Introduction

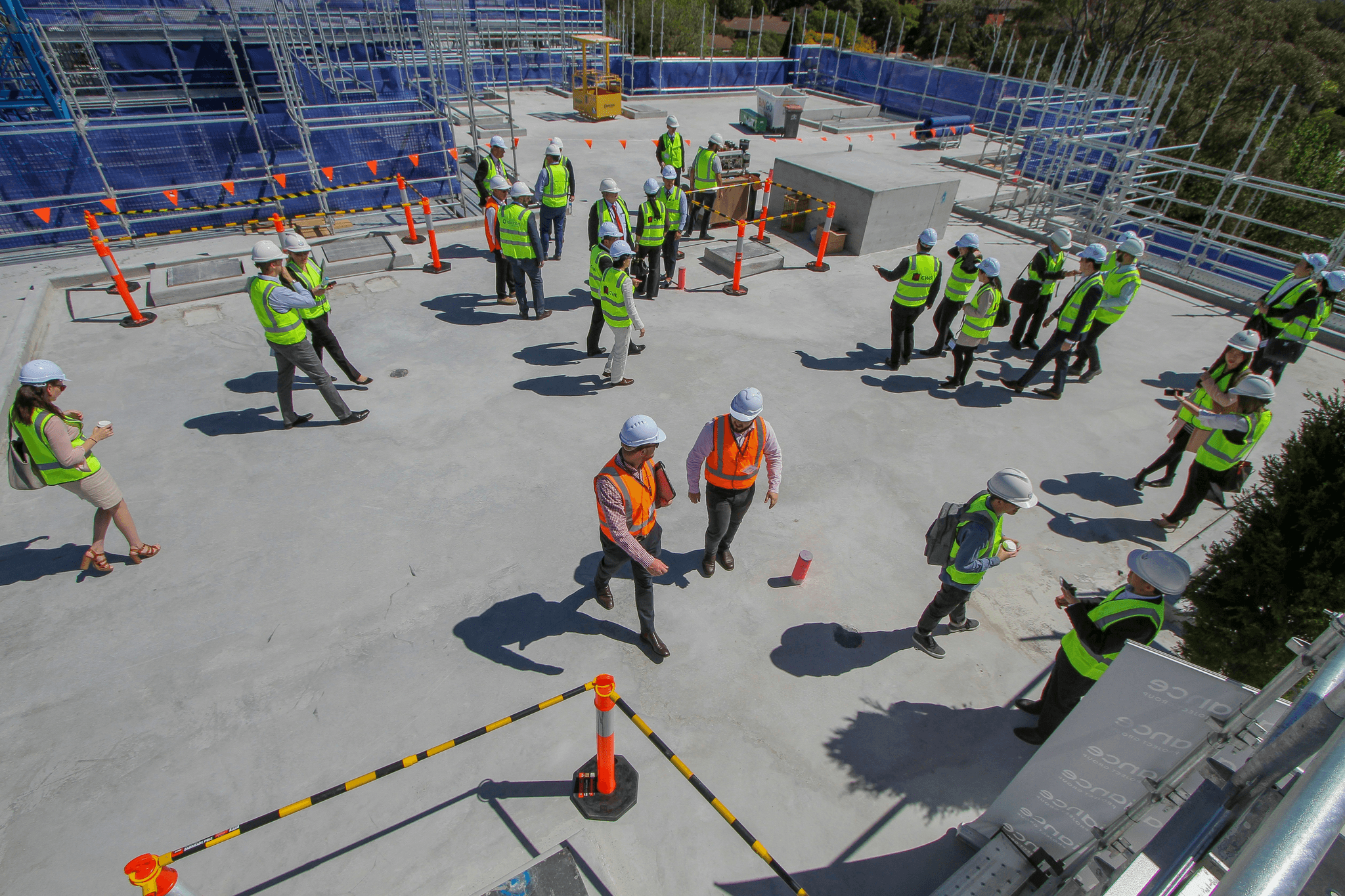

In the ever-evolving landscape of construction, on-site quality control has emerged as a cornerstone for delivering projects that meet or exceed expectations. This meticulous approach not only ensures that structures are built to last but also fosters a culture of excellence among teams. By understanding the intricacies of on-site quality control, stakeholders can significantly enhance project outcomes and client satisfaction.

Understanding On-Site Quality Control

On-site quality control encompasses a series of systematic processes designed to monitor and manage the quality of construction activities in real-time. It involves rigorous inspections, adherence to established standards, and proactive problem-solving to mitigate risks before they escalate. By embedding these practices into daily operations, teams can ensure that every aspect of the project aligns with predefined quality objectives.

Importance of Quality Objectives in Construction

Quality objectives serve as guiding stars in the chaotic realm of construction projects, providing clear benchmarks for success. These objectives help align team efforts with client expectations while ensuring compliance with regulatory requirements and industry standards. Moreover, establishing robust quality objectives allows for continuous assessment and adjustment throughout the project lifecycle, paving the way for enhanced performance.

Overview of Effective Quality Management Techniques

Effective quality management techniques are essential for creating a cohesive framework that supports on-site quality control initiatives. From developing a comprehensive quality manual to implementing rigorous document control systems, these techniques foster accountability and transparency within teams. Additionally, streamlining process management and resource management strategies ensures optimal utilization of assets while enhancing product realization procedures across all phases of construction.

Establishing Quality Objectives

Establishing clear quality objectives is the cornerstone of effective on-site quality control in construction projects. These objectives not only guide the team but also ensure that every aspect of the project aligns with the desired outcomes. By setting robust quality objectives, teams can enhance their focus on delivering superior results while adhering to industry standards.

Setting Clear and Measurable Goals

To kick off the process, it's essential to set clear and measurable goals that can be tracked throughout the project lifecycle. This involves defining specific metrics for success—such as reducing defects or improving client satisfaction—that can be quantified and evaluated regularly. Such clarity helps teams understand what is expected, allowing them to align their efforts with the overarching quality manual and ultimately improve on-site quality control.

Moreover, measurable goals encourage accountability among team members, fostering a culture of responsibility where everyone knows their role in achieving these targets. Regularly revisiting these goals ensures they remain relevant as the project evolves, making adjustments as necessary to keep everyone aligned with project specifications. In this way, setting clear and measurable goals becomes a dynamic process that drives continuous improvement.

Aligning Objectives with Project Specifications

Once clear goals are established, aligning these objectives with project specifications is crucial for ensuring successful outcomes. This alignment guarantees that all stakeholders—from contractors to suppliers—are working toward a common vision that meets both client expectations and regulatory requirements. By integrating quality objectives into daily operations, teams can maintain a consistent focus on delivering high-quality results.

Furthermore, this alignment facilitates better communication among team members regarding what constitutes acceptable performance levels in terms of resource management and product realization processes. When everyone understands how their tasks contribute to overall project success, it enhances collaboration and minimizes misunderstandings related to quality standards outlined in the quality manual. Ultimately, this synergy fosters an environment where on-site quality control thrives.

Continuous Monitoring and Adjustment

Continuous monitoring and adjustment are vital for maintaining momentum toward achieving established quality objectives throughout a project's lifespan. Implementing regular check-ins allows teams to assess if they are meeting their goals while identifying areas needing improvement or recalibration based on real-time feedback from document control systems or process management strategies already in place.

This iterative approach not only helps catch potential issues early but also reinforces a culture of adaptability within teams—an essential trait for successful resource management amid changing circumstances on-site. By embracing flexibility while staying committed to predefined objectives, organizations can ensure ongoing progress toward optimal product realization without compromising overall construction integrity or timelines.

In summary, establishing well-defined quality objectives is fundamental for effective construction projects focused on enhancing on-site quality control practices through strategic goal-setting aligned with specifications alongside continuous monitoring efforts.

Developing a Comprehensive Quality Manual

A well-crafted Quality Manual is the backbone of effective on-site quality control in construction. It serves as a guiding document that outlines the quality objectives and processes necessary to achieve high standards throughout the project lifecycle. By detailing procedures, responsibilities, and standards, a Quality Manual ensures everyone involved understands their role in maintaining quality.

Key Components of a Quality Manual

The key components of a Quality Manual include clear definitions of quality objectives, detailed process management protocols, and guidelines for document control. Each section should be tailored to fit specific project requirements while also aligning with overarching industry standards. Additionally, it should encompass resource management strategies that outline how personnel and materials are allocated to meet these quality objectives.

Moreover, incorporating sections on product realization can greatly enhance the manual’s effectiveness. This means including best practices for developing products that meet client expectations while adhering to safety regulations. A comprehensive approach ensures that all aspects of construction are covered, promoting consistency in on-site quality control.

Ensuring Compliance with Industry Standards

Compliance with industry standards is crucial for any construction project aiming for success and sustainability. The Quality Manual must reference applicable regulations and best practices that govern construction activities within your region or sector. Regular reviews and updates will help ensure ongoing compliance as industry standards evolve over time.

Furthermore, ensuring compliance not only protects your organization from potential legal issues but also enhances your reputation among clients and stakeholders alike. By demonstrating adherence to established norms through your Quality Manual, you reinforce trust in your capabilities regarding on-site quality control measures. This trust translates into long-term relationships with clients who value consistent quality outcomes.

Training Staff on Quality Manual Implementation

Training staff effectively is essential for successful implementation of the Quality Manual across all levels of an organization. This involves conducting workshops or seminars focused on key elements such as document control procedures and process management techniques outlined in the manual. Engaging employees through hands-on training fosters a culture where everyone takes ownership of their role in achieving quality objectives.

Beyond initial training sessions, continuous learning opportunities should be provided to keep staff updated about changes in industry standards or internal processes related to resource management and product realization strategies. Encouraging feedback during these sessions can also lead to improvements in both the manual itself and its implementation practices on site. Ultimately, well-trained personnel are pivotal for ensuring that every aspect of construction aligns with established quality benchmarks.

Implementing Document Control Systems

In the fast-paced world of construction, implementing robust document control systems is crucial for maintaining on-site quality control. Efficient document management ensures that all project-related documents, from contracts to quality manuals, are organized and accessible. This not only fosters effective communication among stakeholders but also supports the achievement of Quality Objectives throughout the project lifecycle.

Importance of Document Management in Construction

Document management plays a pivotal role in ensuring that construction projects adhere to established Quality Objectives. With multiple teams working simultaneously, having a centralized system for storing and retrieving documents mitigates the risk of miscommunication and errors. Additionally, well-managed documentation supports compliance with industry standards outlined in the Quality Manual, ultimately enhancing overall project success.

Tools for Efficient Document Control

To streamline document control processes, various tools can be utilized to enhance on-site quality control efforts. Digital platforms like cloud storage solutions and project management software enable real-time updates and easy access to critical documents for all team members. These tools not only improve efficiency but also facilitate better resource management by ensuring that everyone is on the same page regarding project specifications and quality requirements.

Regular Audits for Document Accuracy

Conducting regular audits is essential for maintaining document accuracy within any construction project. By systematically reviewing documents against established standards in the Quality Manual, teams can identify discrepancies early on and implement corrective actions promptly. This proactive approach not only boosts confidence in process management but also reinforces commitment to achieving high-quality outcomes through diligent resource management practices.

Streamlining Process Management

Streamlining process management is essential for ensuring that on-site quality control measures are effective and efficient. By focusing on critical processes, organizations can enhance their Quality Objectives and improve overall project outcomes. A well-structured approach to process management not only reduces errors but also fosters a culture of continuous improvement.

Identifying Critical Processes for Quality Control

To achieve effective on-site quality control, it’s crucial to identify the critical processes that directly impact quality outcomes. These processes often include material procurement, construction techniques, and inspection protocols outlined in the Quality Manual. By mapping out these key areas, teams can prioritize their efforts and allocate resources more effectively towards maintaining high standards.

Identifying these critical processes also allows for better alignment with project specifications and Quality Objectives. When everyone understands which processes matter most, it becomes easier to implement targeted training programs and document control measures that support quality goals. Furthermore, regular reviews of these identified processes ensure that they remain relevant as projects evolve.

Techniques for Process Optimization

Once critical processes are identified, the next step is optimizing them to maximize efficiency while ensuring compliance with the Quality Manual. Techniques such as process mapping can help visualize workflows and pinpoint bottlenecks that hinder productivity. Additionally, employing performance metrics allows teams to assess how well each process meets established Quality Objectives.

Another effective technique is the application of root cause analysis to address recurring issues within these processes. By systematically investigating problems, teams can implement corrective actions that enhance both efficiency and quality assurance efforts on site. Ultimately, optimized processes contribute significantly to achieving desired outcomes in product realization.

Utilizing Lean Principles for Efficiency

Lean principles offer a powerful framework for streamlining process management in construction projects focused on on-site quality control. By eliminating waste—whether it be time, materials, or labor—organizations can direct resources toward activities that add value in line with their Quality Objectives. This approach not only improves productivity but also enhances overall project satisfaction among stakeholders.

Implementing lean techniques requires a cultural shift where every team member actively participates in identifying inefficiencies and proposing improvements based on real-time feedback loops from ongoing work activities. Regular training sessions ensure everyone is equipped with the knowledge needed to apply lean methods effectively while adhering to the guidelines set forth in the Quality Manual. As a result, organizations can foster an environment of continuous improvement leading to superior product realization outcomes.

Effective Resource Management Strategies

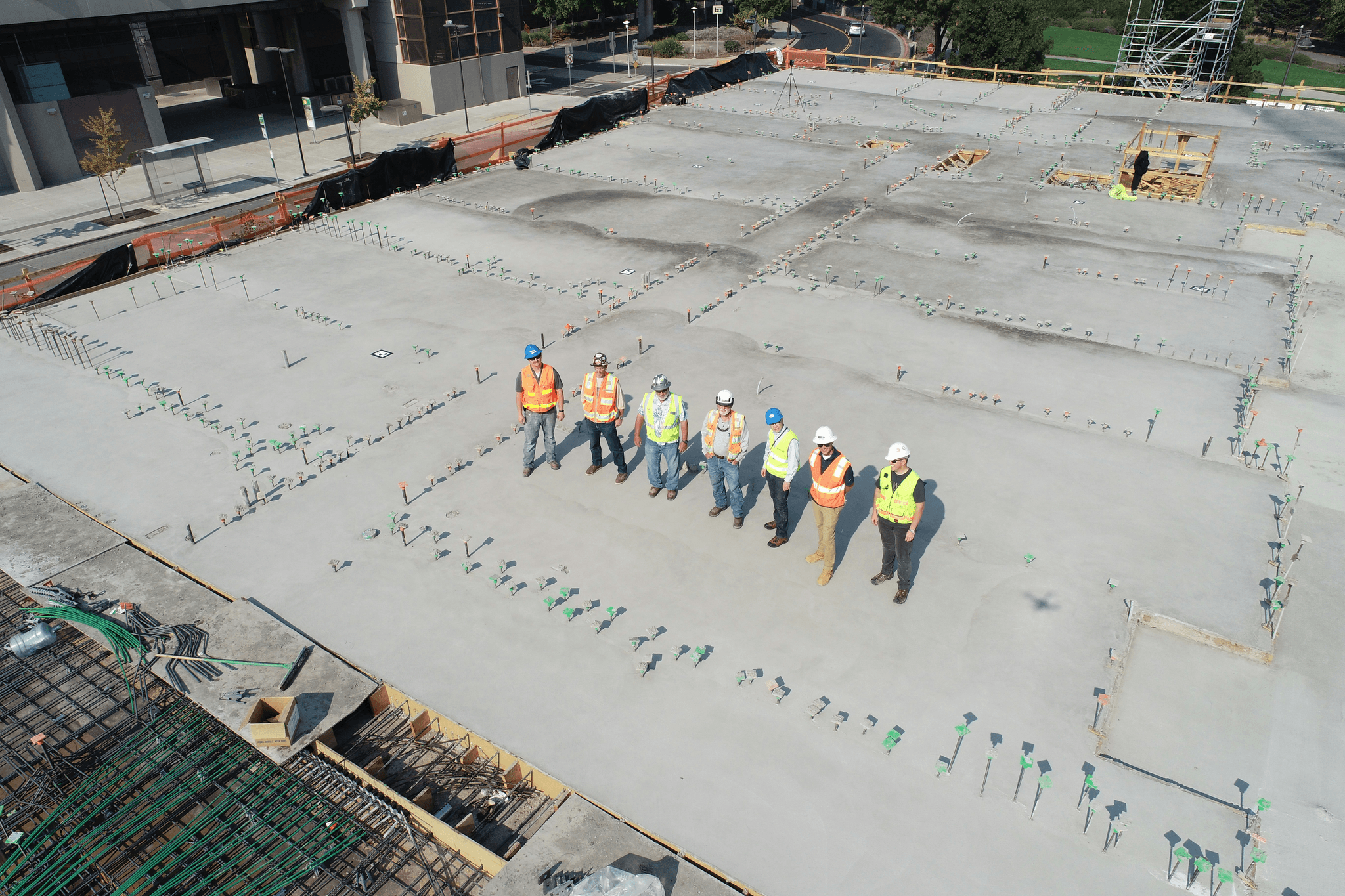

Effective resource management is essential for achieving quality objectives in construction projects. It involves the strategic allocation of resources—be it manpower, materials, or equipment—to ensure that on-site quality control measures are met. When resources are managed effectively, teams can focus on maintaining high standards outlined in the quality manual while minimizing waste and inefficiencies.

Allocating Resources for Quality Assurance

Allocating resources strategically is key to ensuring robust quality assurance practices. This means not only assigning sufficient personnel to oversee on-site quality control but also ensuring that they have access to the right tools and materials necessary for their tasks. By aligning resource allocation with defined quality objectives, project managers can create an environment where adherence to the quality manual is seamless and effective.

Moreover, proper resource allocation allows for flexibility in addressing unexpected challenges that may arise during construction. For instance, if a particular process management issue is identified, having additional resources on standby can facilitate rapid adjustments without compromising overall project timelines or budgets. This proactive approach ultimately enhances product realization by ensuring that every aspect of the project adheres to established standards.

Training and Development of Personnel

Training and development are critical components of effective resource management strategies in construction environments focused on on-site quality control. Investing in regular training sessions equips personnel with the latest techniques and knowledge needed to uphold quality objectives consistently across various projects. A well-trained workforce not only understands the importance of following the quality manual but also feels empowered to contribute ideas for continuous improvement.

Furthermore, fostering a culture of ongoing education helps reinforce commitment among team members towards achieving high-quality outcomes. Workshops focusing on document control practices ensure that everyone knows how to manage important paperwork efficiently while adhering to compliance requirements set by industry standards. As a result, staff becomes adept at handling processes related to product realization effectively.

Impact of Resource Management on Quality Outcomes

The impact of resource management on overall quality outcomes cannot be overstated; it directly influences both efficiency and effectiveness in achieving predefined goals. When resources are allocated wisely and personnel are adequately trained, teams can maintain high levels of performance throughout all phases of construction projects—ultimately supporting successful product realization initiatives as well as meeting client expectations.

Additionally, effective resource management contributes significantly towards minimizing errors and rework associated with poor-quality outputs—a common pitfall in many construction endeavors when oversight is lacking or mismanaged. By prioritizing both human capital development through training programs and strategic material/resource allocation based upon documented needs from previous projects (as outlined in a comprehensive quality manual), organizations position themselves favorably within competitive markets.

In conclusion, integrating these effective resource management strategies ensures that all aspects—from document control systems to process management—come together harmoniously toward delivering exceptional results aligned with established quality objectives.

Enhancing Product Realization Procedures

To ensure that construction projects meet their intended goals, enhancing product realization procedures is crucial. This involves integrating effective strategies that align with on-site quality control and Quality Objectives, ensuring that every phase of product development is meticulously managed. By focusing on best practices, feedback mechanisms, and real-world examples, organizations can significantly improve their overall performance.

Best Practices for Product Development

Best practices in product development serve as the backbone of any successful construction project. These practices emphasize the importance of adhering to a comprehensive Quality Manual that outlines specific standards and processes necessary for achieving desired outcomes. Additionally, employing robust Document Control systems allows teams to maintain accurate records and facilitate efficient communication throughout the project lifecycle.

Incorporating Process Management techniques ensures that each step in product realization is optimized for quality and efficiency. By identifying key processes that directly impact on-site quality control, organizations can streamline workflows and reduce waste. Ultimately, these best practices not only enhance productivity but also reinforce the commitment to Quality Objectives across all levels of the project.

Incorporating Feedback Loops for Continuous Improvement

Feedback loops are essential for fostering an environment of continuous improvement within product realization procedures. Regularly soliciting input from team members involved in on-site quality control can uncover valuable insights into potential issues or areas for enhancement. By systematically analyzing this feedback, organizations can make informed adjustments to their Resource Management strategies and overall execution plans.

Moreover, establishing a culture where constructive criticism is welcomed encourages innovation and adaptability among personnel. This proactive approach not only bolsters adherence to the Quality Manual but also ensures alignment with evolving industry standards and client expectations. Ultimately, incorporating these feedback mechanisms leads to more refined processes and higher-quality outcomes.

Case Studies: Successful Product Realization

Examining case studies of successful product realization offers practical insights into effective strategies used by leading construction firms. For instance, one company implemented a rigorous Document Control system that streamlined communication among team members while maintaining compliance with its Quality Manual guidelines. This initiative resulted in significant improvements in on-site quality control measures while meeting critical deadlines.

Another example highlights how a firm leveraged Resource Management techniques to allocate skilled personnel effectively during high-demand phases of a project. By aligning their workforce capabilities with defined Quality Objectives, they achieved remarkable efficiency gains without compromising quality standards or safety protocols. These case studies illustrate how integrating best practices within product realization can lead to exceptional results across various construction projects.

Conclusion

As we wrap up our exploration of quality management in construction, it becomes clear that consistent quality control is not just a nice-to-have; it's essential. The construction industry thrives on the ability to deliver projects that meet or exceed expectations, and this hinges on effective on-site quality control practices. By establishing robust Quality Objectives and adhering to them throughout the project lifecycle, stakeholders can mitigate risks and enhance overall project outcomes.

Importance of Consistent Quality Control

Consistent quality control serves as the backbone of successful construction projects, ensuring that every phase aligns with established standards and specifications. It fosters a culture of accountability among team members, where everyone understands their role in maintaining high-quality output. Moreover, effective Document Control mechanisms are crucial for tracking changes and maintaining transparency throughout the process—without them, chaos reigns.

Leveraging Expertise from China Inspection Pro

Partnering with organizations like China Inspection Pro can significantly elevate your quality management efforts by providing specialized knowledge and resources tailored to your needs. Their expertise in developing comprehensive Quality Manuals ensures that all processes—from Resource Management to Product Realization—are documented meticulously for ease of reference and compliance. By leveraging their insights, companies can navigate complex regulatory landscapes while enhancing their own on-site quality control measures.

Future Trends in Construction Quality Management

Looking ahead, several trends are set to reshape how we approach construction quality management. The integration of advanced technologies such as AI and IoT will streamline Process Management by enabling real-time monitoring and data analysis for proactive decision-making. Additionally, an increasing focus on sustainability will drive innovation in Resource Management strategies—ensuring that projects not only meet today's demands but also contribute positively to future generations.