Introduction

In the world of manufacturing and production, the significance of inspection methods cannot be overstated. These techniques serve as the backbone of quality assurance, ensuring that products meet rigorous standards before they reach consumers. By exploring various types of inspection methods, we can better understand how quality and assurance work hand in hand to enhance overall product integrity.

Understanding Inspection Methods

Inspection methods are diverse and can be categorized into several types, each with its own unique set of advantages and limitations. From visual inspections to advanced non-destructive testing (NDT), these approaches play a crucial role in maintaining quality assurance throughout the production process. Recognizing the different types of inspection methods equips organizations with the knowledge needed to implement effective quality control measures.

Importance of Quality Assurance

Quality assurance is not just a buzzword; it’s a fundamental aspect of any successful business strategy. The relationship between quality and quality assurance is pivotal, as it directly influences customer satisfaction and brand reputation. By prioritizing quality assurance practices, companies can minimize defects, reduce waste, and ultimately save costs—key components for achieving Six Sigma levels of performance.

Overview of Inspection Techniques

The landscape of inspection techniques is vast and continually evolving with technological advancements. From traditional visual assessments to sophisticated automated systems, each method contributes uniquely to ensuring product reliability and safety. Training programs aimed at enhancing understanding and application of these techniques are essential for fostering a culture committed to excellence in both quality and assurance.

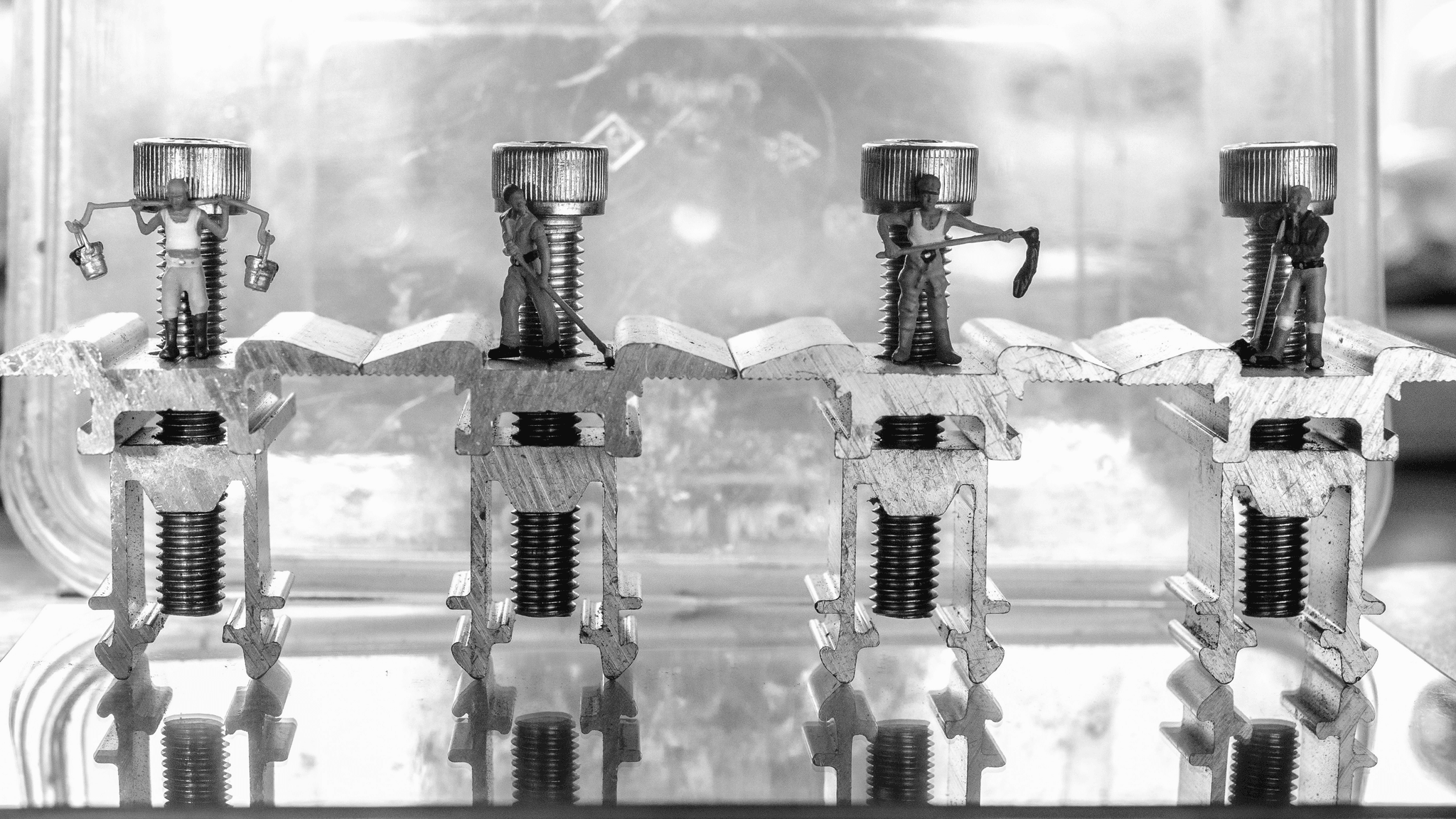

Visual Inspection Techniques

Visual inspection techniques are fundamental in the realm of quality assurance, serving as the first line of defense against defects and inconsistencies. This type of inspection method relies on the human eye or basic optical tools to assess products, ensuring that they meet predefined standards. The simplicity and accessibility of visual assessments make them an attractive option for many industries focused on maintaining high quality and assurance levels.

Benefits of Visual Assessment

One of the primary benefits of visual assessment is its cost-effectiveness; it requires minimal investment in equipment compared to more sophisticated types of inspection methods. Additionally, visual inspections can be performed quickly, allowing for immediate feedback on product quality and quality assurance processes. This rapid evaluation helps organizations implement corrective actions swiftly, enhancing overall quality and quality assurance within their operations.

Moreover, visual inspections can easily be integrated into existing workflows without extensive training programs or specialized skills. Employees can often be trained in basic visual assessment techniques within a short period, promoting a culture of vigilance regarding quality and assurance throughout the organization. By fostering this awareness among staff, companies can improve their Six Sigma initiatives by reducing defects at every stage of production.

Common Applications in Industries

Visual inspection techniques are prevalent across various industries, including manufacturing, construction, and food processing. In manufacturing settings, these assessments are used to check for surface defects such as scratches or dents that could compromise product integrity; this is vital for maintaining high standards in both quality and assurance practices. Similarly, in construction projects, visual inspections help ensure that materials meet regulatory requirements before installation.

In food processing industries, visual assessments play a crucial role in identifying contamination or spoilage before products reach consumers—ensuring safety while adhering to stringent health regulations. The versatility across different sectors showcases how essential these types of inspection methods are for consistent quality control efforts globally. Ultimately, effective use of visual inspections contributes significantly to maintaining high-quality standards across diverse applications.

Limitations and Considerations

While visual inspection techniques offer numerous advantages, they also come with limitations that should not be overlooked when discussing quality assurance strategies. One major drawback is subjectivity; different inspectors may interpret what constitutes an acceptable standard differently based on their experience or training programs they've undergone—leading to inconsistencies in evaluations over time. This variability can hinder efforts aimed at achieving uniformity in both quality and assurance processes.

Additionally, certain defects may not be visible to the naked eye; flaws occurring beneath surfaces or within materials often require more advanced types of inspection methods like non-destructive testing (NDT) for accurate detection and analysis. As a result, relying solely on visual assessments could lead organizations to overlook critical issues that impact overall product reliability—compromising long-term goals related to Six Sigma six initiatives aimed at minimizing defects.

Finally, environmental factors such as lighting conditions can also influence the effectiveness of visual inspections; poor visibility may result in missed defects during evaluations—which ultimately affects overall product integrity regarding both quality and assurance measures taken by businesses involved in production activities.

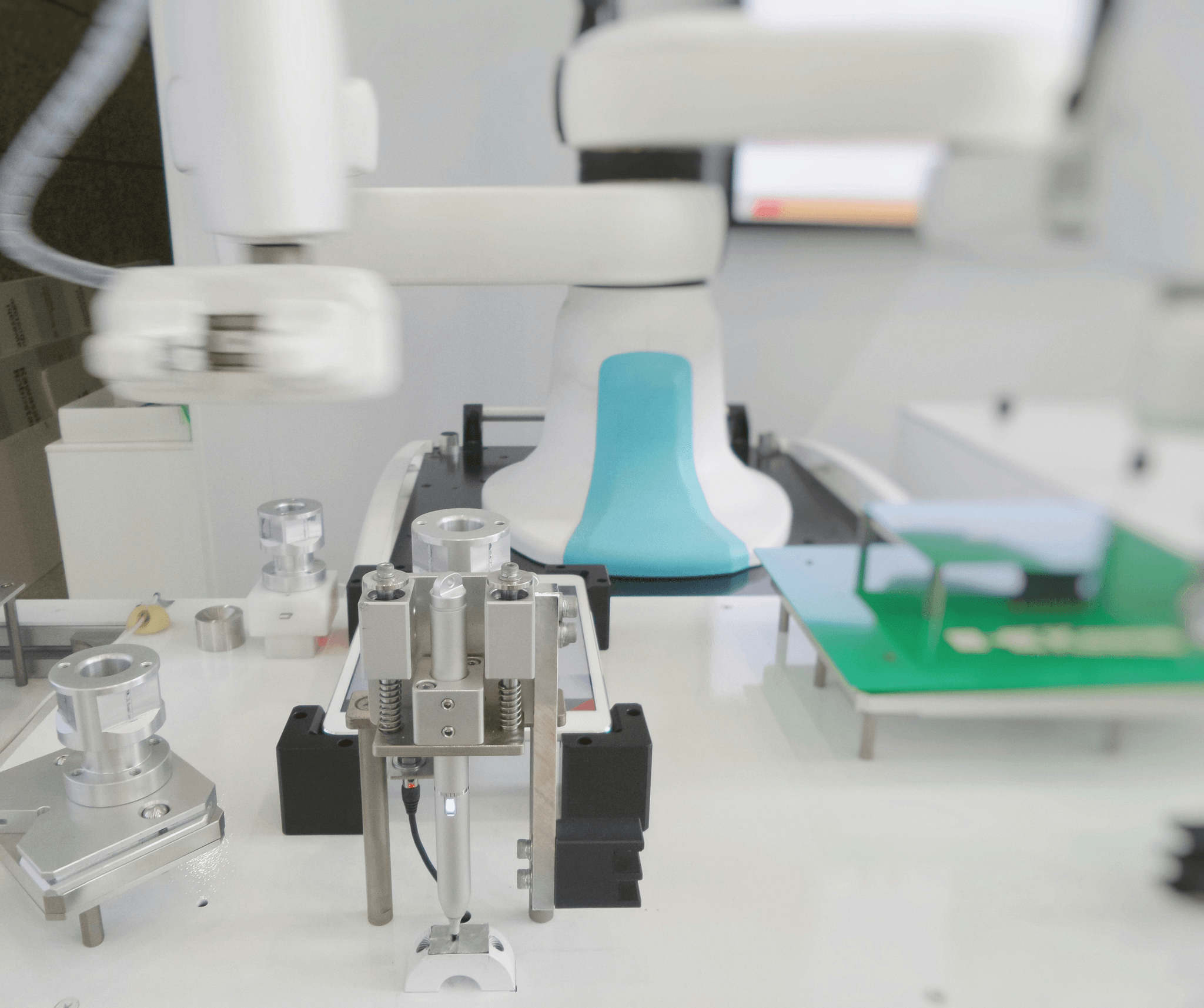

Non-Destructive Testing Methods

Non-Destructive Testing (NDT) methods are essential for ensuring quality assurance without compromising the integrity of the materials being inspected. These techniques allow inspectors to assess quality and quality assurance in products and structures while maintaining their usability. By employing various NDT methods, industries can identify potential issues early, preventing costly failures down the line.

Overview of NDT Techniques

NDT encompasses a variety of inspection methods that do not alter the material or component being tested. Common types include ultrasonic testing, radiographic testing, magnetic particle testing, and dye penetrant testing, each serving unique purposes in assessing quality and assurance. These techniques are designed to detect flaws such as cracks, corrosion, and structural weaknesses without causing any damage.

Key Industries Utilized

The application of non-destructive testing spans numerous industries where safety and reliability are paramount. Key sectors include aerospace, automotive, oil and gas, manufacturing, and construction—each relying on these types of inspection methods to uphold rigorous quality assurance standards. By integrating NDT into their processes, these industries enhance both product safety and operational efficiency.

Advantages for Quality Assurance

One significant advantage of non-destructive testing is its ability to ensure ongoing quality without sacrificing materials or components—this is crucial for maintaining high levels of quality assurance in production environments. Additionally, NDT contributes to cost savings by identifying defects early in the manufacturing process before they escalate into more significant issues requiring extensive repairs or replacements. Furthermore, training programs focused on NDT methodologies equip professionals with the skills needed to enhance both quality and assurance practices within their organizations.

Destructive Testing Approaches

Destructive testing approaches are pivotal in the realm of quality assurance, offering insights that non-destructive methods simply cannot. By intentionally damaging a material or component, these tests reveal crucial information about its structural integrity and performance under stress. This section delves into the key types of destructive tests, their significance in quality assessment, and their real-world applications across various industries.

Key Types of Destructive Tests

There are several types of inspection methods categorized under destructive testing, each with its unique focus and methodology. Common tests include tensile testing, where materials are stretched until they break to determine their strength; impact testing, which assesses how materials withstand sudden forces; and fatigue testing to evaluate durability over repeated stress cycles. These methods not only help in understanding the material properties but also play an essential role in ensuring that products meet quality assurance standards.

In addition to these standard approaches, there are specialized tests like hardness testing and creep testing that provide further insights into material behavior under specific conditions. Each test type contributes vital data that can inform design choices and manufacturing processes, ultimately enhancing overall quality and assurance practices within industries.

Importance in Quality Assessment

Destructive testing is indispensable for maintaining high standards of quality assurance across various sectors. By revealing potential weaknesses or failures before products reach consumers, these tests significantly reduce the risk of catastrophic failures in critical applications such as aerospace or medical devices. The knowledge gained from destructive tests feeds directly into quality management systems like Six Sigma Six training programs, which emphasize defect reduction and process improvement.

Moreover, understanding how materials behave when subjected to extreme conditions allows companies to refine their production processes continually. This iterative approach not only boosts product reliability but also aligns with broader goals of achieving quality excellence throughout the supply chain—a true win-win for both manufacturers and consumers alike.

Real-World Applications

The real-world applications of destructive testing span numerous industries where safety is paramount—think aerospace engineering or automotive manufacturing. In aerospace, for example, components undergo rigorous tensile and fatigue tests to ensure they can withstand the harsh conditions encountered during flight operations; failure is simply not an option here! Similarly, automotive manufacturers utilize these techniques extensively to guarantee that every part meets stringent safety regulations before vehicles hit the road.

Additionally, construction materials undergo various destructive tests to assess their suitability for building projects—after all, nobody wants a crumbling skyscraper! These applications highlight how critical destructive testing is for maintaining high levels of quality assurance across different fields while ensuring compliance with industry standards.

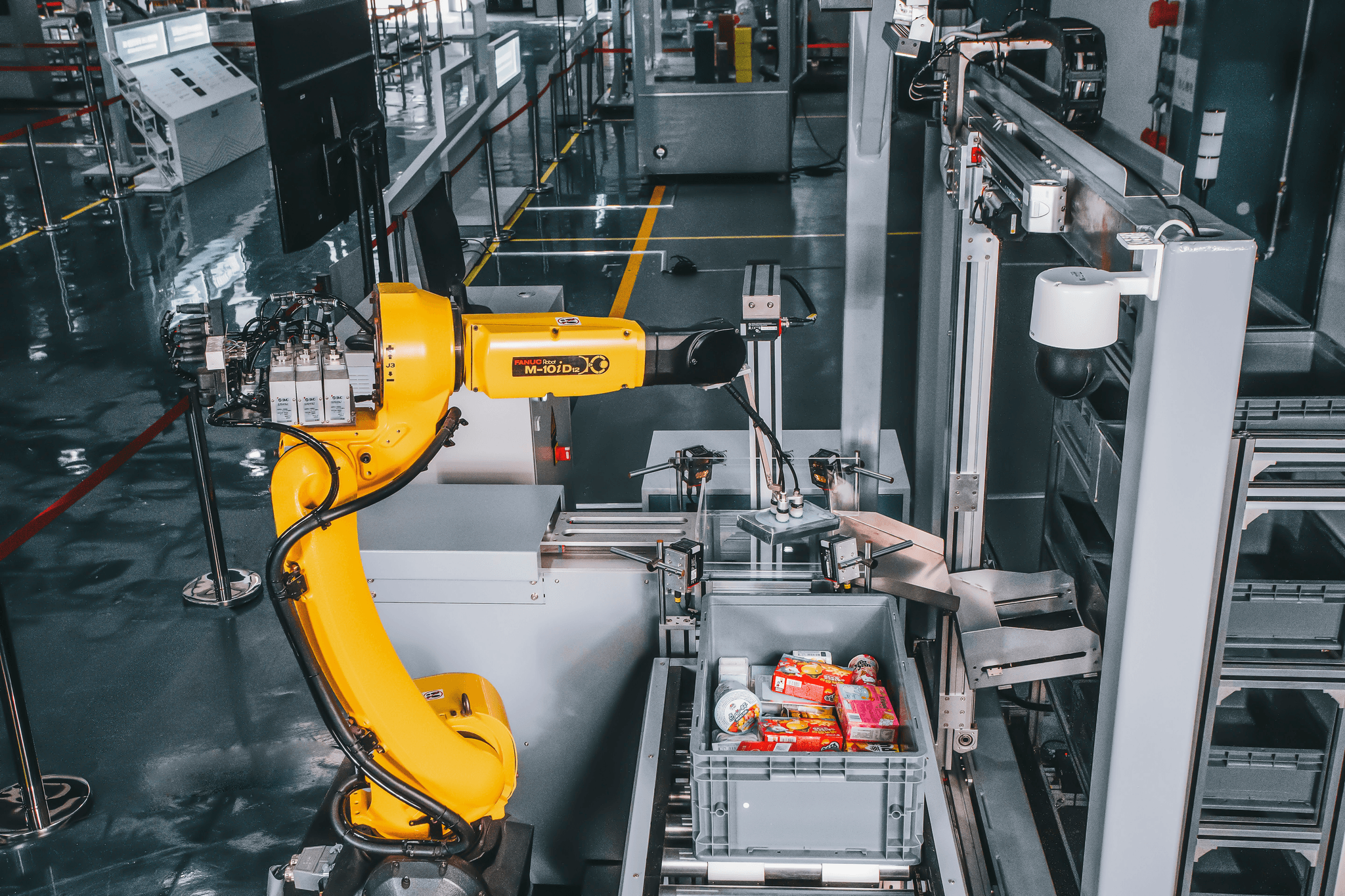

Automated Inspection Processes

In the realm of quality assurance, automated inspection processes are revolutionizing how industries ensure product integrity. By leveraging technology, organizations can streamline their inspection methods, enhancing both speed and accuracy. This shift towards automation not only facilitates a more consistent approach to quality and assurance but also reduces human error, which is critical in maintaining high standards.

Role of Technology in Inspections

Technology plays a pivotal role in modern inspection methods, transforming traditional practices into sophisticated automated systems. With advancements such as machine learning and artificial intelligence, inspections can now be conducted with greater precision and efficiency than ever before. These technologies allow for real-time data analysis, enabling businesses to make informed decisions quickly regarding quality assurance quality.

Advancements in Automated Systems

Recent advancements in automated systems have introduced various types of inspection methods that cater to diverse industry needs. For instance, vision systems equipped with high-resolution cameras can detect defects at speeds unattainable by human inspectors alone. Additionally, training programs focused on Six Sigma techniques are being integrated into these systems to further enhance the quality and quality assurance processes within organizations.

Impact on Quality and Efficiency

The impact of automated inspection processes on quality and efficiency is profound; they significantly reduce the time taken for inspections while increasing the reliability of results. By minimizing manual intervention, companies can ensure higher levels of consistency in their products, directly influencing customer satisfaction and trust in their brand's commitment to quality assurance. Ultimately, this evolution towards automation not only enhances operational performance but also redefines what it means to achieve excellence in quality and assurance.

Compliance and Regulatory Inspections

In the realm of quality assurance, compliance and regulatory inspections serve as critical checkpoints to ensure that products and services meet established standards. These inspections not only verify adherence to legal requirements but also reinforce the commitment to quality and assurance in various industries. Understanding these processes is essential for organizations aiming to maintain high-quality outputs and enhance their reputation.

Understanding Compliance Standards

Compliance standards are established guidelines that dictate how products should be manufactured, tested, and maintained to ensure safety, reliability, and performance. Different industries have specific compliance requirements; for instance, aerospace might adhere to AS9100 standards while food production follows HACCP protocols. Familiarity with these types of inspection methods helps organizations align their quality assurance practices with regulatory expectations, ultimately leading to improved quality quality assurance outcomes.

Importance of Regulatory Inspections

Regulatory inspections play a vital role in safeguarding public health and safety by ensuring that companies adhere to compliance standards. These inspections can identify potential issues before they escalate into significant problems, thus protecting both consumers and businesses alike from costly recalls or legal repercussions. Moreover, regular regulatory oversight enhances an organization's reputation by demonstrating a commitment to quality and assurance through consistent adherence to industry benchmarks.

How China Inspection Pro Ensures Quality

China Inspection Pro stands out as a leader in ensuring quality through rigorous compliance and regulatory inspections tailored for various sectors. By employing a range of inspection methods—both destructive and non-destructive—this organization ensures that products meet stringent international standards while fostering an environment of continuous improvement through training programs like Six Sigma Six. With their expertise in navigating complex regulations, China Inspection Pro effectively supports businesses in achieving optimal levels of quality assurance while minimizing risks associated with non-compliance.

Conclusion

In wrapping up our exploration of inspection methodologies, it's clear that the landscape of quality assurance is both diverse and essential. The types of inspection methods discussed—ranging from visual assessments to advanced automated processes—highlight the multifaceted nature of ensuring quality and quality assurance in various industries. Each method serves a unique purpose, contributing to the overarching goal of maintaining high standards in production and service delivery.

Summary of Inspection Methodologies

Throughout this discussion, we have delved into several types of inspection methods, including visual inspections, non-destructive testing (NDT), destructive testing approaches, and automated systems. Each methodology plays a critical role in enhancing quality assurance by identifying defects or deviations before they escalate into larger issues. By employing a combination of these techniques, organizations can bolster their quality assurance quality and ensure that their products meet stringent industry standards.

Enhancing Quality Assurance Practices

To truly enhance quality assurance practices, training programs play a pivotal role in equipping personnel with the necessary skills to implement various types of inspection methods effectively. The integration of six sigma six principles can further refine these practices by emphasizing data-driven decision-making and reducing variability in processes. Ultimately, continuous improvement through training ensures that both employees and organizations are prepared to uphold high levels of quality and assurance.

The Future of Inspection Techniques

Looking ahead, the future of inspection techniques appears promising with ongoing advancements in technology shaping new possibilities for quality control. As industries increasingly adopt automation and artificial intelligence within their inspection processes, we can expect significant improvements in efficiency and accuracy across all types of inspection methods. This evolution will not only enhance overall product integrity but also revolutionize how we perceive quality and quality assurance moving forward.