Introduction

In today’s fast-paced world, the significance of food quality checking cannot be overstated. Consumers are more discerning than ever, demanding not only delicious food but also products that meet stringent safety and quality standards. This growing awareness means that businesses must prioritize effective quality inspection services to ensure their offerings meet both regulatory requirements and consumer expectations.

Understanding the Importance of Food Quality

Food quality is integral to public health and consumer trust; it directly influences purchasing decisions and brand loyalty. High-quality food products reduce the risk of contamination and promote overall well-being, making rigorous quality inspection services essential for manufacturers. Moreover, establishing robust food quality standards can help businesses avoid costly recalls and legal issues associated with subpar products.

Key Elements of Effective Quality Inspection

The most common form of quality control includes systematic checks at various production stages, ensuring compliance with established standards. Key elements such as thorough documentation, employee training in garment checking methods, and real-time monitoring play a crucial role in maintaining high food quality. By integrating these components into their operations, companies can enhance their reputation while safeguarding consumers' health.

How to Implement Quality Control Methods

Implementing effective quality control methods requires a strategic approach tailored to specific business needs. Companies should consider utilizing modern technologies alongside traditional practices like garment checking methods to streamline their processes and improve accuracy in inspections. Additionally, understanding where to find children's product certificates can further enhance compliance with safety regulations, ensuring that all products meet necessary criteria before reaching consumers.

Defining Food Quality Standards

Defining food quality standards is crucial for ensuring that products meet both regulatory requirements and consumer expectations. These standards serve as a benchmark for food quality checking, guiding companies in their quality inspection services. By establishing clear criteria, businesses can maintain consistency and enhance their reputation in the market.

The Role of Regulatory Bodies

Regulatory bodies play a pivotal role in defining food quality standards that protect public health and ensure safety. They establish guidelines that dictate everything from ingredient sourcing to final product testing, making them an essential part of any food production process. Understanding these regulations helps companies align their own quality inspection services with industry norms, ensuring compliance and consumer trust.

Establishing Company-Specific Criteria

While regulatory standards provide a foundation, establishing company-specific criteria is equally important for effective food quality checking. These tailored guidelines should reflect the unique values and goals of the organization while also considering market demands and customer preferences. By integrating garment checking methods into these criteria, companies can enhance their overall production processes and maintain high-quality outputs.

Aligning with Market Expectations

Aligning food quality standards with market expectations is vital for maintaining competitiveness in a crowded marketplace. Customers today are more discerning than ever; they demand transparency and high-quality products that adhere to both safety regulations and ethical practices. To meet these expectations, businesses must continually adapt their quality inspection services to incorporate emerging trends while ensuring they remain compliant with established food safety protocols.

Training Staff on Quality Inspection

Training staff on quality inspection is a critical component of ensuring food safety and maintaining high standards in food quality checking. Employees are the frontline defenders against subpar products and potential hazards, making their education paramount. A well-trained workforce not only enhances the effectiveness of quality inspection services but also fosters a sense of responsibility towards maintaining company standards.

Importance of Employee Education

Employee education in quality inspection is vital for several reasons. First, knowledgeable staff can identify issues early in the production process, which is essential for effective food quality checking. Moreover, when employees understand the significance of their roles in maintaining quality standards, they become more engaged and motivated to uphold those standards consistently.

In addition to enhancing product safety, investing in employee education can lead to reduced waste and improved efficiency. The most common form of quality control includes systematic training that equips employees with the skills necessary for identifying defects or inconsistencies during production. This proactive approach not only minimizes risks but also boosts overall productivity within the organization.

Techniques for Effective Training

Implementing effective training techniques is crucial to ensure that employees grasp the concepts of food quality checking thoroughly. Hands-on training sessions are particularly beneficial; they allow staff to practice garment checking methods and familiarize themselves with real-world scenarios they might encounter on the job. Furthermore, using visual aids and interactive tools can enhance understanding and retention among team members.

Regular workshops or refresher courses should be part of an ongoing training program to keep staff updated on industry standards and best practices related to food safety and PCB quality control. Role-playing scenarios can also be an engaging way for employees to learn how to respond effectively when faced with potential quality issues during inspections. By diversifying training methods, companies can cater to different learning styles while reinforcing critical information.

Creating a Quality-Conscious Culture

Creating a culture that prioritizes quality across all levels of an organization is essential for long-term success in food production environments. When leadership emphasizes the importance of food quality checking through clear communication and recognition programs, it instills a shared sense of accountability among employees. This collective commitment fosters an environment where everyone actively participates in maintaining high-quality standards.

To further embed this culture into daily operations, organizations should encourage open dialogue about quality issues without fear of repercussions—after all, addressing problems head-on leads to continuous improvement practices that benefit everyone involved. Regularly sharing success stories related to effective inspections reinforces positive behaviors while illustrating how individual contributions impact overall product safety and consumer trust.

Ultimately, investing time into employee education, employing diverse training techniques, and cultivating a culture centered around excellence will yield significant dividends in terms of product integrity—and that's something every company should strive for!

Utilizing Quality Inspection Services

In the intricate world of food production, quality inspection services play a pivotal role in ensuring that products meet established standards. These professional checks not only help maintain food quality but also safeguard consumer health and brand reputation. By leveraging expert services, businesses can streamline their processes and focus on what they do best—creating delicious and safe food.

Benefits of Professional Quality Checks

When it comes to food quality checking, the benefits of employing professional quality inspection services are manifold. First off, these experts bring a wealth of experience and knowledge, ensuring that all aspects of food safety are meticulously addressed. Additionally, utilizing such services can significantly reduce the likelihood of costly recalls or compliance issues down the line—after all, prevention is better than cure!

Moreover, professional inspectors often employ advanced garment checking methods and technologies that may not be available in-house. This means businesses can benefit from cutting-edge practices without the burden of investment in new equipment or training programs. Ultimately, investing in quality inspection services translates into peace of mind for producers and consumers alike.

Overview of China Inspection Pro

China Inspection Pro is a leading provider specializing in comprehensive quality inspection services tailored for various industries including food production. Their team comprises seasoned professionals adept at conducting thorough inspections to ensure compliance with international standards and regulations. With a strong focus on food quality checking, they utilize state-of-the-art techniques to identify potential issues before products reach consumers.

One standout feature of China Inspection Pro is their commitment to transparency throughout the inspection process. Clients receive detailed reports outlining findings along with actionable recommendations for improvement—this level of insight fosters trust between producers and stakeholders alike. Furthermore, they offer flexible service packages designed to meet specific needs, making them an ideal partner for businesses aiming to enhance their quality control measures.

Choosing the Right Inspection Partner

Selecting the right partner for your quality inspection needs can be as critical as choosing your ingredients! When evaluating potential partners like China Inspection Pro or others in the market, consider factors such as expertise in food safety regulations and familiarity with garment checking methods relevant to your industry. A solid track record is essential; look for testimonials or case studies that showcase their ability to deliver consistent results.

Another important aspect is communication—your chosen partner should be willing to engage openly about their processes and findings throughout your collaboration. This ensures you remain informed about any issues detected during inspections so you can address them promptly before they escalate into larger problems down the line! Lastly, always inquire about their approach to continuous improvement practices; after all, a proactive partner will help you stay ahead in maintaining high standards.

Implementing Garment Checking Methods

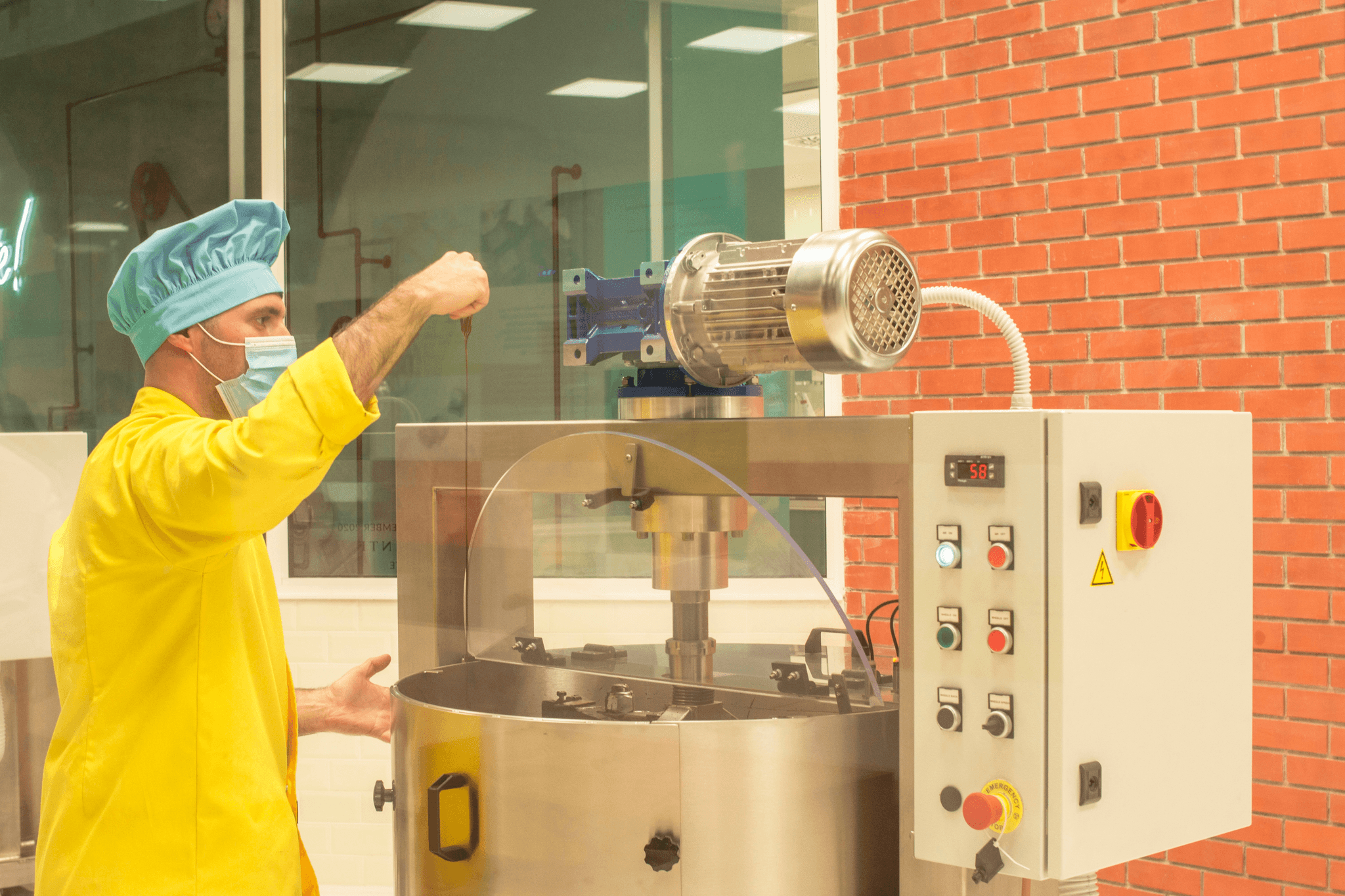

When it comes to food quality checking, the integration of garment checking methods may seem a bit unconventional at first glance. However, ensuring that staff wear clean and appropriate clothing during food production is crucial for maintaining hygiene standards. After all, a single loose thread can compromise not just the aesthetic appeal of a dish but also its safety and quality.

Relevance to Food Safety

The relevance of garment checking methods to food safety cannot be overstated. Proper attire helps mitigate risks associated with contamination, which is paramount in any food production environment. By enforcing strict garment inspection protocols, businesses can significantly reduce the likelihood of introducing harmful pathogens into their products.

Moreover, understanding that employees are often the most significant factor in maintaining food quality is key. If workers are dressed appropriately—think hairnets and gloves—they contribute positively to overall hygiene practices. This is where effective quality inspection services come into play; they help ensure that garment standards are met consistently throughout the production process.

Popular Garment Checking Techniques

Some of the most common forms of quality control include visual inspections and adherence checks for employee uniforms in food production settings. Visual inspections can identify issues such as worn-out uniforms or improper gear that could lead to contamination risks. Additionally, implementing checklists for garment compliance helps keep everyone accountable for their role in maintaining high-quality standards.

Another popular technique involves using color-coded garments to signify different roles within the production process—this not only enhances safety but also streamlines operations by reducing confusion among team members regarding their responsibilities. Furthermore, regular training sessions on proper attire can reinforce these protocols and emphasize their importance in ensuring top-notch food quality checking.

Integrating Methods into Food Production

Integrating garment checking methods into existing food production processes requires a strategic approach that balances efficiency with thoroughness. Start by incorporating routine inspections as part of your daily operations; this ensures that employees understand the significance of wearing appropriate clothing at all times while working with food products.

Additionally, leveraging technology can enhance your monitoring efforts—consider using RFID tags on uniforms to track compliance easily across various shifts and departments within your facility. Finally, fostering an environment where staff feel empowered to speak up about non-compliance or potential hygiene issues will create a culture committed to excellence in both garment standards and overall product safety.

Monitoring Food Quality Throughout Production

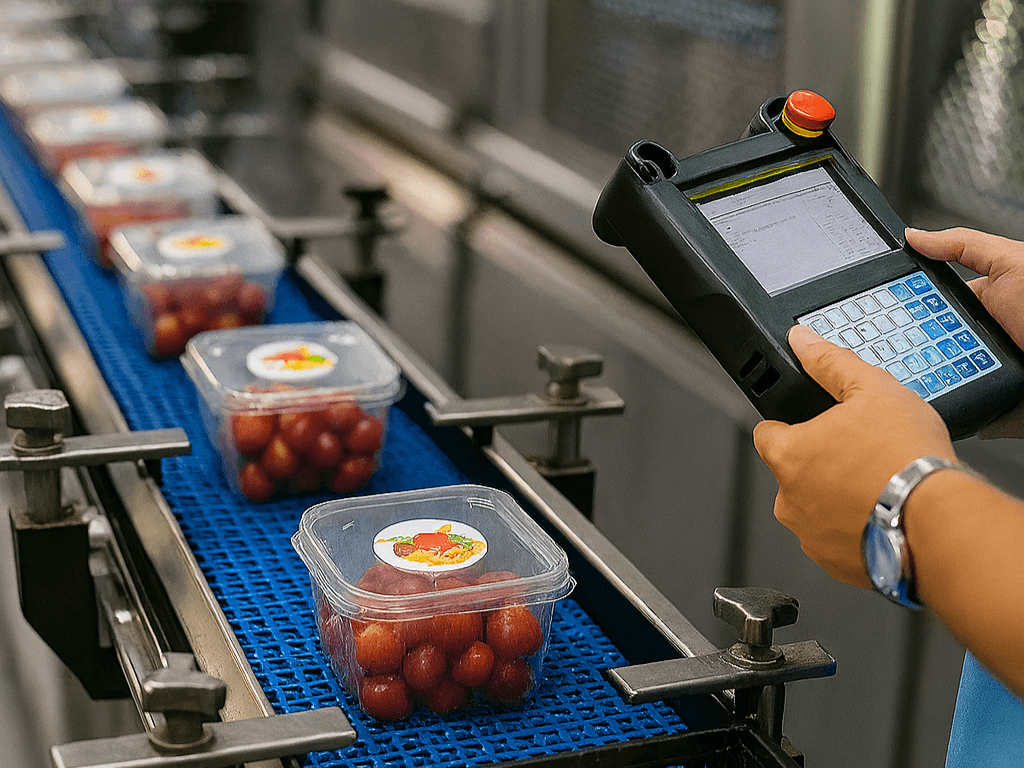

Monitoring food quality throughout production is crucial for ensuring that products meet safety and quality standards. This process involves continuous oversight at various stages of production, allowing for timely interventions when issues arise. By implementing effective monitoring practices, companies can enhance their food quality checking efforts and maintain consumer trust.

Key Stages for Quality Monitoring

The most common form of quality control includes several key stages, each critical to maintaining high standards. These stages often encompass raw material inspection, in-process checks during production, and final product evaluations before distribution. Each stage presents unique challenges and opportunities for implementing quality inspection services to ensure that only the best products reach consumers.

Initial monitoring begins with the sourcing of ingredients, where suppliers must meet established food quality standards. Following this, in-process checks allow teams to identify deviations from these standards early on, minimizing waste and ensuring compliance with safety regulations. Finally, a thorough evaluation of finished products is essential; this step often requires garment checking methods adapted for food items to assess packaging integrity and labeling accuracy.

Tools and Technologies for Real-Time Checking

Advancements in technology have revolutionized how food quality checking is conducted throughout production processes. Tools such as sensors, automated inspection systems, and data analytics software provide real-time insights into product quality at every stage of manufacturing. Utilizing these technologies not only streamlines operations but also enhances the effectiveness of traditional quality inspection services.

For instance, integrating PCB quality control techniques can significantly improve the reliability of electronic components used in food processing machinery. Moreover, mobile applications designed for on-the-go inspections allow staff to document findings instantly while accessing historical data to inform their decisions better. The use of these tools fosters a proactive approach toward identifying potential issues before they escalate into larger problems.

Adapting to Changes in Production

In an ever-evolving market landscape, adapting monitoring practices is essential for maintaining high-quality standards in food production. As consumer preferences shift or new regulations emerge—such as where to find children's product certificates—companies must be agile enough to adjust their processes accordingly without compromising product integrity. This flexibility ensures that organizations remain compliant while meeting customer expectations.

Furthermore, seasonal variations or changes in supply chain dynamics may necessitate adjustments in monitoring protocols or frequency of inspections. Embracing a culture that prioritizes continuous improvement will empower staff members to respond effectively when challenges arise during production runs. By remaining vigilant and adaptable through robust monitoring systems, businesses can uphold their commitment to exceptional food quality checking while fostering long-term success.

Conducting Regular Quality Audits

Regular quality audits are the backbone of a robust food quality checking system. They ensure that all processes align with established standards and help identify any deviations before they escalate into larger issues. By incorporating routine inspections, companies can maintain high-quality products that meet consumer expectations and adhere to regulatory requirements.

Importance of Routine Inspections

Routine inspections serve as a proactive measure in food quality checking, allowing businesses to catch potential problems early on. The most common form of quality control includes these scheduled audits, which can lead to significant improvements in product safety and consistency. Regular checks not only enhance operational efficiency but also build trust with consumers who expect safe and high-quality food products.

Developing an Audit Checklist

Creating an effective audit checklist is crucial for conducting thorough quality inspections. This checklist should encompass key areas such as compliance with health regulations, adherence to company-specific criteria, and the implementation of garment checking methods where applicable. A well-structured checklist helps streamline the audit process, ensuring that nothing slips through the cracks during evaluations.

Analyzing Audit Findings for Improvement

After conducting audits, analyzing the findings is essential for continuous improvement in food quality checking practices. Identifying trends or recurring issues can inform necessary adjustments in production or training methods, ultimately enhancing overall product quality. Moreover, sharing these insights with relevant stakeholders fosters transparency and encourages a culture of accountability within the organization.

Responding to Quality Issues

In the world of food production, responding to quality issues swiftly and effectively is crucial for maintaining standards and consumer trust. When problems arise during food quality checking, having a robust strategy in place can mitigate risks and prevent future occurrences. This section delves into effective problem resolution strategies, communication with stakeholders, and practices for continuous improvement.

Strategies for Effective Problem Resolution

The most common form of quality control includes identifying the root cause of a problem before jumping to conclusions or solutions. Utilizing techniques from garment checking methods can be particularly beneficial; for instance, visual inspections can help pinpoint defects that might have slipped through standard checks. Once the issue is identified, it’s vital to implement corrective actions promptly while documenting each step for future reference.

Moreover, engaging your team in brainstorming sessions can foster innovative solutions that may not have been considered initially. Make sure to involve staff who are directly impacted by the quality issues; their insights could lead to more practical resolutions. Remember that effective problem resolution isn't just about fixing what's broken—it's about learning from these experiences to enhance overall processes.

Communicating Findings to Stakeholders

Transparency is key when communicating findings related to food quality checking issues with stakeholders such as suppliers, management, and customers. Clear communication helps build trust and ensures everyone is on the same page regarding any necessary actions or adjustments needed in response to identified problems. Utilize reports that summarize findings succinctly while highlighting both the issue at hand and proposed solutions.

Incorporating visuals such as charts or graphs can make complex data easier to digest for stakeholders who may not be familiar with technical jargon related to quality inspection services or specific metrics like PCB quality control outcomes. Regular updates are essential; keeping everyone informed of progress reassures them that you’re committed to resolving any concerns swiftly and effectively.

Continuous Improvement Practices

Adopting a mindset focused on continuous improvement practices is essential in maintaining high standards in food production environments. This involves regularly revisiting your procedures related to food quality checking and evaluating their effectiveness against industry benchmarks and market expectations. By integrating lessons learned from past incidents into training programs or operational protocols, you create a culture of proactive problem-solving rather than reactive fixes.

Additionally, leveraging technology plays a significant role in enhancing your practices—real-time monitoring tools can provide invaluable insights into production processes before issues escalate into larger problems. Don’t forget about feedback loops; encourage employees at all levels to share their observations regarding potential improvements based on their day-to-day experiences with garment checking methods or other relevant practices within your operations.

Conclusion

In summary, food quality checking is a multifaceted process that encompasses various stages, from defining standards to implementing effective inspection methods. Key aspects include training staff, utilizing quality inspection services, and conducting regular audits to ensure compliance with both regulatory and market expectations. By integrating garment checking methods into food production practices, companies can enhance their overall quality control efforts.

Recap of Food Quality Checking Steps

To recap the essential steps in food quality checking: first, establish clear quality standards based on regulatory guidelines and company-specific criteria. Next, train employees effectively to recognize these standards and utilize appropriate techniques for inspection. Finally, implement ongoing monitoring through regular audits and professional quality checks to address any issues that arise promptly.

The Impact of Quality on Consumer Trust

The impact of consistent food quality checking on consumer trust cannot be overstated; when customers know they can rely on the safety and quality of their food products, they are more likely to remain loyal to a brand. Quality inspection services play a pivotal role in building this trust by ensuring that products meet established criteria before reaching consumers' hands. Furthermore, transparency in the production process fosters confidence among consumers who are increasingly aware of where their food comes from.

Future Trends in Quality Control Practices

Looking ahead, future trends in quality control practices will likely focus on technological advancements such as real-time monitoring systems and PCB quality control methods that enhance efficiency and accuracy in inspections. Additionally, the integration of data analytics will help organizations predict potential issues before they arise by analyzing patterns in production processes. As consumer demands evolve—especially regarding safety certifications like where to find children's product certificates—companies must adapt their strategies for effective food quality checking to stay competitive.