Introduction

In the world of manufacturing and production, ensuring that products meet quality standards is paramount. This is where concepts like Acceptable Quality Level (AQL) and inspection levels come into play, serving as essential tools for quality control. Understanding how to select AQL and inspection level effectively can mean the difference between a successful product launch and costly recalls.

Understanding AQL and Inspection Levels

AQL stands for Acceptable Quality Level, a statistical measure used in quality inspection to determine the maximum number of defective items considered acceptable in a sample batch. By grasping the nuances of AQL and its associated inspection levels, manufacturers can tailor their quality checks in manufacturing processes to align with production quality goals. The right selection of these parameters not only enhances product reliability but also boosts customer satisfaction.

Importance of Quality Control

Quality control is not just an optional extra; it’s a fundamental aspect of any manufacturing process that directly impacts brand reputation and profitability. Implementing robust quality checks ensures that products meet specified standards before they reach consumers, reducing the risk of defects and enhancing overall product performance. In this competitive market, businesses that prioritize effective quality control are more likely to thrive than those who overlook it.

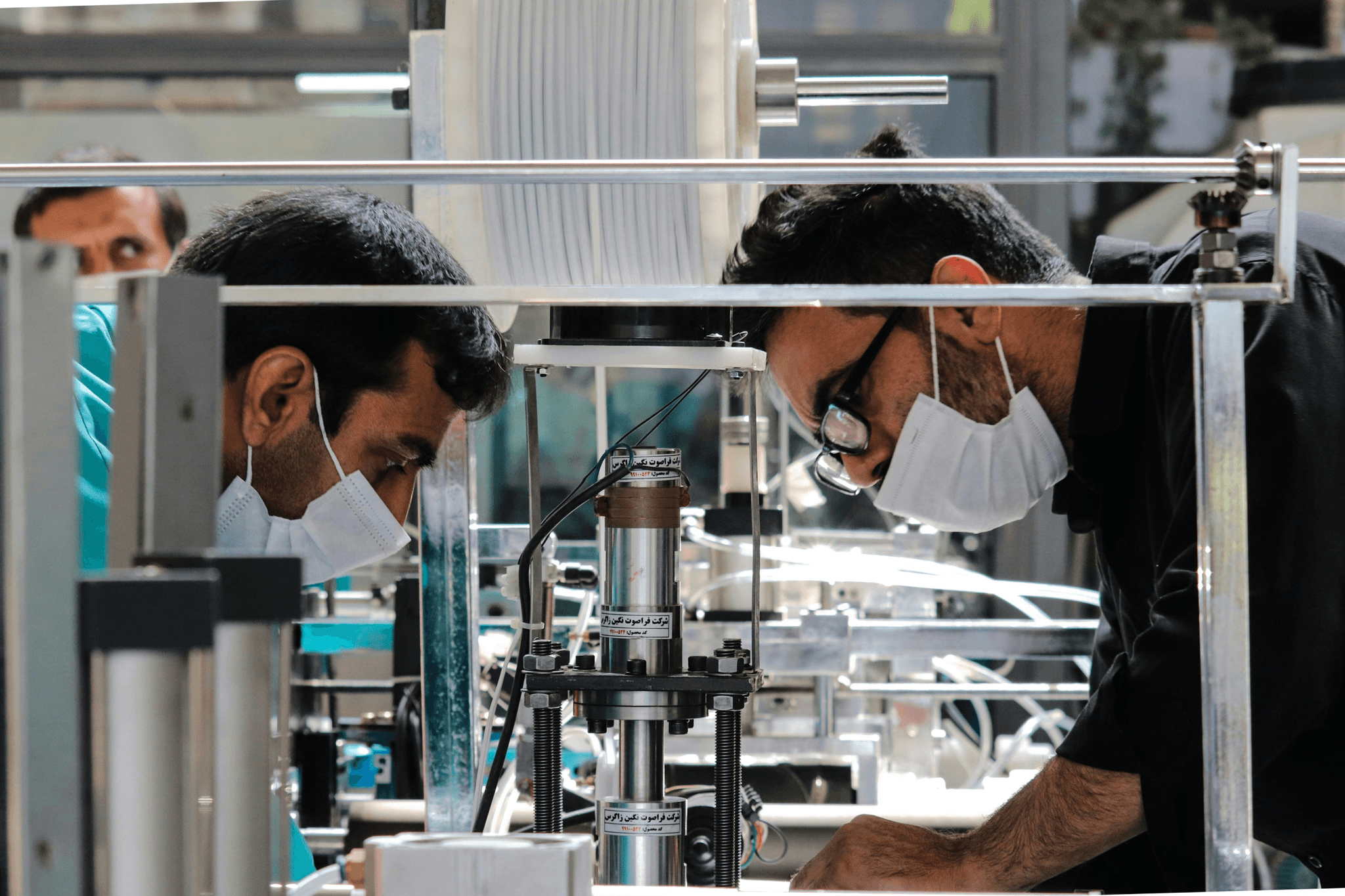

Role of Inspection in Production

Inspection plays a critical role in maintaining high standards throughout the production cycle, acting as the gatekeeper for product quality. Regular inspections help identify issues early on, enabling manufacturers to make necessary adjustments before items are shipped out. By integrating AQL sampling techniques into their workflow, companies can streamline their inspection processes while ensuring consistent quality production across all stages.

What is AQL?

In the realm of quality control, understanding Acceptable Quality Level (AQL) is crucial for ensuring that products meet specific standards before reaching consumers. AQL serves as a benchmark that defines the maximum number of defective items considered acceptable during quality inspection. This concept plays a pivotal role in maintaining high production quality and minimizing waste, ultimately benefiting manufacturers and consumers alike.

Definition of Acceptable Quality Level

Acceptable Quality Level (AQL) refers to the maximum allowable number of defective items in a sample batch, reflecting an organization’s tolerance for defects. Essentially, it helps businesses determine how many imperfections they can accept while still meeting their quality production goals. By establishing an AQL, companies can effectively balance cost and quality checks in manufacturing, ensuring that they maintain customer satisfaction without incurring excessive losses.

Historical Context and Development

The concept of AQL emerged from the need for more systematic approaches to quality control during the mid-20th century when mass production became prevalent. Early pioneers recognized that inspecting every single item was impractical; thus, they developed sampling methods to streamline the process while still safeguarding product integrity. Over time, AQL has evolved into a standard practice in various industries, adapting to changing technologies and consumer expectations—making it essential for anyone looking to understand how to select AQL and inspection level effectively.

AQL in Quality Inspection Standards

AQL is now embedded within numerous quality inspection standards globally, such as ISO 2859-1 and MIL-STD-105E, providing guidelines on how to implement effective sampling plans. These standards help organizations establish clear criteria for acceptable levels of defects based on statistical principles, allowing them to make informed decisions about their production processes. By adhering to these established norms, companies can enhance their overall quality control efforts while ensuring compliance with industry regulations—ultimately facilitating smoother operations when considering how to select AQL and inspection level.

Different Inspection Levels Explained

These levels dictate how rigorously products are examined and can significantly impact production quality. By navigating through these options, manufacturers can ensure that their quality checks in manufacturing align with their overall goals.

Types of Inspection Levels

Inspection levels are typically categorized into three main types: General Inspection Levels (I, II, III), Special Inspection Levels (S1, S2, S3), and Reduced Inspection Levels (R). General levels focus on a baseline of acceptable quality level (AQL) checks that most manufacturers adhere to. Special levels cater to more critical items where defects could lead to significant issues, while reduced levels are used when a product's history shows consistent reliability.

Each type serves a specific purpose in the realm of quality production and helps businesses determine how to select AQL and inspection level based on their unique requirements. For instance, if you're dealing with high-value items or components critical to safety, you might lean towards a special inspection level for enhanced scrutiny. Conversely, for products with a proven track record of reliability, reduced inspections can save time and resources without sacrificing overall product integrity.

Selecting Appropriate Levels for Your Needs

Selecting the appropriate inspection level involves analyzing several factors related to your production environment and product characteristics. Considerations such as the complexity of the item being inspected, historical defect rates, and customer expectations all play vital roles in this decision-making process. The goal is always to align your AQL with your production quality objectives while ensuring that inspections are efficient yet thorough.

For example, if you manufacture electronic devices known for occasional malfunctions due to component failure rates being higher than acceptable limits, you would likely opt for a more stringent inspection level. On the other hand, if your products have consistently met quality standards over time without significant issues reported during previous inspections or AQL sampling methods employed previously yielded favorable results—then perhaps a general or reduced inspection level would suffice. Ultimately, it’s about balancing risk management with operational efficiency.

Impact of Inspection Levels on Quality Checks

The impact of choosing the right inspection level extends beyond mere compliance; it directly affects overall product performance and customer satisfaction in terms of quality checks in manufacturing processes. Higher inspection levels often lead to increased costs due to more extensive testing protocols but can also result in fewer returns and enhanced brand reputation over time—all invaluable assets in today's competitive market landscape.

Moreover, implementing an appropriate inspection strategy ensures that teams remain focused on maintaining high standards throughout production cycles while minimizing waste from defective products slipping through unnoticed—something every manufacturer dreads! By carefully assessing how different levels influence AQL sampling outcomes and adjusting accordingly based on real-world data trends observed during inspections allows businesses not only to meet but exceed customer expectations consistently.

How to Select AQL and Inspection Level

Selecting the appropriate Acceptable Quality Level (AQL) and inspection level is crucial for effective quality control in manufacturing. This decision-making process involves understanding various influencing factors, aligning AQL with production quality goals, and learning from real-world cases. By mastering how to select AQL and inspection level, businesses can enhance their quality checks in manufacturing, ensuring that products meet or exceed customer expectations.

Factors Influencing AQL Selection

When determining how to select AQL and inspection level, several factors come into play, including the nature of the product, customer expectations, and regulatory standards. For instance, high-risk products such as medical devices typically require a lower AQL due to stringent safety regulations. Conversely, less critical items might allow for a higher acceptable quality level without jeopardizing consumer safety or satisfaction.

Another key consideration is the cost associated with achieving certain quality levels. Striking a balance between acceptable quality levels and budget constraints is essential for sustainable production practices. Additionally, historical data on defects can guide manufacturers in setting realistic yet effective AQL benchmarks tailored to their specific needs.

Finally, industry standards often dictate acceptable thresholds for various sectors. Understanding these standards helps organizations make informed decisions about their own quality control processes while remaining compliant with market demands.

Aligning AQL with Production Quality Goals

Aligning your chosen AQL with production quality goals is vital for maintaining consistency across your manufacturing processes. When establishing these goals, consider both internal benchmarks and external customer requirements; this ensures that your acceptable quality level reflects what is necessary for success in your marketplace. By doing so, you not only meet regulatory demands but also enhance overall customer satisfaction through reliable product performance.

Moreover, it's essential to communicate these goals throughout your organization so that everyone involved understands the importance of adherence to established standards during production cycles. This communication fosters a culture of accountability where team members are motivated to prioritize quality checks in manufacturing processes actively.

Additionally, regular reviews of both production outcomes and market feedback will allow you to adjust your AQL as needed over time—keeping pace with evolving consumer preferences while ensuring continuous improvement in your overall production quality.

Case Studies: Real-World Examples

Real-world examples provide valuable insights into how companies successfully navigate the complexities of selecting their AQL levels and inspection methods effectively. For instance, consider a leading electronics manufacturer that faced challenges related to product reliability due to high defect rates observed during initial inspections—prompting them to reevaluate their acceptable quality levels significantly downward without sacrificing efficiency.

Following this adjustment led not only to improved product reliability but also enhanced brand reputation among consumers who valued higher-quality goods over mere quantity produced at lower costs—a classic case of prioritizing long-term success over short-term gains!

Another example involves a clothing manufacturer that implemented rigorous sampling techniques aligned with an aggressive marketing campaign promising premium-quality apparel; by closely monitoring defects through enhanced inspections based on meticulously selected AQLs tailored specifically for different fabric types—the company was able to maintain its promise while reducing returns significantly!

AQL Sampling Techniques

When it comes to quality control, understanding AQL sampling techniques is essential for ensuring that your products meet the required standards without breaking the bank. The right sampling methods can help streamline your quality inspection process and enhance overall production quality. By selecting appropriate AQL levels and inspection strategies, manufacturers can effectively manage risks while maintaining a commitment to excellence.

Common Sampling Plans and Methods

There are several common sampling plans that organizations often utilize when determining how to select AQL and inspection level. The most widely recognized plans include single sampling, double sampling, and multiple sampling methods. Each plan has its own merits; for instance, single sampling is straightforward and cost-effective, while double or multiple sampling allows for more thorough checks without excessive resource expenditure.

In addition to these plans, specific statistical approaches such as ANSI/ASQC Z1.4 or ISO 2859 are commonly employed in quality inspection scenarios. These standards provide guidelines on acceptable quality levels (AQL) based on the lot size and desired confidence levels. Ultimately, choosing the right method hinges on balancing thoroughness with efficiency in your quality checks in manufacturing.

Effective Sampling Strategies for Quality Production

To ensure effective AQL sampling that supports high-quality production, manufacturers should consider a variety of strategies tailored to their unique needs. First and foremost is defining clear objectives aligned with production quality goals—this will guide how to select AQL and inspection level effectively. Additionally, leveraging random sampling techniques can minimize bias and yield more representative results.

Another key strategy involves integrating real-time data analysis into your quality control processes; this allows you to adapt swiftly if trends indicate potential issues in product consistency or defects. Furthermore, involving cross-functional teams in the development of these strategies fosters collaboration across departments—ensuring that everyone is committed to maintaining high standards during the entire production cycle.

Analyzing Results from AQL Sampling

Once you've conducted your AQL sampling, analyzing the results becomes critical in assessing overall product integrity and compliance with established benchmarks. Start by comparing defect rates against your predetermined acceptable quality levels (AQL) to determine if any adjustments are necessary in your manufacturing processes or materials used. This step not only informs immediate decisions but also aids in long-term improvements within your operations.

Moreover, documenting findings from each round of inspections helps create a valuable database from which trends can be identified over time—enabling proactive measures rather than reactive fixes when issues arise in production quality. Regularly reviewing this data allows manufacturers to refine their approach continually as they learn what works best for their specific context while optimizing future inspections.

Quality Production and Inspection Best Practices

Maintaining high standards in quality production requires a structured approach to quality checks in manufacturing. Implementing effective quality control measures not only ensures that products meet the acceptable quality level but also enhances overall operational efficiency. By integrating systematic quality inspection processes, manufacturers can minimize defects and improve customer satisfaction.

Implementing Quality Checks in Manufacturing

To truly understand how to select AQL and inspection levels, organizations must first establish robust quality checks in manufacturing. This involves setting clear criteria for acceptable quality levels and determining the appropriate sampling methods to monitor production effectively. Regular inspections at various stages of production help identify potential issues early, allowing for timely interventions that can save time and resources.

Incorporating technology into these checks can further streamline processes, making it easier to track compliance with established standards. Automated systems can provide real-time data on production quality, enabling teams to adjust practices as needed based on immediate feedback. Ultimately, effective implementation of these checks fosters a culture of accountability and excellence within the organization.

Continuous Improvement in Quality Control

Quality control is not a one-time effort; it's an ongoing journey that thrives on continuous improvement principles. By regularly reviewing inspection processes and results from AQL sampling, manufacturers can identify trends that may indicate underlying issues or opportunities for enhancement. Adopting methodologies like Six Sigma or Lean Manufacturing can also support efforts toward achieving higher production quality by reducing waste and variability.

Encouraging employee involvement in the continuous improvement process is vital as well; their insights often lead to innovative solutions that enhance quality checks in manufacturing. Training programs focused on best practices for AQL selection will empower staff to make informed decisions when it comes to maintaining acceptable quality levels throughout the production cycle. Thus, cultivating an environment of learning will drive long-term success in any organization’s commitment to quality.

Leveraging Services like China Inspection Pro

In today's global marketplace, leveraging specialized services like China Inspection Pro can significantly bolster your approach to quality control and inspection practices. These services provide expert guidance on how to select AQL and inspection levels tailored specifically for your product type and market requirements. By outsourcing inspections to experienced professionals, companies can ensure rigorous adherence to international standards while freeing up internal resources for other critical tasks.

Moreover, partnering with such services offers access to advanced technologies and methodologies that may not be feasible in-house due to cost or expertise constraints. This collaboration enhances the overall effectiveness of AQL sampling strategies by ensuring comprehensive evaluations are conducted efficiently across different manufacturing sites worldwide. Ultimately, utilizing external expertise allows businesses not only to maintain but also elevate their standards of product excellence.

Conclusion

In wrapping up our exploration of AQL and inspection levels, it’s crucial to recognize their significance in the realm of quality control. Understanding how to select AQL and inspection level is not merely a checkbox exercise; it’s a strategic decision that can have far-reaching impacts on production quality. By implementing effective quality checks in manufacturing, businesses can ensure that they deliver products that meet or exceed customer expectations.

Key Takeaways on AQL and Inspection Levels

The concept of Acceptable Quality Level (AQL) serves as a vital benchmark for determining acceptable limits in quality inspection. Knowing how to select AQL and inspection level allows organizations to tailor their approach based on specific production needs, minimizing waste while maximizing efficiency. Ultimately, the right combination of AQL sampling techniques and inspection levels will enhance overall product reliability and customer satisfaction.

Enhancing Quality Through Smart Choices

Making informed decisions about AQL selection is essential for aligning with production quality goals. By understanding various sampling methods and applying them effectively, companies can elevate their quality production standards significantly. Implementing rigorous quality checks in manufacturing not only reduces defects but also fosters a culture of continuous improvement within the organization.

Future Trends in Quality Control Practices

As industries evolve, so too do the practices surrounding quality control and inspection levels. The integration of advanced technologies such as AI and machine learning will likely transform how businesses approach how to select AQL and inspection level strategies moving forward. Staying ahead of these trends will be key for organizations aiming to maintain high-quality standards while adapting to changing market demands.