Introduction

In today's global marketplace, ensuring product quality before shipment is more crucial than ever. This is where preshipment inspection comes into play, serving as a vital checkpoint in the supply chain process. By understanding what a preshipment inspection entails, businesses can safeguard their interests and maintain high standards.

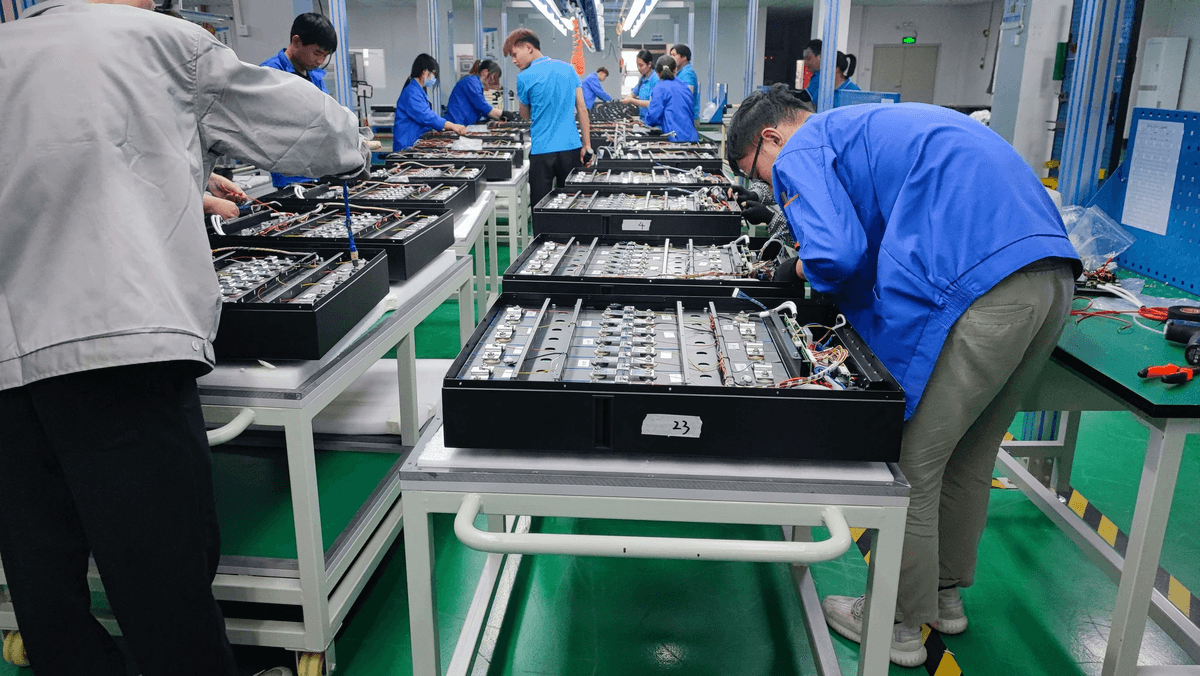

Understanding Pre-Shipment Inspection

A preshipment inspection is a thorough evaluation conducted on goods before they leave the manufacturer’s facility. The primary purpose of this inspection is to verify that products meet specified quality standards and contractual obligations. By identifying potential issues early on, companies can avoid costly mistakes down the line.

Importance of Quality Control

Quality control is not just a buzzword; it’s an essential practice that ensures customer satisfaction and brand integrity. Implementing effective quality control measures, such as preshipment inspections, helps mitigate risks associated with defective products reaching consumers. This proactive approach not only enhances product reliability but also fosters long-term relationships with clients.

Overview of the Inspection Process

The preshipment inspection process typically involves several key steps that help ensure compliance with quality standards. Inspectors focus on critical aspects such as quantity verification, packaging quality, and overall product integrity during their evaluations. By following a structured process, businesses can gain actionable insights into their products' readiness for market entry.

What is a Pre-Shipment Inspection?

Pre-shipment inspection (PSI) is a crucial quality control process that takes place before goods are shipped from the manufacturer to the buyer. The primary purpose of this inspection is to ensure that products meet specific quality standards, specifications, and contractual obligations. By conducting a pre-shipment inspection, companies can identify potential issues early on, thus preventing costly mistakes down the line.

Definition and Purpose

At its core, a pre-shipment inspection serves as a final checkpoint for products before they leave the production facility. Inspectors evaluate various aspects of the goods including quality verification, quantity verification, and packaging quality to confirm that everything aligns with the buyer's requirements. This process not only protects buyers from receiving subpar products but also helps manufacturers maintain their reputation by ensuring consistent quality.

History and Evolution

The concept of pre-shipment inspections can be traced back to the early days of international trade when merchants sought assurance about product quality before making significant investments. Over time, as global trade expanded and regulations became stricter, PSI evolved into a more structured process involving standardized procedures and certifications. Today, it incorporates advanced technologies and methodologies to enhance accuracy in assessing product compliance.

Key Players in the Process

Several key players contribute to the success of pre-shipment inspections: manufacturers, buyers, third-party inspectors, and regulatory bodies all play vital roles in this intricate dance of commerce. Manufacturers are responsible for producing goods that meet specified standards while buyers rely on inspectors to verify compliance with their requirements. Third-party inspection agencies act as impartial evaluators who provide objective assessments based on established criteria—ensuring transparency throughout the supply chain.

Why Perform a Pre-Shipment Inspection?

When it comes to ensuring the integrity of products before they hit the shelves, performing a pre-shipment inspection is not just a smart move—it's essential. This process serves multiple purposes, from safeguarding against defects to ensuring compliance with international standards. As businesses navigate the complexities of global trade, understanding why to perform a pre-shipment inspection becomes crucial for maintaining quality and trust.

Risk Mitigation Strategies

In today's fast-paced market, risk mitigation strategies are paramount for any business aiming to thrive. A pre-shipment inspection helps identify potential issues before they escalate into costly problems, such as product recalls or legal disputes. By focusing on quality verification and quantity verification during this inspection process, companies can significantly reduce their exposure to risks associated with subpar products.

Moreover, by implementing effective risk mitigation strategies through preshipment inspections, businesses can enhance their reputation and foster long-term relationships with clients and consumers alike. When customers know that you prioritize quality control, they are more likely to trust your brand and remain loyal. Ultimately, these proactive measures not only protect your investment but also contribute positively to your bottom line.

Cost Efficiency and Savings

Cost efficiency is another compelling reason for conducting a pre-shipment inspection; after all, nobody wants to throw money down the drain! By catching defects early through rigorous quality verification processes, companies can save on expensive returns or rework costs later on. Additionally, by ensuring proper packaging quality during inspections, businesses can prevent damage during transit that might otherwise lead to financial losses.

Investing in preshipment inspections may seem like an upfront cost; however, the savings realized from avoiding defective merchandise far outweigh this initial expense over time. Furthermore, when companies demonstrate their commitment to quality control through these inspections, they often see increased customer satisfaction—leading to repeat business and positive word-of-mouth referrals that bolster profitability in ways hard numbers can't always capture.

Compliance with Regulations

Compliance with regulations is non-negotiable in today’s global marketplace; failing to adhere could spell disaster for any business involved in international trade. A thorough pre-shipment inspection ensures that products meet specific regulatory requirements set forth by various governments or industry standards—be it safety guidelines or labeling laws—and thus minimizes legal risks down the line. Inspectors focus on both quantity verification and packaging quality during this stage of evaluation because even minor oversights can result in significant penalties or shipment delays.

Moreover, staying compliant not only protects your organization but also enhances its credibility among consumers who increasingly prioritize ethical practices when making purchasing decisions. In an era where transparency is key for brand loyalty and trustworthiness among buyers globally—conducting preshipment inspections becomes more than just good practice; it's essential for survival in competitive markets.

What Inspectors Look for in a Pre-Shipment Inspection

When it comes to a preshipment inspection, inspectors have a keen eye for detail, ensuring that products meet the required standards before they leave the manufacturer. The inspection process is crucial not just for quality assurance but also for maintaining trust in supply chains. Understanding what inspectors look for can help businesses grasp the importance of this step and why performing a pre-shipment inspection is essential.

Quality Verification

Quality verification is at the heart of any preshipment inspection, acting as the gatekeeper to product excellence. Inspectors evaluate various aspects, such as material quality, workmanship, and adherence to specifications outlined in purchase orders. By scrutinizing these elements, they ensure that only high-quality products make their way to consumers, ultimately safeguarding brand reputation.

In this phase of the inspection process, inspectors may employ various testing methods to assess durability and performance under real-world conditions. If defects are identified during quality verification, companies can take corrective actions before shipment—saving time and reducing costs associated with returns or replacements later on. This proactive approach reinforces the value of understanding what is a pre-shipment inspection and how it can protect your business interests.

Quantity Verification

Quantity verification plays an equally important role in the preshipment inspection process by ensuring that the number of items shipped matches what was ordered. Inspectors meticulously count items against packing lists or invoices to confirm that no discrepancies exist between what was requested and what is being sent out. This step helps prevent costly overages or shortages that could disrupt supply chain operations.

Moreover, quantity verification also involves checking for damaged or missing items within shipments—a critical aspect when dealing with large orders or fragile products. By identifying these issues early on through effective quantity verification processes, businesses can address problems swiftly and maintain smooth operations without unnecessary delays or losses. Thus, it’s clear why performing a pre-shipment inspection is vital; it ensures accuracy from start to finish.

Packaging Quality

Packaging quality might seem like an afterthought compared to quality and quantity verification; however, it plays a significant role in protecting products during transit. Inspectors assess whether packaging materials are appropriate for safeguarding goods against damage while being transported over long distances—especially relevant when considering international shipping scenarios where conditions can be unpredictable.

Inspectors look at aspects like sturdiness of boxes, proper cushioning materials inside packages, and labeling accuracy during this stage of evaluation as well. High-quality packaging not only protects products but also enhances brand image by presenting goods attractively upon arrival at their destination—an often-overlooked factor in customer satisfaction! Therefore, understanding what inspectors look for in terms of packaging quality reinforces just how comprehensive preshipment inspections truly are.

Steps Involved in the Pre-Shipment Inspection Process

The pre-shipment inspection process is a critical step in ensuring that products meet quality standards before they reach their destination. This multi-faceted approach not only safeguards against potential issues but also enhances overall customer satisfaction. To fully grasp the importance of this process, let’s break it down into three key components: initial documentation review, on-site inspection procedures, and reporting and recommendations.

Initial Documentation Review

Before any physical inspection takes place, a thorough review of all relevant documentation is essential. This includes purchase orders, specifications, and any previous inspection reports that may highlight past issues or concerns. By examining these documents closely, inspectors can establish a baseline for what to expect during the preshipment inspection and identify specific areas that may require more attention.

Additionally, this initial review helps ensure compliance with regulations and standards set forth by both importing and exporting countries. It acts as a roadmap for inspectors to understand what is required in terms of quality verification and quantity verification—two vital aspects of the overall assessment process. Ultimately, this step lays the groundwork for an effective on-site inspection by pinpointing potential red flags early on.

On-Site Inspection Procedures

Once the documentation has been reviewed, it's time for inspectors to roll up their sleeves and conduct the actual on-site preshipment inspection. During this phase, inspectors evaluate various aspects of the products being shipped—including quality verification to ensure that items meet specified standards. They meticulously check each product against its specifications while also assessing packaging quality to confirm it can withstand transit conditions.

In addition to checking individual items for defects or inconsistencies, quantity verification plays a crucial role in this stage as well. Inspectors will count items carefully to ensure that shipments match order quantities accurately—because no one wants surprises when opening a shipment! The combination of these checks provides a comprehensive overview of product readiness while mitigating risks associated with shipping subpar goods.

Reporting and Recommendations

After completing the on-site inspections, it’s time for inspectors to compile their findings into a detailed report outlining all observations made during the preshipment inspection process. This report typically includes sections dedicated to quality verification results, quantity verification outcomes, and notes about packaging quality—allowing companies to see where they stand regarding compliance with industry standards.

Moreover, actionable recommendations are often provided based on identified issues or trends observed during inspections. These insights can help companies improve their processes moving forward—ultimately enhancing supply chain efficiency and building trust with consumers who rely on consistent product quality. By taking these recommendations seriously, businesses can foster long-term relationships with suppliers while ensuring customer satisfaction remains high.

The Role of Companies like China Inspection Pro

In the realm of global trade, companies like China Inspection Pro play a pivotal role in ensuring that products meet stringent quality standards before they reach consumers. Their expertise in preshipment inspection is invaluable for businesses looking to mitigate risks associated with product defects, compliance issues, and supply chain inefficiencies. By leveraging professional quality assurance services, these companies help manufacturers and importers maintain high standards throughout the production process.

Professional Quality Assurance Services

Professional quality assurance services provided by firms like China Inspection Pro are essential for businesses aiming to uphold their reputation in the marketplace. These services encompass a comprehensive range of preshipment inspection activities designed to assess various aspects of products before shipment. From evaluating the manufacturing processes to conducting detailed checks on final outputs, these inspections ensure that every product meets the required specifications and industry standards.

Moreover, understanding What is a Pre-Shipment Inspection? is crucial for companies seeking to implement effective quality control measures. These inspections not only verify compliance with contractual obligations but also enhance customer satisfaction by ensuring consistent product quality. With a focus on risk mitigation strategies, professional inspectors provide businesses with peace of mind knowing that their products have undergone rigorous scrutiny.

Thorough Examination of Products

When it comes to What Inspectors Look for in a Pre-Shipment Inspection, thorough examination is key. Inspectors meticulously assess multiple facets including quality verification, quantity verification, and packaging quality during their evaluations. This multifaceted approach ensures that any discrepancies or potential issues are identified early on, allowing businesses to address them before products leave the factory.

The thoroughness of these examinations can significantly impact cost efficiency and savings for companies engaged in international trade. By catching problems early during preshipment inspections, businesses can avoid costly returns or rework after products have been shipped. In this way, a diligent inspection process not only safeguards product integrity but also contributes positively to overall supply chain efficiency.

Actionable Insights for Improvement

One major benefit derived from engaging companies like China Inspection Pro lies in the actionable insights they provide post-inspection. After completing preshipment inspections, inspectors compile detailed reports highlighting areas needing improvement—whether it’s related to quantity verification or enhancing packaging quality protocols. This feedback loop empowers manufacturers with valuable information that can lead to better production practices and increased customer satisfaction.

Additionally, these insights often help companies understand why performing a pre-shipment inspection is critical in today’s competitive market landscape. Continuous improvement based on inspection findings fosters innovation while ensuring compliance with regulations across different markets globally. As such, actionable insights not only enhance product quality but also build trust with consumers who demand reliability from brands they choose.

Conclusion

In the world of global trade, ensuring that products meet quality standards before they hit the market is crucial. Pre-shipment inspection plays a vital role in this process, acting as a safety net to catch potential issues related to quality, quantity, and packaging. By implementing effective pre-shipment inspection practices, companies can maximize product quality and safety while minimizing risks associated with non-compliance.

Maximizing Product Quality and Safety

To truly understand the importance of pre-shipment inspection, one must consider its direct impact on product quality and safety. Quality verification during these inspections ensures that only products meeting specified standards make it to consumers, ultimately safeguarding brand reputation. Additionally, inspectors meticulously assess packaging quality to prevent damage during transit and ensure that items are presented attractively upon arrival.

Enhancing Supply Chain Efficiency

Why perform a pre-shipment inspection? The answer lies in its ability to streamline supply chain processes significantly. By identifying potential issues early through quantity verification and thorough inspections, businesses can avoid costly delays and rework down the line. This proactive approach not only saves time but also enhances overall efficiency by allowing companies to focus on delivering high-quality products without unnecessary setbacks.

Building Trust with Consumers

When consumers purchase a product, they expect it to meet certain standards of quality and reliability. Conducting rigorous pre-shipment inspections builds trust by demonstrating a commitment to product excellence and consumer satisfaction. With every successful inspection that verifies quality and quantity while ensuring proper packaging quality, businesses reinforce their reputation as trustworthy providers in an increasingly competitive market.