Introduction

In the world of manufacturing and product development, quality is king. Understanding the importance of inspection is crucial for ensuring that products not only meet industry standards but also satisfy customer expectations. The various types of inspection in quality control serve as essential checkpoints throughout the production process, reinforcing the integrity of a brand and its offerings.

Understanding the Importance of Inspection

Inspection acts as a safety net, catching potential flaws before they reach consumers. It plays a vital role in quality assurance by identifying issues early on, which can save companies from costly recalls and damage to their reputations. By implementing robust inspection services, businesses can foster trust with their clients and maintain high standards within their quality management system.

Overview of Quality Control Types

Quality control encompasses several methodologies designed to ensure that products adhere to specified requirements. These include visual inspections, dimensional checks, functional testing, and non-destructive testing—each playing a unique role in maintaining product integrity. Understanding these types of inspection in quality control allows organizations to implement tailored strategies that enhance overall product reliability.

The Role of Inspections in Product Quality

Inspections are the backbone of effective quality assurance processes; they provide critical insights into product performance before reaching the market. With services like those offered by China Inspection Pro, businesses can leverage expert knowledge to streamline their quality testing services and ensure compliance with industry standards. Ultimately, thorough inspections not only elevate product quality but also bolster consumer confidence and loyalty.

Visual Inspection

Visual inspection serves as the foundational step in quality assurance, acting as the first line of defense against potential defects and flaws. This type of inspection in quality control is crucial because it can quickly identify obvious issues that may affect product performance or consumer safety. By prioritizing visual inspection, companies can save time and resources by addressing problems early in the manufacturing process.

Essential First Step in Quality Assurance

In the realm of quality assurance, visual inspection is indispensable for maintaining high standards across products. It allows inspectors to conduct a straightforward assessment of items without the need for complex tools or equipment, making it highly efficient. As part of a robust quality management system, this initial step helps establish a baseline for further inspections and testing.

Identifying Surface Flaws and Defects

Visual inspection focuses primarily on identifying surface flaws such as scratches, dents, or discoloration that could compromise product integrity. These minor defects may not always affect functionality but can significantly impact consumer perception and satisfaction. By catching these issues early through effective quality inspection processes, businesses can enhance their overall reputation while minimizing costly rework or returns.

How China Inspection Pro Ensures Accuracy

China Inspection Pro employs highly trained inspectors who utilize systematic approaches to ensure accuracy during visual inspections. Our team is committed to delivering top-notch inspection services by combining experience with state-of-the-art technology to detect even the most subtle defects. With our focus on quality testing services, clients can trust that their products meet stringent standards before reaching the market.

Dimensional Inspection

Dimensional inspection is a critical component of quality assurance within the realm of quality control. It focuses on measuring products to ensure they meet specified tolerances and dimensions, which are crucial for functionality and compatibility in various applications. By employing precise dimensional inspection techniques, businesses can avoid costly errors and maintain high standards in their products.

Measuring Tolerance and Specifications

Measuring tolerance and specifications is fundamental to the types of inspection in quality control, as it determines whether a product adheres to its design requirements. Tolerances define the allowable variations in measurements, ensuring that parts fit together correctly without compromising performance. Accurate measurement ensures that manufacturers can deliver products that not only meet customer expectations but also comply with industry standards.

Tools and Techniques for Precision

To achieve precision in dimensional inspections, various tools and techniques are employed, including calipers, micrometers, and coordinate measuring machines (CMM). These instruments allow for highly accurate measurements that are essential for effective quality testing services. The use of advanced technology enhances the reliability of quality assurance inspections by providing detailed insights into product specifications.

Ensuring Compliance with Quality Standards

Ensuring compliance with quality standards is paramount in any effective IT quality management system. Dimensional inspections play a vital role in verifying that products conform to regulatory requirements and industry benchmarks, ultimately safeguarding end-users from defective items. By partnering with professionals like China Inspection Pro for your inspection services, businesses can enhance their commitment to quality assurance while minimizing risks associated with non-compliance.

Functional Testing

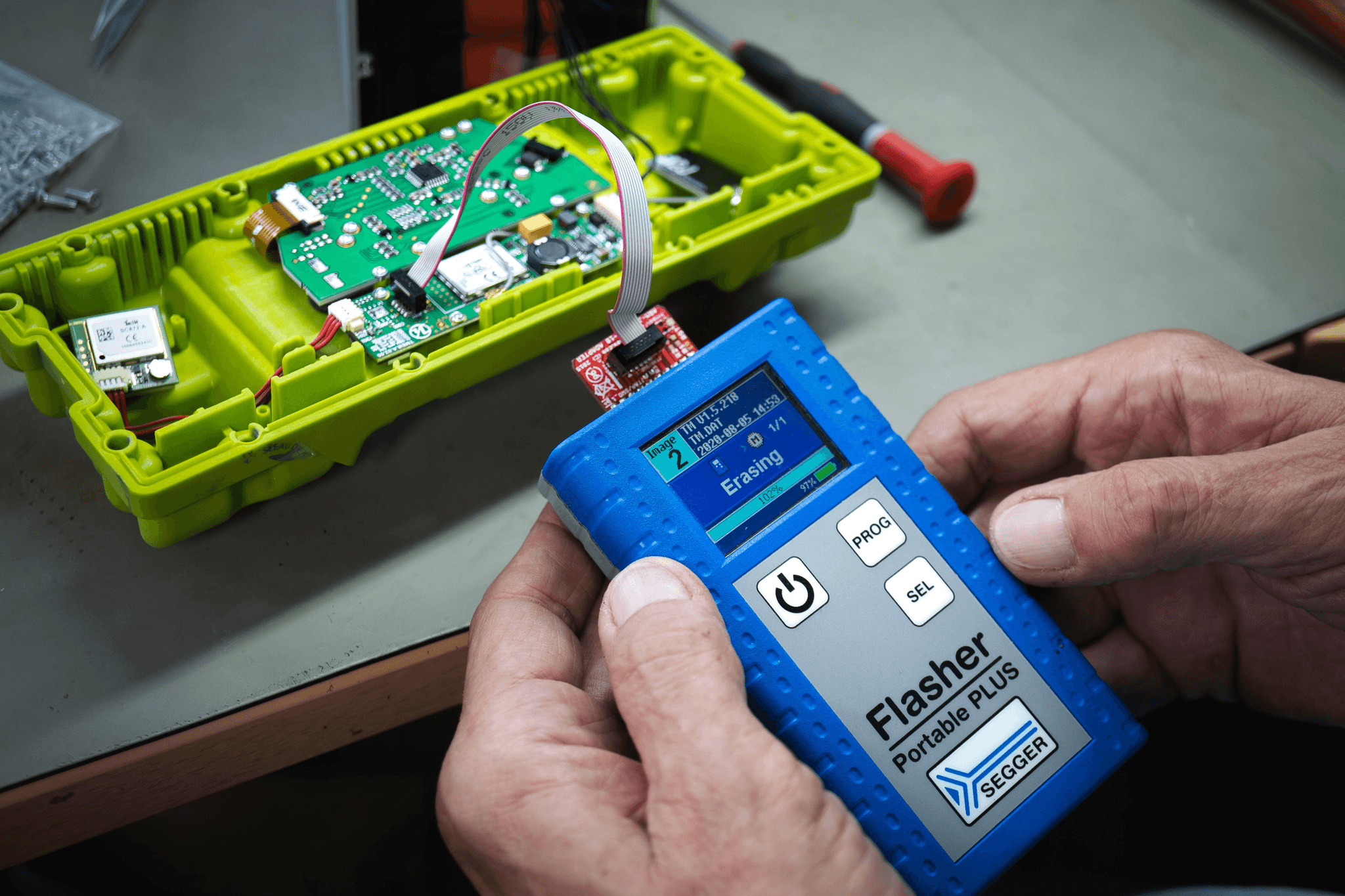

Functional testing plays a pivotal role in the overarching framework of quality assurance by evaluating how well a product performs its intended tasks. This type of inspection in quality control goes beyond mere visual assessments, delving into the operational capabilities of products to ensure they meet specified requirements. By rigorously analyzing product performance, companies can identify potential issues before they reach consumers, ultimately enhancing customer satisfaction and trust.

Assessing Product Performance

When it comes to assessing product performance, functional testing serves as a critical benchmark for quality control. This process involves evaluating whether a product operates according to its design specifications and meets the expected standards of functionality. With effective quality assurance inspection practices in place, businesses can mitigate risks associated with defective products and ensure their offerings are reliable and efficient.

Real-World Scenarios for Quality Testing

Real-world scenarios provide invaluable insights during functional testing, allowing businesses to simulate actual usage conditions that their products will face post-launch. For instance, electronics might be tested under varying temperature conditions to assess their durability, while mechanical parts may undergo stress tests to evaluate their strength. By incorporating these practical assessments into their quality testing services, companies can better understand how their products will perform in everyday situations and adjust designs accordingly.

The Impact of Quality Inspection on Reliability

Quality inspection has a profound impact on the reliability of products offered in the market; it ensures that each item not only meets but exceeds consumer expectations. By implementing rigorous functional testing as part of an effective IT quality management system, organizations can foster confidence among customers regarding product durability and performance longevity. Partnering with professionals like China Inspection Pro enhances this process further by providing expert inspection services that ensure compliance with industry standards throughout manufacturing and shipping processes.

Non-Destructive Testing

Non-destructive testing (NDT) is a crucial aspect of quality assurance that allows for the evaluation of materials and components without causing any damage. This method is essential in various industries, including manufacturing and construction, where maintaining the integrity of products is paramount. By employing NDT techniques, businesses can ensure that their products meet the rigorous standards set by quality control protocols.

Methods for Safe Quality Assurance

There are several methods of non-destructive testing used in quality assurance to ensure product reliability without compromising structural integrity. Common techniques include ultrasonic testing, radiographic testing, magnetic particle inspection, and dye penetrant inspection. Each method has its unique strengths and applications, making them vital tools within the larger framework of types of inspection in quality control.

For example, ultrasonic testing uses high-frequency sound waves to detect internal flaws in materials while leaving them unharmed. Similarly, radiographic testing employs X-rays or gamma rays to reveal hidden defects within a product's structure. These methods not only enhance safety but also provide detailed insights into product quality during the quality assurance inspection process.

Technologies Used in Non-Destructive Inspection

The technological advancements in non-destructive inspection have significantly improved the accuracy and efficiency of quality testing services. Modern NDT technologies include digital radiography systems, automated ultrasonic testing equipment, and advanced imaging techniques that allow inspectors to visualize internal structures with precision. These innovations enable companies like China Inspection Pro to deliver thorough inspection services that identify potential issues before they escalate into costly problems.

Moreover, integrating these technologies into an IT quality management system can streamline data collection and reporting processes during inspections. Manufacturers can leverage software tools that analyze results from various NDT methods to maintain compliance with industry-specific standards effectively. This technological synergy ensures a comprehensive approach to achieving optimal product performance while adhering to strict quality control requirements.

Benefits of Quality Testing Services in Manufacturing

Implementing non-destructive testing as part of your overall quality assurance strategy brings numerous benefits to manufacturing processes. Firstly, it enhances safety by identifying potential defects early on without compromising product integrity—allowing manufacturers to address issues proactively rather than reactively during later stages of production or after shipping products out into the market.

Secondly, utilizing professional inspection services like those offered by China Inspection Pro helps businesses build trust with their customers by ensuring consistent product quality throughout manufacturing cycles. By investing in robust non-destructive testing methodologies within their IT quality management systems, organizations can reduce risks associated with defective products entering the market—ultimately protecting brand reputation and customer satisfaction.

Lastly, incorporating NDT into your routine inspections leads not only to improved compliance with regulatory standards but also fosters a culture of continuous improvement within your organization’s operations—making it an indispensable element among types of inspection in quality control strategies today.

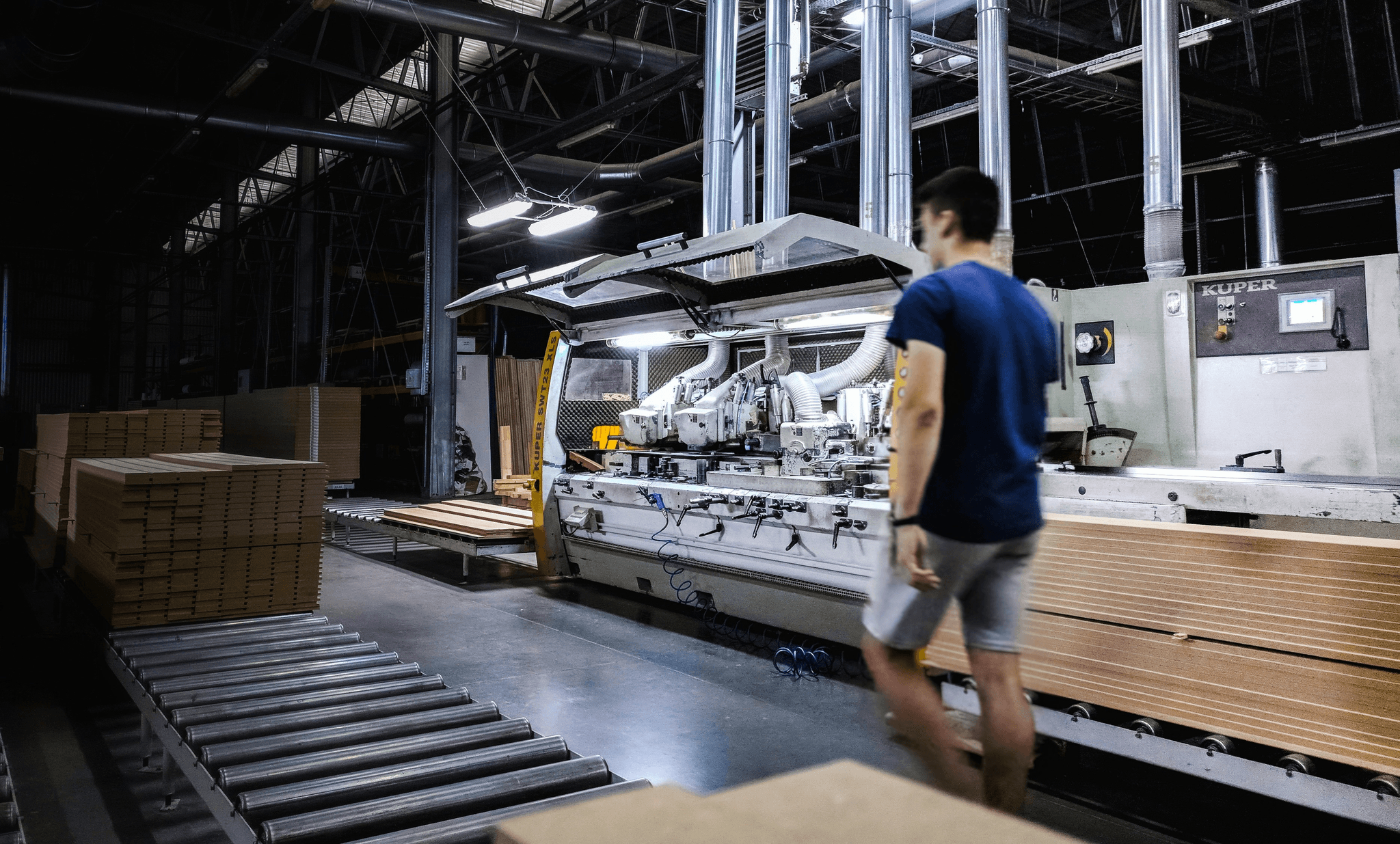

Final Quality Assurance Inspection

In the world of manufacturing, the final quality assurance inspection is not just a formality; it's a critical step that ensures products are market-ready. This stage involves a thorough examination of goods to confirm they meet established quality standards and specifications before reaching consumers. By implementing effective quality control measures during this phase, companies can significantly reduce the likelihood of defects slipping through the cracks.

Preparing Products for Market Readiness

Preparing products for market readiness involves meticulous attention to detail and adherence to various types of inspection in quality control. This includes ensuring that each item meets its design specifications and functions as intended, which is essential for consumer satisfaction and brand reputation. Quality assurance inspections at this stage help identify any last-minute issues that could affect product performance or safety, allowing manufacturers to rectify them before shipping.

The Last Line of Defense in Quality Control

The final quality assurance inspection serves as the last line of defense in a company's quality control strategy, ensuring that only products meeting stringent standards reach customers. It's a safeguard against potential recalls or customer dissatisfaction stemming from defects or non-compliance with regulations. With effective inspection services in place, businesses can confidently launch their products into the market, knowing they've taken every precaution to uphold their commitment to quality.

Trusting Experts like China Inspection Pro

When it comes to executing thorough quality assurance inspections, trusting experts like China Inspection Pro can make all the difference. With their extensive experience in providing top-notch quality testing services, they help businesses navigate the complexities of maintaining product integrity throughout manufacturing and shipping processes. By partnering with professionals who specialize in types of inspection in quality control, companies can enhance their overall IT quality management system while building trust with consumers around the globe.

Conclusion

In summary, understanding the various types of inspection in quality control is crucial for maintaining high standards in product quality. Each inspection type, from visual to non-destructive testing, plays a vital role in ensuring that products meet the required specifications and performance criteria. Quality assurance is not just a checkbox; it’s an integral part of establishing trust with consumers and partners alike.

Key Takeaways from Inspection Types

The types of inspection in quality control encompass a range of methodologies designed to address specific quality issues. Visual inspections help identify surface flaws, while dimensional inspections ensure products adhere to precise measurements and tolerances. Functional testing assesses real-world performance, and non-destructive testing guarantees safety without compromising product integrity—each method contributing significantly to overall quality assurance.

Implementing Effective Quality Control Strategies

To implement effective quality control strategies, businesses must first understand the importance of integrating various types of inspection into their it quality management system. Consistent application of these strategies can lead to early detection of defects and ultimately reduce costly recalls or customer dissatisfaction. By prioritizing comprehensive quality inspection processes, organizations can foster a culture of excellence that resonates throughout their manufacturing practices.

Partnering for Better Quality Assurance

Partnering with professional services like China Inspection Pro ensures that your business benefits from expert knowledge in the field of quality testing services. With their commitment to delivering accurate and timely inspections, businesses can navigate the complexities of global trade with confidence. Trusting experienced inspectors allows companies to focus on innovation while maintaining high-quality standards through reliable quality assurance inspections.