Introduction

In today’s fast-paced food industry, food quality control has emerged as a critical component in ensuring that consumers receive safe and high-quality products. With rising consumer awareness and regulatory scrutiny, the importance of meticulous food quality checking cannot be overstated. Quality controllers play an essential role in this process, implementing rigorous standards to uphold the integrity of food testing and production.

Importance of Food Quality Control

Food quality control is not just a regulatory requirement; it is a commitment to consumer safety and satisfaction. By establishing robust systems for food quality assurance, businesses can prevent costly recalls and maintain their reputation in the marketplace. Furthermore, effective food quality checking practices help mitigate risks associated with contamination and spoilage, ultimately safeguarding public health.

Overview of Key Quality Control Roles

Within the realm of food quality assurance, various roles contribute to maintaining high standards—each with its unique responsibilities. The quality assurance manager oversees the entire process, ensuring that all protocols are followed diligently while coordinating between different teams. Meanwhile, quality assurance inspectors conduct thorough evaluations during production to ensure compliance with established good manufacturing practices in the food industry.

Significance of Good Manufacturing Practices

Good manufacturing practices are foundational to successful food quality control initiatives; they provide a framework for producing safe and consistent products. By adhering to these guidelines, companies can streamline their processes while minimizing errors that could compromise product integrity during production or distribution. Ultimately, implementing good manufacturing practices not only enhances operational efficiency but also fosters consumer trust through transparent adherence to safety standards.

Understanding Food Quality Assurance

Food quality assurance is a critical component in the food industry, ensuring that products meet established safety and quality standards. It encompasses various practices, roles, and principles that contribute to maintaining high-quality food throughout its lifecycle. By understanding the nuances of food quality control, stakeholders can better safeguard public health and enhance consumer trust.

Defining Food Quality Control

Food quality control refers to the systematic processes implemented to monitor and maintain the safety, consistency, and quality of food products. This involves rigorous food testing procedures that assess everything from raw ingredients to finished goods. The ultimate goal is to ensure compliance with regulatory standards while also meeting consumer expectations for taste, texture, and nutritional value.

Roles of Quality Controllers in Food Testing

Quality controllers play an essential role in the realm of food testing by overseeing the entire production process. Their responsibilities include conducting regular inspections, performing laboratory analyses, and implementing corrective actions when necessary. These professionals act as gatekeepers of food quality control, ensuring that each product adheres to established good manufacturing practices in the food industry.

Principles of Food Quality Assurance

The principles of food quality assurance are built on a foundation of consistency, reliability, and transparency within production processes. Key elements include adherence to good manufacturing practices (GMP), comprehensive training for quality assurance managers and inspectors, and continuous monitoring through effective audits. By embedding these principles into daily operations, companies can foster a culture committed to excellence in food quality assurance.

Best Practices for Quality Control

In the ever-evolving world of the food industry, best practices for quality control are paramount to ensure that products meet safety and quality standards. Implementing effective strategies not only helps in maintaining compliance but also enhances consumer trust in food quality assurance. By focusing on good manufacturing practices, robust techniques for food quality checking, and comprehensive training programs for quality assurance managers, businesses can elevate their operations to new heights.

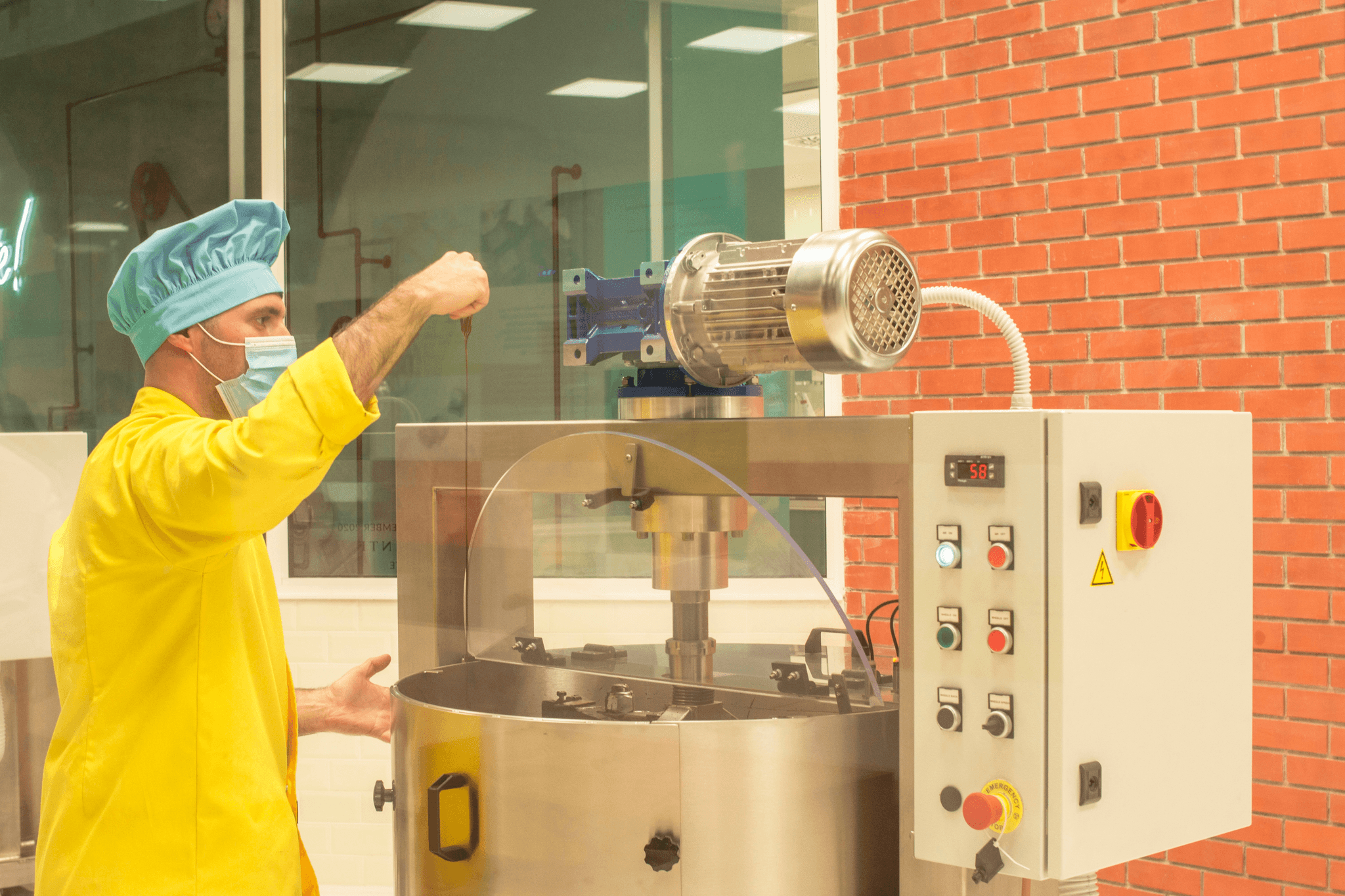

Implementing Good Manufacturing Practices

Good manufacturing practices (GMP) form the backbone of effective food quality control. They encompass a set of guidelines that help ensure products are consistently produced and controlled according to established standards, which is essential for any quality controller working in the food industry. By adhering to GMP, organizations minimize risks associated with food testing and production processes, ultimately leading to safer products for consumers.

A significant aspect of GMP involves maintaining a clean and hygienic environment throughout the production process. This includes regular sanitation of equipment and facilities as well as proper employee training on hygiene protocols—critical areas where a quality assurance inspector plays a vital role. Additionally, documenting all procedures helps maintain accountability and consistency within the organization’s operations.

Furthermore, implementing GMP encourages continuous improvement by fostering an environment where feedback is valued. Quality controllers can identify areas needing enhancement through regular audits and inspections, ensuring that any deviations from established practices are promptly addressed. Ultimately, establishing strong GMP is not just about compliance; it’s about building a culture focused on exceptional food quality assurance.

Techniques for Effective Food Quality Checking

When it comes to effective food quality checking, various techniques can be employed to guarantee that products meet both regulatory requirements and consumer expectations. One such technique involves sensory evaluation—utilizing trained panels or even consumers themselves to assess taste, appearance, aroma, and texture can provide invaluable insights into product acceptance. Coupled with rigorous laboratory testing methods like microbiological analysis or chemical residue checks, these techniques form a comprehensive approach to food testing.

Another essential technique is implementing statistical process control (SPC), which utilizes data analysis tools to monitor production processes in real-time actively. This method enables quality controllers to detect variations from established norms quickly and take corrective actions before issues escalate into larger problems—a key responsibility of any dedicated quality assurance manager or inspector overseeing operations.

Moreover, employing technology such as automated inspection systems can enhance accuracy during the checking process significantly; these systems can identify defects or inconsistencies at speeds far surpassing manual inspections. By integrating these advanced techniques into their workflows, businesses not only streamline their operations but also bolster their overall commitment to high standards in food quality assurance.

Training Programs for Quality Assurance Managers

Training programs tailored specifically for quality assurance managers are crucial in developing skilled professionals who understand the nuances of food safety regulations and best practices in the industry. These programs should cover essential topics such as good manufacturing practices (GMP), risk assessment methodologies related to food safety hazards, and effective communication strategies when collaborating with other team members like inspectors or controllers involved in daily operations.

Additionally, hands-on training sessions that incorporate real-life scenarios allow participants to apply theoretical knowledge practically—preparing them better for challenges they may face during routine inspections or audits aimed at ensuring compliance with strict regulations surrounding food testing procedures. Such immersive experiences foster critical thinking skills necessary when making informed decisions regarding product safety.

Lastly, ongoing education should be encouraged even after initial training programs have been completed; this could involve attending workshops or conferences focused on emerging trends in food safety technology or regulatory changes impacting the industry landscape as a whole—keeping managers well-informed ensures that organizations remain proactive rather than reactive concerning potential issues related to food quality control.

Tools for Effective Quality Control

In the realm of food quality control, having the right tools is paramount for ensuring safety and compliance. These tools range from essential equipment used in food testing to sophisticated software solutions that aid quality assurance managers in their tasks. Automation also plays a critical role, streamlining processes and enhancing efficiency in food quality assurance.

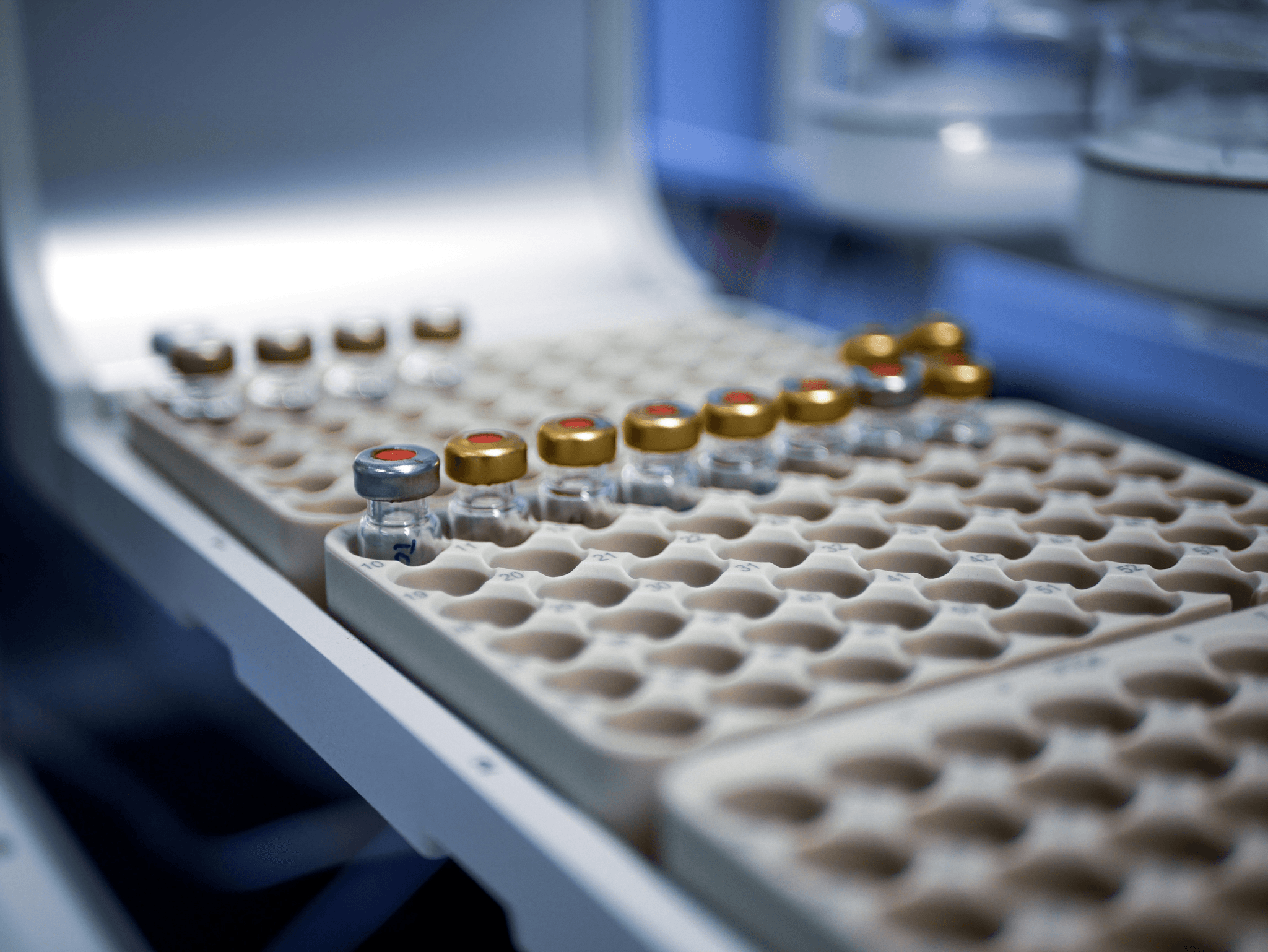

Essential Equipment for Food Testing

When it comes to food quality checking, the right equipment can make all the difference. Essential tools such as pH meters, moisture analyzers, and spectrophotometers are crucial for quality controllers who perform rigorous food testing. Each piece of equipment serves a specific purpose, helping ensure that products meet safety standards and regulatory requirements.

Additionally, temperature probes and microbiological testing kits are vital for monitoring conditions that could affect food quality. Quality assurance inspectors rely on these tools to conduct thorough evaluations and identify potential hazards in production processes. Investing in high-quality equipment not only aids in compliance but also fosters a culture of excellence within the organization.

Software Solutions for Quality Assurance

In today’s digital age, software solutions have become indispensable for effective food quality control management. These programs help quality assurance managers track compliance metrics, manage documentation, and analyze data trends related to food testing outcomes. With real-time reporting capabilities, software can streamline communication between teams and enhance decision-making processes.

Moreover, many platforms offer features like automated alerts for deviations from established good manufacturing practices in the food industry. This proactive approach enables quicker responses to potential issues before they escalate into significant problems. By integrating technology into their operations, organizations can significantly improve their overall efficiency in maintaining high-quality standards.

Automation in Food Quality Control Processes

Automation is revolutionizing how we approach food quality assurance by minimizing human error and increasing efficiency across various processes. Automated systems can perform repetitive tasks such as sampling or data entry at lightning speed while maintaining accuracy—something that manual methods often struggle with during busy production times. This not only enhances productivity but also allows quality controllers more time to focus on critical analysis rather than mundane tasks.

Furthermore, automation facilitates better tracking of compliance with good manufacturing practices in the food industry by providing detailed logs of every step taken during production and testing phases. Quality assurance inspectors benefit immensely from this level of transparency as it simplifies audits and inspections significantly. As technology continues to evolve, embracing automation will be key to staying ahead of industry standards while ensuring consumer trust through reliable food quality checking.

The Role of Quality Assurance Inspectors

Quality assurance inspectors play a pivotal role in the food quality control landscape, ensuring that products meet established standards before reaching consumers. These professionals are the gatekeepers of food safety and quality, meticulously overseeing various aspects of food testing and production processes. Their work not only safeguards public health but also enhances the reputation of food manufacturers by ensuring compliance with good manufacturing practices in the food industry.

Responsibilities of Quality Assurance Inspectors

The responsibilities of quality assurance inspectors are multifaceted, encompassing a range of tasks that ensure adherence to food quality assurance protocols. They conduct rigorous inspections during different stages of production, from raw material sourcing to final product packaging, focusing on critical elements like sanitation and process controls. Additionally, these inspectors serve as educators within their organizations, training staff on proper procedures for effective food quality checking and reinforcing the importance of maintaining high standards.

How Inspectors Ensure Compliance

Inspectors ensure compliance through systematic monitoring and evaluation processes that align with regulatory requirements and industry best practices. By performing regular audits and assessments, they identify any deviations from established protocols that could compromise food safety or quality. Their findings are crucial; they provide actionable insights that help quality controllers implement corrective measures swiftly to maintain compliance with good manufacturing practices in the food industry.

Collaborating with Quality Control Teams

Collaboration between quality assurance inspectors and quality control teams is essential for fostering a culture of excellence in food production environments. These professionals work hand-in-hand to share information regarding potential risks identified during inspections, enabling timely interventions to improve overall product integrity. By leveraging each other's expertise in food testing processes, they create a robust framework for continuous improvement in food quality control efforts.

Case Study: China Inspection Pro

In the realm of food quality control, China Inspection Pro stands out as a beacon of excellence. This company specializes in providing comprehensive services that ensure food products meet stringent safety and quality standards before they reach consumers. With a focus on food quality assurance, they employ skilled quality controllers and inspectors to carry out meticulous food testing.

Overview of China Inspection Pro's Services

China Inspection Pro offers a range of services tailored to the food industry, emphasizing good manufacturing practices in food industry settings. Their offerings include pre-production inspections, in-process checks, and final product evaluations, all designed to uphold high standards of food safety and quality. By leveraging advanced methodologies and technology, their quality assurance managers oversee rigorous protocols that guarantee compliance with international regulations.

Examples of Food Quality Control Successes

One notable success story involves a major client who faced challenges with product consistency across multiple batches. Through diligent food quality checking and targeted interventions by their quality assurance inspectors, China Inspection Pro identified critical points where improvements were needed. The result? A remarkable increase in product uniformity that significantly boosted consumer trust and satisfaction.

Another example highlights their role during an outbreak scare when swift action was required to ensure safety across the supply chain. By conducting thorough inspections and facilitating immediate corrective actions, they not only safeguarded public health but also helped restore confidence among stakeholders in the affected sectors.

Lessons Learned from Professional Quality Inspections

The experiences gleaned from working with various clients have taught valuable lessons about the importance of proactive quality control measures. Regular training programs for quality assurance managers are essential for staying ahead of evolving industry standards and consumer expectations regarding food safety. Moreover, collaboration between quality controllers and inspectors fosters an environment where continuous improvement is prioritized—ultimately leading to enhanced operational efficiency in food testing processes.

In conclusion, insights from China Inspection Pro underscore that effective food quality assurance is not just about compliance; it's about building a culture that values excellence at every level of production.

Conclusion

In the ever-evolving landscape of food production, the importance of robust food quality control cannot be overstated. As we look to the future, it is clear that advancements in technology and heightened consumer awareness will shape the practices surrounding food quality assurance. Emphasizing good manufacturing practices in the food industry will ensure that safety and quality remain paramount.

Future Trends in Food Quality Control

The future of food quality checking is set to embrace automation and artificial intelligence, which promise enhanced precision in food testing. Quality controllers will increasingly rely on sophisticated software solutions that streamline processes and improve accuracy in detecting potential issues before they escalate. Additionally, sustainability will play a crucial role as consumers demand transparency about sourcing and production methods, pushing companies to adopt environmentally-friendly practices.

Building a Culture of Quality Assurance

Creating a culture of quality assurance within organizations starts with strong leadership and commitment from all levels of staff. Quality assurance managers must foster an environment where every employee understands their role in maintaining high standards of food quality control. By prioritizing continuous training and open communication, companies can empower their teams to take ownership of their responsibilities, ultimately leading to improved outcomes in food testing.

Enhancing Consumer Trust through Quality Standards

Consumer trust hinges on consistent adherence to established quality standards; this is where effective collaboration among quality assurance inspectors, controllers, and managers becomes vital. By implementing rigorous protocols for food quality assurance, businesses can demonstrate their commitment to safety and excellence in products offered to consumers. Ultimately, transparency about these processes not only enhances brand reputation but also cultivates lasting relationships with customers who prioritize safe eating experiences.