Introduction

In the realm of manufacturing, ensuring product quality is paramount, and AQL Product Inspection plays a pivotal role in this process. It serves as a systematic approach to identifying defects and ensuring that products meet established standards before they reach consumers. By implementing robust quality control measures, manufacturers can safeguard their reputation and maintain customer satisfaction.

Understanding AQL Product Inspection Importance

AQL Product Inspection is essential for maintaining high standards in quality assurance throughout the production process. This method allows companies to assess a sample of products rather than inspecting every single item, making it both efficient and effective. By focusing on critical aspects of quality checks in manufacturing, businesses can identify issues early on and avoid costly recalls or customer complaints.

The Role of Quality Control in Manufacturing

Quality control is the backbone of successful manufacturing operations, ensuring that products not only meet specifications but also fulfill customer expectations. Through rigorous quality inspection processes, manufacturers can detect deviations from desired outcomes and implement corrective actions promptly. In today's competitive market, partnering with reputable quality control companies enhances a manufacturer's ability to deliver consistent results while minimizing risks associated with poor-quality products.

Overview of Defect Classifications

Understanding defect classifications is crucial for effective quality control and quality assurance strategies within any production environment. Defects are typically categorized into three main types: critical, major, and minor defects—each with varying implications for safety, functionality, and aesthetic appeal. By employing AQL sampling techniques based on these classifications, manufacturers can prioritize their inspection efforts to address the most pressing issues impacting product integrity.

Critical Defects

In the realm of quality control, critical defects represent the most severe issues that can arise during product manufacturing. These defects can compromise safety, violate compliance regulations, and lead to catastrophic failures. Understanding what constitutes a critical defect is essential for effective AQL Product Inspection and overall quality assurance in manufacturing.

Definition and Examples of Critical Defects

Critical defects are flaws that render a product unsafe for use or non-compliant with regulatory standards. For instance, imagine a faulty electrical component that could cause fires or an improperly sealed medical device that risks contamination. Such examples highlight the importance of rigorous quality checks in manufacturing to identify these dangerous shortcomings before products reach consumers.

Impact on Safety and Compliance

The implications of critical defects extend beyond mere inconvenience; they pose significant risks to consumer safety and brand reputation. Non-compliance with industry regulations can lead to recalls, legal actions, and financial losses that could cripple a company. Quality control companies play a crucial role in mitigating these risks by ensuring thorough inspections are conducted to catch critical defects early in the production process.

How AQL Product Inspection Addresses Critical Defects

AQL Product Inspection employs systematic sampling methods designed specifically to detect critical defects during various stages of production. By focusing on key areas where flaws are likely to occur, this approach enhances overall quality assurance efforts while minimizing potential hazards associated with defective products. Implementing robust quality control measures not only safeguards consumers but also fortifies brand integrity through consistent adherence to safety standards.

Major Defects

In the realm of quality assurance, major defects can significantly derail a product's functionality and customer satisfaction. These defects are not just minor annoyances; they can lead to product failures, safety hazards, and a tarnished brand reputation. For manufacturers relying on AQL Product Inspection, identifying and addressing these defects is crucial for maintaining high standards in quality control.

Identifying Major Defects in Products

Identifying major defects in products requires a keen eye and systematic approach during quality checks in manufacturing. These defects often manifest as functional issues that impede the product's intended use or performance. Common examples include mechanical failures, incorrect dimensions, or missing components—all of which can be spotted through rigorous AQL sampling techniques.

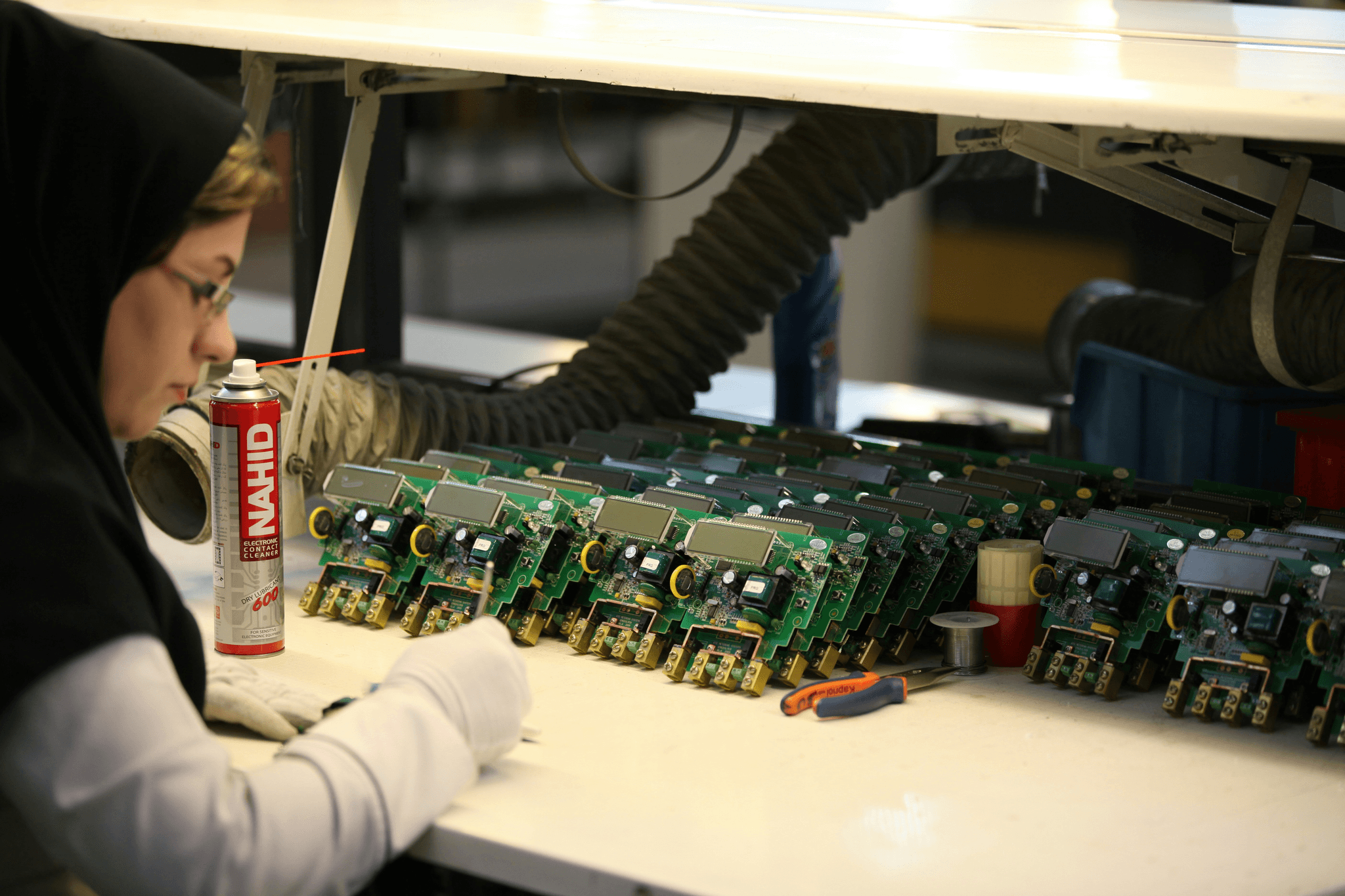

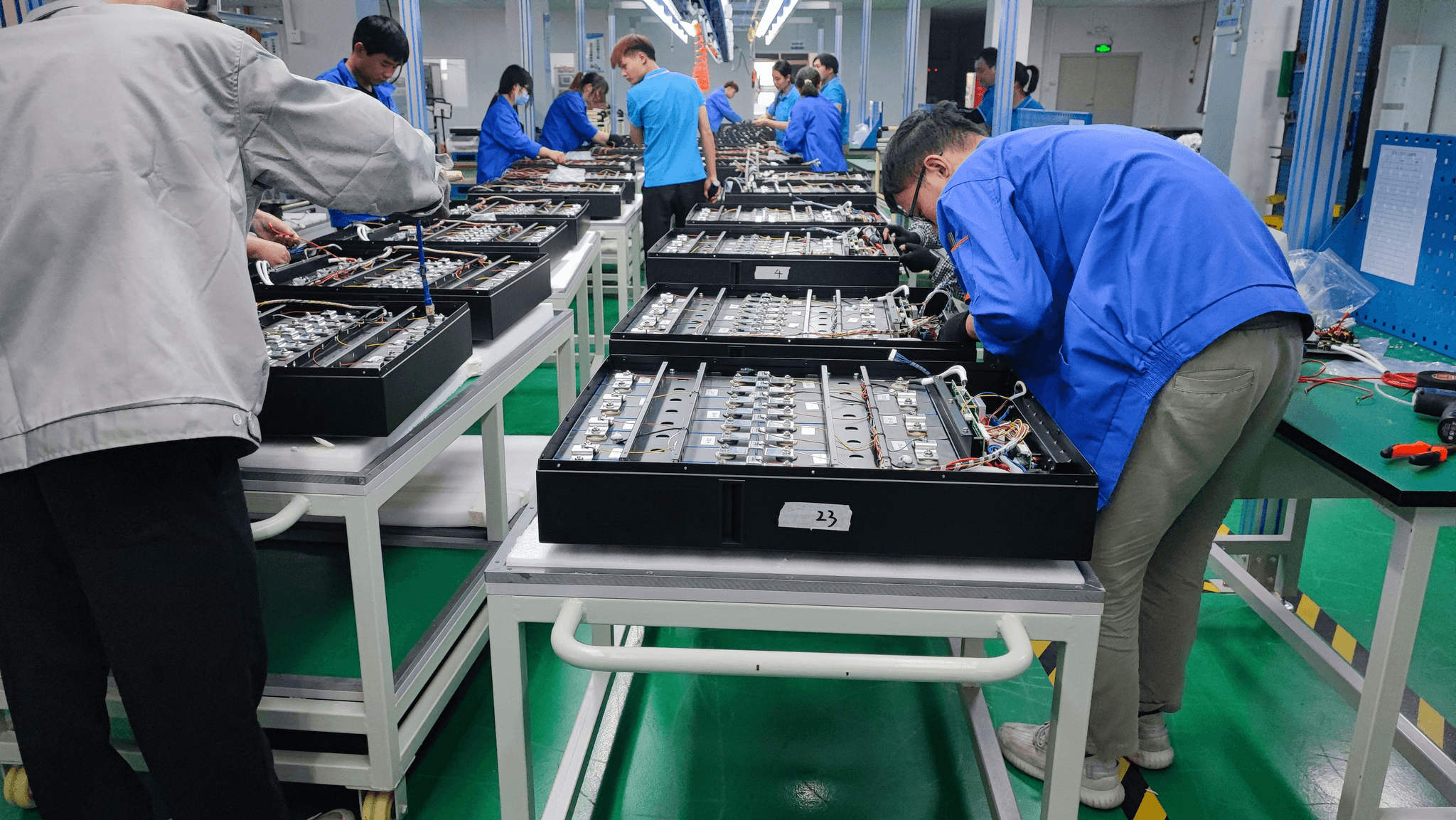

Quality control companies utilize various tools and methodologies to pinpoint these critical flaws effectively. By employing advanced testing procedures and thorough inspections, they can detect major defects before products reach consumers. This proactive stance not only enhances product reliability but also ensures compliance with industry standards.

Consequences for Functionality and Customer Satisfaction

The consequences of major defects extend beyond mere inconvenience; they can severely impact both functionality and customer satisfaction. When customers encounter defective products, their trust in the brand diminishes, leading to negative reviews and decreased loyalty. In competitive markets, where alternatives abound, even a single major defect can drive potential buyers away.

Moreover, the financial implications of recalls or returns due to major defects are significant for manufacturers. They face not only direct costs associated with rectifying issues but also long-term damage to their reputation as reliable providers of quality goods. Thus, addressing these concerns through effective quality control strategies is paramount for sustaining business success.

Tackling Major Defects with Quality Control Strategies

To tackle major defects head-on, manufacturers must implement robust quality control strategies throughout the production process. This begins with establishing clear standards for what constitutes acceptable quality levels during AQL Product Inspection procedures. Regular training sessions for staff involved in quality assurance can help ensure that everyone understands how to identify potential issues early on.

Additionally, employing statistical process control (SPC) methods allows companies to monitor production processes continuously for deviations from established norms—making it easier to catch problems before they escalate into costly defects. Utilizing feedback loops from customers also plays a vital role; by analyzing complaints related to functionality or performance issues, manufacturers can refine their processes accordingly.

Ultimately, embracing a culture of continuous improvement within organizations will enhance overall product quality while minimizing the risk of encountering major defects down the line.

Minor Defects

Minor defects are often the unsung heroes of quality checks in manufacturing, quietly lurking beneath the radar yet still capable of causing a ripple effect on the final product. These imperfections can range from slight cosmetic flaws to minor functional issues that don’t necessarily impede performance but can affect customer perception. Understanding how to identify and address these minor defects is crucial for maintaining high standards in AQL Product Inspection.

Understanding Minor Defects in Quality Checks

In the realm of quality control, minor defects are typically classified as those that do not significantly impact a product's functionality or safety but may affect its overall appearance or perceived value. For instance, a small scratch on a surface or an unevenly applied paint finish might qualify as a minor defect during quality checks in manufacturing. Recognizing these imperfections is essential for effective quality assurance, as they can accumulate and lead to dissatisfaction among consumers if left unchecked.

Implications for Aesthetic and Perceived Quality

While minor defects may not compromise product safety or functionality, they can have significant implications for aesthetic appeal and perceived quality. Customers often equate visual perfection with overall reliability; thus, even small blemishes can tarnish brand reputation and diminish consumer trust in the product's quality control measures. In today’s competitive market, where aesthetics play a pivotal role in purchase decisions, addressing these minor defects through thorough AQL sampling becomes essential to uphold brand integrity.

Managing Minor Defects through Quality Assurance Techniques

To effectively manage minor defects, companies must implement robust quality assurance techniques that focus on early detection and prevention during production processes. Regular inspections using AQL Product Inspection standards allow manufacturers to catch these issues before products reach consumers, ensuring that only items meeting aesthetic standards make it to market. Additionally, training staff on best practices for identifying minor defects can enhance overall quality control efforts and lead to improved customer satisfaction.

Conclusion

In the realm of AQL Product Inspection, understanding defect classifications is crucial for maintaining high standards in quality control and quality assurance. By categorizing defects into critical, major, and minor, manufacturers can implement targeted strategies to address issues effectively. This structured approach not only enhances product reliability but also boosts customer satisfaction and brand reputation.

Summary of Defect Classifications in AQL

The classification of defects within AQL Product Inspection serves as a foundational element in quality checks in manufacturing. Critical defects pose safety risks and compliance issues, while major defects can disrupt functionality and lead to customer dissatisfaction. Minor defects, although less impactful on performance, can still affect the perceived quality of products; hence all levels require attention through effective quality control measures.

Importance of Effective Quality Control Companies

Effective quality control companies play an indispensable role in ensuring that products meet established standards before reaching consumers. They utilize a combination of rigorous testing protocols and AQL sampling techniques to identify and rectify defects at all levels—critical, major, and minor. By investing in robust quality control and quality assurance processes, businesses can reduce returns, enhance customer loyalty, and ultimately drive profitability.

How China Inspection Pro Enhances Quality Inspection Services

China Inspection Pro stands out by providing comprehensive AQL Product Inspection services tailored to meet diverse manufacturing needs. Their expertise enables them to conduct thorough quality checks that identify critical defects early on while implementing solutions for major and minor discrepancies effectively. With a commitment to excellence in both quality control and quality assurance practices, they ensure that clients receive top-notch inspection services that bolster product integrity.