Introduction

In the ever-evolving world of automotive manufacturing, ensuring the quality of parts is not just a good practice; it's essential for safety and performance. Automotive Parts Inspections play a crucial role in identifying defects and ensuring that components meet stringent standards before they reach consumers. With the stakes so high, understanding the nuances of these inspections can make all the difference between a reliable vehicle and one that poses risks on the road.

Understanding the Importance of Inspections

Inspections serve as a vital checkpoint in the automotive supply chain, safeguarding against potential failures that could have catastrophic consequences. By implementing thorough Automotive Parts Inspections, manufacturers can catch issues early on, reducing costs associated with recalls and customer dissatisfaction. This proactive approach not only enhances product reliability but also builds trust with consumers who expect nothing less than excellence from their vehicles.

Key Elements of Automotive Parts Inspections

The landscape of Automotive Parts Inspections is multifaceted, encompassing various elements such as structural integrity checks, functionality assessments, and compliance with industry regulations. Each inspection type plays a pivotal role in verifying that parts are not only manufactured correctly but also function as intended under real-world conditions. A comprehensive Third Party Automotive Parts Inspection Checklist ensures that no detail is overlooked, providing an essential framework for quality assurance.

Benefits of Third Party Inspections

Engaging third-party inspection services offers numerous advantages that go beyond mere compliance; it brings an unbiased perspective to quality control processes. These experts provide rigorous evaluations based on established criteria while offering insights into Quantity Verification and adherence to standards for Style, Color & Documentation. Furthermore, leveraging third-party services like China Inspection Pro enhances overall product excellence by delivering actionable recommendations that help manufacturers navigate complex challenges effectively.

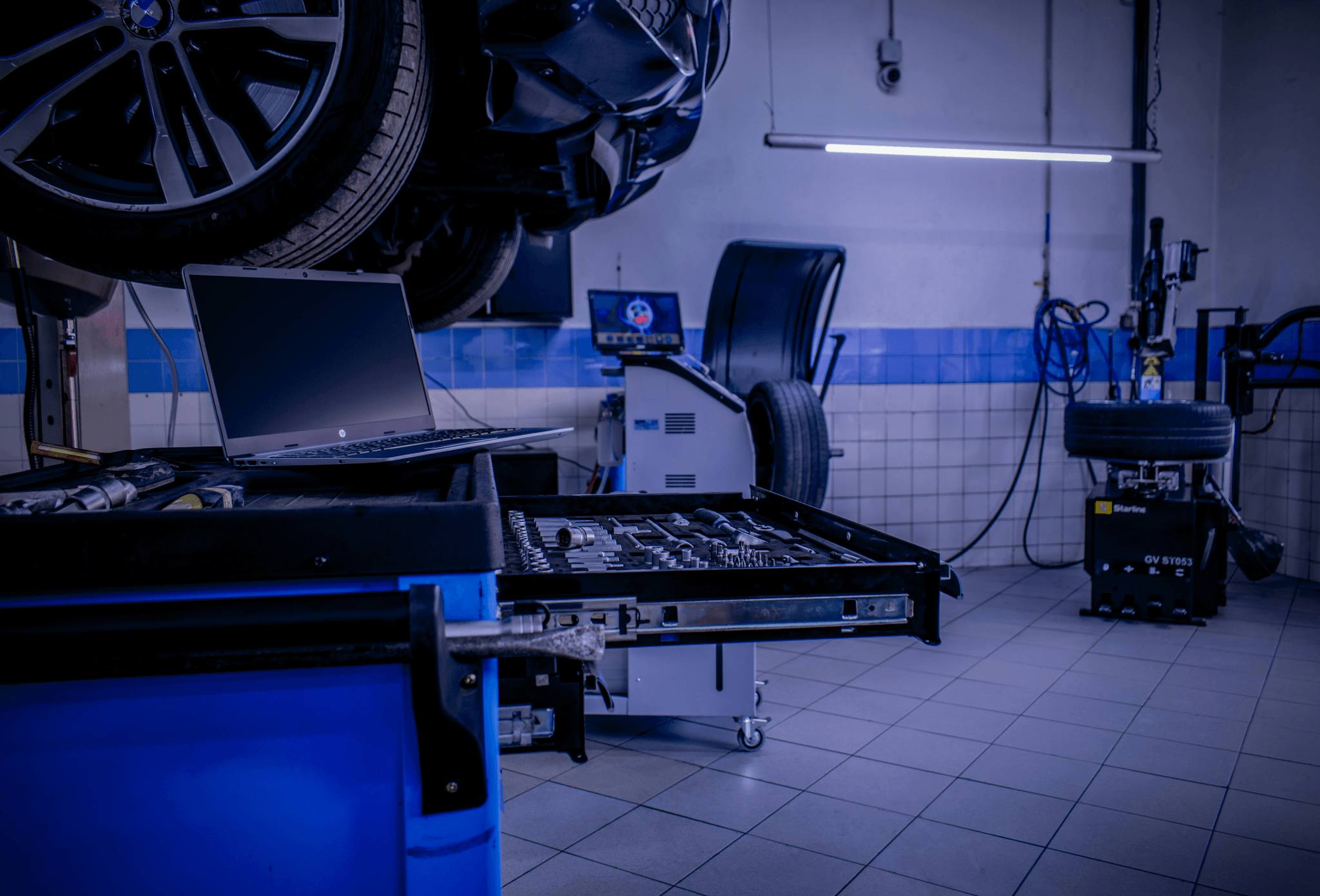

Overview of Automotive Parts Inspections

Automotive parts inspections are critical processes that ensure the quality, safety, and reliability of automotive components before they hit the market. These inspections serve a dual purpose: they help manufacturers maintain high standards while protecting consumers from faulty products. By implementing a thorough inspection regime, companies can prevent costly recalls and enhance their brand reputation.

Definition and Purpose

At its core, automotive parts inspections involve evaluating components for defects or deviations from specifications. The primary purpose is to verify that each part meets predetermined quality standards and regulatory requirements before being used in vehicle assembly. This ensures not only compliance with industry norms but also enhances overall vehicle performance and safety.

Types of Inspections Available

Various types of automotive parts inspections exist to cater to different needs within the manufacturing process. Common methods include visual inspections, functional tests, and dimensional checks to assess size and shape accuracy. Additionally, specialized inspections such as non-destructive testing (NDT) may be employed to evaluate structural integrity without damaging the part itself.

Role of Third Party Inspection Services

Third party inspection services play an essential role in the automotive industry by providing impartial assessments of parts quality. These independent entities utilize a comprehensive Third Party Automotive Parts Inspection Checklist that covers all critical aspects of inspection—including quantity verification, style conformity, and documentation accuracy. By leveraging their expertise, third-party inspectors help manufacturers identify potential issues early on while ensuring compliance with both market expectations and regulatory requirements.

Essential Third Party Automotive Parts Inspection Checklist

When it comes to ensuring the quality and reliability of automotive parts, a comprehensive Third Party Automotive Parts Inspection Checklist is indispensable. This checklist serves as a roadmap for inspectors to systematically evaluate critical aspects of automotive components. By adhering to this checklist, companies can enhance product quality, minimize defects, and ultimately ensure customer satisfaction.

Structural Integrity Checks

Structural integrity checks are fundamental in the realm of Automotive Parts Inspections. These checks assess the physical strength and durability of parts to ensure they can withstand operational stresses without failure. Inspectors typically examine welds, joints, and materials used in production, looking for signs of fatigue or weakness that could compromise safety.

Incorporating structural integrity checks into your Third Party Automotive Parts Inspection Checklist helps identify potential issues before they escalate into serious problems. For instance, a thorough examination can reveal cracks or deformities that may not be visible at first glance but could lead to catastrophic failures during use. Ensuring robust structural integrity is crucial not just for compliance but also for protecting lives on the road.

Functionality and Performance Assessment

Functionality and performance assessments are vital components of any effective inspection process in the automotive industry. Here, inspectors evaluate whether parts perform their intended functions under various conditions while meeting specified performance criteria. This includes testing components like brakes, engines, and electrical systems to verify their efficiency and reliability.

A detailed functionality assessment ensures that all parts meet the necessary operational standards outlined in your Third Party Automotive Parts Inspection Checklist. By simulating real-world conditions during testing, inspectors can identify any discrepancies or malfunctions that could affect overall vehicle performance. Ultimately, this step helps manufacturers deliver high-quality products that exceed consumer expectations.

Compliance with Industry Standards

Inspectors must familiarize themselves with relevant regulations and standards set forth by organizations such as ISO or SAE to ensure adherence during inspections. This involves evaluating documentation as well as conducting physical inspections to confirm compliance across all aspects.

Including compliance verification in your Third Party Automotive Parts Inspection Checklist reinforces accountability throughout the supply chain while safeguarding against legal repercussions down the line. Non-compliance can lead not only to financial losses but also damage a brand's reputation—something no manufacturer wants on their record! Thus, prioritizing compliance ensures both marketability and safety for consumers.

Quantity Verification: Ensuring Accuracy

In the realm of Automotive Parts Inspections, quantity verification is a critical component that ensures businesses receive exactly what they ordered. Accurate quantity checks not only prevent costly production delays but also ensure that inventory levels are maintained effectively. This process is particularly essential when dealing with large shipments or complex orders, where discrepancies can lead to significant operational setbacks.

Importance of Quantity Verification

Quantity verification serves as a safeguard against errors that could disrupt the supply chain and impact production schedules. When automotive parts inspections include thorough quantity checks, they help maintain trust between suppliers and manufacturers by ensuring that all parties are on the same page regarding order fulfillment. Moreover, accurate quantity verification contributes to better inventory management, reducing excess stock and minimizing waste.

Methods to Verify Parts Quantity

There are several effective methods for verifying parts quantity during automotive parts inspections. One common approach is conducting a physical count of items against shipping documents, which helps identify discrepancies early in the process. Another method involves utilizing technology such as barcode scanning or RFID systems to streamline accuracy and efficiency in tracking quantities throughout the supply chain.

Common Pitfalls in Quantity Verification

While quantity verification is essential, there are common pitfalls that can hinder this process during automotive parts inspections. One major issue arises from inadequate documentation; if shipping papers do not match actual counts, confusion can ensue leading to disputes or delays in production timelines. Additionally, relying solely on manual counting methods can introduce human error; thus it's crucial to implement systematic checks and balances within your third-party automotive parts inspection checklist for optimal results.

Evaluating Style, Color & Documentation

In the realm of Automotive Parts Inspections, evaluating style and color is just as critical as checking structural integrity. The aesthetics of automotive parts can significantly impact consumer perception and brand identity, making it essential to adhere to established standards. Additionally, thorough documentation ensures that all specifications are met and that any deviations are properly recorded.

Standards for Style and Color Matching

When it comes to style and color matching in Automotive Parts Inspections, consistency is key. Manufacturers often have specific guidelines outlining acceptable color codes and design elements that must be adhered to for each part. Third Party Automotive Parts Inspection Checklist should include a thorough review against these standards to ensure that all components not only fit functionally but also align visually with the intended design.

Furthermore, variations in color or style can lead to significant issues down the line, including customer dissatisfaction or even product recalls. Therefore, inspectors must employ tools like spectrophotometers for precise color measurements and visual aids for style comparisons. This diligence helps maintain brand integrity while ensuring compliance with industry expectations.

Importance of Documentation and Certifications

Documentation plays a crucial role in the inspection process of automotive parts; it serves as a record of compliance with industry standards and regulations. Certifications from recognized bodies validate that products have undergone rigorous testing and adhere to quality benchmarks set forth by governing organizations. In the context of Automotive Parts Inspections, having complete documentation can streamline processes such as Quantity Verification by providing clear evidence of what has been inspected and approved.

Moreover, accurate documentation allows manufacturers to trace back any issues related to non-conformance effectively. It provides a foundation for accountability within supply chains while promoting transparency among stakeholders involved in production and distribution processes. Without proper certifications or documentation, companies risk facing legal challenges or reputational damage due to subpar products entering the market.

How to Handle Non-Conformance

Non-conformance during inspections can happen despite best efforts; however, how you handle it makes all the difference in maintaining quality assurance standards in automotive parts manufacturing. First off, it's crucial to document any discrepancies thoroughly using your Third Party Automotive Parts Inspection Checklist as a guide; this will help elucidate exactly where things went wrong—whether it's an issue with style mismatching or incorrect colors being used.

Next steps involve communicating these findings promptly with relevant teams—whether they are internal stakeholders or external suppliers—to initiate corrective actions swiftly before they escalate into larger problems impacting Quantity Verification processes down the line. Establishing procedures for addressing non-conformance not only mitigates risks but also fosters a culture of continuous improvement within your organization.

Finally, implementing follow-up inspections after corrective measures have been taken ensures that changes made are effective; this is where China Inspection Pro excels! Their expertise means you’ll get actionable recommendations based on detailed evaluations so you can confidently move forward knowing your automotive parts meet both market expectations and regulatory requirements.

Shipping Mark and Packaging: What to Know

When it comes to Automotive Parts Inspections, the significance of shipping marks and packaging cannot be overstated. Proper shipping marks ensure that parts are easily identifiable, facilitating smooth transit and reducing the risk of mix-ups or damage during transportation. This is particularly crucial in a global supply chain where automotive parts are often shipped across multiple borders before reaching their final destination.

Role of Proper Shipping Marks

Proper shipping marks serve as vital indicators that communicate important information about the contents of a shipment. They provide details such as handling instructions, destination addresses, and contents, which are essential for ensuring that automotive parts reach their intended recipients without mishaps. Furthermore, clear shipping marks help third-party inspection services quickly verify compliance with the Third Party Automotive Parts Inspection Checklist by allowing for immediate identification of parts during inspections.

Incorporating standard symbols and barcodes can enhance efficiency in tracking shipments while minimizing human error. For instance, using QR codes can streamline quantity verification processes by linking directly to digital records of inspected items. Thus, proper shipping marks not only facilitate logistics but also enhance overall quality assurance efforts in automotive parts inspections.

Best Practices for Packaging Automotive Parts

Packaging plays an equally critical role in protecting automotive components throughout their journey from manufacturer to end-user. Best practices suggest using durable materials that can withstand environmental factors such as moisture and temperature fluctuations during transit. Additionally, cushioning materials like foam or bubble wrap should be employed to minimize movement within packages, thereby safeguarding against potential damage during handling.

Another best practice involves labeling packages clearly with both internal content descriptions and external shipping information to streamline the inspection process upon arrival at the destination. This clarity aids third-party inspectors in conducting thorough evaluations based on established standards for style, color & documentation compliance as outlined in prior sections of this guide. Ultimately, well-packaged automotive parts not only protect investments but also contribute significantly to customer satisfaction.

Impact of Packaging on Product Integrity

The integrity of packaged automotive parts is paramount; inadequate packaging can lead to compromised quality even before they reach the inspection phase. Damaged components due to poor packaging may fail quality assurance checks or even result in costly returns or replacements later on—an outcome no business wants to face! Moreover, effective packaging helps maintain compliance with industry standards by ensuring products arrive in pristine condition ready for installation or sale.

Furthermore, well-executed packaging strategies reflect positively on a company's commitment to quality assurance practices like those offered by China Inspection Pro—a leader in delivering professional services focused on product excellence through rigorous inspections and actionable recommendations. By prioritizing proper shipping marks and robust packaging solutions within your operations, you can significantly elevate your overall product integrity while meeting market expectations consistently.

Conclusion

In the fast-paced world of automotive manufacturing, ensuring quality is paramount. Automotive Parts Inspections play a critical role in maintaining high standards and safeguarding against defects that could lead to significant issues down the line. By implementing thorough inspections, companies can enhance product reliability and customer satisfaction, ultimately driving business success.

Enhancing Quality Through Inspections

The importance of a comprehensive Third Party Automotive Parts Inspection Checklist cannot be overstated. This checklist serves as a vital tool for identifying potential problems early in the production process, allowing manufacturers to address issues before they escalate. From structural integrity checks to compliance with industry standards, these inspections are essential for delivering high-quality automotive parts.

Moreover, regular inspections contribute to effective Quantity Verification processes that ensure manufacturers receive the correct number of parts without discrepancies. This level of accuracy not only streamlines production but also builds trust between suppliers and clients. Ultimately, enhancing quality through inspections leads to fewer recalls and greater consumer confidence in automotive products.

Choosing the Right Inspection Service

Selecting an appropriate inspection service is crucial for any organization striving for excellence in automotive parts manufacturing. It’s essential to consider factors such as experience, expertise in specific inspection areas like Style, Color & Documentation, and the ability to provide actionable insights based on findings. A trustworthy inspection partner will also help navigate common pitfalls associated with quantity verification and packaging challenges.

Additionally, inspecting shipping marks and packaging integrity can significantly impact product delivery and customer satisfaction rates. The right inspection service should have proven methodologies tailored specifically for the automotive industry’s unique needs. With a reliable partner by your side, you can rest assured that your products meet or exceed all necessary standards.

The Role of China Inspection Pro in Quality Assurance

China Inspection Pro stands out as a leader in providing top-notch quality assurance services tailored for the automotive sector. Our specialists rigorously examine every detail during Automotive Parts Inspections to ensure compliance with industry regulations while identifying areas for improvement through our comprehensive Third Party Automotive Parts Inspection Checklist. We understand that proper documentation is critical; thus we emphasize Style, Color & Documentation accuracy throughout our processes.

With deep experience and advanced methodologies at our disposal, we guide you through complex challenges related to Quantity Verification and shipping requirements effectively—ensuring your products satisfy market expectations without compromising on quality or safety standards. Trust China Inspection Pro to elevate your quality assurance efforts; we turn findings into clear recommendations that sharpen decision-making across your supply chain.