Introduction

In an increasingly globalized market, ensuring product quality is paramount, and AQL Product Inspection plays a crucial role in this process. AQL, or Acceptable Quality Level, is a statistical measure used to determine the maximum number of defective items allowed in a batch of products. This method helps manufacturers and importers maintain standards across various sectors, including Softlines, Hardlines, Electronic and Electrical Items, and Industrial Components.

Understanding AQL Product Inspection

AQL Product Inspection is not just a buzzword; it's a vital practice that safeguards consumer trust and brand reputation. By systematically assessing products for defects before they reach the market, businesses can minimize risks associated with poor quality. This inspection process encompasses everything from visual checks to functional testing, ensuring that each item meets the necessary specifications.

Importance of Classifying Defects

Classifying defects into categories—major, minor, and critical—enables companies to prioritize their quality control efforts effectively. Each category represents varying levels of severity that can impact product performance and customer satisfaction differently. By understanding these classifications within AQL Product Inspection frameworks, businesses can implement targeted strategies for defect resolution across Softlines, Hardlines, Electronic and Electrical Items, and Industrial Components.

Overview of Defects in Various Categories

Defects come in many shapes and sizes; understanding their nuances is essential for effective management. Major defects may render a product unusable or unsafe; minor defects might affect aesthetics but not functionality; while critical defects could pose serious hazards in Electronic and Electrical Items or Industrial Components. Recognizing these distinctions allows organizations to allocate resources wisely while enhancing overall quality assurance practices.

Major Defects

In the realm of AQL Product Inspection, major defects represent a significant hurdle in ensuring product quality. These defects are not just minor annoyances; they can render a product unusable or unsafe, leading to serious repercussions for manufacturers and consumers alike. Understanding how to identify and manage these defects is crucial for maintaining standards across various sectors including Softlines, Hardlines, Electronic and Electrical Items, and Industrial Components.

Definition and Examples

Major defects are defined as those that compromise the functionality or safety of a product to such an extent that it cannot meet its intended use or regulatory requirements. For instance, in the context of Softlines such as clothing, a major defect might involve incorrect sizing that results in an item being unwearable. In Hardlines like furniture or tools, examples include structural failures or hazardous materials that pose safety risks, while in Electronic and Electrical Items, issues like faulty wiring can lead to dangerous malfunctions.

Impact on Product Quality

The impact of major defects on product quality is profound and far-reaching. These defects can lead to customer dissatisfaction, brand damage, and potential legal liabilities if products fail catastrophically after reaching consumers. Moreover, when dealing with Industrial Components where precision is key, even minor deviations classified as major defects can disrupt entire production lines or compromise machinery performance.

Addressing Major Defects in AQL

To effectively address major defects within the framework of AQL Product Inspection requires a systematic approach rooted in prevention and detection strategies. Regular inspections during production phases help catch these issues early before they escalate into costly recalls or reputation damage. Furthermore, implementing robust training programs for quality control personnel ensures they are equipped with the skills needed to identify major defects across various categories including Softlines and Hardlines.

Minor Defects

Minor defects may not seem like a big deal at first glance, but they can accumulate and lead to significant issues if left unchecked. In the context of AQL Product Inspection, understanding what constitutes a minor defect is crucial for maintaining product quality across various categories, including softlines and hardlines. These defects are often cosmetic or functional in nature but do not render the product unusable.

What Constitutes a Minor Defect

A minor defect is typically defined as an imperfection that does not significantly affect the performance or usability of a product. For instance, small scratches on the surface of an electronic item or slight misalignments in industrial components can be classified as minor defects. While these issues may be noticeable, they generally do not compromise the overall functionality or safety of the product, making them less critical than major or critical defects.

Examples in Softlines and Hardlines

In softlines, which include textiles and apparel, examples of minor defects might include loose threads, slight color variations, or small fabric imperfections that don't detract from the garment's wearability. On the other hand, hardlines—like furniture or home appliances—could exhibit minor defects such as small dents in metal surfaces or paint imperfections that are barely visible upon close inspection. Recognizing these examples during AQL Product Inspection helps manufacturers address them before products reach consumers.

Strategies for Managing Minor Defects

Managing minor defects effectively requires proactive measures throughout the production process. Implementing rigorous quality control checks during manufacturing can help catch these flaws early on; this includes regular inspections and audits to ensure compliance with AQL standards. Additionally, educating workers about common minor defects specific to softlines and hardlines will create a culture of quality awareness that fosters better outcomes and reduces rework costs associated with fixing these imperfections.

Critical Defects

When it comes to AQL Product Inspection, critical defects can be a game changer, particularly in the realm of electronic and electrical items. These defects are those that can pose safety hazards or lead to significant failures in functionality, making their identification absolutely crucial. As we delve deeper into understanding these critical issues, we’ll see how they differ from minor and major defects and why they require immediate attention.

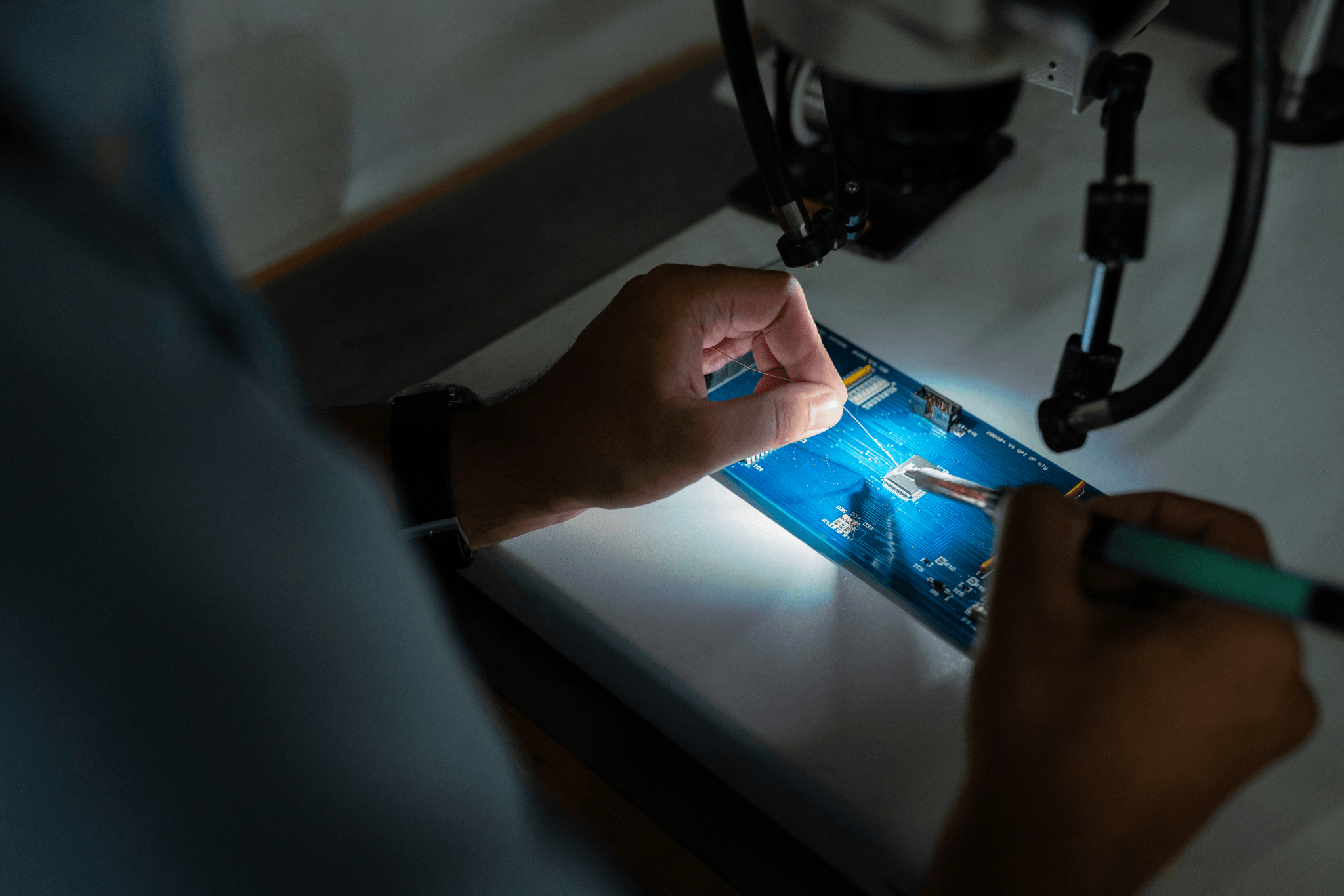

Identifying Critical Defects in Electrical Items

Identifying critical defects in electrical items is no small feat; it requires a keen eye for detail and an understanding of the potential risks involved. Common examples include faulty wiring, improper insulation, or components that do not meet safety standards. In the world of AQL Product Inspection, any oversight can lead to catastrophic results—not just for consumers but also for manufacturers who could face serious liability issues.

The inspection process must include rigorous testing methods to ensure that all electronic and electrical items meet the necessary safety regulations before they hit the market. For instance, a simple short circuit due to poor manufacturing practices can lead to fires or electric shocks—an outcome no one wants on their conscience. Thus, identifying these critical defects early on is essential not only for consumer safety but also for maintaining brand integrity.

Consequences of Critical Defects

The consequences of critical defects extend far beyond immediate safety concerns; they can have lasting impacts on a company's reputation and financial stability as well. If an electronic item fails due to a critical defect—like overheating or causing electric shocks—it could result in product recalls, lawsuits, and loss of customer trust. For manufacturers dealing with hardlines and softlines alike, this means that thorough AQL Product Inspection is non-negotiable.

Moreover, the fallout from such defects often leads to increased scrutiny from regulatory bodies which may impose fines or additional compliance requirements on companies found lacking in quality control measures. This not only strains resources but also diverts attention away from innovation and development efforts within organizations focused on producing high-quality products. Therefore, addressing these issues proactively is key to maintaining operational effectiveness.

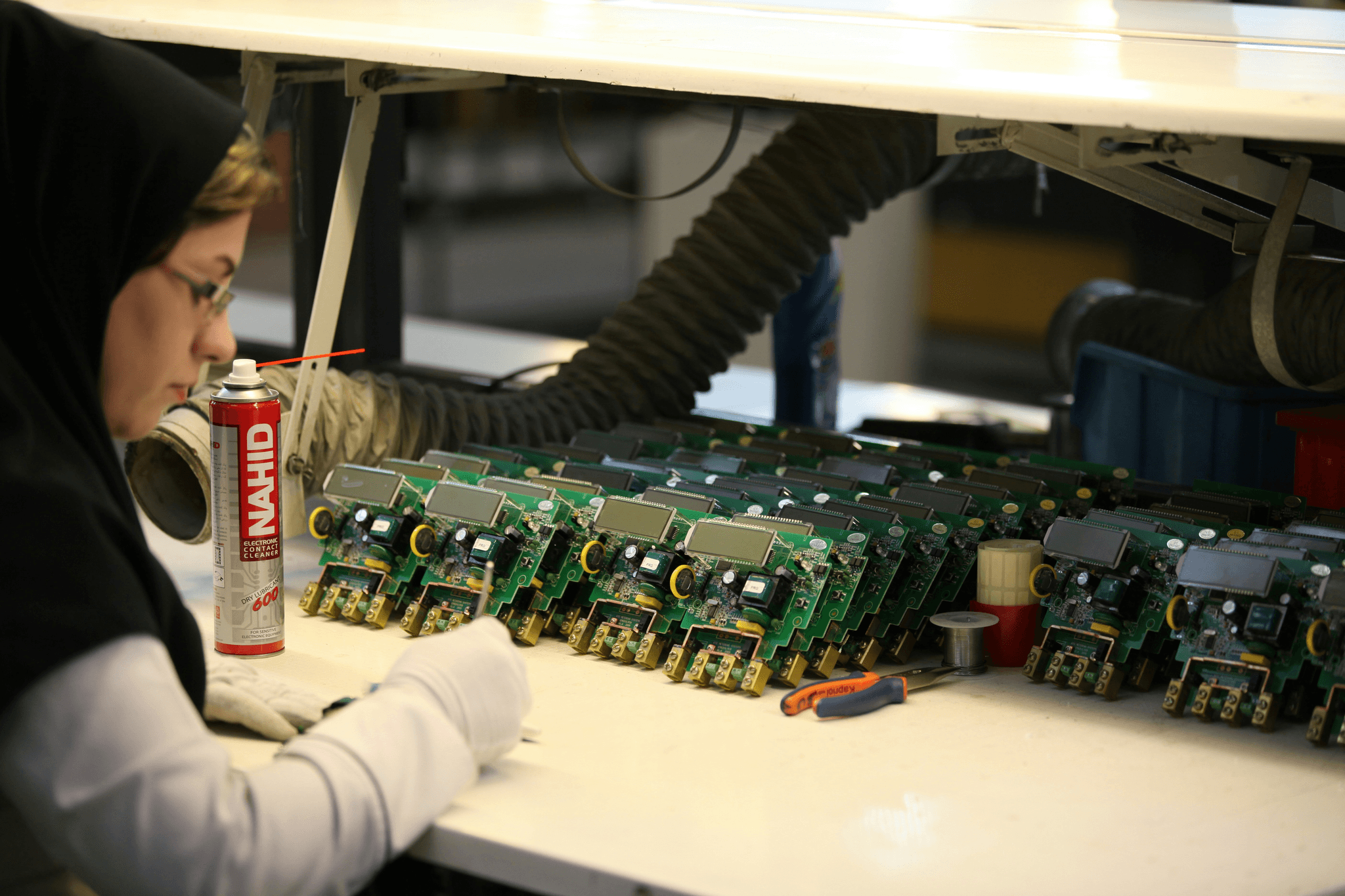

Role of China Inspection Pro in Detection

China Inspection Pro plays a pivotal role in detecting critical defects during the AQL Product Inspection process for various industries including electronics and industrial components. With specialized expertise in identifying potential pitfalls within production lines, this organization ensures that products are compliant with international standards before reaching consumers’ hands. Their trained inspectors utilize advanced techniques to thoroughly assess each item’s quality—leaving no stone unturned when it comes to safeguarding both brands and buyers.

By leveraging technology alongside human expertise, China Inspection Pro offers comprehensive solutions tailored specifically for businesses involved with softlines and hardlines manufacturing processes alike. Their commitment not only helps detect existing flaws but also educates manufacturers about best practices that prevent future occurrences of critical defects—a win-win situation indeed!

In summary, understanding how to identify critical defects within electrical items cannot be overstated; doing so protects consumers while enhancing overall product quality across global supply chains reliant on effective AQL Product Inspections.

Conclusion

In conclusion, understanding defect classification is crucial for maintaining high standards in product quality across various industries. AQL Product Inspection serves as a guiding framework to identify and categorize defects into major, minor, and critical classifications, ensuring that businesses can take the necessary steps to mitigate risks. By recognizing the differences among defects in Softlines, Hardlines, Electronic and Electrical Items, and Industrial Components, companies can enhance their quality control processes effectively.

Key Takeaways on Defect Classification

Defect classification is not just a bureaucratic exercise; it's a vital component of effective quality management. Major defects can lead to significant product failures and customer dissatisfaction, while minor defects may be more about aesthetics but still require attention. Critical defects are a different beast altogether—especially in Electronic and Electrical Items—where safety is paramount; understanding these nuances helps businesses prioritize their inspection efforts during AQL Product Inspection.

Enhancing Quality Control Processes

To enhance quality control processes, companies should implement robust training programs for inspectors focused on recognizing all types of defects across various categories. Regular audits of the inspection process will help ensure that both Softlines and Hardlines are scrutinized under the same rigorous standards set by AQL guidelines. Additionally, leveraging technology such as automated inspection systems can help identify flaws more accurately in Industrial Components or any other category.

The Importance of AQL in Global Trade

The importance of AQL in global trade cannot be overstated; it acts as a common language for manufacturers and buyers worldwide to communicate expectations about product quality. In an increasingly interconnected market where products flow from one country to another—often involving Softlines and Hardlines—it’s essential that everyone adheres to these standards to minimize disputes over defective items. Ultimately, effective use of AQL Product Inspection not only boosts confidence among stakeholders but also helps sustain long-term business relationships.