Introduction

In the bustling world of seafood production and distribution, Quality Control for seafood plays a pivotal role in ensuring that consumers receive safe and high-quality products. With the increasing demand for seafood globally, understanding the nuances of quality control becomes essential not only for regulatory compliance but also for maintaining consumer trust. This introduction sets the stage to explore why quality control for seafood is important, what common quality inspections are conducted, and how these practices shape the industry.

Understanding Quality Control for Seafood

Quality Control for seafood encompasses a series of systematic processes aimed at maintaining and enhancing product quality throughout the supply chain. It involves rigorous testing and inspection protocols that assess various attributes of seafood products, from freshness to safety standards. By implementing effective quality control measures, producers can ensure that their offerings meet both customer expectations and regulatory guidelines.

Importance of Quality Inspections

Why is quality control for seafood important? The answer lies in its ability to protect consumer health by identifying potential hazards such as contaminants or spoilage before products reach the market. Additionally, effective quality inspections help prevent economic losses caused by recalls or reputation damage due to subpar products. As consumers become more health-conscious and discerning about their food choices, maintaining high standards through regular inspections has never been more critical.

Common Practices in Seafood Quality Control

What are common quality inspections for seafood? The industry employs a variety of practices including sensory evaluation techniques that assess appearance, smell, and texture; microbial testing methods that check for harmful bacteria; and chemical residue analysis to ensure compliance with safety regulations. These inspections are vital components of a comprehensive quality management system that not only safeguards public health but also enhances brand reputation in a competitive marketplace.

Overview of Quality Control in Seafood

In the seafood industry, quality control is a systematic approach to ensuring that products meet specific standards and consumer expectations. Effective quality control for seafood encompasses various practices that monitor and evaluate the product from catch to consumption. This segment delves into defining quality control, highlighting key components of quality assurance, and understanding the regulatory landscape that governs seafood safety and quality.

Defining Quality Control for Seafood

Quality control for seafood refers to the processes and procedures implemented to maintain the desired level of quality throughout the supply chain. This involves assessing factors such as freshness, taste, texture, and safety to ensure that consumers receive safe and high-quality products. By establishing clear guidelines and protocols, businesses can mitigate risks associated with spoilage or contamination, which is crucial given the perishable nature of seafood.

Key Components of Quality Assurance

Key components of quality assurance in seafood include sensory evaluations, microbiological testing, and adherence to established standards. Sensory evaluations focus on visual appearance, smell, texture, and taste—essential attributes that contribute to consumer satisfaction. Additionally, rigorous microbial testing methods are employed to detect pathogens or spoilage organisms in seafood products; this is vital when considering why is quality control for seafood important? Ensuring that products are free from harmful microorganisms protects consumer health while also safeguarding brand reputation.

Regulatory Standards and Compliance

Regulatory standards play a pivotal role in maintaining quality control for seafood by providing guidelines on acceptable practices within the industry. Organizations such as the Food Safety Authority (FSA) set forth regulations that ensure compliance with safety protocols during harvesting, processing, distribution, and sale of seafood products. Companies must adhere to these regulations not only to avoid legal repercussions but also because compliance fosters trust among consumers who demand safe eating experiences.

Why is Quality Control for Seafood Important?

Quality control for seafood is not just a regulatory checkbox; it’s a lifeline for consumers, businesses, and the entire industry. The stakes are high when it comes to ensuring that seafood products are safe, fresh, and of high quality. This section delves into three critical reasons why quality control for seafood is essential: protecting consumer health, preventing economic losses, and enhancing brand reputation.

Protecting Consumer Health

One of the primary reasons why quality control for seafood is important is its role in safeguarding consumer health. Contaminated or spoiled seafood can lead to serious health risks such as foodborne illnesses, which can be detrimental not only to individuals but also to public health systems. By implementing robust quality inspections, such as microbial testing methods and sensory evaluations, businesses can ensure their products are safe for consumption.

Moreover, stringent quality control measures help detect harmful substances like heavy metals and pesticides that may infiltrate the supply chain. Regular inspections contribute significantly to maintaining high safety standards in the industry. Ultimately, protecting consumer health through effective quality control fosters trust between producers and consumers alike.

Preventing Economic Losses

Economic losses due to poor-quality seafood can be staggering—think recalls, lost sales, and damaged reputations! Quality control for seafood plays a pivotal role in mitigating these risks by identifying issues before they escalate into costly problems. For example, if a batch of fish fails inspection due to spoilage or contamination, addressing the issue early can save companies from significant financial fallout.

Additionally, maintaining consistent quality helps businesses avoid penalties associated with non-compliance with regulatory standards. The investment in regular quality inspections pays off by ensuring that products meet market expectations while reducing waste and inefficiencies in production processes. In short, effective quality control translates directly into healthier profit margins.

Enhancing Brand Reputation

In today’s competitive marketplace, brand reputation is everything—and nothing tarnishes it faster than poor-quality products! Quality control for seafood enhances brand reputation by ensuring that consumers receive only the best products available. When companies prioritize rigorous inspections and adhere to high-quality standards consistently, they build loyalty among customers who value safety and reliability.

Furthermore, positive word-of-mouth generated from satisfied customers can serve as powerful marketing—after all, who doesn’t want to recommend a trustworthy brand? Engaging with organizations like China Inspection Pro can help businesses adopt best practices in quality management while reinforcing their commitment to excellence within the industry. By investing in robust quality assurance processes today, companies lay the groundwork for lasting success tomorrow.

What Are Common Quality Inspections for Seafood?

Quality inspections are crucial in maintaining the integrity and safety of seafood products. In the pursuit of ensuring top-notch Quality Control for seafood, various inspection methods are employed to evaluate freshness, safety, and compliance with regulatory standards. Understanding these common quality inspections can shed light on Why is quality control for seafood important?

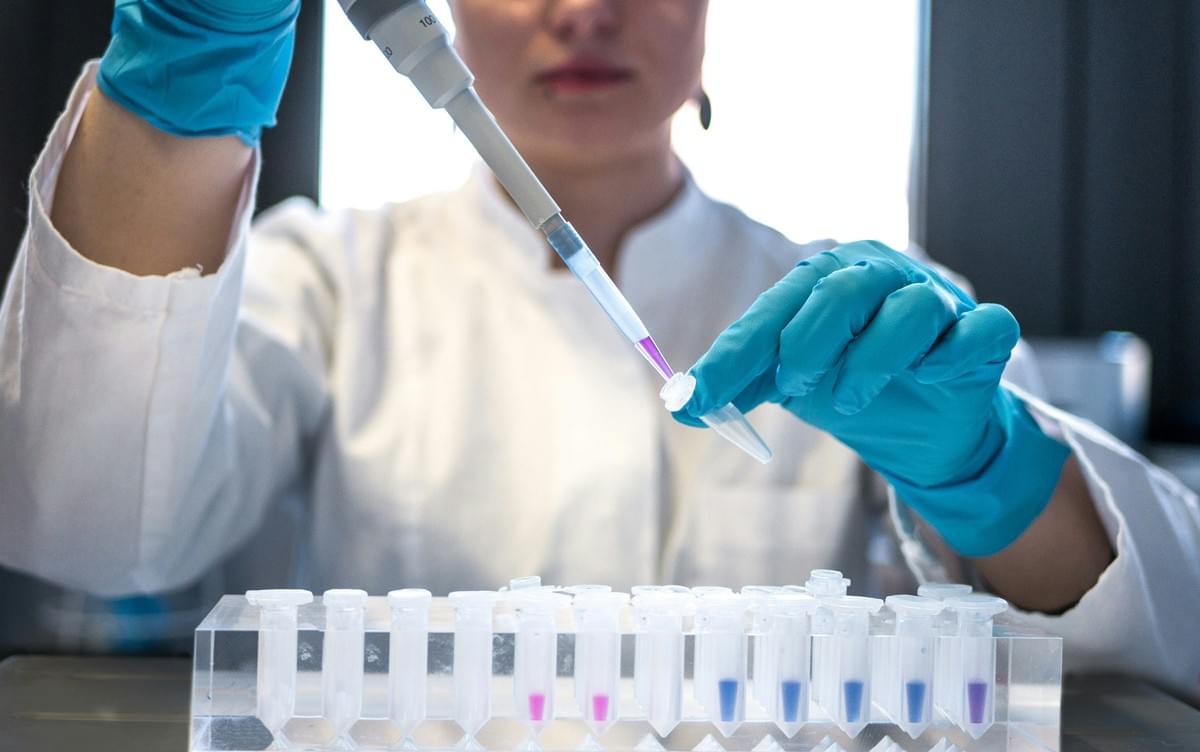

Sensory Evaluation Techniques

Sensory evaluation techniques are fundamental in assessing the quality of seafood through human senses—sight, smell, taste, touch, and hearing. Trained inspectors examine factors such as color, texture, odor, and overall appearance to gauge freshness and quality. This method not only provides immediate feedback but also helps identify any off-flavors or spoilage issues that could impact consumer health.

Incorporating sensory evaluation into Quality Control for seafood allows companies to ensure their products meet high standards before they reach consumers’ plates. By relying on experienced assessors who can detect subtle nuances in flavor and texture, businesses can significantly reduce the risk of delivering subpar products to market. Ultimately, this technique reinforces Why is quality control for seafood important? by directly influencing consumer satisfaction.

Microbial Testing Methods

Microbial testing methods play a vital role in safeguarding public health by detecting harmful bacteria and pathogens in seafood products. These tests often involve sampling raw materials at various stages of production to ensure compliance with food safety regulations. Common tests include detecting Salmonella spp., Listeria monocytogenes, and Vibrio species—all notorious culprits behind foodborne illnesses.

Implementing rigorous microbial testing is a critical aspect of Quality Control for seafood that helps prevent economic losses associated with product recalls or reputational damage from food safety incidents. Companies that prioritize these tests demonstrate their commitment to protecting consumers while enhancing their brand reputation within a competitive marketplace. When stakeholders understand Why is quality control for seafood important? they recognize that microbial testing is more than just a regulatory requirement; it's essential for trust-building with consumers.

Chemical Residue Analysis

Chemical residue analysis involves scrutinizing seafood products for contaminants such as pesticides, heavy metals, or veterinary drugs that may pose health risks to consumers. This analysis ensures that all products comply with established regulatory standards while providing transparency regarding what goes into our food supply chain. With increasing public awareness about food safety issues globally, this type of inspection has become increasingly relevant.

Conducting thorough chemical residue analysis is an indispensable part of Quality Control for seafood operations because it assures customers about the purity and safety of what they consume. Moreover, it addresses concerns related to environmental sustainability by monitoring harmful substances entering marine ecosystems from agricultural runoff or industrial processes. By understanding What are common quality inspections for seafood?, stakeholders can appreciate how chemical residue analysis contributes significantly to Why is quality control for seafood important?

Role of Technology in Seafood Quality Control

In the ever-evolving landscape of seafood quality control, technology plays a pivotal role in enhancing efficiency and precision. As the industry faces increasing demands for transparency and safety, integrating advanced technological solutions becomes essential. This section delves into automation in quality inspections, data analytics for quality improvement, and traceability systems that ensure a robust seafood supply chain.

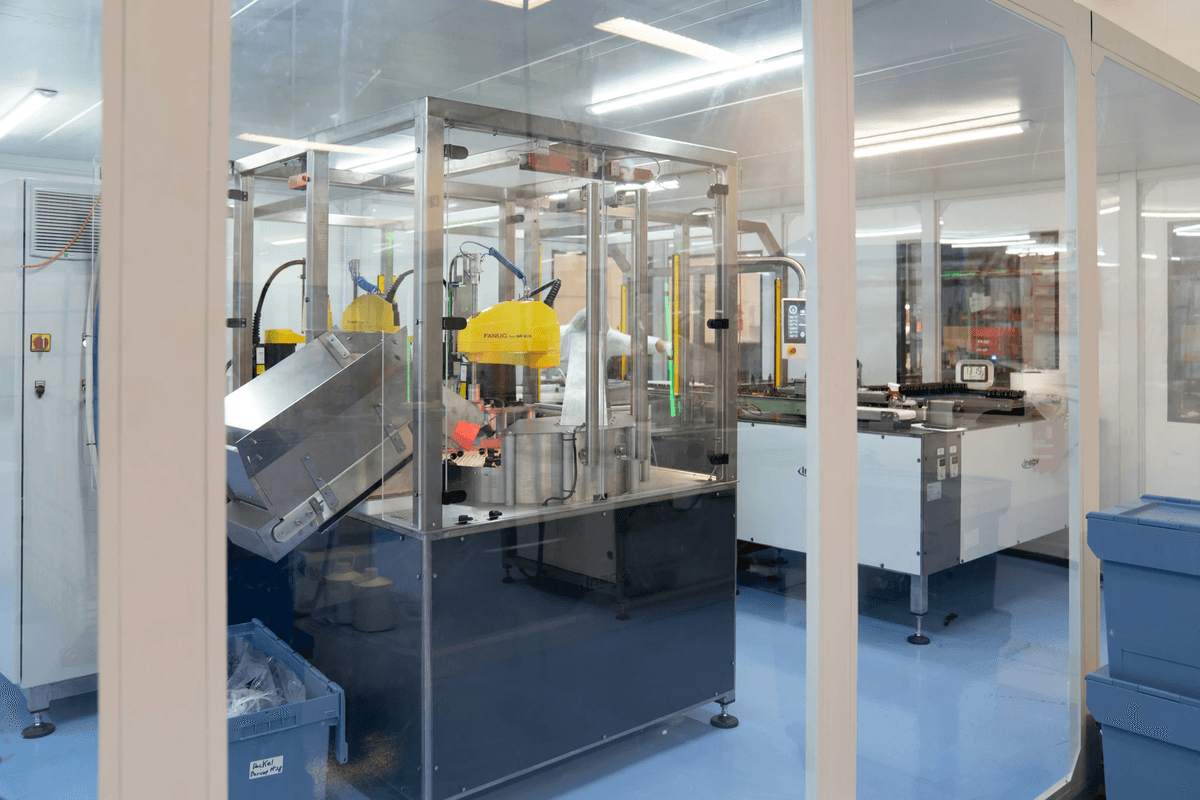

Automation in Quality Inspections

Automation is revolutionizing quality control for seafood by streamlining inspection processes and reducing human error. Automated systems utilize advanced imaging technologies and sensors to assess product quality rapidly, ensuring consistency across batches. With automation, companies can conduct real-time inspections that not only enhance accuracy but also significantly reduce inspection times—an essential factor given the perishable nature of seafood.

Moreover, automated inspections can be integrated with machine learning algorithms to adapt and improve over time based on historical data. This adaptability allows for more nuanced assessments of what constitutes acceptable quality standards within the seafood industry. By employing automation in quality inspections, businesses can better address the question: Why is quality control for seafood important? The answer lies in enhanced safety measures and increased consumer trust.

Data Analytics for Quality Improvement

Data analytics serves as a cornerstone for continuous improvement within seafood quality control practices. By collecting extensive data from various stages of production—from harvesting to distribution—companies can identify trends and potential areas of concern related to product quality. This analytical approach enables businesses to make informed decisions that proactively address issues before they escalate into larger problems.

Additionally, leveraging data analytics allows firms to benchmark their performance against industry standards or competitors, providing insights into where improvements are needed most urgently. The ability to transform raw data into actionable recommendations is vital; it enhances overall product excellence while addressing common inquiries about what are common quality inspections for seafood. Ultimately, effective use of data analytics leads not only to improved products but also reinforces brand reputation among consumers who prioritize safety.

Traceability Systems in Seafood Supply Chain

Traceability systems have become indispensable tools in ensuring accountability throughout the seafood supply chain—a crucial element when discussing why is quality control for seafood important? These systems enable stakeholders at every level—from fishermen to retailers—to track products from their origin through processing and distribution channels seamlessly. In an era where consumers demand transparency regarding food sources, such traceability fosters trust while ensuring compliance with regulatory standards.

Implementing robust traceability systems also helps mitigate risks associated with recalls or contamination events by allowing companies to quickly identify affected batches and take corrective action promptly. Moreover, these systems provide valuable insights that can inform future production practices aimed at improving overall product integrity within the industry’s framework of common quality inspections for seafood. As technology continues evolving, so too will these traceability solutions—ultimately shaping a safer and more reliable marketplace.

Real-World Examples of Quality Control in Action

Quality control for seafood is not just a theoretical concept; it’s a practice that has been successfully implemented in various countries. These real-world examples illustrate the importance of quality inspections and how they can impact consumer safety, economic stability, and brand reputation. By examining these case studies, we can glean insights into effective quality control practices that can be adopted globally.

Case Study: Norway’s Seafood Inspection Protocols

Norway is renowned for its stringent seafood inspection protocols that ensure high-quality standards throughout the supply chain. The country employs a comprehensive approach to quality control for seafood, which includes regular audits, sensory evaluations, and rigorous testing for contaminants. Why is quality control for seafood important in Norway? It not only protects consumer health but also enhances the global reputation of Norwegian seafood products.

The Norwegian Food Safety Authority (Mattilsynet) oversees these inspection protocols and collaborates with industry stakeholders to ensure compliance with regulatory standards. Their proactive measures include training programs for fishermen and processors to understand the significance of quality inspections. As a result, Norway has established itself as a leader in seafood quality management, showcasing how effective practices can yield positive outcomes.

Insights from China Inspection Pro

China Inspection Pro provides valuable insights into the complexities of implementing quality control for seafood in one of the world’s largest markets. Their approach focuses on delivering professional services aimed at product excellence through meticulous inspections that adhere to international standards. What are common quality inspections for seafood conducted by China Inspection Pro? They include microbial testing methods and chemical residue analysis to ensure products meet safety regulations.

Their specialists conduct thorough examinations at every stage of production, turning findings into clear recommendations that enhance decision-making processes within companies. This commitment to excellence highlights why is quality control for seafood crucial—not only does it safeguard public health, but it also helps businesses avoid economic losses due to non-compliance or product recalls. By leveraging advanced methodologies and deep expertise, China Inspection Pro exemplifies how robust inspection protocols can elevate overall industry standards.

Lessons from the U.S. Seafood Industry

The U.S. seafood industry offers a wealth of lessons regarding effective quality control practices aimed at ensuring safe consumption and maintaining brand integrity. Various federal agencies oversee strict regulatory frameworks that dictate common quality inspections for seafood products—ranging from sensory evaluation techniques to extensive microbial testing methods tailored to specific species and regions.

One notable initiative is the Seafood Hazard Analysis Critical Control Point (HACCP) program which emphasizes preventive measures throughout production processes to mitigate risks associated with contamination or spoilage. Understanding why is quality control for seafood vital within this context helps stakeholders appreciate its role in enhancing brand reputation while protecting consumer health against potential hazards inherent in marine products.

By learning from these diverse examples—whether it's Norway's rigorous inspection protocols or China's innovative approaches through China Inspection Pro—the global community can adopt best practices that elevate the standard of safety and excellence across all facets of the seafood industry.

Conclusion

In the world of seafood, quality control is not just a regulatory requirement; it's a vital part of maintaining consumer trust and ensuring product excellence. As we’ve explored, understanding why quality control for seafood is essential helps stakeholders appreciate its role in safeguarding public health and enhancing brand reputation. By implementing rigorous quality inspections, the seafood industry can mitigate risks associated with contamination and spoilage, thereby reinforcing its commitment to delivering safe and high-quality products.

Key Takeaways on Seafood Quality Control

Quality control for seafood encompasses a variety of practices aimed at ensuring that products meet safety standards and consumer expectations. Among the key takeaways is the importance of common quality inspections for seafood, which include sensory evaluations, microbial testing, and chemical residue analysis. Additionally, regulatory compliance plays a crucial role in maintaining industry credibility; adhering to established guidelines not only protects consumers but also supports businesses in avoiding costly legal repercussions.

Impact of Quality Inspections on the Industry

The impact of quality inspections on the seafood industry cannot be overstated. These inspections serve as a critical line of defense against potential health hazards that could arise from contaminated or subpar products. Furthermore, by prioritizing quality control for seafood through systematic inspection processes, companies can enhance their brand reputation and build consumer loyalty—factors that are increasingly important in today’s competitive marketplace.

Future Trends in Seafood Quality Management

Looking ahead, several trends are likely to shape the future landscape of seafood quality management. The integration of technology will play an increasingly pivotal role; automation and data analytics will streamline inspection processes while improving accuracy in detecting issues before they escalate. Moreover, advancements in traceability systems will empower consumers with greater visibility into product origins—an essential factor as they become more conscious about food safety practices related to quality control for seafood.