Introduction

In today's fast-paced marketplace, ensuring product quality is non-negotiable. This is where third-party quality inspection services come into play, providing an essential layer of quality assurance that helps businesses maintain high standards. From manufacturing to retail, the importance of quality control cannot be overstated; it not only safeguards a company's reputation but also enhances customer satisfaction.

Understanding Third-Party Inspection

Third-party inspection refers to the evaluation of products or services by an independent entity, separate from both the manufacturer and the buyer. This process involves rigorous quality inspection protocols designed to assess compliance with specified standards and regulations. By leveraging third-party quality inspection services, companies can ensure that their products meet industry benchmarks and consumer expectations.

Importance of Quality Control

Quality control is vital for businesses aiming to deliver consistent and reliable products to their customers. Effective quality control measures help identify defects early in the production process, reducing waste and saving costs in the long run. Moreover, robust quality assurance practices foster trust among consumers, making it imperative for companies to prioritize their approach to quality control and assurance.

Overview of Third-Party Services

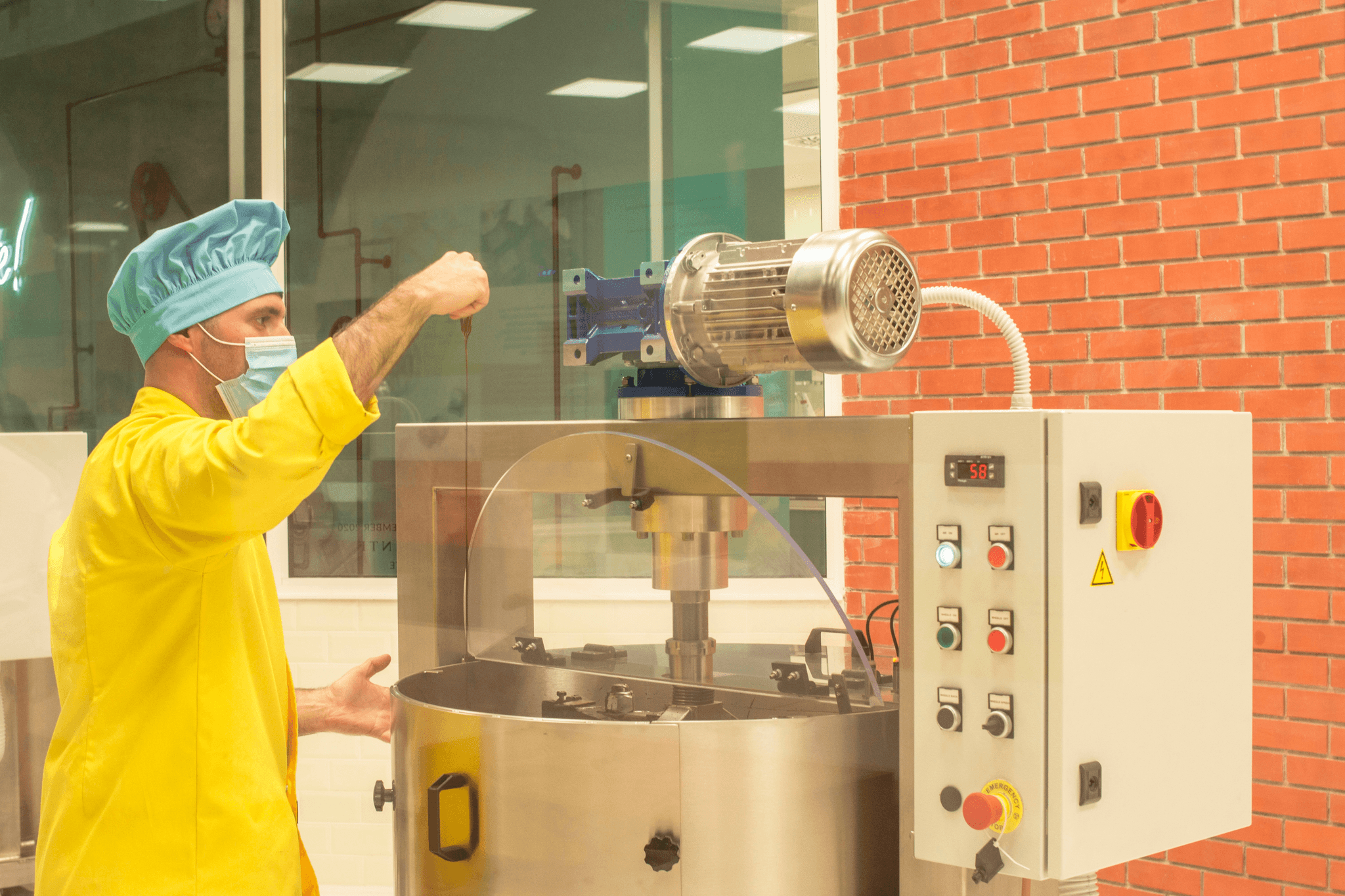

Third-party services encompass a wide range of offerings aimed at enhancing product integrity through systematic inspections and evaluations. From pre-production assessments to final product checks before shipment, these services provide crucial insights into product performance and compliance with safety standards. Engaging reputable quality control companies ensures that manufacturers can focus on production while experts handle the complexities of quality inspection.

What is Third-Party Inspection?

When we talk about third-party inspection, we’re diving into a realm of quality assurance that ensures products meet specific standards before they reach consumers. This process involves an independent entity evaluating the quality control of goods and services, providing an unbiased assessment. Third-party quality inspection services play a crucial role in maintaining product integrity and compliance with industry regulations.

Definition and Process

Third-party inspection refers to the evaluation conducted by an external organization that specializes in quality control and assurance. The process typically involves assessing various aspects of production, from raw materials to finished products, ensuring they adhere to predefined standards. This systematic approach not only identifies defects but also helps companies implement corrective measures, ultimately enhancing their overall quality control efforts.

The steps generally include planning the inspection criteria, executing the assessment on-site or remotely, and delivering a comprehensive report detailing findings and recommendations. By employing third-party quality inspection services, businesses can ensure their products are consistently meeting customer expectations while minimizing risks associated with poor-quality outputs.

Key Players in the Industry

The landscape of third-party inspection is populated by various key players who specialize in different sectors and types of inspections. These include independent testing laboratories, certification bodies, and specialized consultancy firms that focus on specific industries such as manufacturing, food safety, or construction. Quality control companies often partner with these entities to enhance their service offerings and provide clients with robust solutions for quality assurance.

These organizations are pivotal in establishing benchmarks for compliance and safety across diverse sectors. They bring expertise not only in conducting inspections but also in understanding regulatory requirements that businesses must adhere to within their respective markets.

Who Needs These Services?

A wide range of industries requires third-party inspection services to ensure product integrity and compliance with regulations. Manufacturers looking to enhance their credibility often seek these services to validate their production processes against industry standards. Retailers also benefit from independent evaluations as they strive for consistent product quality across multiple suppliers.

Moreover, companies entering new markets or launching new products may find it essential to engage third-party inspectors to navigate complex regulatory landscapes effectively. In essence, anyone involved in the supply chain—from producers to end-users—can gain significant advantages from implementing robust quality control practices through third-party inspections.

The Role of Quality Assurance

Quality assurance plays a pivotal role in the framework of third-party quality inspection services, ensuring that products meet established standards before reaching consumers. It's about creating a systematic approach to prevent defects and enhance product quality through planned and systematic activities. By integrating quality assurance into the production process, companies can significantly improve their overall operational efficiency.

Quality Assurance Principles

At the heart of quality assurance are several fundamental principles that guide organizations in maintaining high standards. These principles include customer focus, leadership commitment, engagement of people, process approach, improvement, evidence-based decision making, and relationship management. Embracing these principles helps companies establish robust quality control and assurance systems that not only meet but exceed customer expectations.

Moreover, these principles foster an environment where continuous improvement is encouraged. By regularly assessing processes and outcomes through third party quality inspection services, businesses can identify areas for enhancement. This commitment to ongoing development leads to better product consistency and reliability—key factors for any successful brand.

Quality Control and Assurance Explained

Quality control is often confused with quality assurance; however, they serve different purposes in the realm of product management. While quality control focuses on identifying defects in finished products through rigorous testing and inspection processes, quality assurance emphasizes preventing those defects from occurring in the first place through well-defined procedures and standards. Together—quality control and assurance—create a comprehensive approach to maintaining product integrity.

Third-party inspection plays a crucial role in this ecosystem by providing independent verification of both processes and products. These inspections ensure compliance with industry standards while also offering insights into potential improvements within supply chains or manufacturing practices. By leveraging third party quality inspection services alongside internal efforts, companies can create a seamless flow from production to market.

Impact on Product Success

The impact of effective quality assurance on product success cannot be overstated; it directly influences customer satisfaction and brand loyalty. When consumers are confident that they are purchasing high-quality products backed by rigorous testing protocols—including third-party inspections—they are more likely to become repeat customers or even brand advocates. This trust translates into increased sales and market share over time.

Additionally, strong quality control measures help mitigate risks associated with recalls or defective products entering the market—issues that can be costly both financially and reputationally for any business involved in manufacturing or distribution. By prioritizing comprehensive strategies around quality assurance alongside reliable third party quality inspection services, companies position themselves for long-term success while fostering positive relationships with suppliers.

Advantages of Third-Party Quality Inspection Services

In today's competitive market, third-party quality inspection services have become a cornerstone for businesses aiming to maintain high standards. These services not only enhance product quality but also play a vital role in mitigating risks and costs associated with production failures. By leveraging quality assurance practices, companies can ensure their products meet stringent criteria, ultimately leading to improved market confidence.

Enhanced Product Quality

One of the most significant advantages of third-party quality inspection services is the enhancement of product quality. These services provide an independent assessment that ensures products adhere to defined specifications and regulations, thus eliminating potential defects before they reach consumers. With rigorous quality control measures in place, businesses can enjoy peace of mind knowing their products are reliable and safe.

Moreover, consistent quality inspections foster a culture of excellence within organizations by promoting adherence to best practices in quality control and assurance. When manufacturers prioritize third-party inspections, they signal their commitment to delivering superior products, which can lead to increased customer satisfaction and loyalty. Ultimately, enhanced product quality through these inspections translates into better brand reputation and market positioning.

Mitigated Risks and Costs

Another compelling benefit of utilizing third-party inspection services is the mitigation of risks and costs associated with poor-quality products. By identifying defects early in the production process through effective quality control measures, companies can avoid costly recalls or rework expenses later on. This proactive approach not only saves money but also minimizes disruptions in supply chain operations.

Additionally, engaging reputable quality control companies helps businesses navigate complex regulatory requirements that could otherwise result in penalties or legal issues if neglected. The expertise offered by these companies ensures compliance with industry standards while reducing liability risks associated with subpar products entering the market. Consequently, organizations can allocate resources more efficiently while safeguarding their bottom line.

Improved Market Confidence

Third-party quality inspection services significantly contribute to improved market confidence among consumers and stakeholders alike. When customers know that rigorous inspections have been conducted on a product before it reaches them, their trust in the brand increases dramatically; after all, no one wants to gamble on faulty goods! This trust translates into higher sales volumes as satisfied customers become repeat buyers who advocate for your brand.

Furthermore, demonstrating a commitment to quality through independent verification enhances relationships with suppliers as well as retailers who prefer working with brands known for maintaining high-quality standards via effective quality control processes. By establishing credibility through regular inspections and transparent communication about your commitment to quality assurance practices, you position your business as a leader in your industry—one that prioritizes excellence above all else.

Key Benefits of Third-Party Inspection

When it comes to ensuring product quality and maintaining industry standards, third-party inspection services play a pivotal role. These services not only provide an extra layer of scrutiny but also foster trust among stakeholders. Let's delve into some of the key benefits that highlight the importance of independent quality assurance in today's competitive market.

Independent Verification of Quality

One of the standout advantages of third-party quality inspection services is their ability to provide independent verification of quality. This means that products are assessed by unbiased professionals who adhere to stringent quality control measures, ensuring that goods meet specified standards before reaching consumers. With this level of oversight, companies can confidently assure their clients that they are receiving high-quality products, which ultimately enhances brand reputation.

Furthermore, independent verification acts as a safeguard against potential fraud or misrepresentation by suppliers. By relying on established quality control companies for inspections, businesses can mitigate risks associated with poor-quality goods entering the market. This not only protects consumer interests but also supports overall industry integrity through consistent adherence to quality assurance protocols.

Consistency Across Suppliers

In a globalized marketplace where businesses often source materials from multiple suppliers, consistency becomes paramount. Third-party inspection services help maintain uniformity in product quality across diverse suppliers by implementing standardized evaluation processes. This ensures that regardless of where a product is sourced from, it meets the same high standards set forth by the company.

Moreover, consistent quality control and assurance practices lead to streamlined operations and reduced variability in production outcomes. When all suppliers adhere to similar inspection criteria, it simplifies logistics and helps avoid costly discrepancies in product batches. As a result, organizations can enhance their operational efficiency while building stronger relationships with reliable suppliers who value consistency.

Strengthening Supplier Relationships

Engaging third-party inspection services not only benefits businesses but also strengthens relationships with suppliers in meaningful ways. By involving an impartial entity in the quality control process, companies demonstrate their commitment to maintaining high standards for both their products and partnerships. This fosters mutual respect between manufacturers and suppliers as they work collaboratively towards shared goals.

Additionally, when suppliers know they will be subject to regular inspections from reputable third-party organizations, they are incentivized to uphold rigorous quality standards themselves. This proactive approach encourages open communication about expectations surrounding product specifications and timelines—ultimately leading to improved collaboration and trust between parties involved in the supply chain.

Choosing the Right Quality Control Companies

Selecting the right quality control companies is crucial for ensuring that your products meet industry standards and customer expectations. The landscape of third-party quality inspection services can be overwhelming, with numerous options available. Therefore, it’s essential to have a clear understanding of what to look for when evaluating potential partners in quality assurance.

Criteria for Selection

When choosing a provider of third-party quality inspection services, several criteria should guide your decision-making process. First and foremost, consider their reputation in the industry; feedback from previous clients can provide valuable insights into their reliability and effectiveness in quality control. Additionally, assess their range of services—do they offer comprehensive solutions that encompass both quality assurance and quality control?

Another critical factor is the provider's certification and accreditation status. Valid certifications ensure that the company adheres to recognized standards in quality inspection, which is essential for maintaining product integrity across various markets. Finally, consider geographical coverage—selecting a company with local expertise can enhance communication and efficiency during inspections.

Evaluating Capability and Experience

Once you have established selection criteria, it's time to evaluate potential candidates based on their capability and experience in the field of quality control and assurance. Start by reviewing case studies or client testimonials that illustrate their past performance with similar products or industries. This will help you gauge whether they possess the necessary skills to meet your specific needs.

Moreover, inquire about their team’s qualifications—do they employ certified inspectors who are well-versed in industry regulations? A knowledgeable team can make all the difference when it comes to conducting thorough inspections and providing actionable insights on product quality. Lastly, consider how long they've been in business; experience often correlates with reliability.

Spotlight on China Inspection Pro

One standout option among quality control companies is China Inspection Pro—a leader in third-party inspection services known for its commitment to excellence in quality assurance. With years of experience operating within diverse industries, they specialize in providing comprehensive solutions tailored to meet individual client needs while ensuring high standards are maintained throughout every step of production.

China Inspection Pro boasts a robust network of certified inspectors who are not only trained but also familiar with local compliance regulations—making them an invaluable partner for businesses looking to navigate complex supply chains effectively. Their focus on transparency ensures clients receive detailed reports post-inspection, allowing companies to make informed decisions related to product development or supplier relationships.

In summary, selecting the right partner for your third-party quality inspection services involves careful consideration of criteria such as reputation, capability, experience, and specialization within your industry niche—especially when it comes to critical aspects like quality control and assurance.

Conclusion

In the ever-evolving landscape of manufacturing and production, the importance of third-party quality inspection services cannot be overstated. These services serve as a crucial line of defense against potential defects and inconsistencies, ensuring that products meet rigorous quality standards before reaching consumers. By integrating quality control and assurance into their processes, businesses can significantly enhance their reputation and operational efficiency.

Summary of Third-Party Inspection Benefits

Third-party inspection provides a multitude of benefits that extend beyond mere compliance with regulations. First, independent verification through quality inspection helps to elevate product quality by identifying issues early in the production process. Additionally, these services mitigate risks and costs associated with product recalls or customer dissatisfaction, ultimately fostering trust between manufacturers and consumers.

Furthermore, using third-party quality inspection services reinforces the commitment to quality assurance within an organization. This not only leads to better products but also cultivates stronger relationships with suppliers who are held accountable for their output. In a competitive marketplace, these advantages translate into improved market confidence and increased sales potential.

Elevating Standards in Quality Control

The role of third-party inspection in elevating standards in quality control cannot be underestimated. By adhering to established principles of quality assurance, companies can ensure that their products consistently meet or exceed industry benchmarks. This commitment to high-quality standards not only enhances brand reputation but also encourages a culture of excellence throughout the supply chain.

Moreover, as businesses increasingly operate on a global scale, maintaining consistent quality across diverse suppliers becomes paramount. Third-party inspections provide an effective solution by standardizing evaluation processes across different locations and manufacturers. As such, organizations can confidently navigate international markets while upholding rigorous quality control measures.

Making Informed Decisions with Quality Assurance

Incorporating third-party inspection services into business operations empowers companies to make informed decisions regarding their production processes. With comprehensive data on product performance from independent assessments, organizations can pinpoint areas for improvement while reinforcing successful practices in quality control and assurance. This strategic approach leads to better resource allocation and optimized operations overall.

Additionally, when selecting reliable quality control companies for partnerships or collaborations, businesses must consider factors such as experience and capability in delivering robust inspections tailored to specific needs. With informed decision-making rooted in thorough evaluations from reputable third-party providers, companies can confidently pursue growth opportunities without compromising on product integrity.