Introduction

In the global marketplace, understanding China QC (Quality Control) for importers is crucial. With the vast array of products manufactured in China, ensuring quality standards can make or break a business. This introduction will explore the significance of quality control in manufacturing and provide an overview of inspection services that can help safeguard your investments.

Understanding China QC for Importers

China QC encompasses a range of practices aimed at maintaining product quality throughout the manufacturing process. For importers, navigating the complexities of Chinese manufacturing requires a solid grasp of these quality assurance inspection protocols. Engaging with reliable inspection services can help identify potential issues early on, ensuring that your products meet international standards before they reach your market.

Importance of Quality Control in Manufacturing

Quality control in manufacturing is not just a checkbox; it's a fundamental aspect that influences customer satisfaction and brand reputation. Implementing effective QA inspections helps mitigate risks associated with defective products and enhances overall operational efficiency. By prioritizing quality control, businesses can foster trust with their customers and maintain a competitive edge in an increasingly crowded marketplace.

Overview of Inspection Services

Inspection services play a pivotal role in the quality assurance landscape, offering various types of assessments tailored to different stages of production. From pre-production checks to final pre-shipment inspections, these 3rd party inspection services ensure that every aspect of product quality is scrutinized thoroughly. A well-documented inspection report serves as both a benchmark for compliance and a roadmap for continuous improvement in manufacturing processes.

The Basics of Quality Control in Manufacturing

Quality control (QC) is a crucial aspect of the importing process, especially when dealing with products from China. It encompasses a series of processes and inspections that ensure products meet specific quality standards before they reach the market. By implementing effective QC practices, importers can minimize risks, reduce costs associated with defective goods, and enhance customer satisfaction.

Defining QC in Importing

In the context of importing, quality control refers to the systematic approach used to monitor and evaluate the quality of products throughout the manufacturing process. This includes everything from raw materials to final outputs, ensuring compliance with both international standards and buyer specifications. Understanding QC in importing is essential for establishing trust between buyers and suppliers while safeguarding against potential losses due to subpar products.

Key Terms in Quality Assurance Inspection

Navigating quality assurance inspection requires familiarity with key terms that are often used in this field. For instance, 3rd party inspection refers to an independent entity conducting inspections on behalf of an importer or exporter, ensuring unbiased evaluations. Other important terms include inspection report, which documents findings from inspections, and inspector certification, indicating that inspectors have met specific qualifications to assess product quality effectively.

Benefits of Implementing QC Practices

Implementing robust QC practices offers numerous benefits for businesses engaged in importing from China. First and foremost, it helps identify defects early in the production cycle, reducing waste and minimizing costs associated with returns or rework. Additionally, regular QA inspections foster stronger relationships with suppliers by promoting transparency and accountability—ultimately leading to better product quality and increased consumer confidence.

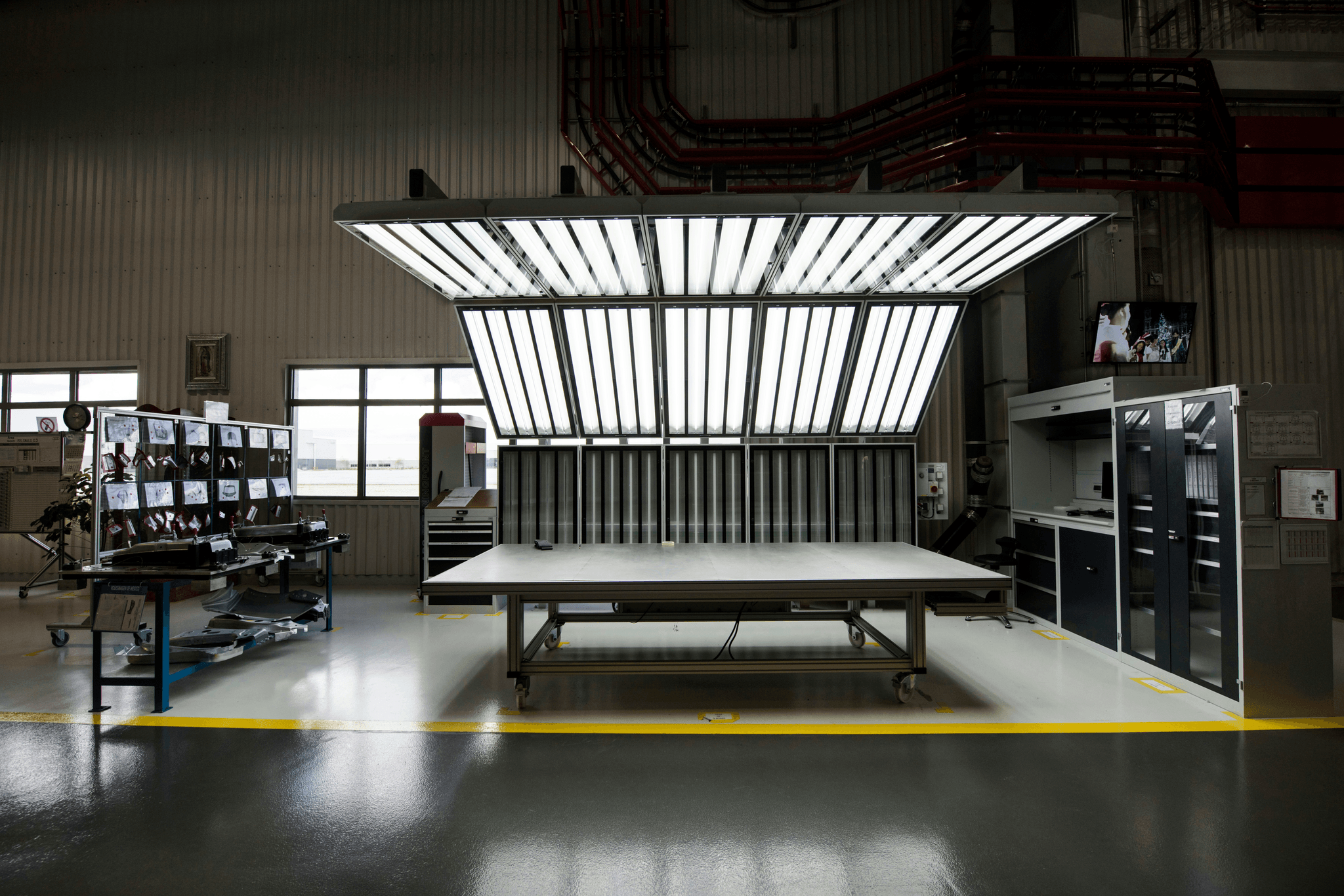

Types of China QC Inspection Services

Each stage of manufacturing has its own unique set of challenges, and the right quality assurance inspection can make all the difference. By utilizing these services, businesses can mitigate risks and enhance their overall quality control in manufacturing.

Pre-production Inspections

Pre-production inspections are a vital step in the quality control process, allowing importers to evaluate materials and components before production begins. This type of inspection ensures that suppliers meet specific standards and requirements, which ultimately contributes to a smoother manufacturing process. During this phase, 3rd party inspection teams assess samples for compliance with specifications outlined in the contract, providing an initial inspection report that highlights any potential issues.

By addressing concerns early on through pre-production inspections, businesses can prevent costly mistakes later in the production cycle. Effective communication between importers and suppliers is key during this phase; it sets a precedent for future interactions throughout the manufacturing journey. With proper inspector certification backing these inspections, businesses can trust that they are receiving accurate assessments tailored to their unique needs.

In-production Inspections

In-production inspections occur at various stages during the manufacturing process and play a crucial role in maintaining consistent product quality. These inspections help identify defects or discrepancies while products are being made rather than waiting until they are completed—saving time and resources down the line. By employing qualified inspectors who understand quality assurance inspection protocols, companies can ensure that their products adhere to industry standards throughout production.

This type of China QC service allows importers to stay informed about progress and address issues immediately as they arise. Regular updates from inspectors provide valuable insights into production efficiency and overall product integrity—information that can be reflected in subsequent inspection reports. Ultimately, these proactive measures contribute significantly to improving overall quality control in manufacturing.

Pre-shipment Inspections

Pre-shipment inspections serve as a final checkpoint before goods leave China for international markets—a critical moment where any remaining issues need to be addressed promptly. These inspections verify that products conform to agreed-upon specifications and are ready for shipment according to buyer requirements or applicable regulations. A thorough pre-shipment inspection not only results in an informative inspection report but also provides peace of mind by reducing risks associated with poor-quality goods reaching customers.

During this stage, inspectors check packaging integrity, product functionality, labeling accuracy, and compliance with safety regulations—all essential aspects of successful QA inspections. Importers benefit from having certified inspectors conduct these evaluations; their expertise ensures adherence to best practices while fostering trust within supplier relationships. Ultimately, conducting pre-shipment inspections helps maintain brand reputation by ensuring high-quality products reach consumers without delay or additional costs.

Navigating the Inspection Process

When it comes to ensuring product quality, navigating the inspection process can feel like a maze. However, understanding how to effectively engage with inspection services can streamline your efforts and lead to better outcomes. From selecting a reliable 3rd party inspection service to preparing adequately for inspections, each step is crucial in maintaining quality control in manufacturing.

Selecting a 3rd Party Inspection Service

Choosing the right 3rd party inspection service is pivotal for effective China QC. You want to partner with an organization that not only understands your product but also has a strong reputation for delivering thorough and unbiased assessments. Look for companies that offer inspector certification and have proven experience in quality assurance inspection across various industries.

Don’t hesitate to ask for references or case studies from potential partners; this will give you insight into their reliability and expertise. Additionally, consider their geographical reach within China—having inspectors located near your manufacturing facilities can facilitate quicker responses and more efficient inspections. Ultimately, selecting the right service will enhance your overall QA inspections and ensure that you’re getting accurate information about your products.

Importance of an Inspection Report

An inspection report is more than just paperwork; it’s the backbone of your quality assurance inspection process. This document provides detailed insights into the findings from the inspections conducted during different stages of production, including pre-production, in-production, and pre-shipment checks. A comprehensive report highlights any discrepancies or issues found during these evaluations, allowing you to take corrective action before products reach consumers.

Moreover, these reports serve as vital communication tools between importers and manufacturers in China QC scenarios. They help ensure everyone is on the same page regarding product standards and expectations while also documenting compliance with regulations or contractual obligations. In short, without a solid inspection report, you're essentially sailing without a map—risking potential pitfalls that could have been avoided.

Steps to Prepare for an Inspection

Preparing for an inspection might seem daunting at first glance, but breaking it down into manageable steps can make all the difference in achieving successful outcomes with quality control in manufacturing processes. Start by reviewing all relevant documentation related to your products—this includes specifications, contracts, and previous inspection reports—to ensure everyone involved understands what’s at stake.

Next, communicate openly with your chosen 3rd party inspection service about specific concerns or areas you want them to focus on during their evaluation. Finally, consider conducting internal checks prior to the official assessment; this proactive approach allows you time to address any issues before inspectors arrive on-site or begin their evaluations remotely.

Working with Certified Inspectors

When it comes to ensuring the integrity of your products through China QC, working with certified inspectors is crucial. These professionals play a pivotal role in the quality assurance inspection process, helping you to navigate the often complex terrain of manufacturing standards. By engaging qualified inspectors, you not only safeguard your investment but also enhance your reputation in the marketplace.

Understanding Inspector Certification

Inspector certification is a key aspect of quality control in manufacturing that cannot be overlooked. Certifications demonstrate that inspectors have undergone rigorous training and possess the necessary knowledge and skills to conduct thorough inspections. By understanding these certifications, importers can better assess the credibility of their 3rd party inspection services and ensure that their products meet international standards.

Moreover, various organizations provide specific certifications for inspectors based on industry standards and practices. Familiarizing yourself with these certifications will empower you to make informed decisions when selecting an inspector for your QA inspections. Ultimately, a well-certified inspector can significantly contribute to producing reliable inspection reports that detail product quality and compliance.

Criteria for Choosing Qualified Inspectors

Selecting qualified inspectors involves more than just checking off boxes on a list; it requires careful consideration of several factors that affect the quality assurance inspection process. First and foremost, look for experience in your specific industry or product category—this ensures they understand the nuances of what you're importing from China QC sources. Additionally, consider their familiarity with relevant regulations and standards that govern your product type.

Another critical criterion is communication skills; an effective inspector should articulate findings clearly within an inspection report so you can easily grasp potential issues or areas for improvement. It’s also wise to verify references or reviews from past clients who have utilized their services—this provides insight into their reliability and professionalism during QA inspections. With these criteria in mind, you’ll be better equipped to choose inspectors who align with your business goals.

Building Trust with Your Inspection Team

Building trust with your inspection team is essential for fostering a productive working relationship throughout the quality control process. Open communication channels are vital; share your expectations upfront regarding both product specifications and timelines so everyone is on the same page from day one. This transparency helps establish a solid foundation where concerns can be addressed promptly without misunderstandings.

Additionally, regular follow-ups after inspections can help reinforce this trust; discuss findings from each inspection report together to identify trends or recurring issues that need attention over time. Engaging actively with your inspectors shows them that you value their expertise while creating an environment conducive to continuous improvement in product quality through effective QA inspections. Remember, trust takes time but pays dividends when it comes to ensuring high-quality outcomes in manufacturing processes.

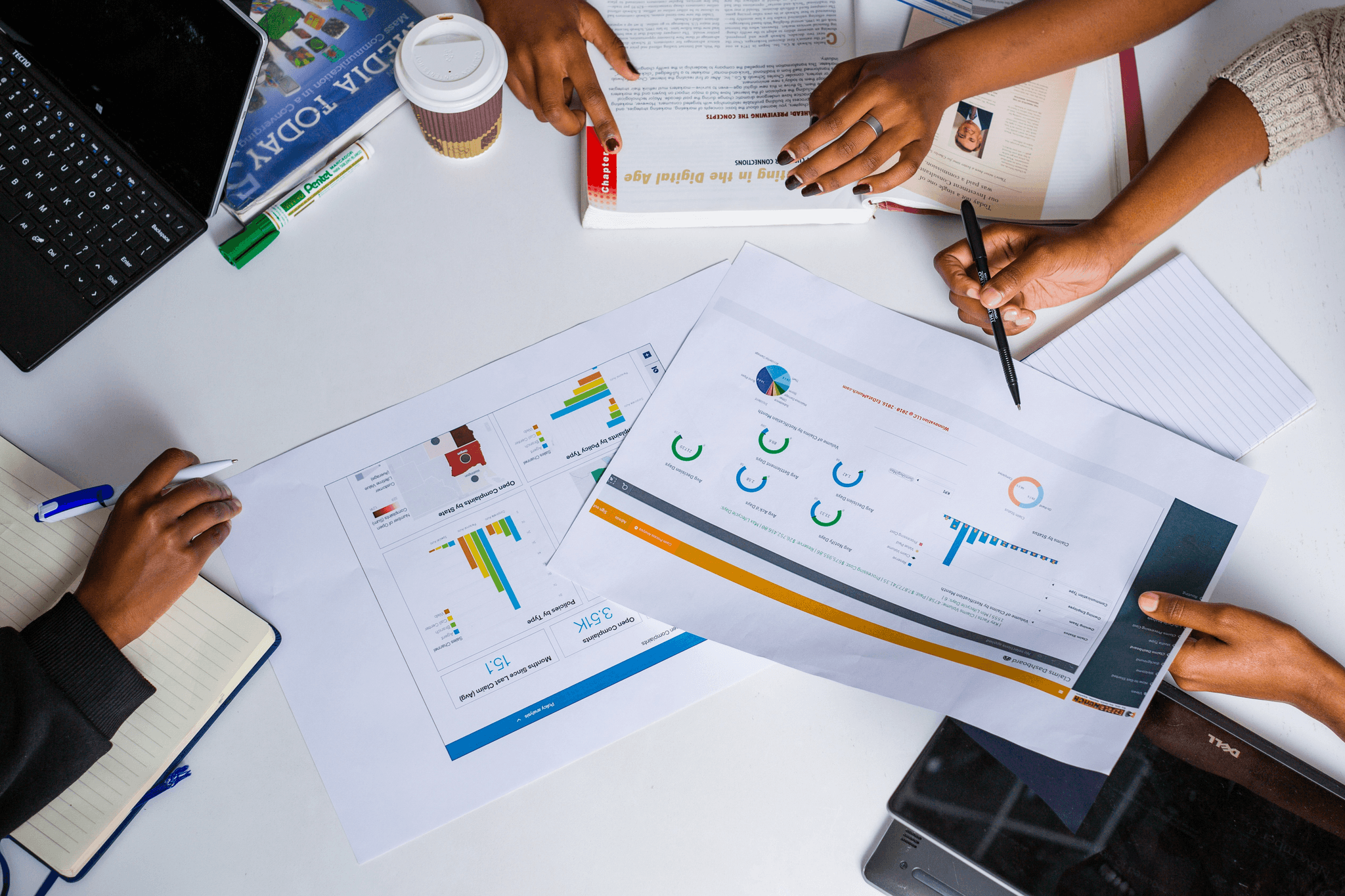

Analyzing Inspection Findings

Once you've received your inspection report, the real work begins. This document is more than just a piece of paper; it’s a treasure trove of insights regarding your product's compliance with quality standards. Understanding the nuances within your inspection report will help you make informed decisions about your manufacturing processes and future orders, ensuring that your investment in China QC yields the best possible outcomes.

Interpreting Your Inspection Report

When delving into an inspection report from a 3rd party inspection service, it's crucial to familiarize yourself with its structure and terminology. The report typically highlights critical areas such as defects found, compliance with specifications, and overall product quality ratings. By carefully analyzing these sections, you can pinpoint specific issues that need addressing and gain a clearer picture of how well your products align with quality control in manufacturing standards.

Moreover, understanding the grading system used in the report can provide valuable context about the severity of any identified issues. For instance, knowing whether a defect is categorized as minor or major can significantly influence your next steps in terms of production adjustments or negotiations with suppliers. Ultimately, interpreting this vital document correctly sets the stage for enhancing product quality through strategic improvements.

Actionable Recommendations for Improvement

After interpreting your inspection report, it’s time to devise actionable recommendations based on its findings. Start by prioritizing issues according to their impact on overall product quality; addressing major defects should take precedence over minor ones. Collaborating closely with your manufacturer and utilizing insights from certified inspectors can lead to practical solutions that minimize defects in future production runs.

Additionally, consider implementing regular QA inspections throughout different stages of production rather than waiting until pre-shipment phases. This proactive approach allows you to catch potential problems early on and fosters a culture of continuous improvement within your supply chain management practices. Remember that every defect identified presents an opportunity for learning and enhancement—embracing this mindset will help elevate your brand's reputation over time.

Enhancing Product Quality Through Feedback

Feedback is an essential component of any successful quality assurance inspection process; it serves as both a mirror reflecting current performance and a compass guiding future actions. After analyzing inspection findings and implementing necessary changes, solicit feedback from various stakeholders involved in the production process—this includes factory workers, managers, and even end consumers if possible. Their perspectives can uncover hidden challenges or additional opportunities for improvement that may not have been apparent during inspections.

Furthermore, establishing an ongoing dialogue with certified inspectors ensures you stay informed about best practices within China QC frameworks while fostering trust between all parties involved in manufacturing processes. Regular communication helps create transparency around expectations regarding quality control standards while reinforcing accountability at every level of production management. By embedding feedback loops into your operations strategy, you'll be better equipped to adapt swiftly to changing market demands while consistently delivering high-quality products.

Conclusion

In wrapping up our discussion on China QC and the importance of quality assurance inspection, it's clear that implementing robust inspection services is essential for any importer looking to maintain high standards. Quality control in manufacturing not only safeguards your reputation but also ensures that your products meet the expectations of your customers. By understanding the nuances of the inspection process, you can make informed decisions that lead to better outcomes.

Key Takeaways for Quality Assurance Inspection

One of the fundamental takeaways from our exploration of quality assurance inspection is the critical role it plays in maintaining product integrity. Regular QA inspections help identify issues before they escalate into larger problems, ensuring compliance with industry standards and customer expectations. Moreover, leveraging 3rd party inspection services can provide an unbiased perspective on your product quality, enhancing trust in your supply chain.

Advantages of Regular QA Inspections

The advantages of conducting regular QA inspections are manifold; they not only prevent costly mistakes but also foster continuous improvement in manufacturing processes. With a consistent focus on quality control in manufacturing, businesses can enhance operational efficiency and reduce waste associated with defective products. Additionally, frequent inspections yield valuable inspection reports that serve as benchmarks for future performance and areas needing attention.

Partnering with China Inspection Pro for Success

To truly maximize your quality control efforts, partnering with a reputable organization like China Inspection Pro can be a game-changer. Their expertise in inspector certification ensures that you are working with qualified professionals who understand the intricacies of China QC standards and practices. By collaborating closely with such a partner, you gain access to tailored solutions that align perfectly with your specific needs while fostering a culture of excellence within your organization.