Introduction

Quality inspection is more than just a checkbox on a manufacturing checklist; it's the backbone of successful international trade, especially in a dynamic market like China. With the rapid growth of the global economy and the increasing complexity of supply chains, understanding the need for thorough quality inspection has never been more critical. Whether you’re sourcing electronics or textiles, ensuring that your products meet high standards can save businesses from costly mistakes and reputational damage.

Understanding the Need for Quality Inspection

In today's interconnected marketplace, consumers expect high-quality products delivered on time, making quality control an essential aspect of any business strategy. Full inspection in China helps to mitigate risks associated with subpar goods, ensuring that products not only meet buyer specifications but also comply with international standards. By employing a quality control inspector during this process, businesses can enhance their credibility and build long-lasting relationships with clients.

The Role of Inspection Companies in China

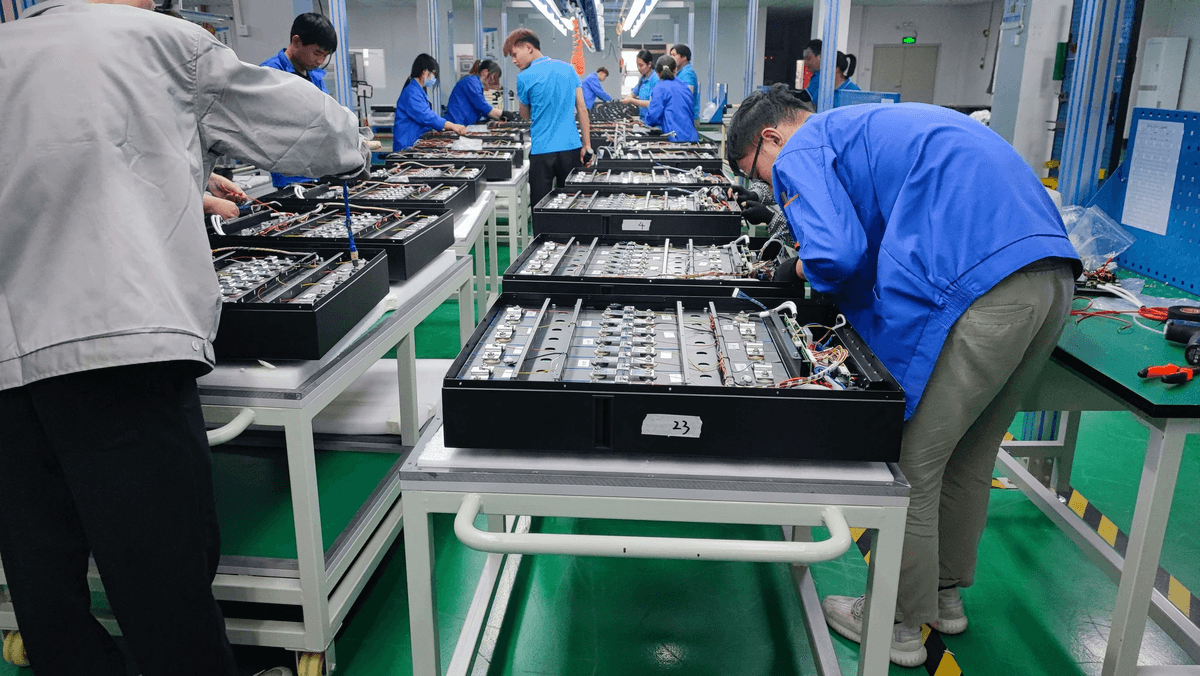

Inspection companies play a pivotal role in safeguarding product quality throughout the manufacturing process in China. These firms specialize in conducting comprehensive inspections that cover everything from raw materials to finished goods, providing invaluable insights into potential issues before they escalate. By partnering with an established inspection services provider, businesses can navigate China's intricate landscape while ensuring compliance with both local regulations and global expectations.

How Full Inspection Elevates Product Standards

Full inspection elevates product standards by meticulously evaluating every aspect of production before items reach consumers or retailers. This rigorous approach not only identifies defects but also reinforces best practices within factories, fostering a culture of continuous improvement. Ultimately, effective product inspection leads to higher customer satisfaction rates and strengthens brand loyalty—key ingredients for success in today’s competitive market.

The Basics of Full Inspection in China

In the bustling world of manufacturing, full inspection in China serves as a crucial pillar for ensuring product quality. This rigorous process is designed to scrutinize products thoroughly before they reach the market, guaranteeing that they meet both local and international standards. Understanding the nuances of full inspection can help businesses mitigate risks and enhance their reputation among consumers.

Defining Full Inspection and Its Importance

Full inspection is a comprehensive evaluation of products at various stages of production, focusing on quality control and adherence to specifications. It plays an essential role in identifying defects or discrepancies that could lead to costly recalls or consumer dissatisfaction. By investing in quality inspection through reputable inspection companies, businesses can bolster their credibility and ensure that their products consistently meet market demands.

Overview of the Quality Control Process

The quality control process typically begins with pre-production inspections, where materials are evaluated before manufacturing commences. This step is followed by in-line inspections during production to catch any issues early on, ultimately culminating in final random inspections before shipment. Each phase is critical; a diligent quality control inspector ensures that every product meets established criteria throughout its lifecycle.

Key Players in the Chinese Inspection Landscape

China's inspection landscape features several key players, ranging from local firms to international giants specializing in inspection services. These companies often possess extensive networks and knowledge about regional regulations, making them invaluable partners for foreign businesses navigating this complex environment. Collaborating with a well-established inspection company not only streamlines the quality control process but also enhances overall operational efficiency.

Benefits of Hiring a Quality Control Inspector

Ensuring Compliance with Global Standards

One of the primary benefits of engaging in thorough quality inspection services is ensuring compliance with global standards. Different markets have specific requirements, and a quality control inspector will guide you through these regulations, ensuring your products are up to par. By adhering to these standards through meticulous product inspection, you reduce the risk of costly recalls and legal issues down the line.

Moreover, compliance is not just about avoiding penalties; it’s about building trust with customers who expect high-quality products. An effective quality control process will help demonstrate that your commitment to excellence extends beyond borders. Ultimately, this dedication can enhance your brand's credibility and open doors in new markets.

Reducing Risk and Increasing Buyer Confidence

When you hire an inspection company for full inspection in China, you're proactively reducing risks associated with poor-quality goods. A dedicated quality control inspector identifies potential defects or issues before they become major problems, giving you peace of mind as you navigate international trade. This proactive approach not only safeguards financial investments but also enhances buyer confidence significantly.

Buyers are more likely to engage with brands that prioritize quality assurance through rigorous inspections. When clients know that each product has undergone thorough scrutiny by professionals, they feel more secure in their purchasing decisions. Consequently, this can lead to increased sales and long-term customer loyalty.

Saving Time and Money in the Long Run

Investing in a qualified quality control inspector may seem like an expense at first glance; however, it saves time and money over time by preventing costly mistakes down the road. The efficiency gained from having expert oversight during the production process means fewer delays due to rework or returns because of defective items. In industries where margins are tight, this efficiency translates directly into improved profitability.

Additionally, when businesses partner with reputable inspection services early on, they often find that their overall operational costs decrease significantly over time due to fewer disruptions related to quality failures. It’s like having insurance against those unexpected bumps along the road! With fewer headaches related to product discrepancies or compliance issues, companies can focus on what really matters: growth and innovation.

China's Unique Challenges in Quality Inspection

Navigating the waters of quality inspection in China can feel like trying to steer a ship through a dense fog. The cultural nuances and regulatory frameworks can be perplexing, especially for foreign businesses unfamiliar with local practices. Understanding these differences is crucial for ensuring that the full inspection process is not only compliant but also effective in maintaining high product standards.

Navigating Cultural and Regulatory Differences

Cultural differences play a significant role in how quality inspection is conducted in China. For instance, the concept of guanxi, or relationships, often influences business dealings and inspections, making it essential to build trust with local partners.

The Chinese government has established various regulations aimed at enhancing product safety and quality; however, these regulations can be complex and subject to change. This fluidity means that companies must stay informed about current laws to avoid compliance issues during their quality control processes. Engaging a knowledgeable inspection company can help navigate these challenges effectively.

Common Issues Faced by Foreign Businesses

Foreign businesses often encounter several hurdles when conducting product inspections in China. Language barriers can lead to misunderstandings during the inspection process, potentially resulting in overlooked defects or miscommunication about quality standards. Moreover, time zone differences may complicate coordination efforts between overseas teams and local inspectors.

Another common issue is the lack of transparency within some Chinese factories regarding their production processes and capabilities. This opacity can hinder effective quality control measures if inspectors cannot access critical information about manufacturing practices or material sourcing. Consequently, hiring experienced quality control inspectors who understand both local practices and international standards becomes vital for mitigating risks.

The Importance of Local Expertise

Local expertise cannot be overstated when it comes to successful inspections in China’s unique landscape. An experienced inspection services provider will not only have an intimate understanding of regional regulations but also possess insights into cultural norms that could affect the quality control process. Their familiarity with local suppliers enables them to identify potential issues before they escalate into costly problems.

Moreover, having boots on the ground allows for real-time monitoring during production runs—something that remote oversight simply cannot achieve effectively. With dedicated local inspectors on-site, companies are better equipped to ensure compliance with both domestic and international standards throughout every stage of product inspection. Ultimately, investing in local expertise pays dividends by enhancing buyer confidence while minimizing risks associated with overseas manufacturing.

Choosing the Right Inspection Company

Selecting the right inspection company is crucial for ensuring that your products meet the necessary standards in quality inspection. With so many options available, it's essential to know what to look for in an inspection services provider that can effectively carry out a full inspection in China. A well-chosen quality control inspector can make all the difference, transforming potential pitfalls into success stories.

What to Look for in an Inspection Services Provider

When searching for an inspection services provider, prioritize experience and expertise in the quality control process specific to your industry. An ideal company should have a proven track record of conducting thorough product inspections and understanding local regulations and cultural nuances that could impact quality assurance. Additionally, consider their responsiveness and customer support; after all, clear communication is key when navigating the complexities of full inspection in China.

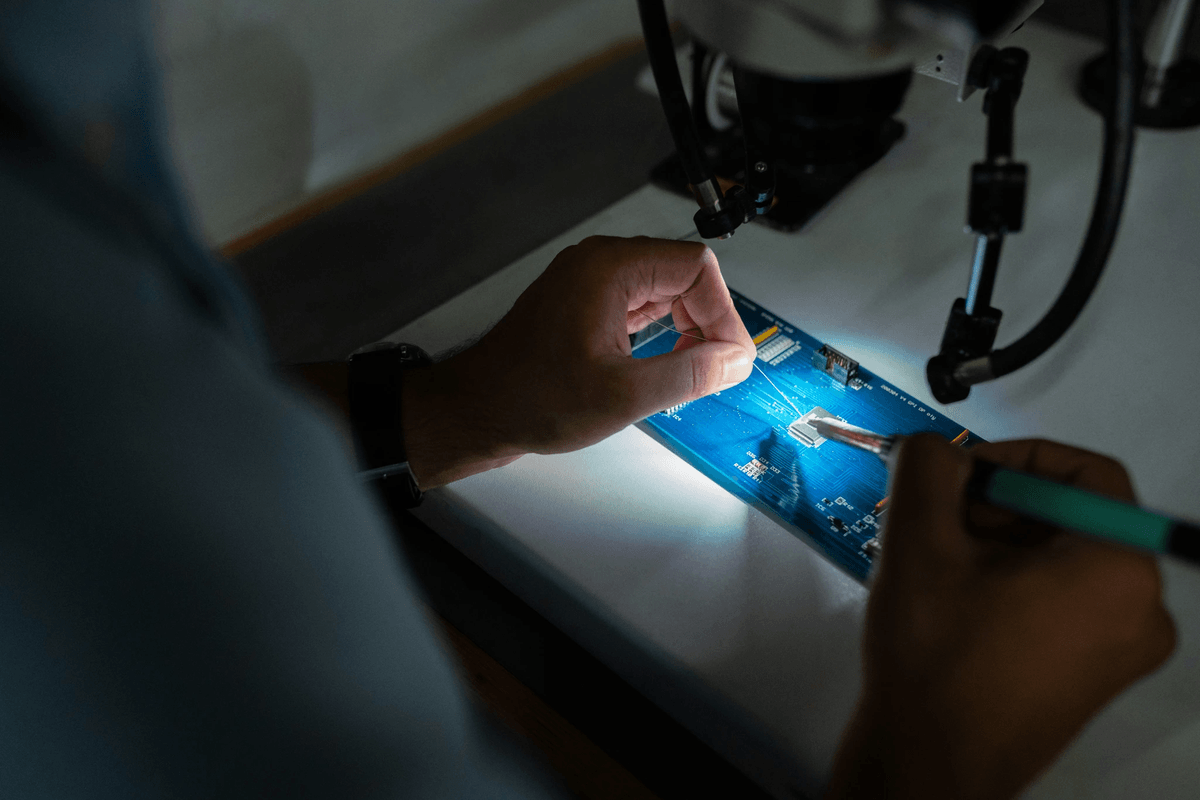

Another critical factor is technology adoption—look for companies that utilize advanced tools and techniques during their inspections. This not only enhances accuracy but also streamlines reporting processes, giving you timely insights into your product's compliance with global standards. Lastly, ensure they offer flexibility in their services; whether you need pre-production checks or final inspections before shipping, having a provider who can adapt to your needs is invaluable.

Comparing China Inspection Pro with Other Companies

China Inspection Pro stands out among other companies due to its comprehensive approach to quality inspection tailored specifically for foreign businesses operating in China. Their team of skilled quality control inspectors is adept at navigating local challenges while providing detailed reports on product inspections that highlight any issues before they escalate into costly problems. By comparing their offerings with competitors, you'll notice a commitment to transparency and customer satisfaction that sets them apart.

Moreover, while many companies may offer basic inspection services, China Inspection Pro goes above and beyond by integrating real-time updates into their process—keeping you informed every step of the way. This level of service not only builds trust but significantly reduces risks associated with overseas manufacturing partnerships. When evaluating options, consider how each company's capabilities align with your specific needs; this will help ensure you choose a partner who truly understands the intricacies of full inspection in China.

Evaluating Reputation and Track Record

A company’s reputation speaks volumes about its reliability as an inspection services provider; therefore, research thoroughly before making a decision on which one to partner with for your quality control needs. Look for reviews from previous clients regarding their experiences with product inspections conducted by various companies—this can provide valuable insight into what you might expect from them as well as highlight any red flags worth considering.

Additionally, ask potential partners about case studies or examples of successful projects they've undertaken involving full inspections in China. This not only demonstrates their capability but also showcases how they handle challenges unique to different industries or products during the quality control process. Ultimately, choosing an experienced company with a solid reputation will give you peace of mind knowing your products are being inspected by professionals who care about maintaining high-quality standards.

Real-World Case Studies of Successful Inspections

When it comes to quality inspection, real-world examples often speak louder than theoretical discussions. In this section, we’ll delve into some fascinating success stories from China Inspection Pro that showcase the power of full inspection in China. These cases illustrate how effective quality control processes can transform product outcomes and enhance buyer confidence.

Success Stories with China Inspection Pro

One standout success story involves a prominent electronics manufacturer that partnered with China Inspection Pro for a comprehensive full inspection in China. By implementing rigorous quality control measures, the company was able to identify and rectify potential defects before shipment, resulting in a 30% reduction in returns due to faulty products. This not only saved them significant costs but also bolstered their reputation among international buyers who value reliability and quality.

Another case highlights a fashion brand that faced challenges with inconsistent product quality from multiple suppliers. After engaging an experienced quality control inspector from China Inspection Pro, they established standardized inspection services across all their production lines. The result? A cohesive look and feel across their entire collection, leading to increased customer satisfaction and sales growth.

These success stories underscore the importance of hiring reputable inspection companies like China Inspection Pro to navigate the complex landscape of product inspections in China effectively.

Lessons Learned from Failed Quality Control

While success stories are encouraging, they often come with valuable lessons learned from failures as well. One notable case involved a furniture exporter that neglected thorough inspections before shipping their products overseas. As a result, several containers arrived damaged or below expected standards, leading to hefty financial losses and strained relationships with clients.

This situation serves as a reminder that overlooking the importance of the quality control process can have dire consequences for businesses operating in competitive markets. Companies must recognize that cutting corners on inspections can lead to long-term damage far outweighing any short-term savings.

Ultimately, these lessons emphasize the necessity of investing in reliable inspection services and employing skilled quality control inspectors who can catch issues early on—before they escalate into costly problems.

Strategies for Effective Product Inspection

To ensure successful outcomes during product inspections, businesses should adopt several strategic approaches when working with inspection companies in China. First and foremost is establishing clear communication channels between your team and your chosen quality control inspector; this fosters transparency about expectations and standards throughout the entire process.

Additionally, creating detailed checklists tailored specifically for each type of product being inspected can streamline operations significantly during the quality control process. By outlining critical parameters—such as material specifications or functionality tests—you empower inspectors to focus on what truly matters while minimizing oversight risks.

Lastly, it’s crucial to stay informed about evolving industry standards and regulations affecting your products; this knowledge enables you to adapt your practices accordingly while ensuring compliance during inspections—ultimately enhancing overall buyer confidence when entering new markets.

Conclusion

In summary, the landscape of quality inspection in China is intricate yet crucial for businesses aiming to maintain high product standards. Full inspection in China is not merely a checklist; it’s a comprehensive approach that ensures compliance and enhances buyer confidence. By understanding the nuances of the quality control process and leveraging local expertise, companies can significantly mitigate risks associated with overseas manufacturing.

Key Takeaways on Quality Inspection

Quality inspection is an essential step in the supply chain that cannot be overlooked, especially when engaging with Chinese manufacturers. The full inspection process provides a thorough assessment of products, ensuring they meet both global standards and specific buyer requirements. Engaging a qualified quality control inspector can save time and money while boosting overall satisfaction with your products.

Final Thoughts on Partnering with Inspection Companies

Partnering with a reputable inspection company can make or break your business dealings in China. These companies not only bring local knowledge but also offer invaluable insights into navigating cultural and regulatory challenges. By selecting the right inspection services provider, you empower your business to thrive in a competitive marketplace while ensuring that quality remains non-negotiable.

Future Trends in Quality Control in China

Looking ahead, we can expect significant advancements in technology to reshape the future of quality control processes in China. Automation and artificial intelligence will likely play pivotal roles in enhancing efficiency and accuracy during inspections, leading to even higher standards of product quality. As consumer expectations continue to rise globally, embracing these trends will be vital for businesses seeking success through effective product inspection strategies.