Introduction

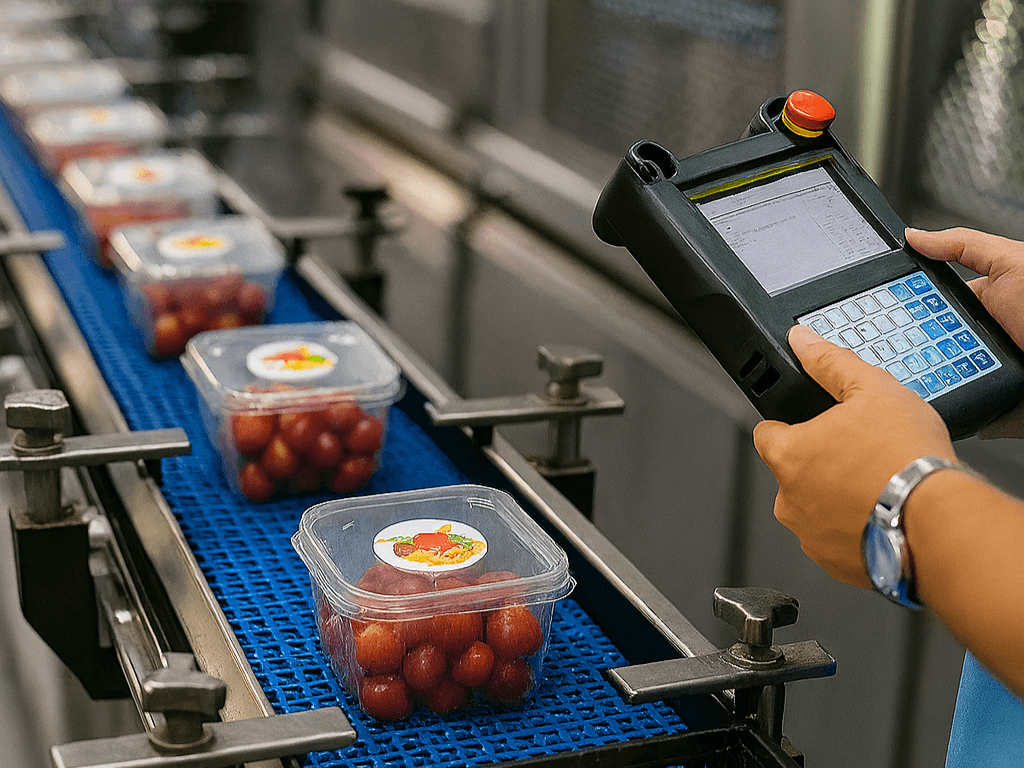

In today's global marketplace, ensuring product quality is not just a preference; it's a necessity. With many businesses sourcing goods from abroad, particularly from China, the importance of rigorous quality control cannot be overstated. Product Inspections in China play a crucial role in maintaining standards and safeguarding brand reputation by identifying potential issues before they escalate.

Understanding the Importance of Quality Control

Quality control is essential for any business that aims to deliver products that meet customer expectations and comply with industry regulations. It helps prevent costly recalls and enhances customer satisfaction by ensuring that every item meets predetermined standards. By implementing effective quality control measures, companies can build trust with their customers and create a loyal client base.

Overview of Product Inspections in China

China has become a manufacturing powerhouse, making it an attractive option for businesses looking to reduce costs while maintaining production efficiency. However, this also means that companies must be vigilant about the quality of their products through various inspection stages. From Pre-Production Inspection (PPI) to Final Random Inspection (PSI), understanding the nuances of Product Inspections in China is vital for success.

Key Types of Product Inspections

There are several key types of inspections that businesses should consider when working with Chinese manufacturers: Pre-Production Inspection (PPI), During Production Inspection (DPI), Final Random Inspection (PSI), and Container Loading Inspection (CLS). Each type serves a specific purpose within The Process of China Factory Inspection, helping to ensure that products are manufactured according to agreed-upon specifications at every stage. By leveraging these inspections effectively, companies can mitigate risks and enhance overall product quality.

The Process of China Factory Inspection

When it comes to ensuring product quality, understanding the process of China factory inspection is essential. This process involves a series of systematic evaluations designed to catch potential issues before they escalate. By engaging in thorough inspections, businesses can safeguard their investments and ensure compliance with industry standards.

Choosing the Right Inspection Company

Selecting the right inspection company is a pivotal step in the product inspections in China process. An experienced provider like China Inspection Pro offers tailored services that align with your specific needs, whether it’s Pre-Production Inspection (PPI), During Production Inspection (DPI), or Final Random Inspection (PSI). Look for companies that have a solid reputation, positive client testimonials, and a deep understanding of local manufacturing practices to ensure you get the best results.

Your chosen inspection partner should not only have expertise in various types of inspections but also be familiar with your industry’s unique requirements. Ask about their methodologies and how they plan to conduct inspections at different stages, such as Container Loading Inspection (CLS). A good inspection company will provide transparency and clarity on their processes while offering actionable insights into quality improvements.

Finally, consider the geographical reach and language capabilities of the inspection company you select. Effective communication is crucial during product inspections in China; therefore, working with inspectors who understand both English and Chinese can bridge potential gaps. This will facilitate smoother interactions with suppliers and help you address any issues promptly.

Developing an Inspection Plan

Once you've selected an inspection company, developing a comprehensive inspection plan is vital for successful product inspections in China. This plan should outline specific quality standards based on your product requirements while detailing when each type of inspection—be it Pre-Production Inspection (PPI), During Production Inspection (DPI), or Final Random Inspection (PSI)—will occur throughout the manufacturing cycle.

Incorporating timelines for each phase ensures that all stakeholders are aligned on expectations and deadlines. Include contingency plans within your strategy to address potential delays or issues that may arise during production or shipping phases like Container Loading Inspection (CLS). Having a well-structured plan allows for flexibility while maintaining focus on quality assurance goals.

Additionally, it's important to share this plan with your suppliers so they understand what is expected at each stage of production. Clear communication regarding quality standards helps ensure supplier compliance from day one—setting everyone up for success as you work towards delivering high-quality products to market.

Understanding Local Regulations

Navigating local regulations is another critical aspect of the process of China factory inspection that cannot be overlooked. Each industry has its own set of regulatory requirements that must be adhered to; failing to comply can lead to costly setbacks or even legal repercussions down the line. Therefore, familiarize yourself with relevant laws governing product safety and quality standards applicable within your sector.

Working closely with an experienced partner like China Inspection Pro can help clarify these regulations while ensuring that all aspects—from Pre-Production Inspections (PPI) through Final Random Inspections (PSI)—are compliant before products hit international markets. Moreover, keeping abreast of any changes in local laws ensures ongoing adherence throughout production cycles.

Lastly, understanding these regulations not only protects your business but also fosters trust among consumers who increasingly value transparency and ethical sourcing practices. By prioritizing compliance through diligent factory inspections—including During Production Inspections (DPI) and Container Loading Inspections (CLS)—you enhance brand credibility while safeguarding against risks associated with non-compliance.

Pre-Production Inspection (PPI)

When it comes to ensuring the quality of products, Pre-Production Inspection (PPI) plays a crucial role in the overall process of China factory inspection. This phase sets the stage for what is to come by establishing clear expectations and standards before production begins. By addressing potential issues early on, businesses can save time, reduce costs, and enhance product quality—ultimately leading to greater customer satisfaction.

Setting Quality Standards Before Production

Establishing quality standards before production kicks off is essential for any successful manufacturing process. During this stage, companies should outline specific criteria that their products must meet, including functionality, aesthetics, and compliance with relevant regulations. By clearly defining these standards upfront, businesses can ensure that everyone involved—from suppliers to manufacturers—understands what is expected throughout the entire production journey.

Moreover, setting these benchmarks allows for smoother transitions into subsequent inspections like During Production Inspection (DPI) and Final Random Inspection (PSI). It creates a solid foundation for evaluating product quality at different stages while reducing ambiguity and misunderstandings later on. With well-defined standards in place, companies can confidently move forward knowing they have established a reliable framework for success.

Evaluating Material Quality

The evaluation of material quality is another critical component of Pre-Production Inspection (PPI). Before any manufacturing commences, it’s vital to assess the raw materials that will be used in production thoroughly. This step not only helps identify any potential defects but also ensures that materials meet the specified quality standards set earlier.

By conducting thorough evaluations of material quality during PPI, businesses can mitigate risks associated with poor-quality inputs that could lead to subpar final products. Additionally, this proactive approach aligns seamlessly with other types of inspections like Container Loading Inspection (CLS), where ensuring high-quality materials translates into better packaging and shipping outcomes. Ultimately, investing time in material evaluation pays off by fostering stronger supplier relationships and enhancing overall product integrity.

Ensuring Supplier Compliance

Ensuring supplier compliance is paramount during the Pre-Production Inspection (PPI) phase as it lays the groundwork for successful collaboration throughout the manufacturing process. Companies need to verify that their suppliers adhere to industry regulations and standards while also meeting specific contractual obligations related to product specifications and timelines. This diligence not only protects brand reputation but also minimizes disruptions down the line.

Regular communication with suppliers during PPI strengthens partnerships and facilitates transparency regarding expectations from both parties involved in Product Inspections in China. Furthermore, maintaining compliance helps ensure smooth transitions into subsequent inspections such as During Production Inspection (DPI) or Final Random Inspection (PSI). By prioritizing supplier compliance from the outset, businesses position themselves for long-term success while safeguarding against potential pitfalls down the road.

During Production Inspection (DPI)

During Production Inspection (DPI) is a critical phase in the overall quality control process, particularly in the context of Product Inspections in China. This stage allows for real-time monitoring of manufacturing activities, ensuring that production aligns with established quality standards set during the Pre-Production Inspection (PPI). By maintaining oversight during this phase, businesses can mitigate risks and enhance product quality before reaching the Final Random Inspection (PSI).

Monitoring Production Progress

Monitoring production progress is essential to ensure that everything runs smoothly on the factory floor. Regular inspections provide insights into how well production adheres to timelines and quality benchmarks, which are crucial for timely delivery and customer satisfaction. By utilizing expert services like those offered by China Inspection Pro, companies can gain a comprehensive understanding of their supply chain's performance.

In this phase, inspectors evaluate various aspects of the manufacturing process, including machinery efficiency and workforce productivity. They also check whether materials used match those approved during the PPI stage. This proactive approach helps catch any discrepancies early on, allowing for timely interventions.

Identifying Issues Early

Identifying issues early is one of the most significant advantages of During Production Inspection (DPI). By keeping a close eye on ongoing operations, inspectors can spot potential problems before they escalate into costly setbacks or defects that might not be caught until Final Random Inspection (PSI). Early detection can save time and resources while preserving product integrity.

For instance, if an inspector notices that a batch of goods deviates from specified standards—whether due to material flaws or incorrect assembly—immediate corrective actions can be implemented. This proactive stance not only safeguards product quality but also strengthens relationships with suppliers by fostering open communication about challenges faced during production.

Communicating with Suppliers

Effective communication with suppliers is paramount throughout the During Production Inspection (DPI) process. Inspectors serve as intermediaries who relay vital information regarding production status and any issues discovered directly to suppliers. This dialogue ensures everyone remains aligned on expectations and facilitates quick resolutions to any concerns that arise.

Moreover, open lines of communication help build trust between manufacturers and brands looking to maintain high-quality standards in their products. When suppliers understand what’s required from them—based on insights gained from DPI—they are more likely to deliver products that meet or exceed expectations set forth during both Pre-Production Inspections (PPI) and subsequent checks like Container Loading Inspections (CLS).

Final Random Inspection (PSI)

The Final Random Inspection (PSI) is a crucial step in the quality control process, ensuring that products meet established standards before they are shipped. This inspection occurs after production but before the goods leave the factory, acting as a final checkpoint to catch any defects or inconsistencies. By integrating PSI into your overall quality assurance strategy, you can significantly reduce the risk of receiving subpar products.

Conducting Comprehensive Product Checks

During the PSI phase, inspectors conduct thorough examinations of the finished products to ensure compliance with quality standards. This includes checking for visual defects, functionality, and adherence to specifications outlined during earlier stages such as Pre-Production Inspection (PPI) and During Production Inspection (DPI). Quality Inspection delivers professional services focused on product excellence, providing an additional layer of assurance that your goods will meet or exceed industry standards.

Sampling Techniques Explained

Sampling techniques play a vital role in the effectiveness of Final Random Inspections (PSI). Inspectors typically use statistical methods to select a representative sample size from the total batch, which allows them to gauge overall product quality without examining every single item. By employing these techniques effectively, companies can identify potential issues early on and address them before shipping—making it an essential part of The Process of China Factory Inspection.

Delivering Final Reports

Once inspections are complete, detailed reports are compiled summarizing findings from the Final Random Inspection (PSI). These reports include information on any defects found, compliance with pre-established standards, and recommendations for improvement if necessary. With clear communication from China Inspection Pro regarding these results, businesses can make informed decisions about their shipments and ensure that their products maintain high-quality standards throughout all stages—from Pre-Production Inspection (PPI) to Container Loading Inspection (CLS).

Container Loading Inspection (CLS)

When it comes to ensuring that your products arrive at their destination in pristine condition, Container Loading Inspection (CLS) plays a pivotal role. This inspection process is the final checkpoint before goods embark on their journey, ensuring that everything is packed securely and ready for transport. By conducting thorough inspections during this phase, you can mitigate risks associated with shipping and enhance the overall efficacy of your logistics.

Ensuring Safe and Secure Shipping

The primary goal of Container Loading Inspection is to guarantee safe and secure shipping of products. Inspectors assess how goods are loaded into containers, checking for proper weight distribution and stability to prevent shifting during transit. A well-executed CLS not only protects your investment but also fosters trust with customers who expect timely deliveries without damage.

In the realm of Product Inspections in China, CLS serves as a critical safeguard against potential losses or damages that could arise during transportation. By employing experienced inspectors who understand the nuances of international shipping regulations, you can rest assured that your products are in capable hands. This level of diligence reinforces your commitment to quality assurance throughout The Process of China Factory Inspection.

Verifying Packaging Standards

Another essential aspect of Container Loading Inspection is verifying packaging standards before goods hit the road—or sea! Inspectors meticulously check that packaging materials meet industry requirements and are appropriate for the type of product being shipped. Proper packaging not only protects items from physical damage but also ensures compliance with various regulations.

Incorporating CLS into your overall quality control strategy enhances efficiency by identifying any discrepancies in packaging early on, thus avoiding costly mistakes later down the line. This attention to detail complements other inspection types like Pre-Production Inspection (PPI), During Production Inspection (DPI), and Final Random Inspection (PSI). As a result, you create a seamless flow from production through delivery—keeping customers happy and products intact.

Preventing Damage During Transit

Preventing damage during transit is paramount for maintaining product integrity and customer satisfaction. Through rigorous inspections during Container Loading Inspection, potential issues such as inadequate cushioning or improper stacking can be identified before they lead to costly damages en route. This proactive approach allows businesses to take corrective actions immediately rather than dealing with fallout after delivery.

Moreover, leveraging services from professionals like China Inspection Pro ensures that every aspect of loading complies with both internal standards and external regulations governing international trade. Their expertise streamlines The Process of China Factory Inspection by providing clear insights into areas needing improvement while enhancing overall operational efficiency across all inspection stages—PPI, DPI, PSI, and CLS alike!

By prioritizing Container Loading Inspections as part of your quality assurance strategy in Product Inspections in China, you’re not just protecting shipments; you're safeguarding brand reputation too!

Conclusion

In the world of international trade, especially when dealing with Product Inspections in China, understanding the various inspection types is crucial. From Pre-Production Inspection (PPI) to Final Random Inspection (PSI), each stage plays a significant role in ensuring that products meet quality standards before they reach consumers. The Process of China Factory Inspection is not merely a formality; it is an essential practice that can save businesses from costly mistakes and dissatisfied customers.

Key Takeaways on Inspection Types

Each type of inspection serves a distinct purpose in the quality assurance process. Pre-Production Inspection (PPI) sets the tone by ensuring that materials meet established quality standards before production begins, while During Production Inspection (DPI) allows for monitoring progress and addressing issues as they arise. Finally, Final Random Inspection (PSI) provides a comprehensive check of finished products, ensuring they are ready for market delivery and meet all regulatory requirements.

Benefits of Partnering with China Inspection Pro

Choosing to partner with China Inspection Pro can significantly enhance your quality assurance efforts. Their expertise in conducting thorough inspections—whether it’s PPI, DPI, PSI, or Container Loading Inspection (CLS)—ensures that every detail is meticulously checked and documented. With their professional services focused on product excellence, you can rest assured that your goods will consistently meet or exceed industry standards.

Final Thoughts on Quality Assurance in China

Quality assurance is not just about compliance; it's about building trust and reliability in your brand's offerings. By implementing robust inspection processes like those provided by China Inspection Pro—covering everything from PPI to CLS—you position yourself for success in competitive markets. Remember, investing time and resources into effective Product Inspections in China will ultimately pay off through enhanced customer satisfaction and loyalty.