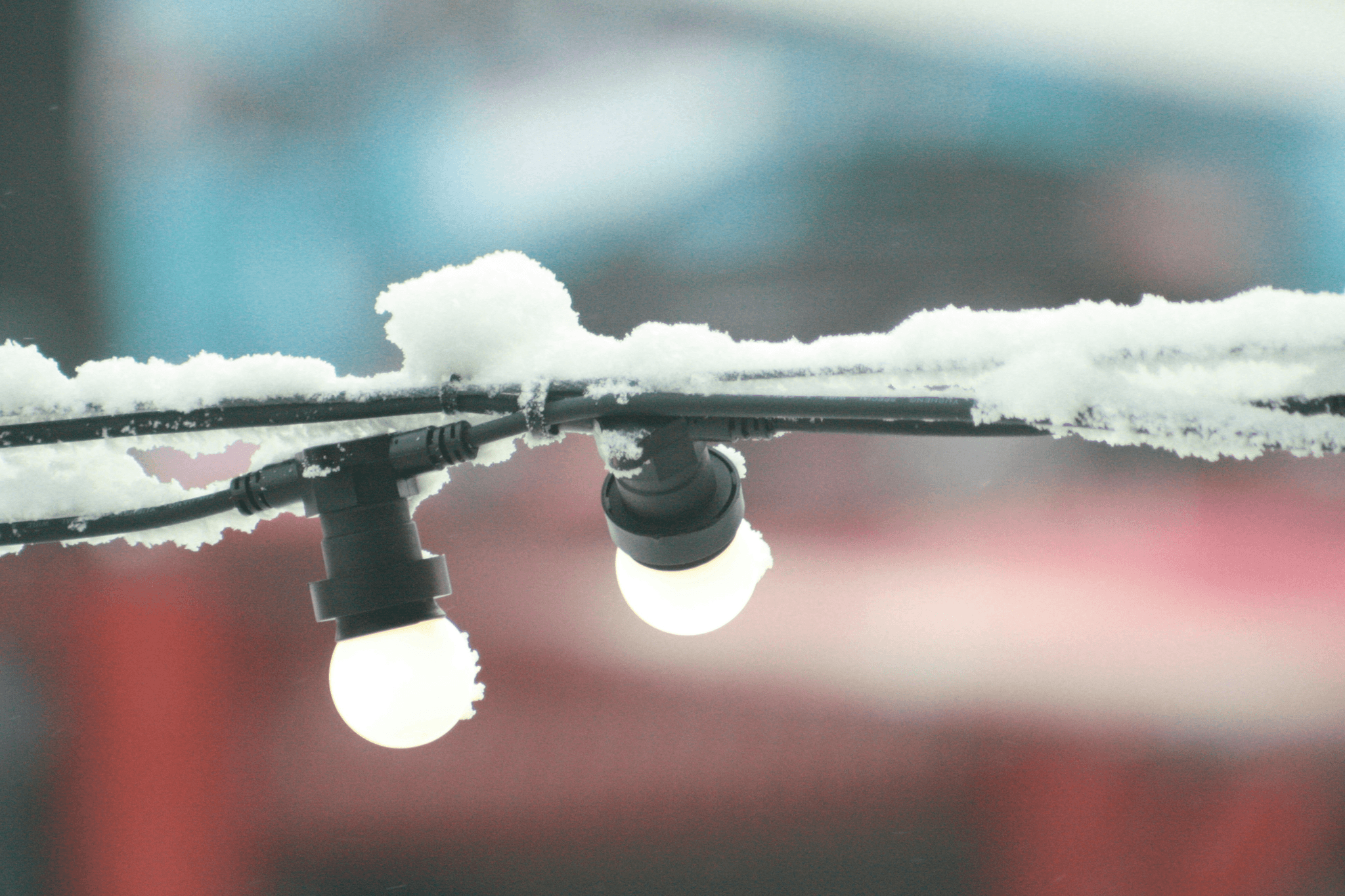

Flickering at Low Temperatures

Flickering lights can be a significant annoyance, especially in colder climates where LED performance tends to dip. Understanding why LEDs flicker at low temperatures is crucial for both consumers and manufacturers aiming to address quality defects in LED lights. By identifying the root causes of this issue, we can implement effective solutions that enhance overall lighting performance.

Why LEDs Flicker in Cold Conditions

LEDs are designed to operate efficiently across various temperatures, but when exposed to cold conditions, their electronic components may struggle. The flickering often stems from reduced current flow through the LED drivers due to lower ambient temperatures, which can lead to inconsistent power supply. This phenomenon not only affects brightness but also contributes to other quality defects in LED lights such as color inconsistency and dimming problems.

Testing LED Performance in Varied Temperatures

To truly understand how LEDs behave under different environmental conditions, rigorous testing is necessary. Manufacturers should simulate a range of temperatures during product development to identify potential flickering issues early on. Such testing helps ensure that products meet industry standards and provides valuable insights into how heat management strategies can be refined for optimal performance.

Solutions to Overcome Cold Flickering

Fortunately, there are several strategies that can mitigate flickering at low temperatures and enhance the durability of LED lights. One effective approach is using high-quality drivers specifically designed for cold environments; these components maintain consistent current flow regardless of temperature fluctuations. Additionally, improving thermal management through better heat dissipation techniques can help maintain optimal operating conditions and minimize lumen depreciation over time.

Conclusion

In the world of LED lighting, recognizing and addressing quality defects is crucial for ensuring optimal performance and longevity. Quality defects in LED lights, such as flickering lights, color inconsistency, and dimming problems, can lead to frustration and dissatisfaction for users. By being proactive in identifying these issues early on, consumers can make informed decisions that enhance their overall lighting experience.

Recognizing and Addressing Quality Defects

Awareness of common quality defects in LED lights is the first step toward effective resolution. Flickering lights may signal underlying electrical issues, while color inconsistency often points to poor manufacturing processes. Dimming problems can arise from incompatible dimmers or low-quality components; thus, understanding these nuances helps users address them promptly.

Consumers should also be vigilant about buzzing noise that can accompany certain LED fixtures; this is often a sign of inadequate heat management or poor design choices. Identifying these quality defects early allows for timely intervention—whether it's replacing faulty units or seeking professional advice on suitable products. Ultimately, recognizing and addressing these quality defects not only improves user satisfaction but also extends the lifespan of the lighting solutions employed.

The Role of China Inspection Pro in Quality Assurance

Quality assurance plays a pivotal role in mitigating quality defects in LED lights before they reach consumers. This is where China Inspection Pro steps in with its comprehensive inspection services focused on product excellence. Our specialists meticulously examine every detail—ensuring that flickering lights are identified before they leave the factory and that color inconsistency is addressed during production.

With rigorous testing protocols, we turn findings into actionable recommendations that help manufacturers improve their processes and products. The result? A significant reduction in common issues like dimming problems or buzzing noise associated with subpar designs. By partnering with China Inspection Pro, manufacturers not only enhance their reputation but also contribute to a more reliable market for consumers seeking high-quality LED solutions.

Long-Term Benefits of Quality LED Lighting

Investing in quality LED lighting yields long-term benefits that extend beyond mere aesthetics or energy savings; it enhances overall user experience as well. When consumers choose products free from common quality defects such as lumen depreciation or flickering at low temperatures, they enjoy consistent performance over time without unexpected disruptions.

Furthermore, effective heat management strategies ensure longer lifespans for LEDs—saving both money and resources long after the initial purchase has been made. In essence, prioritizing high-quality standards leads to durable products that meet consumer expectations while minimizing maintenance costs down the line.